$34

Komatsu D155C-1 PIPELAYER Operation & Maintenance Manual PEN00060-00 – PDF DOWNLOAD

Komatsu D155C-1 PIPELAYER Operation & Maintenance Manual PEN00060-00 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D155C-1 PIPELAYER Operation & Maintenance Manual PEN00060-00 – PDF DOWNLOAD

Language : English

Pages : 226

Downloadable : Yes

File Type : PDF

Size: 6.84 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu D155C-1 PIPELAYER Operation & Maintenance Manual PEN00060-00 – PDF DOWNLOAD

SERIAL NUMBERS 31586 and up

FOREWORD:

This manual provides rules and guidelines which will help you use this machine safely and effectively. The

precautions in this manual must be followed at all times when performing operation and maintenance. Most

accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of

machines. Accidents can be prevented by knowing beforehand conditions that may cause a hazard when

performing operation and maintenance.

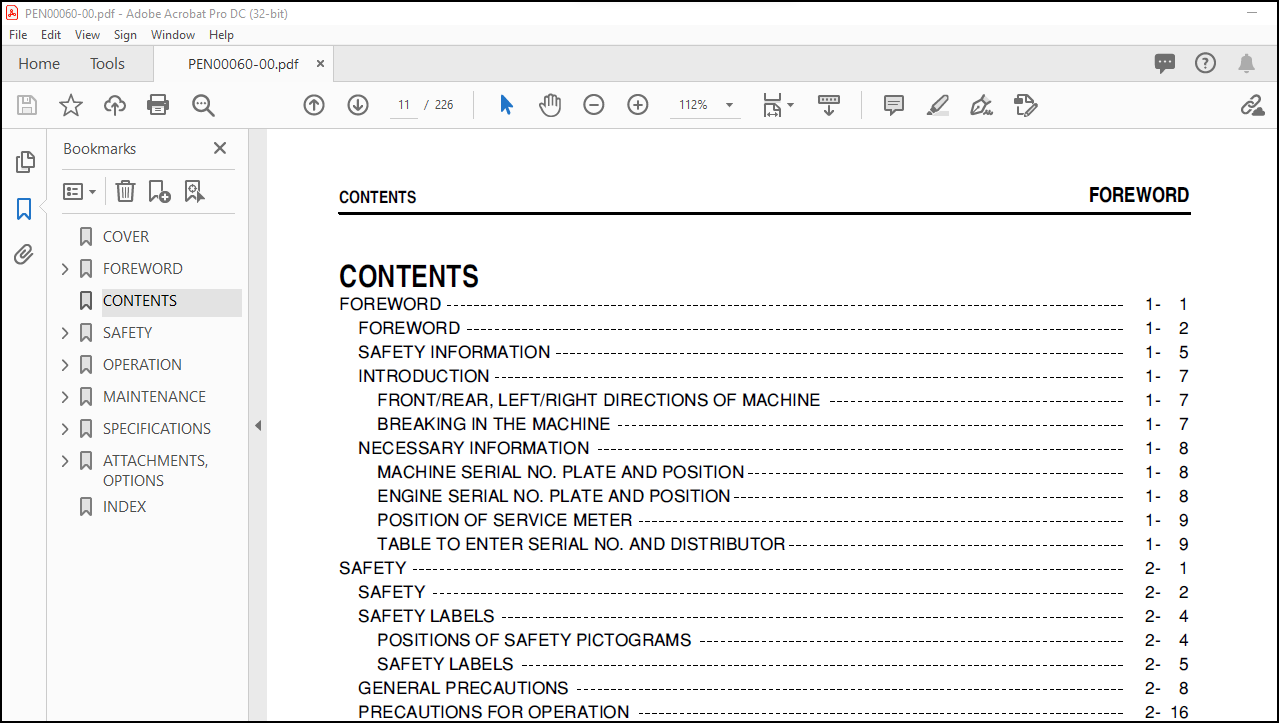

TABLE OF CONTENTS:

Komatsu D155C-1 PIPELAYER Operation & Maintenance Manual PEN00060-00 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………….. 1

FOREWORD………………………………………………………………………………………………….. 2

FOREWORD………………………………………………………………………………………………. 3

SAFETY INFORMATION……………………………………………………………………………………… 6

INTRODUCTION…………………………………………………………………………………………… 8

FRONT/REAR,LEFT/RIGHT DIRECTIONS OF MACHIHE……………………………………………………………. 8

BREAKING THE NEW MACHINE…………………………………………………………………………….. 8

NECESSARY INFORMATION…………………………………………………………………………………… 9

MACHINE SERIAL NO.PLATE AND POSITION………………………………………………………………….. 9

ENGINE SERIAL NO.PLATE AND POSITION…………………………………………………………………… 9

POSISION OF SERVICE METER……………………………………………………………………………. 10

TABLE TO ENTER SERIAL NO.AND DISTRIBUTOR………………………………………………………………. 10

CONTENTS………………………………………………………………………………………………….. 11

SAFETY……………………………………………………………………………………………………. 14

SAFETY………………………………………………………………………………………………… 15

SAFETY LABELS………………………………………………………………………………………….. 17

POSITION OF SAFETY PICTOGRAMS………………………………………………………………………… 17

SAFETY LABELS………………………………………………………………………………………. 18

GENERAL PRECAUTIONS…………………………………………………………………………………….. 21

SAFETY RULES……………………………………………………………………………………….. 21

IF ABNORMALITIES ARE FOUND…………………………………………………………………………… 21

COLTHING AND PERSONAL PROTECTIVE ITEMS………………………………………………………………… 21

FIRE EXTINGUISHER AND FIRST AID KIT…………………………………………………………………… 21

SAFETY FEATURES…………………………………………………………………………………….. 21

KEEP MACHINE CLEAN………………………………………………………………………………….. 22

INSIDE OPERATOR’S COMPARTMENT………………………………………………………………………… 22

ALWAYS APPLY LOCK WHEN LEVAVING OPERATOR’S SEAT………………………………………………………… 22

HANDRAILS AND STEPS…………………………………………………………………………………. 23

MOUNTING AND DISMOUNTING…………………………………………………………………………….. 23

NO PEOPLE ON ATTACHMENTS…………………………………………………………………………….. 23

PREVENTION OF BURNS…………………………………………………………………………………. 24

FIRE PREVENTION…………………………………………………………………………………….. 24

ACTION IF FIRE OCCURS……………………………………………………………………………….. 25

WINDOW WASHER LIQUID………………………………………………………………………………… 25

PRECAUTIONS FOR ATTACHMENTS………………………………………………………………………….. 25

CAB WINDOW GLASSES………………………………………………………………………………….. 25

UNAUTHORIZED MODIFICATION……………………………………………………………………………. 26

SAFETY AT WORKSITE………………………………………………………………………………….. 26

WORKING ON LOOSE GROUND……………………………………………………………………………… 26

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES………………………………………………………………… 27

ENSURE GOOD VISIBILITY………………………………………………………………………………. 27

VENTILATION FOR ENCLOSED AREAS……………………………………………………………………….. 27

CHECKING SIGNALMAN’S SIGNALS AND SIGNS………………………………………………………………… 27

BE CAREFUL ABOUT ASBESTOS DUST……………………………………………………………………….. 28

PRECAUTIONS FOR OPERATION……………………………………………………………………………….. 29

BEFORE STARTING ENGINE………………………………………………………………………………. 29

CHECKS BEFORE STARTING ENGING…………………………………………………………………….. 29

PRECAUTIONS WHEN STARTING………………………………………………………………………… 29

PRECAUTIONS IN COLD AREAS………………………………………………………………………… 30

OPERATION …………………………………………………………………………………………. 31

CHECKS BEFORE OPERATION………………………………………………………………………….. 31

PRECAUTIONS FOR MOVING MACHINE FOEWARD OR IN REVERSE………………………………………………… 31

PRECAUTIONS WHEN TRAVELING……………………………………………………………………….. 32

TRAVELING ON SLOPES……………………………………………………………………………… 32

PROHIBITED OPERATIONS …………………………………………………………………………… 32

USING BRAKES……………………………………………………………………………………. 33

OPERATE CAREFULLY ON SNOW………………………………………………………………………… 33

PARKING MACHINE…………………………………………………………………………………. 33

TRANSPORTATION……………………………………………………………………………………… 34

SHIPPING……………………………………………………………………………………….. 34

BATTERY……………………………………………………………………………………………. 35

BATTERY HAZARD PREVENTION………………………………………………………………………… 35

STARTING WITH BOOSTER CABLE………………………………………………………………………. 36

TOWING…………………………………………………………………………………………….. 37

WHEN TOWING…………………………………………………………………………………….. 37

PRECAUTIONS FOR MAINTENANCE……………………………………………………………………………… 38

WARNING TAG………………………………………………………………………………………… 38

KEEP WORK PLACE CLEAN AND TIDY……………………………………………………………………….. 38

APPOINT LEADER WHEN WORKING WITH OTHERS……………………………………………………………….. 38

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE………………………………………………. 39

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING……………………………………………………… 40

PROPER TOOLS……………………………………………………………………………………….. 40

PERSONNEL………………………………………………………………………………………….. 40

ATTACHMENTS………………………………………………………………………………………… 41

WORK UNDER THE MACHINE………………………………………………………………………………. 41

NOISE……………………………………………………………………………………………… 41

PRECAUTIONS WHEN USING HAMMER………………………………………………………………………… 41

REPAIR WELDING……………………………………………………………………………………… 41

REMOVING BATTERY TERMINAL……………………………………………………………………………. 41

PRECAUTIONS WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION………………………………………. 42

DO NOT DISASSEMBLE RECOIL SPRING …………………………………………………………………….. 42

PRECAUTION WHEN HIGH-PRESSURE OIL…………………………………………………………………….. 42

HANDLING HIGH-PRESSURE HOSES…………………………………………………………………………. 43

WASTE MATERIAL …………………………………………………………………………………….. 43

MAINTENANCE FOR AIR CONDITIONER………………………………………………………………………. 43

COMPRESSED AIR……………………………………………………………………………………… 43

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS………………………………………………………….. 43

OPERATION…………………………………………………………………………………………………. 44

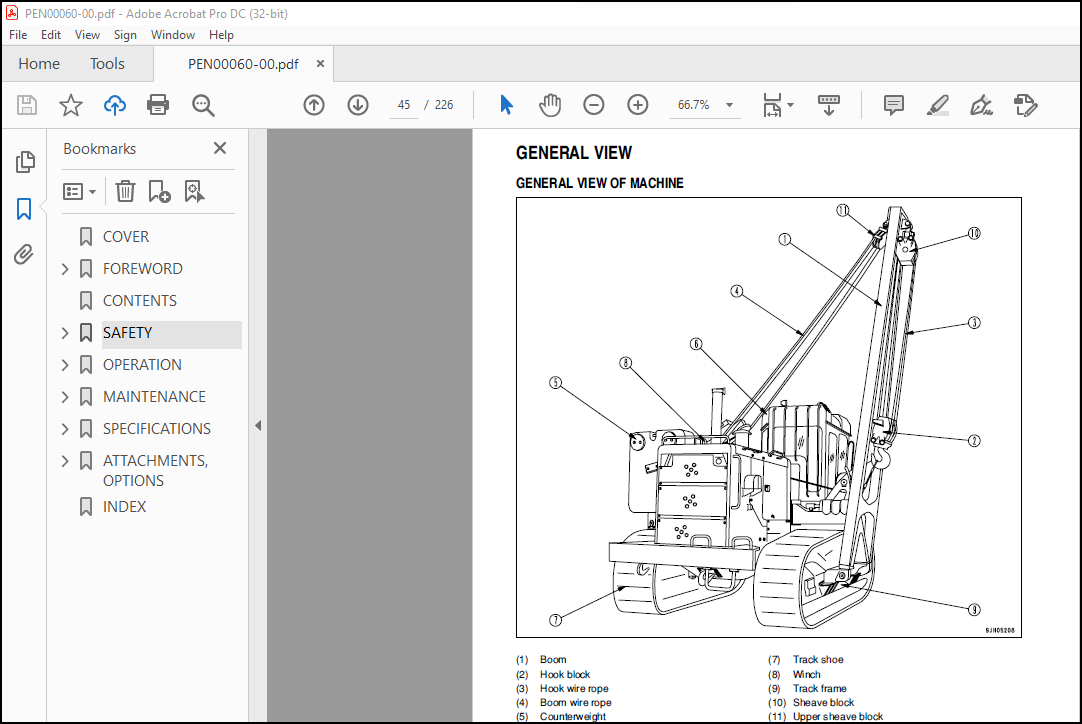

GENERAL VIEW…………………………………………………………………………………………… 45

GENERAL VIEW OF MACHINE……………………………………………………………………………… 45

GENERAL VIEW OF CONTROLS AND GAUGES…………………………………………………………………… 46

EXPLANATION OF COMPONENTS……………………………………………………………………………….. 48

FRONT PANEL………………………………………………………………………………………… 48

SWITCHES…………………………………………………………………………………………… 57

CONTROL LEVERS, PEDALS………………………………………………………………………………. 61

FUSE BOX…………………………………………………………………………………………… 77

DOOR OPEN LOCK……………………………………………………………………………………… 79

ASHTRAY……………………………………………………………………………………………. 79

TOOL BOX…………………………………………………………………………………………… 79

HEATER, HANDLING……………………………………………………………………………………. 80

AIR CONDITIONER, HANDLING……………………………………………………………………………. 81

OPERATION……………………………………………………………………………………………… 85

CHECK BEFORE STARTING ENGINE, ADJUST………………………………………………………………….. 85

STARTING ENGINE (NORMAL, IN COLD WEATHER)………………………………………………………………102

OPERATIONS AND CHECKS AFTER STARTING ENGINE (NORMAL, IN COLD WEATHER)……………………………………..106

STOPPING ENGINE……………………………………………………………………………………..110

MOVING MACHINE………………………………………………………………………………………111

STOPPING MACHINE…………………………………………………………………………………….113

SHIFTING GEAR……………………………………………………………………………………….113

SHIFTING BETWEEN FORWARD AND REVERSE…………………………………………………………………..114

STEERING MACHINE…………………………………………………………………………………….115

PRECAUTIONS FOR OPERATION…………………………………………………………………………….119

PARKING MACHINE……………………………………………………………………………………..121

CHECK AFTER FINISHING WORK……………………………………………………………………………123

LOCKING…………………………………………………………………………………………….123

TIPS FOR LONGER UNDERCARRIAGE LIFE…………………………………………………………………….124

TRANSPORTATION………………………………………………………………………………………….126

TRANSPORTATION PROCEDURE……………………………………………………………………………..126

LOADING, UNLOADING WORK………………………………………………………………………………126

PRECAUTIONS FOR LOADING………………………………………………………………………………126

METHOD OF LIFTING MACHINE…………………………………………………………………………….127

PRECAUTIONS FOR TRANSPORTATION………………………………………………………………………..127

TRAVELING ON ROADS…………………………………………………………………………………..127

PROCEDURE FOR REMOVAL AND INSTALLATION OF CAB…………………………………………………………..128

PROCEDURE FOR REMOVAL AND INSTALLATION OF BOOM………………………………………………………….130

PROCEDURE FOR REMOVAL AND INSTALLATION OF COUNTER WEINGHT………………………………………………..132

COLD WEATHER OPERATION…………………………………………………………………………………..134

PRECAUTIONS FOR LOW TEMPERATURE……………………………………………………………………….134

AFTER COMPLETION OF WORK……………………………………………………………………………..136

AFTER COLD WEATHER…………………………………………………………………………………..136

LONG-TERM STORAGE……………………………………………………………………………………….137

BEFORE STORAGE………………………………………………………………………………………137

DURING STORAGE………………………………………………………………………………………137

AFTER STORAGE……………………………………………………………………………………….137

TROUBLESHOOTING…………………………………………………………………………………………138

AFTER RUNNING OUT OF FUEL…………………………………………………………………………….138

METHOD OF TOWING MACHINE……………………………………………………………………………..138

IF BATTERY IS DISCHARGED……………………………………………………………………………..139

OTHER TROUBLE……………………………………………………………………………………….142

MAINTENANCE………………………………………………………………………………………………..145

GUIDES TO MAINTENANCE……………………………………………………………………………………146

OUTLINES OF SERVICE……………………………………………………………………………………..148

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…………………………………………………..148

OUTLINE OF ELECTRIC SYSTEM……………………………………………………………………………150

WEAR PARTS LIST…………………………………………………………………………………………151

WEAR PARTS LIST……………………………………………………………………………………..151

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE………………………………………….152

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS………………………………………………………..152

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS……………………………………………………………..157

TORQUE LIST…………………………………………………………………………………………157

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS………………………………………………………………158

SAFETY CRITICAL PARTS………………………………………………………………………………..158

MAINTENANCE SCHEDULE CHART……………………………………………………………………………….159

MAINTENANCE SCHEDULE CHART……………………………………………………………………………159

SERVICE PROCEDURE……………………………………………………………………………………….161

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)……………………………………………….161

WHEN REQUIRED……………………………………………………………………………………….162

CLEAN INSIDE OF COOLING SYSTEM…………………………………………………………………….162

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT………………………………………………………..165

CHECK AND ADJUST TRACK TENSION…………………………………………………………………….167

CHECK AND TIGHTEN TRACK SHOE BOLTS…………………………………………………………………169

CHECK ELECTRICAL INTAKE AIR HEATER…………………………………………………………………169

ADJUST IDLER CLEARANCE……………………………………………………………………………170

CLEAN AND CHECK RADIATOR FINS……………………………………………………………………..170

CLEAN FUEL TANK STRANER…………………………………………………………………………..171

DRAIN WATER AND SEDIMENT IN FUEL TANK………………………………………………………………171

REPLACE ALTERNATOR DRIVE BELT……………………………………………………………………..172

CHECK UNDERCARRIAGE OIL…………………………………………………………………………..173

CLEAN AIR CONDITIONER AIR FILTER (FRESH/RECIRC FILTER)……………………………………………….174

CHECK AIR CONDITIONER REFRIGER ANT GAS LEVEL………………………………………………………..174

LUBRICATE DOOR HINGE……………………………………………………………………………..175

CHECK DOOR LATCH…………………………………………………………………………………175

REPLACE WIPER BLADE………………………………………………………………………………176

BLEEDING AIR IN HYDRAULIC SYSTEM…………………………………………………………………..177

LUBRICATING……………………………………………………………………………………..177

CHECK BEFORE STARTING………………………………………………………………………………..178

EVERY 250 HOURS SERVICE………………………………………………………………………………179

LUBRICATING……………………………………………………………………………………..179

CHECK ALTERNATOR DRIVE BELT TENSION, ADJUST…………………………………………………………180

CHECK LEVEL OF BATTERY ELECTROLYTE…………………………………………………………………181

CHECK BRAKE PERFORMANCE…………………………………………………………………………..184

CHECK OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE………………………………………185

CHECK OIL LEVEL IN FINAL DRIVE CASE,ADD OIL…………………………………………………………186

CHECK OIL LEVEL IN COUNTERWEIGHT TANK,ADD OIL……………………………………………………….187

REPLACE TRANSMISSION FILTER ELEMENT………………………………………………………………..188

REPLACE STEERING CLUTCH CASE FILTER ELEMENT…………………………………………………………189

CHECK OPERATION OF MOMENT LIMITER………………………………………………………………….190

EVERY 500 HOURS SERVICE………………………………………………………………………………191

REPLACE FUEL FILTER CARTRIDGE……………………………………………………………………..191

CLEAN FINAL DRIVE CASE BREATHER……………………………………………………………………192

CLEAN STEERIMG CLUTCH CASE BREATHER………………………………………………………………..192

CLEAN WINCH CASE BREATHER…………………………………………………………………………192

EVERY 1000 HOURS SERVICE……………………………………………………………………………..193

CHANGE OIL IN STEERING CLUTCH CASE, (INCLUDING TRAINSMISSION CASE, TORGUE CONVERTER CASE), CLEAN STRAINER….193

CHANGE OIL IN FINAL DRIVE CASE…………………………………………………………………….195

CHANGE OIL IN WINCH CASE,CLEAN STRAINER…………………………………………………………….195

CHECK, CLEAN FUEL STRAINER………………………………………………………………………..197

CHECK IN UNDERCARRIAGE PARTS………………………………………………………………………197

CHECK OIL LEVEL IN RECOIL SPRING CASE, ADD OIL………………………………………………………198

CHECK, CLEAN RADIATOR FIN…………………………………………………………………………198

LUBRICATING……………………………………………………………………………………..199

REPLACE CORROSION RESISTOR CARTRIDGE……………………………………………………………….200

CHECK TIGTENING PARTS OF TURBOCHARGER………………………………………………………………200

EVERY 2000 HOURS SERVICE……………………………………………………………………………..201

LUBRICATING……………………………………………………………………………………..201

CHANGE OIL IN COUNTERWEIGHT TANK,REPLACE FIFLER ELEMENT………………………………………………204

CLEAN ENGINE BREATHER ELEMENT……………………………………………………………………..206

CLEAN AND CHECK TURBOCHARGER………………………………………………………………………206

CHECK PLAY OF TURBOCHAGER ROTOR……………………………………………………………………206

CHCEK ALTEMATOR, STARTING MOTOR……………………………………………………………………206

CHECK ENGINE VALVE CLEARANCE, ADJUST……………………………………………………………….206

EVERY 4000 HOURS SERVICE……………………………………………………………………………..207

CHECK WATER PUMP…………………………………………………………………………………207

CHECK VIBRATION DAMPER……………………………………………………………………………207

CHECK FAN PULLEY AND TENSION PULLEY………………………………………………………………..207

SPECIFICATIONS……………………………………………………………………………………………..208

SPECIFICATIONS………………………………………………………………………………………….209

LIFTING LOAD CAPACITY CURVE………………………………………………………………………………210

ATTACHMENTS, OPTIONS………………………………………………………………………………………..211

GENERAL PRECAUTIONS……………………………………………………………………………………..212

PRECAUTIONS RELATED TO SAFETY…………………………………………………………………………212

USING SEAT BELT…………………………………………………………………………………………213

HEADLING SEAT BELT…………………………………………………………………………………..213

SELECTION OF TRACK SHOE………………………………………………………………………………….214

SELECTION OF TRACK SHOES……………………………………………………………………………..214

CAP WITH LOCK, HANDLING………………………………………………………………………………….215

METHOD OF OPENING AND CLOSING CAP WITH LOCK…………………………………………………………….215

EXTERNAL POWER SOURCE ENGINE PREHEATING HEATER……………………………………………………………..216

PROCEDURE FOR SELECTING UP EXTERNAL POWER SOURCE………………………………………………………..216

PROCEDURE FOR HANDLING EXTERNAL POWER SUPPLY……………………………………………………………221

INDEX……………………………………………………………………………………………………..224