$45

Komatsu BR380JG-1E0 Galeo Mobile Crusher Shop Manual (2001 and up) - PDF

Komatsu BR380JG-1E0 Galeo Mobile Crusher Shop Manual (2001 and up)

FILE DETAILS:

Komatsu BR380JG-1E0 Galeo Mobile Crusher Shop Manual (2001 and up)

File Format : PDF

Language : English

Bookmarked : Yes

Searchable : Yes

Printable : Yes

Product Code : SEN01341-03

Total Pages : 841

DESCRIPTION:

Komatsu BR380JG-1E0 Galeo Mobile Crusher Shop Manual (2001 and up)

HOW TO READ THE SHOP MANUAL:

1. Composition of shop manual:

This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword:

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification:

This section explains the specifications of the machine.

10. Structure, function and maintenance standard:

This section explains the structure, function, and maintenance standard values of each component. The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

20. Standard value table:

This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

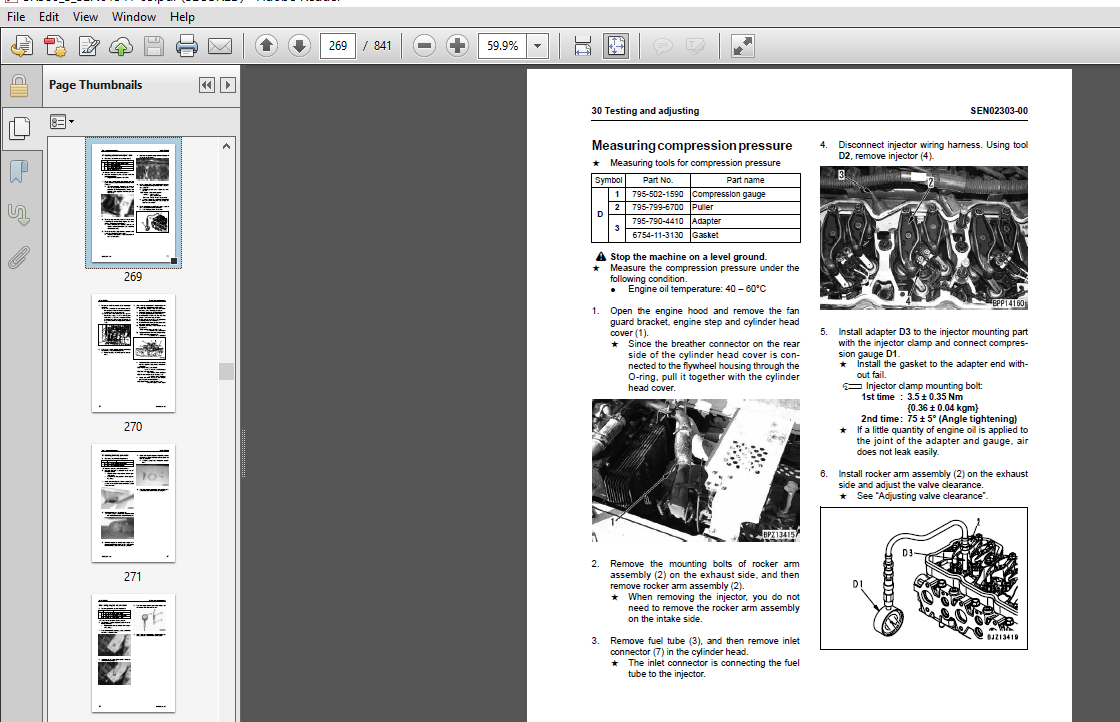

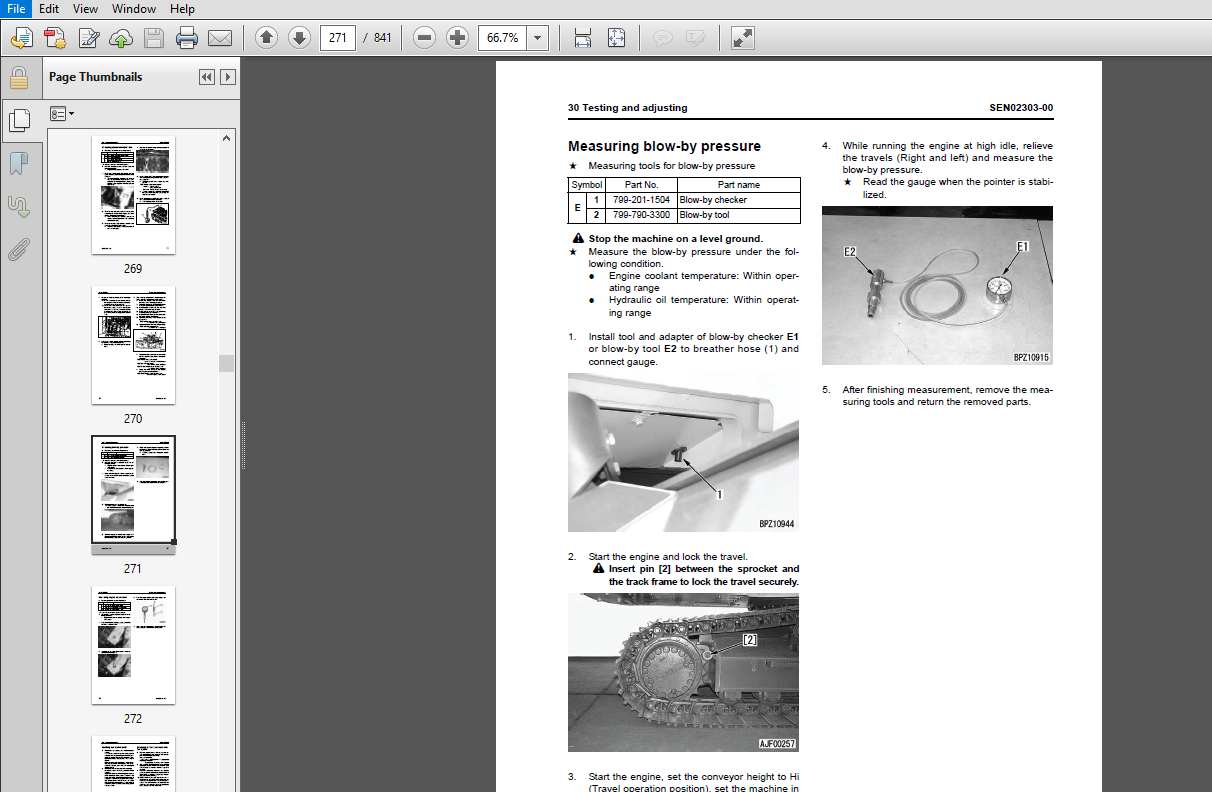

30. Testing and adjusting:

This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

40. Troubleshooting:

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly:

This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume):

- Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams. - Engine volume

This section explains the method of reproducing, repairing, and replacing parts.

TABLE OF CONTENTS:

Komatsu BR380JG-1E0 Galeo Mobile Crusher Shop Manual (2001 and up)

COVER.......................................................................................................... 1 00 INDEX AND FOREWORD.......................................................................................... 0 INDEX...................................................................................................... 3 COMPOSITION OF SHOP MANUAL............................................................................. 4 TABLE OF CONTENTS...................................................................................... 6 FOREWORD AND GENERAL INFORMATION........................................................................... 15 SAFETY NOTICE.......................................................................................... 16 HOW TO READ THE SHOP MANUAL............................................................................ 21 EXPLANATION OF TERMS FOR MAINTENANCE STANDARD.......................................................... 23 HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENT.................................................... 25 HOW TO READ ELECTRIC WIRE CODE......................................................................... 37 PRECAUTIONS WHEN CARRYING OUT OPERATION................................................................ 40 METHOD OF DISASSEMBLING AND CONNECTING PUSH-PULL TYPE COUPLER.......................................... 43 STANDARD TIGHTENING TORQUE TABLE....................................................................... 46 CONVERSION TABLE....................................................................................... 50 01 SPECIFICATION............................................................................................... 0 SPECIFICATION AND TECHNICAL DATA........................................................................... 56 SPECIFICATION DIMENSION DRAWINGS....................................................................... 57 SPECIFICATIONS......................................................................................... 58 WEIGHT TABLE........................................................................................... 60 TABLE OF FUEL, COOLANT AND LUBRICANTS.................................................................. 61 10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD................................................................ 0 ENGINE AND COOLING SYSTEM.................................................................................. 64 ENGINE MOUNT, DAMPER................................................................................... 65 RADIATOR, OIL COOLER AND AFTERCOOLER................................................................... 66 POWER TRAIN................................................................................................ 68 POWER TRAIN............................................................................................ 69 DRIVE SYSTEM FOR COMPONENTS............................................................................ 70 FINAL DRIVE............................................................................................ 71 SPROCKET............................................................................................... 73 UNDERCARRIAGE AND FRAME.................................................................................... 76 TRACK FRAME AND RECOIL SPRING.......................................................................... 77 IDLER.................................................................................................. 79 CARRIER ROLLER......................................................................................... 81 TRACK ROLLER........................................................................................... 82 TRACK SHOE............................................................................................. 83 HYDRAULIC SYSMTEM, PART 1.................................................................................. 88 HYDRAULIC PIPING DRAWING............................................................................... 89 HYDRAULIC TANK AND HYDRAULIC OIL FILTER................................................................ 90 HYDRAULIC PUMP......................................................................................... 91 HYDRAULIC SYSMTEM, PART 2..................................................................................112 CONTROL VALVE..........................................................................................113 SELF PRESSURE REDUCING VALVE...........................................................................120 CLSS...................................................................................................125 FUNCTIONS AND OPERATION BY VALVE.......................................................................129 HYDRAULIC SYSMTEM, PART 3..................................................................................144 CRUSHER MOTOR..........................................................................................145 GRIZZLY FEEDER MOTOR...................................................................................149 CONVEYOR MOTOR.........................................................................................150 TRAVEL MOTOR...........................................................................................151 VALVE CONTROL..........................................................................................158 SOLENOID VALVE.........................................................................................168 EPC VALVE..............................................................................................170 ELECTROMAGNETIC SELECTOR VALVE.........................................................................174 HYDRAULIC CYLINDER.....................................................................................176 WORK EQUIPMENT.............................................................................................179 GRIZZLY FEEDER SEMIAUTOMATIC SYSTEM....................................................................180 ABNORMAL LOAD STOP SYSTEM..............................................................................181 PRIMARY BELT CONVEYOR..................................................................................182 GRIZZLY FEEDER.........................................................................................185 CRUSHER................................................................................................186 CRUSHER TOOTH TIP ADJUSTMENT SYSTEM....................................................................190 VIBRATOR...............................................................................................193 ELECTRICAL SYSTEM..........................................................................................196 ENGINE CONTROL.........................................................................................197 WORK EQUIPMENT AND PUMP CONTROLLER.....................................................................206 ELECTRONIC CONTROL SYSTEM..............................................................................209 MACHINE MONITOR SYSTEM.................................................................................222 SENSOR.................................................................................................246 20 STANDARD VALUE TABLE........................................................................................ 0 STANDARD SERVICE VALUE TABLE...............................................................................251 STANDARD VALUE TABLE FOR ENGINE........................................................................252 STANDARD VALUE TABLE FOR CHASSIS.......................................................................253 30 TESTING AND ADJUSTING....................................................................................... 0 TESTING AND ADJUSTING, PART 1..............................................................................259 TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING......................................................261 MEASURING ENGINE SPEED.................................................................................264 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE).........................................................265 CHECKING EXHAUST GAS COLOR.............................................................................266 ADJUSTING VALVE CLEARANCE..............................................................................267 MEASURING COMPRESSION PRESSURE.........................................................................269 MEASURING BLOW-BY PRESSURE.............................................................................271 MEASURING ENGINE OIL PRESSURE..........................................................................272 HANDLING FUEL SYSTEM PARTS.............................................................................273 RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM...........................................................273 MEASURING FUEL PRESSURE................................................................................274 MEASURING FUEL RETURN RATE AND LEAKAGE.................................................................276 BLEEDING AIR FROM FUEL CIRCUIT.........................................................................278 CHECKING FUEL CIRCUIT FOR LEAKAGE......................................................................280 CHECKING AND ADJUSTING TRACK SHOE TENSION..............................................................281 MEASURING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT AND TRAVEL CIRCUITS.............................283 MEASURING CONTROL CIRCUIT BASIC PRESSURE...............................................................287 MEASURING AND ADJUSTING OIL PRESSURE IN PUMP PC CONTROL CIRCUIT........................................288 MEASURING AND ADJUSTING OIL PRESSURE IN PUMP LS CONTROL CIRCUIT........................................291 MEASURING SOLENOID VALVE OUTPUT PRESSURE...............................................................295 MEASURING PPC VALVE OUTPUT PRESSURE....................................................................298 MEASURING OIL LEAKAGE..................................................................................299 BLEEDING AIR FROM EACH PART............................................................................300 TESTING TRAVEL DEVIATION...............................................................................303 ADJUSTING MIRRORS......................................................................................304 TESTING AND ADJUSTING, PART 2..............................................................................307 SPECIAL FUNCTIONS OF MACHINE MONITOR...................................................................308 TESTING AND ADJUSTING, PART 3..............................................................................342 CHECK AND ADJUSTMENT OF JAW CRUSHER....................................................................343 CHECK AND ADJUSTMENT OF OUTLET CLEARANCE...............................................................345 ADJUSTING TENSION OF CRUSHER DRIVE V-BELT..............................................................378 CHECK AND ADJUSTMENT OF PRIMARY CONVEYOR...............................................................379 INSPECTION AND MAINTENANCE OF MAGNETIC SEPARATOR.......................................................385 CHECK AND ADJUSTMENT OF MUCK DISCHARGE CONVEYOR........................................................387 LIST OF COMPANIES WHICH HANDLES RADIO CONTROLLERS......................................................389 HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER..........................................................390 PROCEDURE FOR TURNING ON KOMTRAX TERMINAL..............................................................391 KOMTRAX TERMINAL LAMP INDICATIONS......................................................................394 PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL SYSTEM.............................................397 PROCEDURE FOR TESTING DIODES...........................................................................401 40 TROUBLESHOOTING............................................................................................. 0 FAILURE CODE TABLE AND FUSE LOCATIONS......................................................................404 FAILURE CODE TABLE.....................................................................................405 FUSE LOCATIONS.........................................................................................408 GENERAL INFORMATION ON TROUBLESHOOTING.....................................................................412 POINTS TO REMEMBER WHEN TROUBLESHOOTING................................................................413 SEQUENCE OF EVENTS IN TROUBLESHOOTING..................................................................414 CHECKS BEFORE TROUBLESHOOTING..........................................................................415 CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING.......................................................417 CONTENTS OF TROUBLESHOOTING TABLE......................................................................421 WIRING TABLE FOR CONNECTOR PIN NUMBERS.................................................................423 T-ADAPTER BOX AND T-ADAPTER TABLE......................................................................456 TROUBLESHOOTING BY FAILURE CODE, PART 1....................................................................460 FAILURE CODE [7RC1KB] SHORT CIRCUIT CONVEYOR ON SWITCH.................................................462 FAILURE CODE [7RC2KA] DISCONNECTION IN CONVEYOR OFF SWITCH.............................................464 FAILURE CODE [7RC5KB] SHORT CIRCUIT IN FEEDER ON SWITCH................................................466 FAILURE CODE [7RD2KB] SHORT CIRCUIT IN CONVEYOR REVERSE RELAY..........................................468 FAILURE CODE [7RD2KZ] DISCONNECTION OR SHORT CIRCUIT IN CONVEYOR REVERSE RELAY.........................470 FAILURE CODE [7RE1KB] SHORT CIRCUIT IN CRUSHER ON SWITCH...............................................472 FAILURE CODE [7RE2KA] DISCONNECTION IN CRUSHER OFF SWITCH..............................................474 FAILURE CODE [7RE6KB] SHORT CIRCUIT IN MUCK DISCHARGE CONVEYOR ON SWITCH...............................476 FAILURE CODE [7RE7KA] DISCONNECTION IN MUCK DISCHARGE CONVEYOR OFF SWITCH..............................478 FAILURE CODE [7RE8KB] SHORT CIRCUIT IN MAGNETIC SEPARATOR ON SWITCH....................................480 FAILURE CODE [7RE9KA] DISCONNECTION IN MAGNETIC SEPARATOR OFF SWITCH...................................482 FAILURE CODE [7REAKB] SHORT CIRCUIT IN ACCESSORY INPUT CIRCUIT.........................................484 FAILURE CODE [7REDMA] ABNORMALITY IN PRIMARY CONVEYOR PRESSURE SENSOR..................................486 FAILURE CODE [7REEMA] ABNORMALITY IN MUCK CONVEYOR PRESSURE SENSOR.....................................488 FAILURE CODE [7RENKZ] ABNORMALITY IN CLEARANCE POTENTIOMETER...........................................490 FAILURE CODE [7REPKA] DISCONNECTION IN FEEDER OFF SWITCH...............................................492 FAILURE CODE [7RESKB] SHORT CIRCUIT IN ONE-TOUCH START SWITCH..........................................494 FAILURE CODE [7RETKA] DISCONNECTION IN ONE-TOUCH STOP SWITCH...........................................496 FAILURE CODE [7RF2KA] DISCONNECTION IN CRUSHER FORWARD EPC VALVE.......................................498 FAILURE CODE [7RF2KB] SHORT CIRCUIT IN CRUSHER FORWARD EPC VALVE.......................................499 FAILURE CODE [7RF2KY] SHORT CIRCUIT IN CRUSHER FORWARD EPC VALVE.......................................500 FAILURE CODE [7RF3KA] DISCONNECTION IN CRUSHER REVERSE EPC VALVE.......................................501 FAILURE CODE [7RF3KB] SHORT CIRCUIT IN CRUSHER REVERSE EPC VALVE.......................................502 FAILURE CODE [7RF3KY] SHORT CIRCUIT IN CRUSHER REVERSE EPC VALVE.......................................503 FAILURE CODE [7RF4KA] DISCONNECTION IN FEEDER FORWARD EPC VALVE........................................504 FAILURE CODE [7RF4KB] SHORT CIRCUIT IN FEEDER FORWARD EPC VALVE........................................505 FAILURE CODE [7RF4KY] SHORT CIRCUIT IN FEEDER FORWARD EPC VALVE........................................506 TROUBLESHOOTING BY FAILURE CODE, PART 2....................................................................508 FAILURE CODE [7RFAKY] SHORT CIRCUIT IN ENGINE STOP RELAY...............................................510 FAILURE CODE [7RFAKZ] DISCONNECTION OR SHORT CIRCUIT IN ENGINE STOP RELAY..............................512 FAILURE CODE [7RFBKB] SHORT CIRCUIT IN MUCK CONVEYOR SOLENOID..........................................514 FAILURE CODE [7RFBKZ] DISCONNECTION OR SHORT CIRCUIT IN MUCK CONVEYOR SOLENOID.........................515 FAILURE CODE [7RFCKA] DISCONNECTION IN MAGNETIC SEPARATOR SOLENOID.....................................516 FAILURE CODE [7RFCKB] SHORT CIRCUIT IN MAGNETIC SEPARATOR SOLENOID.....................................517 FAILURE CODE [7RFCKY] SHORT CIRCUIT IN MAGNETIC SEPARATOR SOLENOID.....................................518 FAILURE CODE [7RFHKB] SHORT CIRCUIT IN CONVEYOR FORWARD RELAY..........................................519 FAILURE CODE [7RFHKY] SHORT CIRCUIT IN CONVEYOR FORWARD RELAY..........................................521 FAILURE CODE [7RFKKB] SHORT CIRCUIT IN LOCK CYLINDER PULL RELAY........................................523 FAILURE CODE [7RFKKY] SHORT CIRCUIT IN LOCK CYLINDER PULL RELAY........................................525 FAILURE CODE [7RFLKA] DISCONNECTION IN ACCESSORY EPC SOLENOID..........................................527 FAILURE CODE [7RFLKB] SHORT CIRCUIT IN ACCESSORY EPC SOLENOID..........................................528 FAILURE CODE [7RFLKY] SHORT CIRCUIT IN ACCESSORY EPC SOLENOID..........................................529 FAILURE CODE [7RFMKY] SHORT CIRCUIT IN ABNORMAL PRESSURE RELAY.........................................530 FAILURE CODE [7RFMKZ] DISCONNECTION OR SHORT CIRCUIT IN ABNORMAL PRESSURE RELAY........................532 FAILURE CODE [7RFNKA] DISCONNECTION IN LOCK CYLINDER UNLOCK SOLENOID VALVE.............................534 FAILURE CODE [7RFNKB] SHORT CIRCUIT IN LOCK CYLINDER UNLOCK SOLENOID VALVE.............................535 FAILURE CODE [7RFNKY] SHORT CIRCUIT IN LOCK CYLINDER UNLOCK SOLENOID VALVE.............................536 FAILURE CODE [7RFPKB] SHORT CIRCUIT IN LOCK CYLINDER PUSH RELAY........................................537 FAILURE CODE [7RFPKY] SHORT CIRCUIT IN LOCK CYLINDER PUSH RELAY........................................539 FAILURE CODE [7RGAMA] ABNORMALITY IN 2ND CONVEYOR PRESSURE SENSOR......................................541 FAILURE CODE [7RJAKA] DISCONNECTION IN TRAVEL LOCK EPC SOLENOID VALVE..................................543 FAILURE CODE [7RJAKB] SHORT CIRCUIT IN TRAVEL LOCK EPC SOLENOID VALVE..................................545 FAILURE CODE [7RJAKY] SHORT CIRCUIT IN TRAVEL LOCK EPC SOLENOID VALVE..................................547 FAILURE CODE [7RJMMW] LOCK CYLINDER SLIPPING...........................................................548 FAILURE CODE [7RJNMA] ABNORMALITY IN VIBRATORY SCREEN PRESSURE SENSOR..................................549 FAILURE CODE [7RJPKB] SHORT CIRCUIT IN RADIO CONTROL WORK-MODE SWITCH..................................551 FAILURE CODE [7RJQKB] SHORT CIRCUIT IN RADIO CONTROL TRAVEL-MODE SWITCH................................552 FAILURE CODE [7RJRKB] SHORT CIRCUIT ON TRAVEL SIGNAL...................................................553 FAILURE CODE [7RJSMA] ABNORMALITY IN MAGNETIC SEPARATOR PRESSURE SENSOR................................555 FAILURE CODE [AA10NX] AIR CLEANER CLOGGING.............................................................557 FAILURE CODE [AB00KE] CHARGE VOLTAGE TOO LOW...........................................................559 TROUBLESHOOTING BY FAILURE CODE, PART 3....................................................................562 FAILURE CODE [B@BAZG] ENGINE OIL PRESSURE TOO LOW......................................................564 FAILURE CODE [B@BAZK] ENGINE OIL LEVEL REDUCTION.......................................................566 FAILURE CODE [B@BCNS] RADIATOR COOLANT OVERHEAT........................................................567 FAILURE CODE [B@BCZK] RADIATOR COOLANT LEVEL REDUCTION.................................................568 FAILURE CODE [B@HANS] HYDRAULIC OIL OVERHEAT...........................................................570 FAILURE CODE [CA111] ABNORMALITY IN ENGINE CONTROLLER..................................................570 FAILURE CODE [CA115] ABNORMALITY IN ENGINE NE AND BKUP SPEED SENSORS...................................571 FAILURE CODE [CA122] CHARGE PRESSURE SENSOR TOO HIGH...................................................572 FAILURE CODE [CA123] CHARGE PRESSURE SENSOR TOO LOW....................................................574 FAILURE CODE [CA131] THROTTLE SENSOR TOO HIGH..........................................................576 FAILURE CODE [CA132] THROTTLE SENSOR TOO LOW...........................................................578 FAILURE CODE [CA144] COOLANT TEMPERATURE SENSOR TOO HIGH...............................................580 FAILURE CODE [CA145] COOLANT TEMPERATURE SENSOR TOO LOW................................................582 FAILURE CODE [CA153] CHARGE TEMPERATURE SENSOR TOO HIGH................................................584 FAILURE CODE [CA154] CHARGE TEMPERATURE SENSOR TOO LOW.................................................586 FAILURE CODE [CA155] CHARGE TEMPERATURE TOO HIGH AND ENGINE SPEED DERATED..............................588 FAILURE CODE [CA187] SENSOR POWER SOURCE 2 TOO LOW.....................................................589 FAILURE CODE [CA221] AMBIENT PRESSURE SENSOR TOO HIGH..................................................591 FAILURE CODE [CA222] AMBIENT PRESSURE SENSOR TOO LOW...................................................593 FAILURE CODE [CA227] SENSOR POWER SOURCE 2 TOO HIGH....................................................595 FAILURE CODE [CA234] ENGINE OVERSPEED..................................................................596 FAILURE CODE [CA238] ABNORMAL POWER SOURCE FOR NE SPEED SENSOR.........................................597 FAILURE CODE [CA271] SHORT CIRCUIT IN FUEL PUMP ACTUATOR...............................................598 FAILURE CODE [CA272] DISCONNECTION IN FUEL PUMP ACTUATOR...............................................599 FAILURE CODE [CA322] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.1...................................600 FAILURE CODE [CA323] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.5...................................602 FAILURE CODE [CA324] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.3...................................604 FAILURE CODE [CA325] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.6...................................606 FAILURE CODE [CA331] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.2...................................608 FAILURE CODE [CA332] DISCONNECTION OR SHORT CIRCUIT IN INJECTOR NO.4...................................610 TROUBLESHOOTING BY FAILURE CODE, PART 4....................................................................613 FAILURE CODE [CA342] ABNORMALITY IN ENGINE CONTROLLER DATA CONSISTENCY.................................615 FAILURE CODE [CA351] ABNORMALITY IN INJECTOR DRIVE CIRCUIT.............................................616 FAILURE CODE [CA352] SENSOR POWER SOURCE 1 TOO LOW.....................................................618 FAILURE CODE [CA386] SENSOR POWER SOURCE 1 TOO HIGH....................................................620 FAILURE CODE [CA428] WATER DETECTION SENSOR TOO HIGH...................................................621 FAILURE CODE [CA429] WATER DETECTION SENSOR TOO LOW....................................................623 FAILURE CODE [CA435] ABNORMALITY IN ENGINE OIL PRESSURE SWITCH.........................................625 FAILURE CODE [CA441] POWER SOURCE VOLTAGE TOO LOW......................................................626 FAILURE CODE [CA442] POWER SOURCE VOLTAGE TOO HIGH.....................................................628 FAILURE CODE [CA449] COMMON RAIL PRESSURE SENSOR TOO HIGH (2)..........................................630 FAILURE CODE [CA451] COMMON RAIL PRESSURE SENSOR TOO HIGH..............................................631 FAILURE CODE [CA452] COMMON RAIL PRESSURE SENSOR TOO LOW...............................................633 FAILURE CODE [CA488] CHARGE TEMPERATURE TOO HIGH AND TORQUE DERATED....................................635 FAILURE CODE [CA553] COMMON RAIL PRESSURE SENSOR TOO HIGH (1)..........................................635 FAILURE CODE [CA559] SUPPLY PUMP NO PRESSURE...........................................................636 FAILURE CODE [CA689] ABNORMALITY IN ENGINE NE SPEED SENSOR.............................................637 FAILURE CODE [CA731] ABNORMAL PHASE IN ENGINE BKUP SPEED SENSOR........................................639 FAILURE CODE [CA757] LOSS OF ALL ENGINE CONTROLLER DATA................................................640 FAILURE CODE [CA778] ABNORMALITY IN ENGINE BKUP SPEED SENSOR...........................................642 FAILURE CODE [CA1633] CAN COMMUNICATION ERROR (ENGINE CONTROLLER)......................................644 FAILURE CODE [CA2185] THROTTLE PEDAL SENSOR POWER SOURCE TOO HIGH......................................646 FAILURE CODE [CA2186] THROTTLE PEDAL SENSOR POWER SOURCE TOO LOW.......................................647 FAILURE CODE [CA2249] SUPPLY PUMP NO PRESSURE (2)......................................................648 FAILURE CODE [CA2311] ABNORMAL RESISTANCE IN PUMP REGULATOR VALVE......................................649 FAILURE CODE [CA2555] DISCONNECTION IN AIR INTAKE HEATER RELAY.........................................651 FAILURE CODE [CA2556] SHORT CIRCUIT IN AIR INTAKE HEATER RELAY.........................................653 TROUBLESHOOTING BY FAILURE CODE, PART 5....................................................................656 FAILURE CODE [D162KY] SHORT CIRCUIT IN HORN RELAY......................................................658 FAILURE CODE [D162KZ] DISCONNECTION OR SHORT CIRCUIT IN HORN RELAY.....................................660 FAILURE CODE [DA22KK] SOLENOID POWER SOURCE TOO LOW....................................................662 FAILURE CODE [DA25KP] ABNORMALITY IN PRESSURE SENSOR POWER SOURCE......................................664 FAILURE CODE [DA2RMC] CAN COMMUNICATION ERROR (WORK EQUIPMENT AND PUMP CONTROLLER).....................667 FAILURE CODE [DA2SKQ] ABNORMALITY IN MODEL CODE INPUT..................................................669 FAILURE CODE [DAFRMC] CAN COMMUNICATION ERROR (MONITOR CONTROLLER).....................................671 FAILURE CODE [DDA6KA] DISCONNECTION IN ENGINE STOP SWITCH..............................................673 FAILURE CODE [DGH2KB] SHORT CIRCUIT IN HYDRAULIC OIL TEMPERATURE SENSOR................................675 FAILURE CODE [DHPAMA] ABNORMALITY IN F PUMP PRESSURE SENSOR............................................676 FAILURE CODE [DHPBMA] ABNORMALITY IN R PUMP PRESSURE SENSOR............................................678 FAILURE CODE [DUB0KY] SHORT CIRCUIT IN BEACON SOLID STATE RELAY........................................680 FAILURE CODE [DUB0KZ] DISCONNECTION OR SHORT CIRCUIT IN BEACON SOLID STATE RELAY.......................682 FAILURE CODE [DXA0KA] DISCONNECTION IN PC-EPC SOLENOID.................................................684 FAILURE CODE [DXA0KB] SHORT CIRCUIT IN PC-EPC SOLENOID.................................................685 FAILURE CODE [DXA0KY] SHORT CIRCUIT IN PC-EPC SOLENOID.................................................686 FAILURE CODE [DXE0KA] DISCONNECTION IN LS-EPC SOLENOID.................................................687 FAILURE CODE [DXE0KB] SHORT CIRCUIT IN LS-EPC SOLENOID.................................................688 FAILURE CODE [DXE0KY] SHORT CIRCUIT IN LS-EPC SOLENOID.................................................689 TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE)..............................................................691 INFORMATION IN TROUBLESHOOTING TABLE...................................................................693 E-1 ENGINE DOES NOT START (ENGINE DOES NOT TURN).......................................................694 E-2 THE ENGINE STOPS WHILE IT IS RUNNING...............................................................697 E-3 THE AUTOMATIC WARM-UP FUNCTION DOES NOT WORK.......................................................699 E-4 PREHEATER DOES NOT OPERATE.........................................................................700 E-5 THE WHOLE WORK EQUIPMENT STOPS SUDDENLY............................................................702 E-6 THE RED MARK OF EMERGENCY STOP IS INDICATED JUST AFTER THE ENGINE IS STARTED.......................704 E-7 THE MACHINE MONITOR DOES NOT DISPLAY ANY ITEM......................................................707 E-8 SOME ITEMS ARE NOT DISPLAYED ON THE MACHINE MONITOR................................................709 E-9 CONTENTS OF DISPLAY BY MACHINE MONITOR ARE DIFFERENT FROM APPLICABLE MACHINE.......................709 E-10 FUEL LEVEL MONITOR WAS LIGHTED IN RED WHILE ENGINE RUNNING........................................710 E-11 ENGINE COOLANT TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY.......................................711 E-12 THE FUEL LEVEL GAUGE DOES NOT DISPLAY NORMALLY....................................................713 E-13 THE HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT DISPLAY NORMALLY.....................................714 E-14 THE TRAVEL, WORK, AND INSPECTION MODES DO NOT CHANGE..............................................715 E-15 THE CRUSHER CLEARANCE ADJUSTMENT MODE DOES NOT CHANGE.............................................717 E-16 THE CRUSHER ROTATION DIRECTION DOES NOT CHANGE....................................................719 E-17 MACHINE DOES NOT TRAVEL...........................................................................720 E-18 TRAVEL CANNOT BE CONTROLLED BY RADIO CONTROL......................................................722 E-19 THE FEEDER CANNOT BE TURNED ON AND OFF BY RADIO CONTROL...........................................726 E-20 ONE-TOUCH START, STOP SWITCH CANNOT BE OPERATED BY RADIO CONTROL..................................729 E-21 THE MONITOR SWITCHES DO NOT WORK..................................................................732 E-22 THE CRUSHER CANNOT BE OPERATED WITH THE CRUSHER MANUAL FORWARD/REVERSE SWITCH ON THE MONITOR......733 E-23 THE CONVEYOR CANNOT BE OPERATED WITH THE CONVEYOR MANUAL FORWARD/REVERSE SWITCH ON THE MONITOR....734 E-24 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY..........................................................735 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)................................................738 SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS......................................................740 INFORMATION CONTAINED IN TROUBLESHOOTING TABLE.........................................................742 H-1 THE SPEED OR POWER OF THE WHOLE WORK EQUIPMENT AND TRAVEL IS LOW...................................743 H-2 THE ENGINE SPEED LOWERS EXTREMELY OR THE ENGINE STALLS.............................................745 H-3 THE WORK EQUIPMENT AND TRAVEL SYSTEMS DO NOT WORK..................................................746 H-4 ABNORMAL SOUND COMES OUT FROM AROUND THE HYDRAULIC PUMP............................................746 H-5 FINE CONTROL PERFORMANCE OR RESPONSE IS LOW........................................................747 H-6 THE CONVEYOR DOES NOT OPERATE......................................................................748 H-7 THE SPEED OR POWER OF THE CONVEYOR IS LOW..........................................................749 H-8 THE CRUSHER DOES NOT OPERATE.......................................................................750 H-9 THE SPEED OR POWER OF CRUSHER IS LOW...............................................................751 H-10 THE FEEDER DOES NOT OPERATE.......................................................................751 H-11 THE FEEDER DOES NOT FEED SMOOTHLY (VIBRATION FREQUENCY IS LOW)....................................752 H-12 THE MAGNETIC SEPARATOR DOES NOT OPERATE...........................................................752 H-13 THE SPEED OF MAGNETIC SEPARATOR BELT IS LOW.......................................................753 H-14 THE SIDE CONVEYOR DOES NOT OPERATE................................................................753 H-15 THE SPEED OR POWER OF THE SIDE CONVEYOR IS LOW....................................................754 H-16 THE PRIMARY CONVEYOR AND THE SIDE CONVEYOR DO NOT MOVE UP AND DOWN................................755 H-17 THE MACHINE DEVIATES DURING TRAVE.................................................................756 H-18 THE TRAVEL SPEED IS LOW...........................................................................758 H-19 THE MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW..........................................760 H-20 THE TRAVEL MOTOR DOES NOT WORK (ONLY ONE SIDE)....................................................761 H-21 WHEN THE TRAVEL SWITCH OF THE RADIO CONTROLLER IS DEPRESSED, THE MACHINE DOES NOT TRAVEL..........761 H-22 THE CRUSHER CLEARANCE CANNOT BE ADJUSTED..........................................................762 TROUBLESHOOTING OF ENGINE (S-MODE).........................................................................764 METHOD OF USING TROUBLESHOOTING CHART..................................................................766 S-1 STARTING PERFORMANCE IS POOR.......................................................................769 S-2 ENGINE DOES NOT START..............................................................................770 S-3 ENGINE DOES NOT PICK UP SMOOTHLY...................................................................773 S-4 ENGINE STOPS DURING OPERATIONS.....................................................................774 S-5 ENGINE DOES NOT ROTATE SMOOTHLY....................................................................775 S-6 ENGINE LACK OUTPUT (OR LACKS POWER)................................................................776 S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION).....................................................777 S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)............................................778 S-9 OIL BECOMES CONTAMINATED QUICKLY...................................................................779 S-10 FUEL CONSUMPTION IS EXCESSIVE.....................................................................780 S-11 OIL IS IN COOLANT (OR COOLANT SPURTS BACK OR COOLANT LEVEL GOES DOWN).............................781 S-12 OIL PRESSURE DROPS................................................................................782 S-13 OIL LEVEL RISES (ENTRY OF COOLANT/FUEL)...........................................................783 S-14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING)................................................784 S-15 ABNORMAL NOISE IS MADE............................................................................785 S-16 VIBRATION IS EXCESSIVE............................................................................786 50 DISASSEMBLY AND ASSEMBLY.................................................................................... 0 GENERAL INFORMATION ON DISASSEMBLY AND ASSEMBLY............................................................788 HOW TO READ THIS MANUAL................................................................................789 COATING MATERIALS LIST.................................................................................791 WORK EQUIPMENT.............................................................................................796 DISASSEMBLY AND ASSEMBLY OF CRUSHER....................................................................797 REPLACING CHEEK PLATES.................................................................................798 TURNING OVER AND REPLACING FIXED JAW PLATE.............................................................799 TURNING OVER AND REPLACING SWING JAW PLATE.............................................................800 REPLACING TOGGLE PLATE.................................................................................802 REPLACING TOGGLE SEATS.................................................................................805 DISASSEMBLY AND ASSEMBLY OF LOCK CYLINDER..............................................................806 REMOVAL AND INSTALLATION OF PRIMARY CONVEYOR ASSEMBLY..................................................810 REPLACEMENT OF BELT....................................................................................813 REPLACEMENT PROCEDURE FOR PRIMARY BELT CONVEYOR MOTOR..................................................815 REPLACEMENT PROCEDURE FOR PRIMARY BELT CONVEYOR HEAD PULLEY FRAME......................................817 PROCEDURE FOR FOLDING ENGINE FRONT COVER...............................................................826 90 DIAGRAMS AND DRAWINGS....................................................................................... 0 HYDRAULIC DIAGRAMS AND DRAWINGS............................................................................830 HYDRAULIC CIRCUIT DIAGRAM (1/2)........................................................................831 HYDRAULIC CIRCUIT DIAGRAM (2/2)........................................................................832 ELECTRICAL DIAGRAMS AND DRAWINGS...........................................................................834 ELECTRICAL CIRCUIT DIAGRAM (1/4).......................................................................835 ELECTRICAL CIRCUIT DIAGRAM (2/4).......................................................................836 ELECTRICAL CIRCUIT DIAGRAM (3/4).......................................................................837 ELECTRICAL CIRCUIT DIAGRAM (4/4) ......................................................................838 CONNECTOR ARRANGEMENT DIAGRAM (1/2)....................................................................839 CONNECTOR ARRANGEMENT DIAGRAM (2/2)....................................................................840

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: