$45

Komatsu D155AX-6 Bulldozer (80001 and up) Shop Manual - PDF DOWNLOAD

Komatsu D155AX-6 Bulldozer (80001 and up) Shop Manual

FILE DETAILS:

Komatsu D155AX-6 Bulldozer (80001 and up) Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : SEN00596-09

Total Pages : 1146

DESCRIPTION:

Komatsu D155AX-6 Bulldozer (80001 and up) Shop Manual

HOW TO READ THE SHOP MANUAL:

1. Composition of shop manual:

This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword:

This section explains the shop manuals list, table of contents, safety, and basic information.

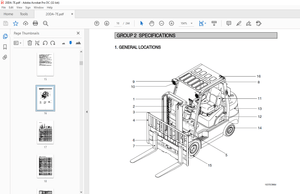

01. Specification:

This section explains the specifications of the machine.

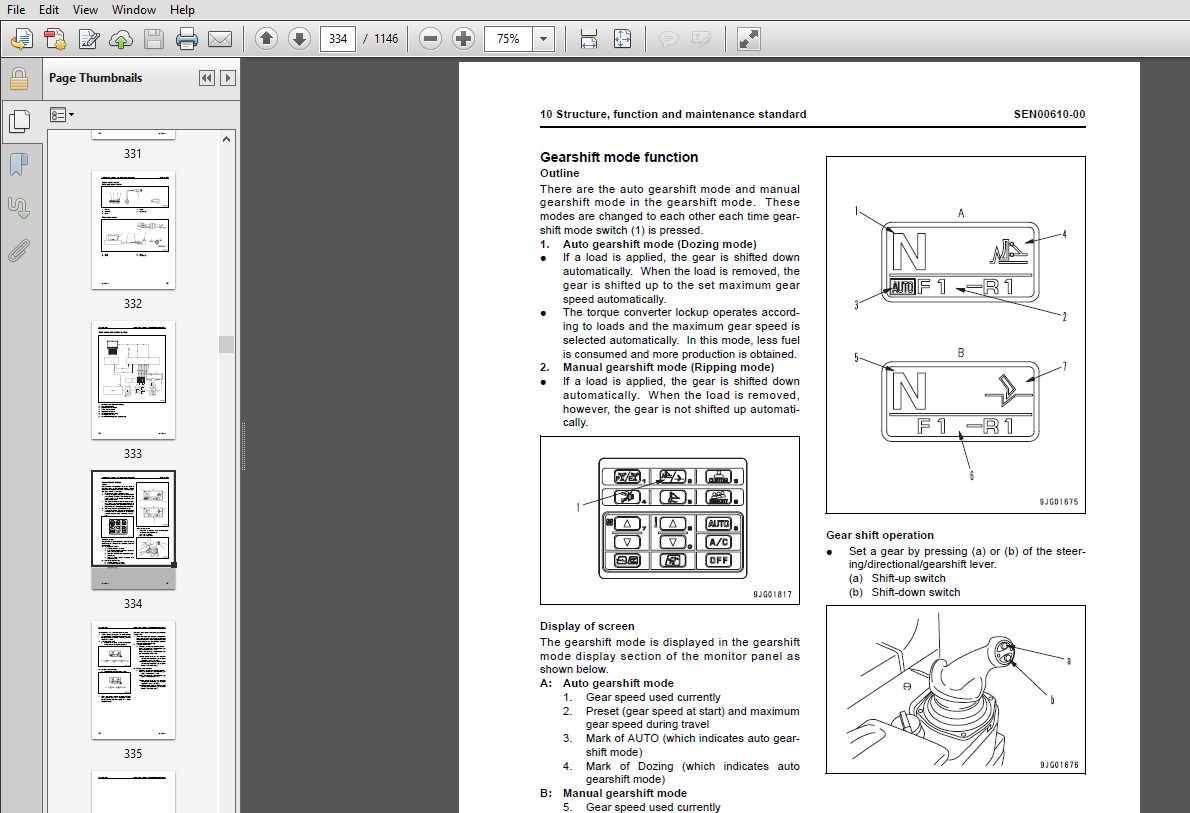

10. Structure, function and maintenance standard:

This section explains the structure, function, and maintenance standard values of each component. The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

20. Standard value table:

This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting:

This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

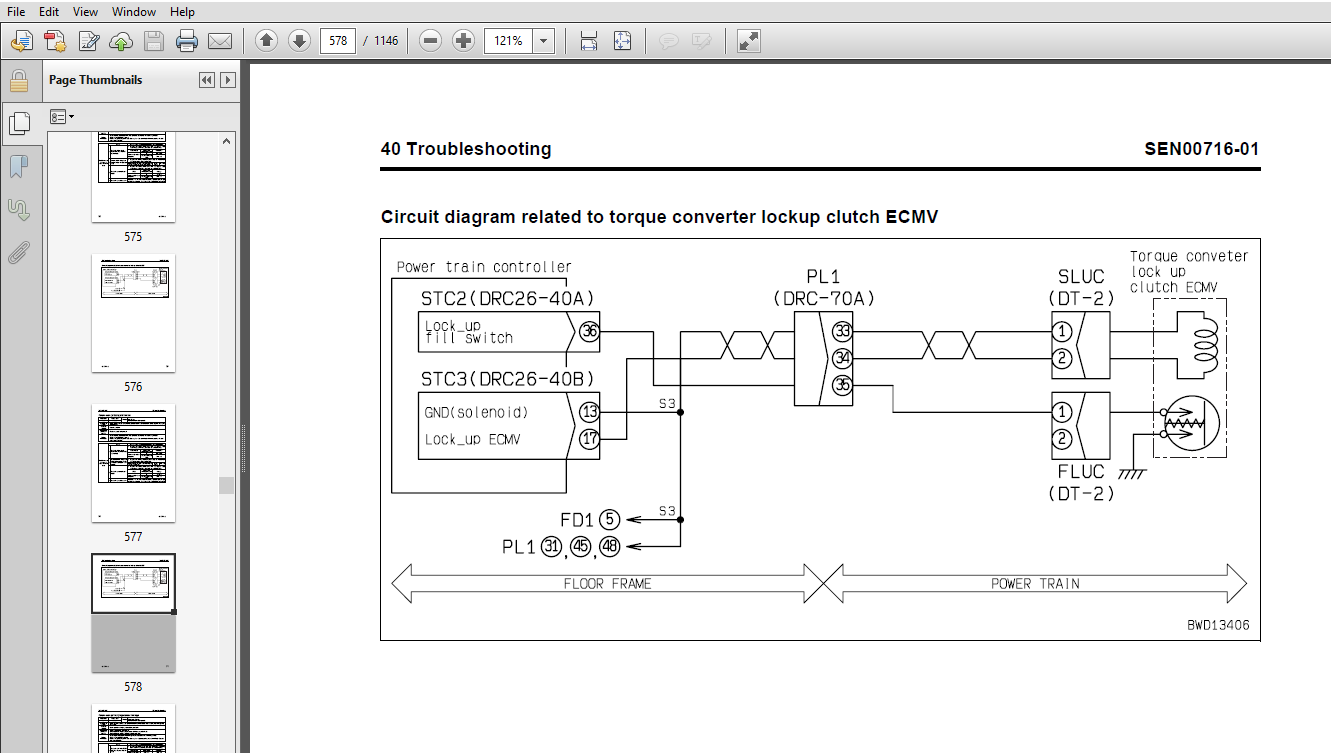

40. Troubleshooting:

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

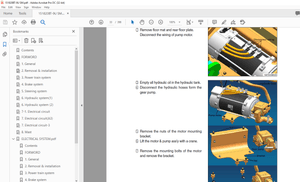

50. Disassembly and assembly:

This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume):

- Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams. - Engine volume

This section explains the method of reproducing, repairing, and replacing parts

TABLE OF CONTENTS:

Komatsu D155AX-6 Bulldozer (80001 and up) Shop Manual

COVER............................................................................................... 1 00 INDEX AND FOREWORD............................................................................... 0 INDEX........................................................................................... 2 ORGANIZATION LIST OF THE SHOP MANUAL........................................................ 3 TABLE OF CONTENTS........................................................................... 5 FOREWORD AND GENERAL INFORMATION................................................................ 17 SAFETY NOTICE .............................................................................. 18 HOW TO READ THE SHOP MANUAL ................................................................ 22 EXPLANATION OF TERMS FOR MAINTENANCE STANDARD............................................... 24 HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENT......................................... 26 HOW TO READ ELECTRIC WIRE CODE.............................................................. 34 METHOD OF DISASSEMBLING AND CONNECTING PUSH-PULL TYPE COUPLER............................... 37 STANDARD TIGHTENING TORQUE TABLE ........................................................... 40 CONVERSION TABLE ........................................................................... 44 01 SPECIFICATION.................................................................................... 0 SPECIFICATION AND TECHNICAL DATA................................................................ 50 SPECIFICATION DIMENSION DRAWINGS............................................................ 51 SPECIFICATIONS.............................................................................. 52 WEIGHT TABLE................................................................................ 58 TABLE OF FUEL, COOLANT AND LUBRICANTS....................................................... 61 10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD..................................................... 0 ENGINE AND COOLING SYSTEM....................................................................... 64 RADIATOR, OIL COOLER........................................................................ 65 ENGINE MOUNT................................................................................ 68 COOLING FAN PUMP............................................................................ 69 COOLING FAN MOTOR........................................................................... 76 POWER TRAIN SYSTEM, PART 1...................................................................... 83 POWER TRAIN SKELETON........................................................................ 84 OVERALL DRAWING OF POWER TRAIN UNIT......................................................... 86 POWER TRAIN HYDRAULIC PIPING DRAWING ....................................................... 88 DAMPER, UNIVERSAL JOINT..................................................................... 90 TORQUE CONVERTER, PTO....................................................................... 92 TORQUE CONVERTER CONTROL VALVE.............................................................. 101 LOCKUP CLUTCH ECMV, STATOR CLUTCH ECMV...................................................... 102 TRANSMISSION CONTROL........................................................................ 107 TRANSMISSION................................................................................ 109 TRANSMISSION ECMV........................................................................... 121 MAIN RELIEF VALVE AND TORQUE CONVERTER RELIEF VALVE......................................... 127 LUBRICATION RELIEF VALVE.................................................................... 129 SCAVENGING PUMP............................................................................. 130 POWER TRAIN AND STEERING LUBRICATION PUMP................................................... 131 POWER TRAIN SYSTEM, PART 2...................................................................... 134 HSS SYSTEM.................................................................................. 135 HSS MOTOR................................................................................... 137 HYDRAULIC, HSS PUMP......................................................................... 145 HYDRAULIC OIL COOLER BYPASS VALVE........................................................... 167 STEERING, BRAKE CONTROL..................................................................... 168 STEERING UNIT............................................................................... 170 BRAKE CONTROL VALVE......................................................................... 186 BRAKE ECMV.................................................................................. 188 PARKING BRAKE SOLENOID VALVE................................................................ 193 SUDDEN STOP PREVENTION VALVE................................................................ 195 FINAL DRIVE ................................................................................ 197 SPROCKET.................................................................................... 201 UNDERCARRIAGE AND FRAME......................................................................... 204 TRACK FRAME................................................................................. 205 RECOIL SPRING............................................................................... 207 IDLER....................................................................................... 209 TRACK ROLLER................................................................................ 211 CARRIER ROLLER.............................................................................. 213 TRACK SHOE.................................................................................. 215 MAIN FRAME.................................................................................. 220 SUSPENSION.................................................................................. 222 HYDRAULIC SYSTEM................................................................................ 225 WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM..................................................... 226 WORK EQUIPMENT CONTROL PIPING DIAGRAM....................................................... 229 WORK EQUIPMENT CONTROL...................................................................... 230 HYDRAULIC TANK AND FILTER................................................................... 232 ACCUMULATOR................................................................................. 234 PCCS LEVER.................................................................................. 235 WORK EQUIPMENT LOCK VALVE................................................................... 239 CONTROL VALVE............................................................................... 240 WORK EQUIPMENT CYLINDER..................................................................... 