$45

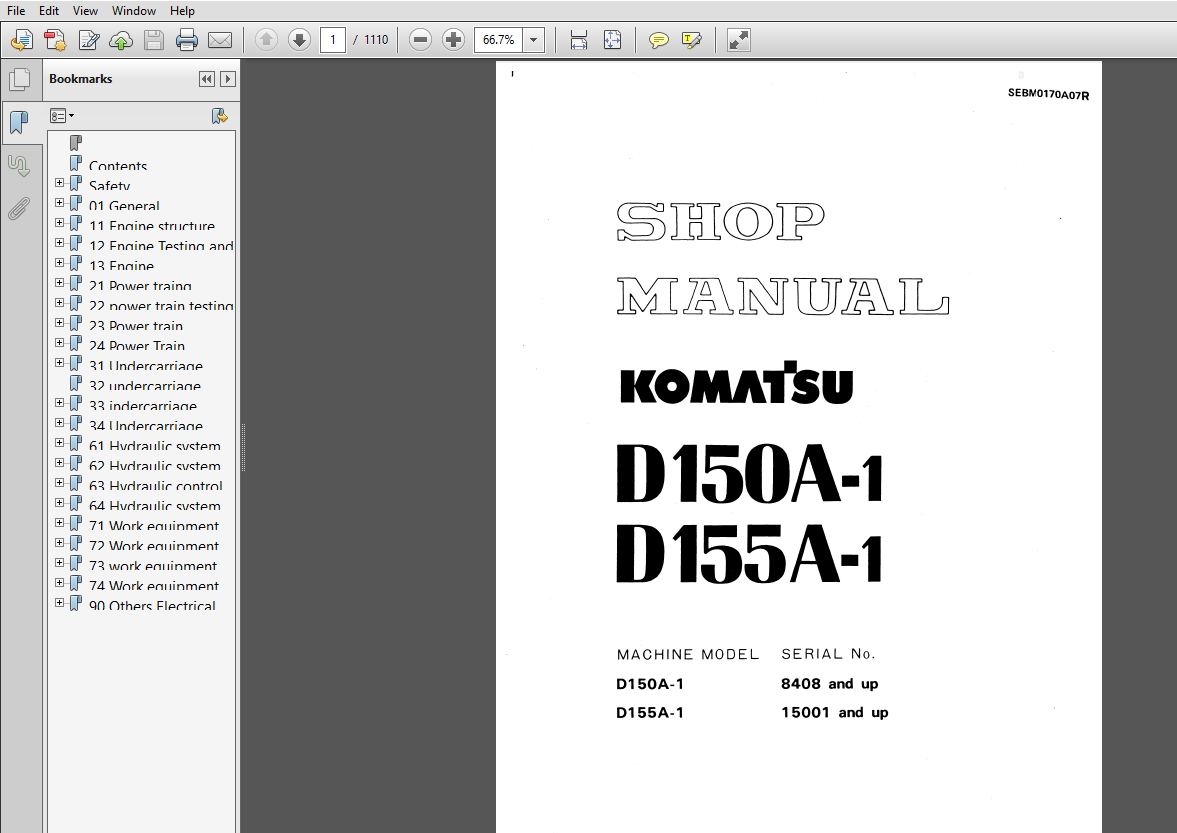

Komatsu D150A-1, D155A-1 Bulldozer Shop Manual PDF DOWNLOAD

Komatsu D150A-1 D155A-1 Bulldozer WorkShop Service Repair Manual

DESCRIPTION:

Komatsu D150A-1 D155A-1 Bulldozer WorkShop Service Repair Manual

FOREWORD:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the servicemen an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding. the manual is divided into chapters for each main group of components: these chapters are further divided into the following sections.

