$34

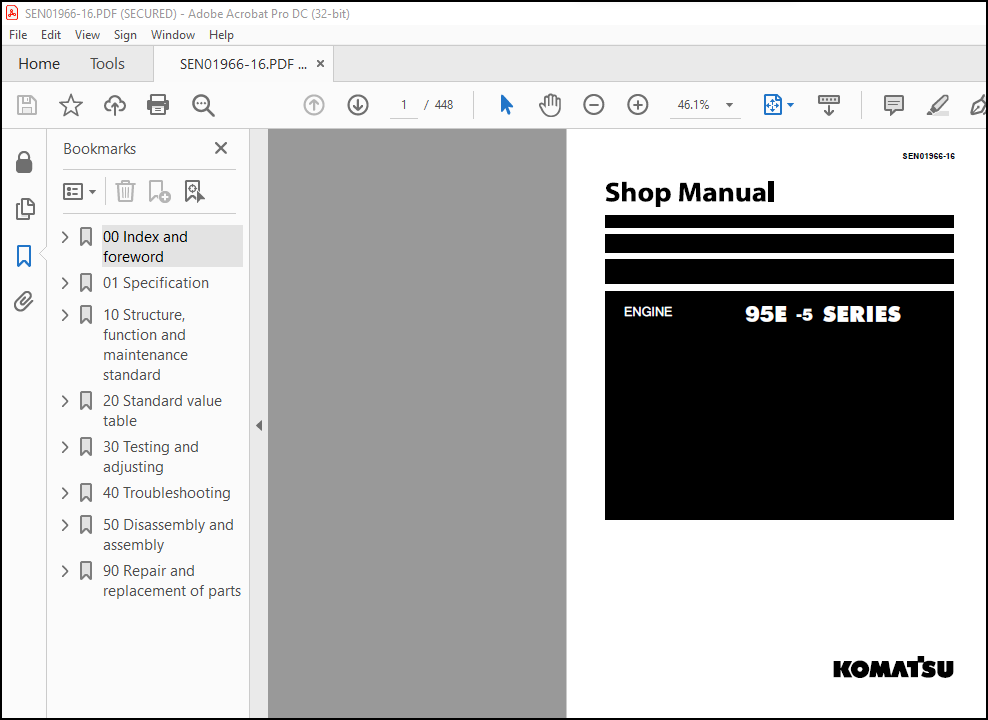

Komatsu 95E-5 Series Engine Shop Manual SEN01966-16 – PDF DOWNLOAD

Komatsu 95E-5 Series Engine Shop Manual SEN01966-16 – PDF DOWNLOAD

FILE DETAILS:

Komatsu 95E-5 Series Engine Shop Manual SEN01966-16 – PDF DOWNLOAD

Language : English

Pages : 448

Downloadable : Yes

File Type : PDF

Size: 18.4 MB

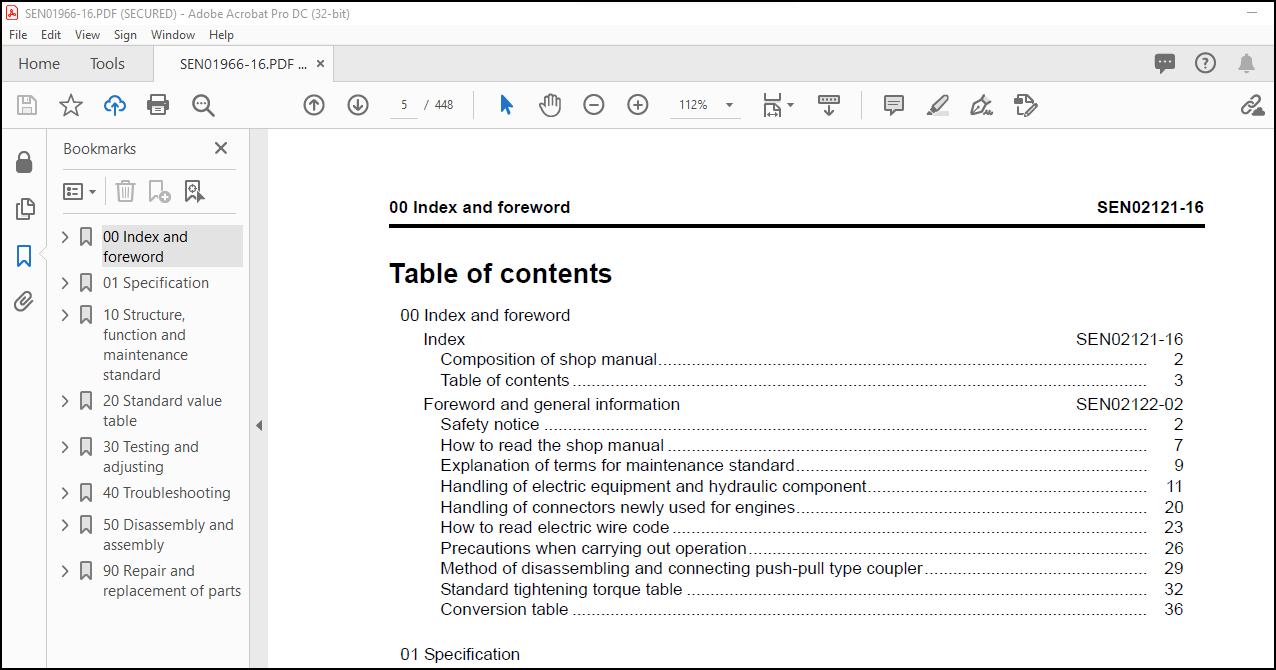

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu 95E-5 Series Engine Shop Manual SEN01966-16 – PDF DOWNLOAD

How to read the shop manual

1. Composition of shop manual

This shop manual contains the necessary technical information for services performed in a workshop.

For ease of understanding, the manual is divided into the following sections.

00. Index and foreword

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification

This section explains the specifications of the machine.

10. Structure, function and maintenance standard

This section explains the structure, function, and maintenance standard values of each component.

The structure and function sub-section explains the structure and function of each component. It

serves not only to give an understanding of the structure, but also serves as reference material for

troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly

and service.

20. Standard value table

This section explains the standard values for new machine and judgement criteria for testing,

adjusting, and troubleshooting. This standard value table is used to check the standard values in

testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting

This section explains measuring instruments and measuring methods for testing and adjusting, and

method of adjusting each part. The standard values and judgement criteria for testing and adjusting

are explained in Testing and adjusting.

40. Troubleshooting

This section explains how to find out failed parts and how to repair them. The troubleshooting is

divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also

explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly

This section explains the special tools and procedures for removing, installing, disassembling, and

assembling each component, as well as precautions for them. In addition, tightening torque and

quantity and weight of coating material, oil, grease, and coolant necessary for the work are also

explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume)

q Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams.

q Engine volume

This section explains the method of reproducing, repairing, and replacing parts.

TABLE OF CONTENTS:

Komatsu 95E-5 Series Engine Shop Manual SEN01966-16 – PDF DOWNLOAD

00 Index and foreword……………………………………………………….. 0

Index………………………………………………………………….. 3

Composition of shop manual……………………………………………. 4

Table of contents……………………………………………………. 5

Foreword and general information………………………………………….. 11

Safety notice……………………………………………………….. 12

How to read the shop manual…………………………………………… 17

Explanation of terms for maintenance standard…………………………… 19

Handling of electric equipment and hydraulic component…………………… 21

Handling of connectors newly used for engines…………………………… 30

How to read electric wire code………………………………………… 33

Precautions when carrying out operation………………………………… 36

Method of disassembling and connecting push-pull type coupler…………….. 39

Standard tightening torque table………………………………………. 42

Conversion table…………………………………………………….. 46

01 Specification……………………………………………………………. 0

Specification and technical data………………………………………….. 53

General information………………………………………………….. 54

Specifications………………………………………………………. 56

General view………………………………………………………… 64

Weight table………………………………………………………… 73

Engine performance curves…………………………………………….. 74

10 Structure, function and maintenance standard………………………………… 0

Structure, function and maintenance standard, Part 1………………………… 83

General structure……………………………………………………. 86

Air intake and exhaust unit…………………………………………… 88

Air cleaner…………………………………………………………. 90

Turbocharger………………………………………………………… 92

Muffler…………………………………………………………….. 95

Cylinder head……………………………………………………….. 96

Cylinder block………………………………………………………. 98

Cylinder…………………………………………………………….101

Main moving parts…………………………………………………….102

Crankshaft…………………………………………………………..104

Camshaft…………………………………………………………….105

Piston, piston ring and piston pin……………………………………..106

Connecting rod……………………………………………………….107

Flywheel and flywheel housing………………………………………….110

Timing gear………………………………………………………….112

Valve system…………………………………………………………116

Valve, valve guide……………………………………………………118

Rocker arm shaft, push rod and tappet…………………………………..119

Structure, function and maintenance standard, Part 2…………………………121

Lubrication system diagram…………………………………………….123

Oil pump…………………………………………………………….124

Regulator valve………………………………………………………126

Oil filter…………………………………………………………..127

Fuel system diagram…………………………………………………..129

Supply pump………………………………………………………….130

Fuel injection nozzle…………………………………………………132

Fuel filter………………………………………………………….133

Common rail………………………………………………………….134

Various sensor……………………………………………………….136

Cooling system diagram………………………………………………..138

Water pump…………………………………………………………..139

Cooling fan drive and thermostat……………………………………….142

Starting and charging system electrical circuit diagram…………………..146

Alternator…………………………………………………………..147

Starting motor……………………………………………………….151

Starting aid…………………………………………………………153

Engine controller…………………………………………………….154

20 Standard value table……………………………………………………… 0

Standard service value table………………………………………………157

Standard service value table for testing, adjusting, and troubleshooting……158

Running-in standard and performance test standard………………………..164

30 Testing and adjusting…………………………………………………….. 0

Testing and adjusting…………………………………………………….173

Testing and adjusting tools list……………………………………….175

Sketches of special tools……………………………………………..177

Measuring intake air pressure………………………………………….178

Testing exhaust temperature……………………………………………179

Adjusting valve clearance……………………………………………..180

Testing compression pressure…………………………………………..182

Testing blow-by pressure………………………………………………184

Testing oil pressure………………………………………………….185

Handling fuel system parts…………………………………………….186

Releasing residual pressure in fuel system………………………………186

Testing fuel pressure…………………………………………………187

Reduced cylinder mode operation………………………………………..188

No-injection cranking…………………………………………………188

Testing leakage from pressure limiter and return rate from injector………..189

Bleeding air from fuel circuit…………………………………………192

Testing fuel system for leakage………………………………………..194

Testing and adjusting alternator belt tension……………………………195

Handling controller voltage circuit…………………………………….196

40 Troubleshooting………………………………………………………….. 0

General information on troubleshooting……………………………………..199

Points on troubleshooting……………………………………………..200

Error code and failure code table………………………………………202

Information in troubleshooting table……………………………………204

Connection table for connector pin numbers………………………………206

T- branch box and T- branch adapter table……………………………….242

Troubleshooting of electrical system (E-mode), Part 1………………………..247

E-1 Code [111/CA111] ECM Critical Internal Failure……………………….250

E-2 Code [115/CA115] Eng. Ne and Bkup Speed Sensor Error………………….253

E-3 Code [122/CA122] Charge Air Press Sensor High Error…………………..254

E-4 Code [123/CA123] Charge Air Press Sensor Low Error……………………256

E-5 Code [131/CA131] Throttle Sensor High Error………………………….257

E-6 Code [132/CA132] Throttle Sensor Low Error…………………………..260

E-7 Code [144/CA144] Coolant Temp. Sensor High Error……………………..262

E-8 Code [145/CA145] Coolant Temp. Sensor Low Error………………………264

E-9 Code [153/CA153] Charge Air Temp. Sensor High Error…………………..266

E-10 Code [154/CA154] Charge Air Temp. Sensor Low Error…………………..268

E-11 Code [187/CA187] Sensor Sup. 2 Volt. Low Error………………………269

E-12 Code [221/CA221] Ambient Air Press. Sensor High Error………………..270

E-13 Code [222/CA222] Ambient Air Press. Sensor Low Error…………………272

E-14 Code [227/CA227] Sensor Sup. 2 Volt. High Error……………………..273

E-15 Code [234/CA234] Eng. Overspeed……………………………………274

E-16 Code [238/CA238] Ne Speed Sensor Sup. Volt. Error……………………276

E-17 Code [271/CA271] IMV Short Error…………………………………..278

E-18 Code [272/CA272] IMV Open Error……………………………………280

E-19 Code [322/CA322] Injector #1 System Open/Short Error…………………282

E-20 Code [324/CA324] Injector #3 System Open/Short Error…………………284

E-21 Code [331/CA331] Injector #2 System Open/Short Error…………………286

E-22 Code [332/CA332] Injector #4 System Open/Short Error…………………288

E-23 Code [351/CA351] INJ. Drive Circuit Error…………………………..290

E-24 Code [352/CA352] Sensor Sup. 1 Volt. Low Error………………………293

E-25 Code [386/CA386] Sensor Sup. 1 Volt. High Error……………………..294

E-26 Code [431/CA431] Idle Validation SW Low error……………………….296

E-27 Code [432/CA432] Idle Validation Process error………………………296

E-28 Code [435/CA435] Abnormality in engine oil pressure switch……………297

E-29 Code [441/CA441] Battery voltage low error………………………….298

E-30 Code [442/CA442] Battery voltage high error…………………………298

Troubleshooting of electrical system (E-mode), Part 2………………………..301

E-31 Code [449/CA449] Rail Press. Very High Error………………………..303

E-32 Code [451/CA451] Rail Press. Sensor High Error………………………304

E-33 Code [452/CA452] Rail Press. Sensor Low Error……………………….306

E-34 Code [553/CA553] Rail Press. High Error…………………………….307

E-35 Code [559/CA559] Rail Press. Low Error……………………………..308

E-36 Code [689/CA689] Eng. Ne Speed Sensor Error…………………………312

E-37 Code [731/CA731] Eng. Bkup Speed Sensor Phase Error………………….314

E-38 Code [757/CA757] All Persistent Data Lost Error……………………..315

E-39 Code [778/CA778] Eng. Bkup Speed Sensor Error……………………….316

E-40 Code [1633/CA1633] KOMNET Dtalink Timeout Error……………………..318

E-41 Code [2185/CA2185] Throttle Sens. Sup. Volt. High Error………………319

E-42 Code [2186/CA2186] Throttle Sens. Sup. Volt. Low Error……………….322

E-43 Code [2249/CA2249] Rail Press. Very Low Error……………………….323

E-44 Code [2311/CA2311] Abnormality in IMV solenoid………………………324

E-45 Code [2555/CA2555] Grid Heater Relay Volt. Low Error…………………325

E-46 Code [2556/CA2556] Grid Heater Relay Volt. High Error………………..326

E-47 Code [(—)/B@BAZG] Eng. Oil press. Low Speed Derate…………………328

E-48 Code [(—)/B@BAZG] Eng. Oil press. Torque Derate……………………328

E-49 Code [(—)/B@BCNS] Eng. Overheat………………………………….329

Troubleshooting of mechanical system (S-mode)……………………………….331

Method of using troubleshooting charts………………………………….334

S-1 Starting performance is poor……………………………………….338

S-2 Engine does not start……………………………………………..339

S-3 Engine does not pick up smoothly……………………………………342

S-4 Engine stops during operations……………………………………..343

S-5 Engine does not rotate smoothly…………………………………….344

S-6 Engine lacks output (or lacks power)………………………………..345

S-7 Exhaust smoke is black (incomplete combustion)……………………….346

S-8 Oil consumption is excessive (or exhaust smoke is blue)……………….347

S-9 Oil becomes contaminated quickly……………………………………348

S-10 Fuel consumption is excessive……………………………………..349

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)….350

S-12 Oil pressure drops……………………………………………….351

S-13 Oil level rises (Entry of coolant or fuel)………………………….352

S-14 Coolant temperature becomes too high (overheating)…………………..353

S-15 Abnormal noise is made……………………………………………354

S-16 Vibration is excessive……………………………………………355

50 Disassembly and assembly………………………………………………….. 0

General information on disassembly and assembly……………………………..357

How to read this manual……………………………………………….358

Coating materials list………………………………………………..360

Special tools list……………………………………………………363

Sketches of special tools……………………………………………..364

Disassembly and assembly, Part 1…………………………………………..367

General disassembly of engine………………………………………….368

Disassembly and assembly, Part 2…………………………………………..381

General assembly of engine…………………………………………….382

Disassembly and assembly, Part 3…………………………………………..399

Disassembly and assembly procedure for fuel supply pump unit………………400

Disassembly and assembly procedure for oil seal units…………………….402

90 Repair and replacement of parts……………………………………………. 0

Information related to repair and replacement……………………………….405

Special tool table……………………………………………………406

Sketches of special tools……………………………………………..408

Parts related to cylinder head…………………………………………….411

Part names related to cylinder head…………………………………….412

Testing and inspection of cylinder head…………………………………413

Pressure test of cylinder head…………………………………………415

Replacement of valve guide…………………………………………….415

Replacement of valve seat insert……………………………………….417

Repair of cylinder head mounting face by grinding………………………..423

Repair of valve by grinding……………………………………………424

Parts related to cylinder block……………………………………………427

Part names related to cylinder block……………………………………428

Testing and inspection of cylinder block………………………………..429

Part names related to crankshaft……………………………………….432

Testing and inspection of crankshaft……………………………………433

Part names related to connecting rod……………………………………434

Testing and inspection of connecting rod………………………………..435

Replacement of flywheel ring gear………………………………………436

Replacement of crankshaft gear…………………………………………437

Replacement of camshaft gear…………………………………………..437

Replacement of connecting rod small end bushing………………………….438

Replacement of cam bushing…………………………………………….440

Cylinder liner (Special part for repair)………………………………..442

Rework drawing for counter bore………………………………………..443

Repair of crankshaft by grinding……………………………………….444