276 PISTON VALVE................................................................................ 278 QUICK DROP VALVE............................................................................ 279 SELF PRESSURE REDUCING VALVE................................................................ 284 WORK EQUIPMENT.................................................................................. 292 CYLINDER STAY............................................................................... 293 BLADE....................................................................................... 295 CUTTING EDGE, END BIT....................................................................... 297 RIPPER...................................................................................... 298 CAB AND ITS ATTACHMENTS......................................................................... 303 CAB MOUNT + ROPS PIN........................................................................ 304 ROPS CAB.................................................................................... 305 AIR CONDITIONER............................................................................. 306 ELECTRICAL SYSTEM............................................................................... 308 ENGINE CONTROL.............................................................................. 309 ENGINE CONTROL SYSTEM....................................................................... 310 DECELERATION POTENTIOMETER.................................................................. 311 MONITOR SYSTEM.............................................................................. 312 SENSORS..................................................................................... 330 PALM COMMAND CONTROL SYSTEM................................................................. 333 20 STANDARD VALUE TABLE............................................................................. 0 STANDARD SERVICE VALUE TABLE.................................................................... 337 STANDARD VALUE TABLE FOR ENGINE............................................................. 338 STANDARD VALUE TABLE FOR MACHINE............................................................ 339 30 TESTING AND ADJUSTING ........................................................................... 0 TESTING AND ADJUSTING, PART 1................................................................... 348 TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING .......................................... 350 MEASURING ENGINE SPEED...................................................................... 352 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE).............................................. 354 MEASURING EXHAUST TEMPERATURE............................................................... 355 MEASURING EXHAUST GAS COLOR................................................................. 357 ADJUSTING VALVE CLEARANCE................................................................... 358 MEASURING COMPRESSION PRESSURE.............................................................. 359 MEASURING BLOW-BY PRESSURE.................................................................. 361 MEASURING ENGINE OIL PRESSURE............................................................... 362 HANDLING FUEL SYSTEM PARTS.................................................................. 363 RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM................................................ 363 MEASURING FUEL PRESSURE..................................................................... 364 MEASURING FUEL RETURN RATE AND FUEL LEAKAGE................................................. 365 BLEEDING AIR FROM FUEL CIRCUIT.............................................................. 369 MEASURING FUEL CIRCUIT FOR LEAKAGE.......................................................... 371 TESTING AND ADJUSTING ALTERNATOR BELT TENSION............................................... 372 TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION............................... 373 MEASURING FAN SPEED......................................................................... 374 MEASURING FAN CIRCUIT OIL PRESSURE.......................................................... 375 BLEEDING AIR FROM FAN PUMP.................................................................. 376 ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL........................................... 377 TESTING AND ADJUSTING, PART 2................................................................... 380 MEASURING POWER TRAIN OIL PRESSURE.......................................................... 382 ADJUSTING TRANSMISSION OUTPUT SHAFT SPEED SENSOR............................................ 390 SIMPLE TEST PROCEDURE FOR BRAKE PERFORMANCE................................................. 391 ADJUSTING BRAKE PEDAL....................................................................... 392 ADJUSTING PARKING BRAKE LEVER............................................................... 394 EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE........................................ 396 ADJUSTING IDLER CLEARANCE................................................................... 399 TESTING AND ADJUSTING TRACK SHOE TENSION.................................................... 400 MEASURING AND ADJUSTING WORK EQUIPMENT AND HSS OIL PRESSURE................................. 401 MEASURING CONTROL CIRCUIT BASIC PRESSURE.................................................... 405 MEASURING WORK EQUIPMENT LOCK SOLENOID VALVE OUTPUT PRESSURE................................ 406 EMERGENCY OPERATION METHOD WHEN WORK EQUIPMENT HAS TROUBLE.................................. 407 MEASURING RIPPER PIN PULLER SOLENOID VALVE OUTPUT PRESSURE.................................. 409 TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF BLADE AND RIPPER............................... 410 MEASURING INTERNAL LEAKAGE OF WORK EQUIPMENT CYLINDER....................................... 411 RELEASING RESIDUAL PRESSURE FROM WORK EQUIPMENT CYLINDER.................................... 412 BLEEDING AIR FROM WORK EQUIPMENT CYLINDER................................................... 412 ADJUSTING WORK EQUIPMENT LOCK LEVER......................................................... 413 ADJUSTING BLADE............................................................................. 414 ADJUSTING OPERATOR'S CAB.................................................................... 416 TESTING AND ADJUSTING, PART 3................................................................... 421 SPECIAL FUNCTIONS OF MACHINE MONITOR (EMMS)................................................. 422 TESTING AND ADJUSTING, PART 4................................................................... 500 HANDLING OF POWER SUPPLY CIRCUIT OF ENGINE CONTROLLER....................................... 501 PREPARATION WORK FOR TROUBLESHOOTING OF ELECTRICAL SYSTEM................................... 502 PM CLINIC................................................................................... 504 40 TROUBLESHOOTING.................................................................................. 0 GENERAL INFORMATION ON TROUBLESHOOTING.......................................................... 515 POINTS TO REMEMBER WHEN TROUBLESHOOTING .................................................... 516 SEQUENCE OF EVENTS IN TROUBLESHOOTING....................................................... 517 CHECK BEFORE TROUBLESHOOTING................................................................ 518 CLASSIFICATION AND PROCEDURES FOR TROUBLESHOOTING........................................... 519 CONNECTOR PIN NOS. AND CONNECTION TABLE..................................................... 522 T-BOXES AND T-ADAPTERS TABLE................................................................ 545 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 1.............................................. 549 FAILURE CODES TABLE......................................................................... 551 BEFORE CARRYING OUT TROUBLESHOOTING WHEN FAILURE CODE IS DISPLAYED.......................... 558 INFORMATION IN TROUBLESHOOTING TABLE........................................................ 562 FAILURE CODE [1500L0] TRANSMISSION CLUTCH: ABNORMAL......................................... 564 FAILURE CODE [15SAL1] FORWARD CLUTCH: FILL HIGH............................................. 565 FAILURE CODE [15SALH] FORWARD CLUTCH: FILL LOW.............................................. 566 FAILURE CODE [15SBL1] REVERSE CLUTCH: FILL HIGH............................................. 567 FAILURE CODE [15SBLH] REVERSE CLUTCH: FILL LOW.............................................. 568 FAILURE CODE [15SEL1] SPEED 1ST CLUTCH: FILL HIGH........................................... 569 FAILURE CODE [15SELH] SPEED 1ST CLUTCH: FILL LOW............................................ 570 FAILURE CODE [15SFL1] SPEED 2ND CLUTCH: FILL HIGH........................................... 571 FAILURE CODE [15SFLH] SPEED 2ND CLUTCH: FILL LOW............................................ 572 FAILURE CODE [15SGL1] SPEED 3RD CLUTCH: FILL HIGH........................................... 573 FAILURE CODE [15SGLH] SPEED 3RD CLUTCH: FILL LOW............................................ 574 FAILURE CODE [15SJL1] L/U: FILL HIGH........................................................ 575 FAILURE CODE [15SJLH] L/U: FILL LOW......................................................... 577 FAILURE CODE [2301L1] RIGHT BRAKE: FILL HIGH................................................ 579 FAILURE CODE [2301LH] RIGHT BRAKE: FILL LOW................................................. 580 FAILURE CODE [2302L1] LEFT BRAKE: FILL HIGH................................................. 581 FAILURE CODE [2302LH] LEFT BRAKE: FILL LOW.................................................. 582 FAILURE CODE [7RFRKA] ECM HOLD RELAY: DISCONNECTION......................................... 583 FAILURE CODE [AA10NX] AIR CLEANER CLOGGING.................................................. 585 FAILURE CODE [AB00MA] BATTERY CHARGE ABNORMAL............................................... 587 FAILURE CODE [B@BAZG] ENG OIL PRESS LOW..................................................... 589 FAILURE CODE [B@BCNS] ENG WATER OVERHEAT.................................................... 589 FAILURE CODE [B@BCZK] ENG WATER LEVEL LOW................................................... 590 FAILURE CODE [B@CENS] T/C OIL OVERHEAT...................................................... 590 FAILURE CODE [B@HANS] HYD OIL OVERHEAT...................................................... 591 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 2.............................................. 593 FAILURE CODE [CA111] EMC CRITICAL INTERNAL FAILURE.......................................... 595 FAILURE CODE [CA115] ENG NE AND BKUP SPEED SENS ERROR....................................... 597 FAILURE CODE [CA122] CHG AIR PRESS SENSOR HIGH ERROR........................................ 598 FAILURE CODE [CA123] CHG AIR PRESS SENSOR LOW ERROR......................................... 600 FAILURE CODE [CA131] THROTTLE SENSOR HIGH ERROR............................................. 601 FAILURE CODE [CA132] THROTTLE SENSOR LOW ERROR.............................................. 603 FAILURE CODE [CA135] ENG OIL PRESS SENSOR HIGH ERROR........................................ 604 FAILURE CODE [CA141] ENG OIL PRESS SENSOR LOW ERROR......................................... 606 FAILURE CODE [CA144] COOLANT TEMP SENS HIGH ERROR........................................... 607 FAILURE CODE [CA145] COOLANT TEMP SENS LOW ERROR............................................ 609 FAILURE CODE [CA153] CHG AIR TEMP SENSOR HIGH ERROR......................................... 610 FAILURE CODE [CA154] CHG AIR TEMP SENSOR LOW ERROR.......................................... 612 FAILURE CODE [CA187] SENS SUPPLY 2 VOLT LOW ERROR........................................... 612 FAILURE CODE [CA221] AMBIENT PRESS SENS HIGH ERROR.......................................... 613 FAILURE CODE [CA222] AMBIENT PRESS SENS LOW ERROR........................................... 615 FAILURE CODE [CA227] SENS SUPPLY 2 VOLT HIGH ERROR.......................................... 616 FAILURE CODE [CA234] ENG OVERSPEED.......................................................... 618 FAILURE CODE [CA238] NE SPEED SENS SUPPLY VOLT ERROR........................................ 619 FAILURE CODE [CA263] FUEL TEMP SENSOR HIGH ERROR............................................ 621 FAILURE CODE [CA265] FUEL TEMP SENSOR LOW ERROR............................................. 622 FAILURE CODE [CA271] PCV1 SHORT ERROR....................................................... 623 FAILURE CODE [CA272] PCV1 OPEN ERROR........................................................ 624 FAILURE CODE [CA273] PCV2 SHORT ERROR....................................................... 625 FAILURE CODE [CA274] PCV2 OPEN ERROR........................................................ 626 FAILURE CODE [CA322] INJ #1 (L#1) OPEN/SHORT ERROR.......................................... 627 FAILURE CODE [CA323] INJ #5 (L#5) OPEN/SHORT ERROR.......................................... 628 FAILURE CODE [CA324] INJ #3 (L#3) OPEN/SHORT ERROR.......................................... 629 FAILURE CODE [CA325] INJ #6 (L#6) OPEN/SHORT ERROR.......................................... 630 FAILURE CODE [CA331] INJ #2 (L#2) OPEN/SHORT ERROR.......................................... 631 FAILURE CODE [CA332] INJ #4 (L#4) OPEN/SHORT ERROR.......................................... 632 FAILURE CODE [CA342] CALIBRATION CODE INCOMPATIBILITY....................................... 633 FAILURE CODE [CA351] INJECTORS DRIVE CIRCUIT ERROR.......................................... 634 FAILURE CODE [CA352] SENS SUPPLY 1 VOLT LOW ERROR........................................... 636 FAILURE CODE [CA286] SENS SUPPLY 1 VOLT HIGH ERROR.......................................... 637 FAILURE CODE [CA441] BATTERY VOLTAGE LOW ERROR.............................................. 639 FAILURE CODE [CA442] BATTERY VOLTAGE HIGH ERROR............................................. 639 FAILURE CODE [CA449] RAIL PRESS VERY HIGH ERROR............................................. 640 FAILURE CODE [CA451] RAIL PRESS SENSOR HIGH ERROR........................................... 641 FAILURE CODE [CA452] RAIL PRESS SENSOR LOW ERROR............................................ 643 FAILURE CODE [CA553] RAIL PRESS HIGH ERROR.................................................. 643 FAILURE CODE [CA554] RAIL PRESS SENSOR IN RANGE ERROR....................................... 644 FAILURE CODE [CA559] RAIL PRESS LOW ERROR................................................... 645 FAILURE CODE [CA689] ENG NE SPEED SENSOR ERROR.............................................. 649 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 3.............................................. 652 FAILURE CODE [CA731] ENG BKUP SPEED SENS PHASE ERROR........................................ 654 FAILURE CODE [CA757] ALL CONTINUOUS DATA LOST ERROR......................................... 654 FAILURE CODE [CA778] ENG BKUP SPEED SENSOR ERROR............................................ 655 FAILURE CODE [CA1228] EGR VALVE SERVO ERROR 1............................................... 657 FAILURE CODE [CA1625] EGR VALVE SERVO ERROR 2............................................... 658 FAILURE CODE [CA1626] BP VALVE SOL CURRENT HIGH ERROR....................................... 659 FAILURE CODE [CA1627] BP VALVE SOL CURRENT LOW ERROR........................................ 661 FAILURE CODE [CA1628] BYPASS VALVE SERVO ERROR 1............................................ 662 FAILURE CODE [CA1619] BYPASS VALVE SERVO ERROR 2............................................ 663 FAILURE CODE [CA1631] BP VALVE POS SENS HIGH ERROR.......................................... 664 FAILURE CODE [CA1632] BP VALVE POS SENS LOW ERROR........................................... 666 FAILURE CODE [CA1633] KOMNET DATALINK TIMEOUT ERROR......................................... 667 FAILURE CODE [CA1642] EGR INLET PRESS SENS LOW ERROR........................................ 669 FAILURE CODE [CA1653] EGR INLET PRESS SENS HIGH ERROR....................................... 670 FAILURE CODE [CA2185] THROT SENS SUP VOLT HIGH ERROR........................................ 672 FAILURE CODE [CA2186] THROT SENS SUP VOLT LOW ERROR......................................... 674 FAILURE CODE [CA2249] RAIL PRESS VERY LOW ERROR............................................. 674 FAILURE CODE [CA2271] EGR VALVE POS SENS HIGH ERROR......................................... 675 FAILURE CODE [CA2272] EGR VALVE POS SENS LOW ERROR.......................................... 677 FAILURE CODE [CA2351] EGR VALVE SOL CURRENT HIGH ERROR...................................... 678 FAILURE CODE [CA2352] EGR VALVE SOL CURRENT LOW ERROR....................................... 680 FAILURE CODE [CA2555] GRID HTR RELAY VOLT LOW ERROR......................................... 681 FAILURE CODE [CA2556] GRID HTR RELAY VOLT HIGH ERROR........................................ 682 FAILURE CODE [D110KA] BATTERY RELAY: DISCONNECTION.......................................... 684 FAILURE CODE [D110KB] BATTERY RELAY: DRIVE SHORT CIRCUIT.................................... 686 FAILURE CODE [D130KA] NEUTRAL RELAY: DISCONNECTION.......................................... 688 FAILURE CODE [D130KB] NEUTRAL RELAY: SHORT CIRCUIT.......................................... 690 FAILURE CODE [D161KA] BACK-UP ALARM RELAY: DISCONNECTION.................................... 692 FAILURE CODE [D161KB] BACK-UP ALARM RELAY: SHORT CIRCUIT.................................... 694 FAILURE CODE [D190KA] ACC SIGNAL RELAY: DISCONNECTION....................................... 696 FAILURE CODE [D190KB] ACC SIGNAL RELAY: SHORT CIRCUIT....................................... 698 FAILURE CODE [D5ZKKX] THROTTLE DIAL: OUT OF NORMAL RANGE.................................... 700 FAILURE CODE [DAFRKR] CAN DISCONNECTION (MONITOR)........................................... 702 FAILURE CODE [DB2RKR] CAN DISCONNECTION (ENGINE CONTROLLER)................................. 704 FAILURE CODE [DB90KK] WE CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 706 FAILURE CODE [DB90KR] PT CONTROLLER: CAN COMMUNICATION LOST................................. 708 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 4.............................................. 711 FAILURE CODE [DB90KT] WE CONTROLLER: ABNORMALITY IN CONTROLLER.............................. 713 FAILURE CODE [DB95KK] WE CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 714 FAILURE CODE [DB97KK] WE CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 716 FAILURE CODE [DB99KQ] WE CONTROLLER: TYPE SELECT SIGNAL..................................... 718 FAILURE CODE [DB9RKR] WE CONTROLLER: CAN COMMUNICATION LOST................................. 719 FAILURE CODE [DBE0KK] PT CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 721 FAILURE CODE [DBE0KT] PT CONTROLLER: ABNORMALITY IN CONTROLLER.............................. 723 FAILURE CODE [DBE6KK] PT CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 724 FAILURE CODE [DBE7KK] PT CONTROLLER: SOURCE VOLTAGE REDUCTION............................... 726 FAILURE CODE [DBE9KQ] PT CONTROLLER: TYPE SELECT SIGNAL..................................... 728 FAILURE CODE [DD12KA] SHIFT UP SW: DISCONNECTION............................................ 729 FAILURE CODE [DD12KB] SHIFT UP SW: SHORT CIRCUIT............................................ 731 FAILURE CODE [DD13KA] SHIFT DOWN SW: DISCONNECTION.......................................... 733 FAILURE CODE [DD13KB] SHIFT DOWN SW: SHORT CIRCUIT.......................................... 735 FAILURE CODE [DD14KA] PARKING LEVER SW: DISCONNECTION....................................... 737 FAILURE CODE [DD14KB] PARKING LEVER SW: SHORT CIRCUIT....................................... 739 FAILURE CODE [DDDDKA] BACK UP BRAKE SW: DISCONNECTION....................................... 741 FAILURE CODE [DDDDKB] BACK UP BRAKE SW: SHORT CIRCUIT....................................... 743 FAILURE CODE [DDDDKX] BACK UP BRAKE SW: SIGNAL MISMATCH..................................... 745 FAILURE CODE [DDN7KA] WEQ KNOB SW (DOWN): DISCONNECTION..................................... 746 FAILURE CODE [DDN7KB] WEQ KNOB SW (DOWN): SHORT CIRCUIT..................................... 748 FAILURE CODE [DDN9KA] WEQ KNOB SW (UP): DISCONNECTION....................................... 750 FAILURE CODE [DDN9KB] WEQ KNOB SW (UP): SHORT CIRCUIT....................................... 752 FAILURE CODE [DDNLKA] WEQ LOCK SW: DISCONNECTION............................................ 754 FAILURE CODE [DDNLKB] WEQ LOCK SW: SHORT CIRCUIT............................................ 756 FAILURE CODE [DDTSL1] S/C: FILL HIGH........................................................ 758 FAILURE CODE [DDTSLH] S/C: FILL LOW......................................................... 760 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 5.............................................. 763 FAILURE CODE [DFA4KX] BL LEVER 1: OUT OF NORMAL RANGE....................................... 765 FAILURE CODE [DFA4KZ] BL LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 765 FAILURE CODE [DFA4L8] BL LEVER: SIGNAL MISMATCH............................................. 766 FAILURE CODE [DFA5KA] BL LEVER 1: DISCONNECTION............................................. 767 FAILURE CODE [DFA5KB] BL LEVER 1: SHORT CIRCUIT............................................. 769 FAILURE CODE [DFA6KA] BL LEVER 2: DISCONNECTION............................................. 771 FAILURE CODE [DFA6KB] BL LEVER 2: SHORT CIRCUIT............................................. 773 FAILURE CODE [DFA7KX] BT LEVER 1: OUT OF NORMAL RANGE....................................... 775 FAILURE CODE [DFA7KZ] BT LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 775 FAILURE CODE [DFA7L8] BT LEVER: SIGNAL MISMATCH............................................. 776 FAILURE CODE [DFA8KA] BT LEVER 1: DISCONNECTION............................................. 777 FAILURE CODE [DFA8KB] BT LEVER 1: SHORT CIRCUIT............................................. 779 FAILURE CODE [DFA9KA] BT LEVER 2: DISCONNECTION............................................. 781 FAILURE CODE [DFA9KB] BT LEVER 2: SHORT CIRCUIT............................................. 783 FAILURE CODE [DFAAKX] RL LEVER 1: OUT OF NORMAL RANGE....................................... 785 FAILURE CODE [DFAAKZ] RL LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 785 FAILURE CODE [DFAAL8] RL LEVER: SIGNAL MISMATCH............................................. 786 FAILURE CODE [DFABKA] RL LEVER 1: DISCONNECTION............................................. 787 FAILURE CODE [DFABKB] RL LEVER 1: SHORT CIRCUIT............................................. 789 FAILURE CODE [DFACKA] RL LEVER 2: DISCONNECTION............................................. 791 FAILURE CODE [DFACKB] RL LEVER 2: SHORT CIRCUIT............................................. 793 FAILURE CODE [DFADKX] RL LEVER 1: OUT OF NORMAL RANGE....................................... 795 FAILURE CODE [DFADKZ] RL LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 795 FAILURE CODE [DFADL8] RL LEVER: SIGNAL MISMATCH............................................. 796 FAILURE CODE [DFAEKA] RL LEVER 1: DISCONNECTION............................................. 797 FAILURE CODE [DFAEKB] RL LEVER 1: SHORT CIRCUIT............................................. 799 FAILURE CODE [DFAFKA] RL LEVER 2: DISCONNECTION............................................. 801 FAILURE CODE [DFAFKB] RL LEVER 2: SHORT CIRCUIT............................................. 803 FAILURE CODE [DGT1KA] T/C OIL TEMP SENSOR: ABNORMAL......................................... 805 FAILURE CODE [DGT1KX] T/C OIL TEMP SENSOR: ABNORMAL......................................... 807 FAILURE CODE [DH21KA] WEQ PRESSURE SENSOR: DISCONNECTION.................................... 809 FAILURE CODE [DH21KB] WEQ PRESSURE SENSOR: SHORT CIRCUIT.................................... 811 FAILURE CODE [DHT5KA] T/C IN-PRESSURE SENSOR: DISCONNECTION................................. 813 FAILURE CODE [DHT5KB] T/C IN-PRESSURE SENSOR: SHORT CIRCUIT................................. 815 FAILURE CODE [DHT7KA] T/C OUT-PRESSURE SENSOR: DISCONNECTION................................ 817 FAILURE CODE [DHT7KB] T/C OUT-PRESSURE SENSOR: SHORT CIRCUIT................................ 819 FAILURE CODE [DK10KX] FUEL CONTROL DIAL: OUT OF NORMAL RANGE................................ 821 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 6.............................................. 824 FAILURE CODE [DK30KA] ST LEVER 1: DISCONNECTION............................................. 826 FAILURE CODE [DK30KB] ST LEVER 1: SHORT CIRCUIT............................................. 828 FAILURE CODE [DK30KX] ST LEVER 1: OUT OF NORMAL RANGE....................................... 830 FAILURE CODE [DK30KZ] RL LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 830 FAILURE CODE [DK30L8] ST LEVER: SIGNAL MISMATCH............................................. 831 FAILURE CODE [DK31KA] ST LEVER 2: DISCONNECTION............................................. 832 FAILURE CODE [DK31KB] ST LEVER 2: SHORT CIRCUIT............................................. 834 FAILURE CODE [DB40KA] BRAKE POTENTIOMETER: DISCONNECTION.................................... 836 FAILURE CODE [DB40KB] BRAKE POTENTIOMETER: SHORT CIRCUIT.................................... 838 FAILURE CODE [DK55KX] FR LEVER: OUT OF NORMAL RANGE......................................... 840 FAILURE CODE [DK55KZ] FR LEVER: DISCONNECTION OR SHORT CIRCUIT.............................. 840 FAILURE CODE [DK55L8] FR LEVER: SIGNAL MISMATCH............................................. 841 FAILURE CODE [DK56KA] FR LEVER 1: DISCONNECTION............................................. 842 FAILURE CODE [DK56KB] FR LEVER 1: SHORT CIRCUIT............................................. 844 FAILURE CODE [DK57KA] FR LEVER 2: DISCONNECTION............................................. 846 FAILURE CODE [DK57KB] FR LEVER 2: SHORT CIRCUIT............................................. 848 FAILURE CODE [DKH1KA] PITCH ANGLE SENSOR: DISCONNECTION..................................... 850 FAILURE CODE [DKH1KB] PITCH ANGLE SENSOR: SHORT CIRCUIT..................................... 852 FAILURE CODE [DLT3KA] T/M OUT-SPEED SENSOR: DISCONNECTION................................... 854 FAILURE CODE [DLT3KB] T/M OUT-SPEED SENSOR: ABNORMAL........................................ 855 FAILURE CODE [DW7BKA] FAN REV EPC: DISCONNECTION............................................ 856 FAILURE CODE [DW7BKB] FAN REV EPC: SHORT CIRCUIT............................................ 857 FAILURE CODE [DWN1KA] HSS EPC1: DISCONNECTION............................................... 858 FAILURE CODE [DWN1KB] HSS EPC1: SHORT CIRCUIT............................................... 859 FAILURE CODE [DWN1KY] HSS EPC1: SHORT CIRCUIT............................................... 860 FAILURE CODE [DWN2KA] HSS EPC2: DISCONNECTION............................................... 861 FAILURE CODE [DWN2KB] HSS EPC2: SHORT CIRCUIT............................................... 862 FAILURE CODE [DWN2KY] HSS EPC2: SHORT CIRCUIT............................................... 863 FAILURE CODE [DWN3KA] SSP SOLENOID: DISCONNECTION........................................... 864 FAILURE CODE [DWN3KB] SSP SOLENOID: SHORT CIRCUIT........................................... 866 FAILURE CODE [DWN3KY] SSP SOLENOID: SHORT CIRCUIT........................................... 868 FAILURE CODE [DWN5KA] FAN PUMP SOLENOID: DISCONNECTION...................................... 870 FAILURE CODE [DWN5KB] FAN PUMP SOLENOID: SHORT CIRCUIT...................................... 871 FAILURE CODE [DXA0KA] TVC SOL.: DISCONNECTION............................................... 872 FAILURE CODE [DXA0KB] TVC SOL.: SHORT CIRCUIT............................................... 873 FAILURE CODE [DXA0KY] TVC SOL.: SHORT CIRCUIT............................................... 874 FAILURE CODE [DXH1KA] LOCK-UP ECMV: DISCONNECTION........................................... 875 FAILURE CODE [DXH1KB] LOCK-UP ECMV: SHORT CIRCUIT........................................... 877 FAILURE CODE [DXH1KY] LOCK-UP ECMV: SHORT CIRCUIT........................................... 879 FAILURE CODE [DXH4KA] 1ST CLUTCH ECMV: DISCONNECTION........................................ 881 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 7.............................................. 883 FAILURE CODE [DXH4KB] 1ST CLUTCH ECMV: SHORT CIRCUIT........................................ 885 FAILURE CODE [DXH4KY] 1ST CLUTCH ECMV: SHORT CIRCUIT........................................ 886 FAILURE CODE [DXH5KA] 2ND CLUTCH ECMV: DISCONNECTION........................................ 887 FAILURE CODE [DXH5KB] 2ND CLUTCH ECMV: SHORT CIRCUIT........................................ 888 FAILURE CODE [DXH5KY] 2ND CLUTCH ECMV: SHORT CIRCUIT........................................ 889 FAILURE CODE [DXH6KA] 3RD CLUTCH ECMV: DISCONNECTION........................................ 890 FAILURE CODE [DXH6KB] 3RD CLUTCH ECMV: SHORT CIRCUIT........................................ 891 FAILURE CODE [DXH6KY] 3RD CLUTCH ECMV: SHORT CIRCUIT........................................ 892 FAILURE CODE [DXH7KA] R CLUTCH ECMV: DISCONNECTION.......................................... 893 FAILURE CODE [DXH7KB] R CLUTCH ECMV: SHORT CIRCUIT.......................................... 894 FAILURE CODE [DXH7KY] R CLUTCH ECMV: SHORT CIRCUIT.......................................... 895 FAILURE CODE [DXH8KA] F CLUTCH ECMV: DISCONNECTION.......................................... 896 FAILURE CODE [DXH8KB] F CLUTCH ECMV: SHORT CIRCUIT.......................................... 897 FAILURE CODE [DXH8KY] F CLUTCH ECMV: SHORT CIRCUIT.......................................... 898 FAILURE CODE [DXHBKA] RIGHT BRAKE ECMV: DISCONNECTION....................................... 899 FAILURE CODE [DXHBKB] RIGHT BRAKE ECMV: SHORT CIRCUIT....................................... 901 FAILURE CODE [DXHBKY] RIGHT BRAKE ECMV: SHORT CIRCUIT....................................... 903 FAILURE CODE [DXHCKA] LEFT BRAKE ECMV: DISCONNECTION........................................ 905 FAILURE CODE [DXHCKB] LEFT BRAKE ECMV: SHORT CIRCUIT........................................ 907 FAILURE CODE [DXHCKY] LEFT BRAKE ECMV: SHORT CIRCUIT........................................ 909 FAILURE CODE [DXHRKA] BLADE UP EPC: DISCONNECTION........................................... 911 FAILURE CODE [DXHRKB] BLADE UP EPC: SHORT CIRCUIT........................................... 912 FAILURE CODE [DXHRKY] BLADE UP EPC: SHORT CIRCUIT........................................... 913 FAILURE CODE [DXHSKA] BLADE DOWN EPC: DISCONNECTION......................................... 914 FAILURE CODE [DXHSKB] BLADE DOWN EPC: SHORT CIRCUIT......................................... 915 FAILURE CODE [DXHSKY] BLADE DOWN EPC: SHORT CIRCUIT......................................... 916 FAILURE CODE [DXHTKA] BLADE LEFT 1 EPC: DISCONNECTION....................................... 917 FAILURE CODE [DXHTKB] BLADE LEFT 1 EPC: SHORT CIRCUIT....................................... 918 FAILURE CODE [DXHTKY] BLADE LEFT 1 EPC: SHORT CIRCUIT....................................... 919 FAILURE CODE [DXHUKA] BLADE RIGHT 1 EPC: DISCONNECTION...................................... 920 FAILURE CODE [DXHUKB] BLADE RIGHT 1 EPC: SHORT CIRCUIT...................................... 921 FAILURE CODE [DXHUKY] BLADE RIGHT 1 EPC: SHORT CIRCUIT...................................... 922 FAILURE CODE [DXHWKA] RIPPER UP EPC: DISCONNECTION.......................................... 923 FAILURE CODE [DXHWKB] RIPPER UP EPC: SHORT CIRCUIT.......................................... 924 FAILURE CODE [DXHWKY] RIPPER UP EPC: SHORT CIRCUIT.......................................... 925 FAILURE CODE [DXHXKA] RIPPER DOWN EPC: DISCONNECTION........................................ 926 FAILURE CODE [DXHXKB] RIPPER DOWN EPC: SHORT CIRCUIT........................................ 927 FAILURE CODE [DXHXKY] RIPPER DOWN EPC: SHORT CIRCUIT........................................ 928 FAILURE CODE [DXHYKA] RIPPER TILT IN EPC: DISCONNECTION..................................... 929 FAILURE CODE [DXHYKB] RIPPER TILT IN EPC: SHORT CIRCUIT..................................... 930 FAILURE CODE [DXHYKY] RIPPER TILT IN EPC: SHORT CIRCUIT..................................... 931 FAILURE CODE [DXHZKA] RIPPER TILT BACK EPC: DISCONNECTION................................... 932 FAILURE CODE [DXHZKB] RIPPER TILT BACK EPC: SHORT CIRCUIT................................... 933 FAILURE CODE [DXHZKY] RIPPER TILT BACK EPC: SHORT CIRCUIT................................... 934 FAILURE CODE [DXJ4KA] WEQ LOCK SOL.: DISCONNECTION.......................................... 935 FAILURE CODE [DXJ4KB] WEQ LOCK SOL.: SHORT CIRCUIT.......................................... 936 TROUBLESHOOTING BY FAILURE AND ERROR CODES, PART 8.............................................. 938 FAILURE CODE [DXJ8KA] BLADE LEFT 2 EPC: DISCONNECTION....................................... 939 FAILURE CODE [DXJ8KB] BLADE LEFT 2 EPC: SHORT CIRCUIT....................................... 940 FAILURE CODE [DXJ8KY] BLADE LEFT 2 EPC: SHORT CIRCUIT....................................... 941 FAILURE CODE [DXJ9KA] BLADE RIGHT 2 EPC: DISCONNECTION...................................... 942 FAILURE CODE [DXJ9KB] BLADE RIGHT 2 EPC: SHORT CIRCUIT...................................... 943 FAILURE CODE [DXJ9KY] BLADE RIGHT 2 EPC: SHORT CIRCUIT...................................... 944 FAILURE CODE [DXJAKA] Q-DROP EPC: DISCONNECTION............................................. 945 FAILURE CODE [DXJAKB] Q-DROP EPC: SHORT CIRCUIT............................................. 947 FAILURE CODE [DXJAKY] Q-DROP EPC: SHORT CIRCUIT............................................. 949 FAILURE CODE [DXJBKA] S/C ECMV: DISCONNECTION............................................... 951 FAILURE CODE [DXJBKB] S/C ECMV: SHORT CIRCUIT............................................... 953 FAILURE CODE [DXJBKY] S/C ECMV: SHORT CIRCUIT............................................... 955 TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE)................................................... 958 BEFORE CARRYING OUT TROUBLESHOOTING FOR ELECTRICAL SYSTEM................................... 960 INFORMATION IN TROUBLESHOOTING TABLE........................................................ 964 E-1 WHEN STARTING SWITCH TURNED ON, MACHINE MONITOR DISPLAYS NOTHING........................ 965 E-2 WHEN STARTING SWITCH TURNED ON (BEFORE STARTING ENGINE), BASIC CHECK ITEM LIGHTS UP..... 967 E-3 ENGINE DOES NOT START (ENGINE DOES NOT TURN)............................................ 968 E-4 PREHEATER DOES NOT OPERATE.............................................................. 970 E-5 PRECAUTION ITEM LIGHTS UP WHILE ENGINE IS RUNNING....................................... 973 E-6 EMERGENCY STOP ITEM LIGHTS UP WHILE ENGINE IS RUNNING................................... 975 E-7 ENGINE COOLANT TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY............................. 977 E-8 FUEL LEVEL GAUGE DOES NOT INDICATE NORMALLY............................................. 978 E-9 POWER TRAIN OIL TEMPERATURE GAUGE (MULTI-GAUGE) DOES NOT INDICATE NORMALLY.............. 980 E-10 HYDRAULIC TEMPERATURE GAUGE (MULTI-GAUGE) DOES NOT INDICATE NORMALLY................... 981 E-11 CONTENTS OF DISPLAY BY MACHINE MONITOR ARE DIFFERENT FROM APPLICABLE MACHINE........... 984 E-12 MACHINE MONITOR DOES NOT DISPLAY SOME ITEMS............................................ 984 E-13 FUNCTION SWITCH DOES NOT WORK.......................................................... 984 E-14 OPERATION MODE DOES NOT CHANGE......................................................... 985 E-15 GEARSHIFT MODE DOES NOT CHANGE......................................................... 985 E-16 CUSTOMIZE FUNCTION DOES NOT OPERATE NORMALLY........................................... 986 E-17 CUSTOMIZE MEMORY FUNCTION DOES NOT NORMALLY............................................ 986 E-18 FLOAT MODE DOES NOT CHANGE............................................................. 987 E-19 ALARM BUZZER CANNOT BE STOPPED......................................................... 987 E-20 AIR CONDITIONER DOES NOT OPERATE NORMALLY (INCLUDING AIR CONDITIONER FAULT HISTORY).... 988 E-21 WHEN STARTING SWITCH IS TURNED OFF, SERVICE METER IS NOT DISPLAYED.....................1001 E-22 MACHINE MONITOR CANNOT BE SET IN SERVICE MODE..........................................1001 E-23 RIPPER PIN PULLER CYLINDER DOES NOT OPERATE............................................1002 E-24 BACKUP ALARM DOES NOT SOUND OR DOES NOT STOP...........................................1004 E-25 HEADLAMP, REAR LAMP, AND RIPPER POINT LAMP DO NOT LIGHT UP.............................1006 E-26 WINDSHIELD WIPER AND WINDOW WASHER DO NOT OPERATE......................................1010 E-27 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY...............................................1026 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).....................................1028 INFORMATION IN TROUBLESHOOTING TABLE........................................................1030 H-1 POWER IS LOW (DRAWBAR PULL IS LOW)......................................................1031 H-2 MACHINE DOES NOT TRAVEL (AT 2ND OR 3RD GEAR SPEED)......................................1032 H-3 MACHINE DOES NOT START AT ANY GEAR SPEED................................................1033 H-4 MACHINE CAN TRAVEL ONLY FORWARD OR IN REVERSE...........................................1034 H-5 WHEN GEAR SPEED OR TRAVEL DIRECTION IS CHANGED, TIME LAG IS LARGE.......................1035 H-6 MACHINE CANNOT BE STEERED (MACHINE DOES NOT TURN RIGHT OR LEFT).........................1036 H-7 STEERING SPEED OR STEERING FORCE IS LOW.................................................1036 H-8 BRAKE DOES NOT WORK.....................................................................1037 H-9 POWER TRAIN OIL IS OVERHEATED...........................................................1038 H-10 ABNORMAL SOUND COMES OUT FROM AROUND HSS PUMP OR HSS MOTOR.............................1039 H-11 SPEED OF ALL WORK EQUIPMENT IS LOW.....................................................1040 H-12 NO WORK EQUIPMENT MOVES................................................................1041 H-13 BLADE LIFT SPEED OR POWER IS LOW.......................................................1042 H-14 BLADE TILT SPEED OR POWER IS LOW.......................................................1043 H-15 RIPPER LIFT SPEED OR POWER IS LOW......................................................1044 H-16 RIPPER TILT SPEED OR POWER IS LOW......................................................1045 H-17 HYDRAULIC DRIFT OF BLADE LIFT IS LARGE.................................................1045 H-18 HYDRAULIC DRIFT OF BLADE TILT IS LARGE.................................................1046 H-19 HYDRAULIC DRIFT OF RIPPER LIFT IS LARGE................................................1046 H-20 RIPPER PIN PULLER CYLINDER DOES NOT OPERATE............................................1047 H-21 BLADE DOES NOT PITCH...................................................................1047 H-22 ABNORMAL SOUND COMES OUT FROM AROUND WORK EQUIPMENT PUMP...............................1048 TROUBLESHOOTING OF ENGINE (S-MODE)..............................................................1050 METHOD OF USING TROUBLESHOOTING CHART.......................................................1052 S-1 STARTING PERFORMANCE OF ENGINE IS POOR..................................................1055 S-2 ENGINE DOES NOT START...................................................................1057 S-3 ENGINE DOES NOT PICK UP SMOOTHLY........................................................1061 S-4 ENGINE STOPS DURING OPERATION...........................................................1062 S-5 ENGINE DOES NOT ROTATE SMOOTHLY.........................................................1063 S-6 ENGINE LACK OUTPUT (OR LACKS POWER).....................................................1064 S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)............................................1065 S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)...................................1067 S-9 OIL BECOMES DIRTY QUICKLY...............................................................1068 S-10 FUEL CONSUMPTION IS EXCESSIVE..........................................................1069 S-11 OIL IS IN COOLANT (OR COOLANT SPURTS BACK OR COOLANT LEVEL GOES DOWN)..................1070 S-12 OIL PRESSURE DROPS.....................................................................1071 S-13 OIL LEVEL RISES (ENTRY OF COOLANT OR FUEL).............................................1072 S-14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING).....................................1074 S-15 ABNORMAL NOISE IS MADE.................................................................1075 S-16 VIBRATION IS EXCESSIVE.................................................................1076 50 DISASSEMBLY AND ASSEMBLY......................................................................... 0 GENERAL INFORMATION ON DISASSEMBLY AND ASSEMBLY.................................................1078 HOW TO READ THIS MANUAL.....................................................................1079 LIST OF ADHESIVES...........................................................................1081 SPECIAL TOOL LIST...........................................................................1084 ENGINE AND COOLING SYSTEM.......................................................................1086 REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY ......................................1087 REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY..........................................1091 REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY..........................................1096 REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY ..............................................1107 REMOVAL AND INSTALLATION OF AFTERCOOLER ASSEMBLY ...........................................1109 REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY ................................................1111 REMOVAL AND INSTALLATION OF ENGINE HOOD ASSEMBLY ...........................................1115 POWER TRAIN, PART 1 ............................................................................1118 REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY ................................................1119 DISASSEMBLY AND ASSEMBLY OF DAMPER ASSEMBLY.................................................1122 REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY.......................................1128 DISCONNECTION AND CONNECTION OF POWER TRAIN UNIT ASSEMBLY...................................1132 90 DIAGRAMS AND DRAWINGS ........................................................................... 0 HYDRAULIC CIRCUIT DIAGRAM.......................................................................1138 POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM.......................................................1139 HYDRAULIC CIRCUIT DIAGRAM(1/2)..............................................................1140 HYDRAULIC CIRCUIT DIAGRAM(2/2)..............................................................1141 ELECTRICAL CIRCUIT DIAGRAM......................................................................1143 ELECTRICAL CIRCUIT DIAGRAM..................................................................1144 CONNECTORS TABLE AND ARRANGEMENT DRAWING....................................................1145

IMAGES PREVIEW OF THE MANUAL: