$33

Komatsu Backhoe-Loader WB93S-5E0 Shop Manual WEBM008302 – PDF DOWNLOAD

Komatsu Backhoe-Loader WB93S-5E0 Shop Manual WEBM008302 – PDF DOWNLOAD

FILE DETAILS:

Komatsu Backhoe-Loader WB93S-5E0 Shop Manual WEBM008302 – PDF DOWNLOAD

Language : English

Pages : 610

Downloadable : Yes

File Type : PDF

Size: 32.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu Backhoe-Loader WB93S-5E0 Shop Manual WEBM008302 – PDF DOWNLOAD

SERIAL NUMBERWB93S-5E0 F20456 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.PREPARATIONS FOR WORK:

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any other work equipment to the ground. If this is not possible,

use blocks to prevent the work equipment from falling down. In addition, be sure to lock all the control levers and hang warning sign on them.

9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting

work.

10. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine.Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

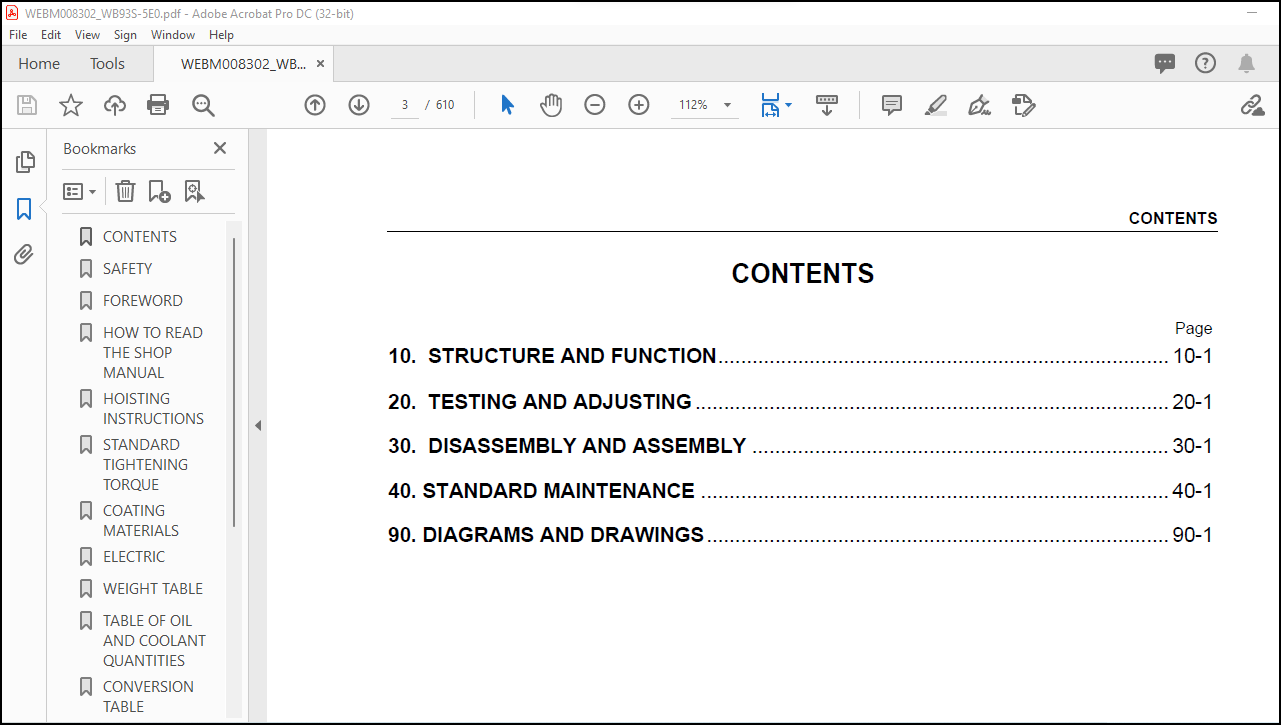

TABLE OF CONTENTS:

Komatsu Backhoe-Loader WB93S-5E0 Shop Manual WEBM008302 – PDF DOWNLOAD

CONTENTS………………………………………………………………………………………. 3

SAFETY………………………………………………………………………………………… 5

FOREWORD………………………………………………………………………………………. 7

HOW TO READ THE SHOP MANUAL……………………………………………………………………… 8

HOISTING INSTRUCTIONS…………………………………………………………………………… 9

STANDARD TIGHTENING TORQUE………………………………………………………………………. 10

COATING MATERIALS………………………………………………………………………………. 12

ELECTRIC………………………………………………………………………………………. 13

WEIGHT TABLE…………………………………………………………………………………… 14

TABLE OF OIL AND COOLANT QUANTITIES………………………………………………………………. 15

CONVERSION TABLE……………………………………………………………………………….. 17

POWER TRAIN……………………………………………………………………………………. 26

10 STRUCTURE AND FUNCTION……………………………………………………………………….. 25

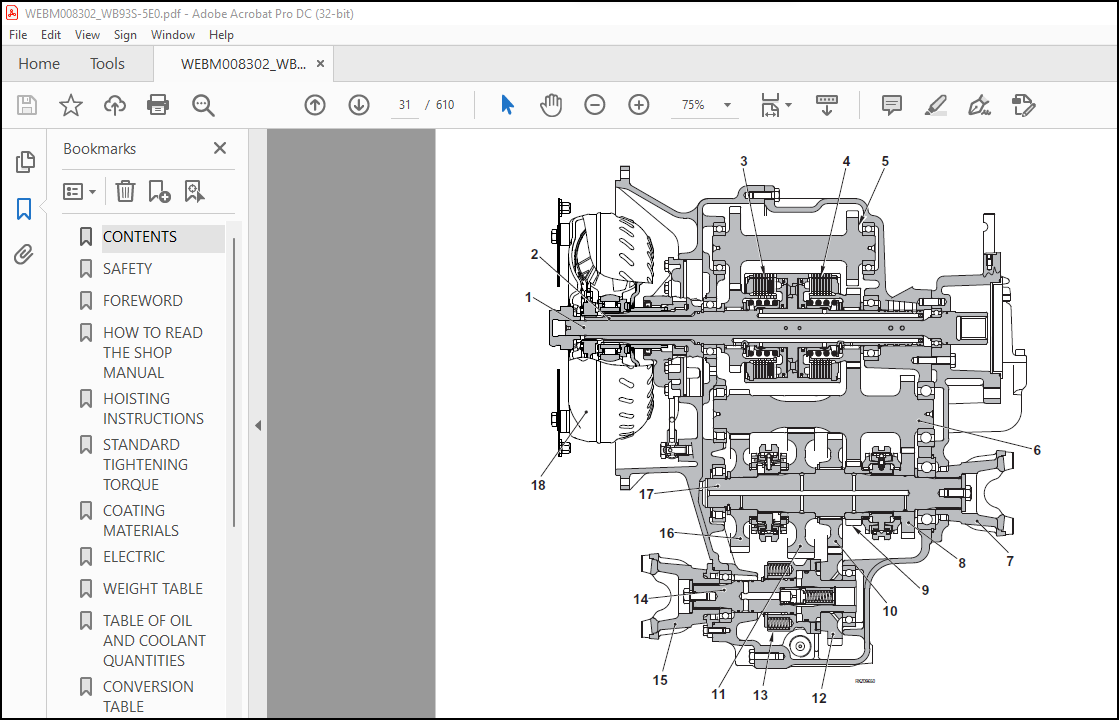

TRANSMISSION (4WD)………………………………………………………………………….. 28

TRANSMISSION……………………………………………………………………………….. 30

DRIVE SHAFTS……………………………………………………………………………….. 33

CONTROL VALVE BLOCK…………………………………………………………………………. 35

FRONT AXLE…………………………………………………………………………………. 36

REAR AXLE………………………………………………………………………………….. 39

STEERING SYSTEM (4WS)……………………………………………………………………….. 43

HYDRAULIC PUMP……………………………………………………………………………… 47

8-SPOOL CONTROL VALVE (WITH MECHANICAL CONTROL)………………………………………………… 61

10-SPOOL CONTROL VALVE (WITH MECHANICAL CONTROL)……………………………………………….. 67

8-SPOOL CONTROL VALVE (WITH SERVOCONTROL)……………………………………………………… 76

10-SPOOL CONTROL VALVE (WITH SERVOCONTROL)…………………………………………………….. 84

CLSS………………………………………………………………………………………. 93

STEERING UNIT……………………………………………………………………………….118

PPC VALVES………………………………………………………………………………….119

PPC VALVE (BACKHOE CONTROLS)………………………………………………………………….134

SOLENOID VALVE GROUP (EV1)……………………………………………………………………140

SOLENOID VALVE GROUP (EV2)……………………………………………………………………143

HAMMER AND JIG ARM SOLENOID VALVE……………………………………………………………..144

HAMMER SOLENOID VALVE………………………………………………………………………..145

JIG ARM SOLENOID VALVE……………………………………………………………………….146

JIG ARM AND SIDE DIGGING BOOM SOLENOID VALVE……………………………………………………147

JIG ARM AND 2-WAY ATTACHMENT SOLENOID VALVE…………………………………………………….148

SIDE DIGGING BOOM SOLENOID VALVE………………………………………………………………149

2-WAY ATTACHMENT SOLENOID VALVE……………………………………………………………….150

SAFETY VALVES……………………………………………………………………………….151

SHOVEL CYLINDERS…………………………………………………………………………….155

BACKHOE CYLINDERS……………………………………………………………………………157

AIR-CONDITIONING UNIT………………………………………………………………………..161

OPERATION OF THE AIR CONDITIONING UNIT…………………………………………………………162

20 TESTING AND ADJUSTMENTS……………………………………………………………………….163

NORMAL OR STANDARD TECHNICAL DATA……………………………………………………………..164

SPECIAL TOOLS……………………………………………………………………………….188

VALVE CLEARANCE ADJUSTING…………………………………………………………………….189

ENGINE SPEED TESTS…………………………………………………………………………..190

TENSIONING THE AIR-CONDITIONING COMPRESSOR BELT…………………………………………………191

BLEEDING AIR FROM CIRCUITS – ELIMINATING RESIDUAL PRESSURE……………………………………….192

ADJUSTING ACCELERATOR PEDAL TRAVEL AND ACCELERATOR LEVER…………………………………………194

ADJUSTING BRAKE PEDAL SLACK/ALIGNMENT………………………………………………………….196

BRAKING SYSTEM CHECKS………………………………………………………………………..197

PARKING BRAKE ADJUSTMENT……………………………………………………………………..199

CHECKING AND SETTING PRESSURE IN THE ATTACHMENTS HYDRAULIC CIRCUIT………………………………..201

CHECKING THE SETTING OF MAIN RELIEF AND SECONDARY VALVES…………………………………………203

SETTING THE MAIN RELIEF VALVES AND THE REDUCING VALVES…………………………………………..206

CHECKING AND ADJUSTING THE LS DIFFERENTIAL PRESSURE – ADJUSTING THE LS VALVE……………………….208

CHECKING AND ADJUSTING SERVOCONTROLS SUPPLY PRESSURE…………………………………………….209

ADJUSTING THE PC VALVE……………………………………………………………………….210

TESTING AND SETTING STEERING CONTROL SYSTEM PRESSURE…………………………………………….211

CHECKING FOR LEAKS IN THE STEERING CYLINDERS……………………………………………………212

TESTING PRESSURES IN THE POWER TRAIN GROUP……………………………………………………..213

TESTING THE CORRECT FUNCTIONING OF THE POWER TRAINCLUTCHES……………………………………….214

ANALYSIS OF CAUSES HYDRAULIC DRIFT…………………………………………………………….215

JIG ARM CLEARANCE ADJUSTMENT………………………………………………………………….220

TESTING THE AIR-CONDITIONING UNIT……………………………………………………………..222

EMPTYING THE AIR-CONDITIONING UNIT…………………………………………………………….224

TROUBLESHOOTING……………………………………………………………………………..225

30 REMOVAL AND INSTALLATION………………………………………………………………………239

HOW TO READ THE MANUAL……………………………………………………………………….240

PRECAUTIONS TO BE TAKEN WHILE WORKING………………………………………………………….241

SPECIAL TOOLS……………………………………………………………………………….242

ENGINE HOOD…………………………………………………………………………………246

FRONT GUARD…………………………………………………………………………………247

RADIATOR GROUP – INTERCOOLER………………………………………………………………….248

INTERCOOLER…………………………………………………………………………………251

CONDENSER (For machines equipped with an air-conditioning unit)…………………………………..253

EXHAUST PIPE………………………………………………………………………………..254

MUFFLER…………………………………………………………………………………….255

AIR FILTER………………………………………………………………………………….256

ENGINE BELT…………………………………………………………………………………257

TURBOCHARGER………………………………………………………………………………..258

AIR-CONDITIONING UNIT COMPRESSOR………………………………………………………………259

AIR-CONDITIONING UNIT COMPRESSOR BELT………………………………………………………….261

FAN AND HEATING GROUP………………………………………………………………………..262

BATTERY…………………………………………………………………………………….267

FUEL TANK…………………………………………………………………………………..268

STEERING WHEEL AND TRANSMISSION-REVERSE, DIRECTION INDICATOR AND HEADLIGHT DIPPER BEAM CONTROL GROUP….269

WORKING BRAKE PUMP GROUP……………………………………………………………………..271

STEERING UNIT……………………………………………………………………………….274

CAB………………………………………………………………………………………..276

HYDRAULIC OIL TANK…………………………………………………………………………..282

HYDRAULIC PUMP………………………………………………………………………………287

TRANSMISSION………………………………………………………………………………..289

CONVERTOR…………………………………………………………………………………..365

ENGINE……………………………………………………………………………………..366

CONTROL VALVE (Standard version)………………………………………………………………369

CONTROL VALVE (version with servocontrol)………………………………………………………372

STEERING SOLENOID VALVE GROUP…………………………………………………………………375

FRONT AXLE………………………………………………………………………………….376

REAR AXLE…………………………………………………………………………………..415

SHOVEL PPC VALVE…………………………………………………………………………….467

SHOVEL LIFT CYLINDERS………………………………………………………………………..469

SHOVEL DUMP CYLINDERS………………………………………………………………………..471

SHOVEL……………………………………………………………………………………..473

FRONT WORKING EQUIPMENT………………………………………………………………………474

BACKHOE PPC VALVES (Optional)…………………………………………………………………476

PPC VALVE SUPPORT RELEASE CABLES………………………………………………………………478

PPC VALVE SUPPORT RETURN GAS SPRING……………………………………………………………480

SOLENOID VALVE GROUP (servocontrol and optional attachment)………………………………………482

BACKHOE BOOM CYLINDER………………………………………………………………………..483

ARM CYLINDER………………………………………………………………………………..485

JIG ARM CYLINDER…………………………………………………………………………….487

OUTRIGGER CYLINDER…………………………………………………………………………..488

BACKHOE SWING CYLINDERS………………………………………………………………………490

BACKHOE BUCKET CYLINDER………………………………………………………………………492

BACKHOE BOOM SAFETY CYLINDER………………………………………………………………….494

CYLINDER……………………………………………………………………………………495

BACKHOE WORKING EQUIPMENT…………………………………………………………………….503

BACKHOE BUCKET………………………………………………………………………………505

BACKHOE BOOM CYLINDER………………………………………………………………………..506

ARM………………………………………………………………………………………..507

JIG ARM…………………………………………………………………………………….509

2nd ARM…………………………………………………………………………………….510

2nd ARM GUIDES………………………………………………………………………………511

BACKHOE SWING BRACKET………………………………………………………………………..512

COMPLETE BACKHOE BACKFRAME……………………………………………………………………513

BACKFRAME LOCK PISTONS……………………………………………………………………….515

40 STANDARD MAINTENANCE………………………………………………………………………….517

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD…………………………………………………..518

TRANSMISSION………………………………………………………………………………..520

FRONT AXLE………………………………………………………………………………….525

REAR AXLE…………………………………………………………………………………..528

HYDRAULIC PUMP………………………………………………………………………………532

CONTROL VALVE……………………………………………………………………………….534

PPC VALVES………………………………………………………………………………….567

SHOVEL CYLINDERS…………………………………………………………………………….569

BACKHOE CYLINDERS……………………………………………………………………………571

FRONT WORKING EQUIPMENT………………………………………………………………………574

SWING BRACKET……………………………………………………………………………….576

BACKHOE WORKING EQUIPMENT…………………………………………………………………….578

90 DIAGRAMS AND DRAWINGS…………………………………………………………………………581

HYDRAULIC CIRCUIT DIAGRAM (MECHANICAL VERSION) – UP TO S/N F20723…………………………………583

HYDRAULIC CIRCUIT DIAGRAM (MECHANICAL VERSION) – FROM S/N F20724 TO F21521…………………………585

HYDRAULIC CIRCUIT DIAGRAM (MECHANICAL VERSION) – FROM S/N F21522 AND UP……………………………587

HYDRAULIC CIRCUIT DIAGRAM (MECHANICAL VERSION) – OPTIONAL………………………………………..589

HYDRAULIC CIRCUIT DIAGRAM (VERSION WITH SERVOCONTROL) – UP TO S/N F20723…………………………..591

HYDRAULIC CIRCUIT DIAGRAM (VERSION WITH SERVOCONTROL) – FROM S/N F20724 TO F20920…………………..593

HYDRAULIC CIRCUIT DIAGRAM (VERSION WITH SERVOCONTROL) – FROM S/N F20921 TO F21521…………………..595

HYDRAULIC CIRCUIT DIAGRAM (VERSION WITH SERVOCONTROL) – FROM S/N F21522 AND UP……………………..597

HYDRAULIC CIRCUIT DIAGRAM (VERSION WITH SERVOCONTROL) – OPTIONAL………………………………….599

HYDRAULIC CIRCUIT DIAGRAM – STEERING…………………………………………………………..601

ELECTRICAL CIRCUIT DIAGRAM (1/3)………………………………………………………………603

ELECTRICAL CIRCUIT DIAGRAM (2/3)………………………………………………………………605

ELECTRICAL CIRCUIT DIAGRAM (3/3)………………………………………………………………607