STRUCTURE AND FUNCTION

Ths section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

Ths section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating ”Problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

The section explains the order to be followed when removing, installing, disassembling or assembling each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

Ths section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

Komatsu D150A-1 D155A-1 Bulldozer WorkShop Service Repair Manual

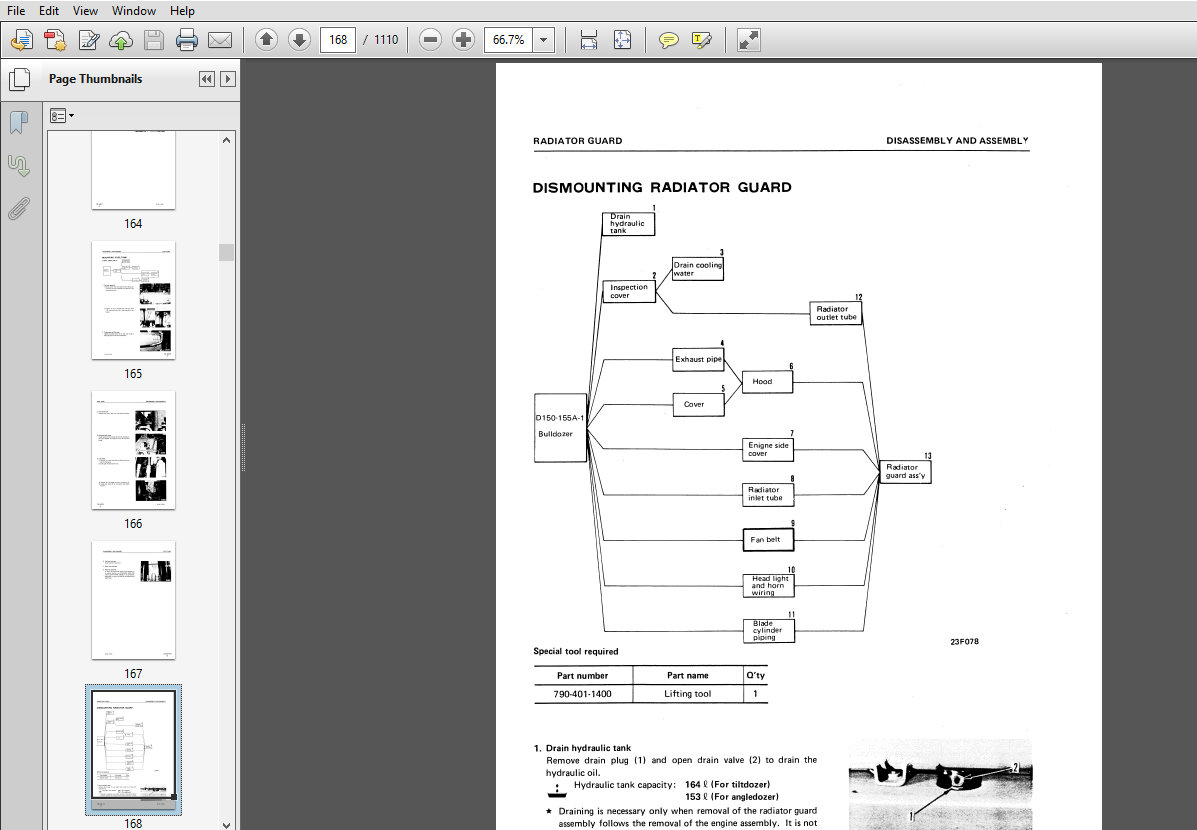

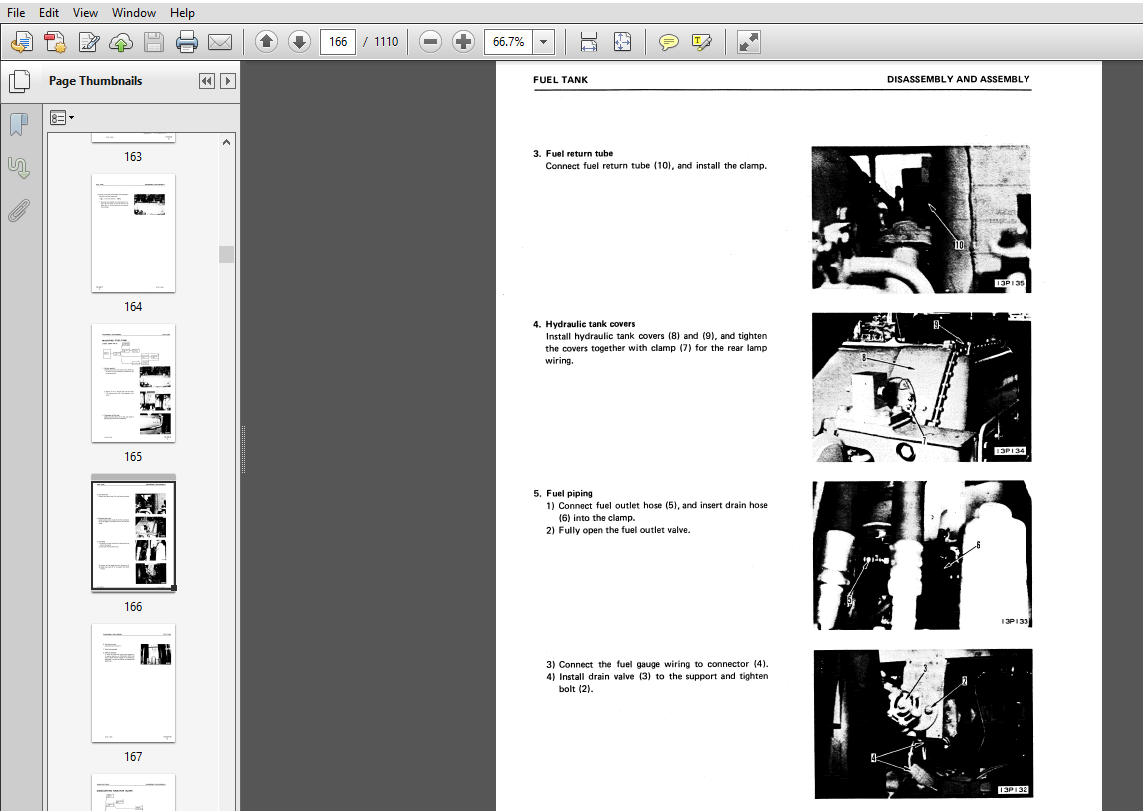

Contents.................................................... 2 Safety...................................................... 9 How to read the shop manual............................. 12 Hoisting instructions................................... 13 Standard tightening torque.............................. 14 01 General.................................................. 17 Specifications.......................................... 28 General assembly drawing................................ 30 Engine specifications................................... 43 Weight table............................................ 46 Position of serial numbers (Engine)..................... 52 Position of serial numbers (body)....................... 53 Table of oil and coolant................................ 54 11 Engine structure and function............................ 61 Radiator, fan........................................... 64 Oil cooler.............................................. 70 P.T.O................................................... 71 Engine control.......................................... 72 Fuel piping............................................. 73 12 Engine Testing and adjusting............................. 75 Tool list............................................... 78 Trouble shooting criteria............................... 79 General instructions.................................... 84 Intake ans exhaust system............................... 86 Engine body............................................. 90 Lubrication system...................................... 92 Fuel system............................................. 94 13 Engine disassembly and assembly.......................... 97 Dismounting turbocharger................................ 100 mounting turbocharger................................... 102 Dismounting engine oil cooler........................... 104 Mounting engine oil cooler.............................. 108 torque convertor oil cooler............................. 112 Nozzle holder........................................... 118 Fuel injection pump..................................... 122 Fan belt................................................ 128 Water pump.............................................. 130 Starting motor.......................................... 134 Alternator.............................................. 137 Cylinder head........................................... 142 Fuel tank............................................... 158 Radiator guard.......................................... 168 Radiator................................................ 176 Engine.................................................. 190 21 Power traing Structure and functions..................... 237 General................................................. 240 Main clutch............................................. 244 Inertia brake........................................... 248 Transmisssion D150A..................................... 254 Double mesh preventive device........................... 261 Torque convertor........................................ 264 Transmission D155A...................................... 268 Torqflow................................................ 278 Transmission lubrication relief vanlve.................. 286 Transmission control valve.............................. 287 Transmission pump....................................... 295 Bevel gear shaft and steering clutch.................... 298 Steering and brake piping............................... 302 steering hydraulic system............................... 306 Brake hydraulic system.................................. 310 Steering brake and booster D150A AND D155A.............. 314 Steering control valve.............................. 318 Steering and brake piping........................... 324 Steering and brake hydraulic circuit................ 327 Steering brake and booster D155A 25001.................. 328 Steering control valve d155a 25001...................... 334 Steering pump........................................... 339 Final drive............................................. 341 22 power train testing and adjusting........................ 345 Main clutch hydraulic control........................... 350 Torqflow hydraulic control.............................. 352 Steering hydraulic control.............................. 358 Brake hydraulic control................................. 364 Table of oil pressure measuring points.................. 368 Procedure for measuring oil pressure and temperature.... 376 Procedure for measurment of lever and pedal travel...... 382 Adjustment procedure for strokes........................ 386 Adjusting main clutch................................... 390 Table of maintenance standerds.......................... 392 23 Power train disassembly and assembly..................... 395 pto and flywheel........................................ 400 Main clutch............................................. 408 Transmission assembly................................... 416 Torque convertor........................................ 434 Torque convertor relief valve........................... 468 Torque converter regulator valve........................ 472 Torqflow transmission D155 15001 - 25000................ 476 Torqflow transmission D155A Sn 25001.................... 516 Mounting Torqflow transmission...................... 521 Dismounting Transmission control valve.............. 526 Mounting transmission control valve................. 528 Transmission lubrication valve...................... 535 Steering clutch..................................... 538 Bevel gear and bevel gear shaft......................... 558 Final drive............................................. 568 Steering control valve.................................. 574 Steering brake interlocking valve....................... 578 Brake safety valve...................................... 586 Brake booster........................................... 594 Final drive............................................. 600 Torqflow pump........................................... 614 Steering pump........................................... 618 Torque converter oil cooler............................. 622 Floor frame............................................. 630 Rops cab................................................ 642 Fuel tank............................................... 656 Radiator................................................ 660 Radiator guard.......................................... 668 24 Power Train Maintenance standard......................... 677 Transmission............................................ 692 Bevel gear shaft and steering system.................... 706 Final drive............................................. 720 31 Undercarriage Structure and function..................... 723 Track................................................... 726 Track group............................................. 730 Recail spring........................................... 731 Idler................................................... 732 Track roller, carrier roller............................ 733 Suspension.............................................. 734 32 undercarriage Testing and adjusting...................... 737 33 indercarriage Disassembly and assembly................... 739 track................................................... 742 Carrier roller.......................................... 750 Track roller............................................ 754 Idler................................................... 758 Recoil spring........................................... 762 Track frame............................................. 774 34 Undercarriage maintenance standard....................... 779 Undercarriage........................................... 782 61 Hydraulic system structure and function.................. 797 Hydraulic control....................................... 800 Hydraulic tank.......................................... 810 Hydraulic control valve................................. 812 Ripper selector valve and pilot check valve............. 816 Pin puller valve........................................ 820 Pilot valve............................................. 824 Rotary servo valve...................................... 827 Servo valve hydralic control/valve...................... 830 Safety valve............................................ 833 Cylinders............................................... 834 Piston valve............................................ 836 Hydraulic control....................................... 838 62 Hydraulic system testing and adjusting................... 863 General description..................................... 866 Hydraulic control....................................... 868 Pin puller control...................................... 870 Measurment of oil pressure and temperature.............. 871 Measurment of operating force........................... 875 Table of maintance standard............................. 878 63 Hydraulic control sysyem Disassembly and assembly........ 881 Disassembly and assembly................................ 883 Hydraulic pump.......................................... 886 Hydraulic tank.......................................... 890 Ripper & blade control valve............................ 898 Blade tilt control valve................................ 909 Blade tilt servo valve.................................. 914 Ripper servo valve...................................... 922 Ripper pin puller valve................................. 926 Ripper selector valve................................... 934 Blade lift cylinder..................................... 953 Blade tilt cylinder..................................... 970 Ripper lift & Tilt cylinder............................. 986 Ripper pin puller cylinder..............................1006 64 Hydraulic system Maintance standard......................1009 Torque specifications for nuts and bolts................1010 Hydraulic control valve.................................1012 Cylinders...............................................1021 71 Work equipment structure and function....................1025 Multi ripper............................................1030 Giant ripper............................................1034 72 Work equipment testing and adjustment....................1041 Straight tilt dozer.....................................1044 73 work equipment disassembly & assembly....................1047 Blade...................................................1050 Ripper..................................................1061 74 Work equipment Maintenance standard......................1073 Torque specifications...................................1074 Straight tilt dozer.....................................1076 Multi ripper............................................1080 Giant ripper............................................1082 90 Others Electrical system.................................1085 Electical circuit diagram...............................1088 Electical wiring diagram................................1096 Warning module..........................................1099 Automatic priming system................................1102

IMAGES PREVIEW OF THE MANUAL: