$34

Komatsu D155C-1 PIPELAYER Shop Manual SEBM032300 – PDF DOWNLOAD

Komatsu D155C-1 PIPELAYER Shop Manual SEBM032300 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D155C-1 PIPELAYER Shop Manual SEBM032300 – PDF DOWNLOAD

Language : English

Pages : 536

Downloadable : Yes

File Type : PDF

Size: 169.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu D155C-1 PIPELAYER Shop Manual SEBM032300 – PDF DOWNLOAD

Machine model Serial number

D155C-1 31586 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.PREPARATIONS FOR WORK:

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any other work equipment to the ground. If this is not possible,

use blocks to prevent the work equipment from falling down. In addition, be sure to lock all the control levers and hang warning sign on them.

9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting

work.

10. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine.Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

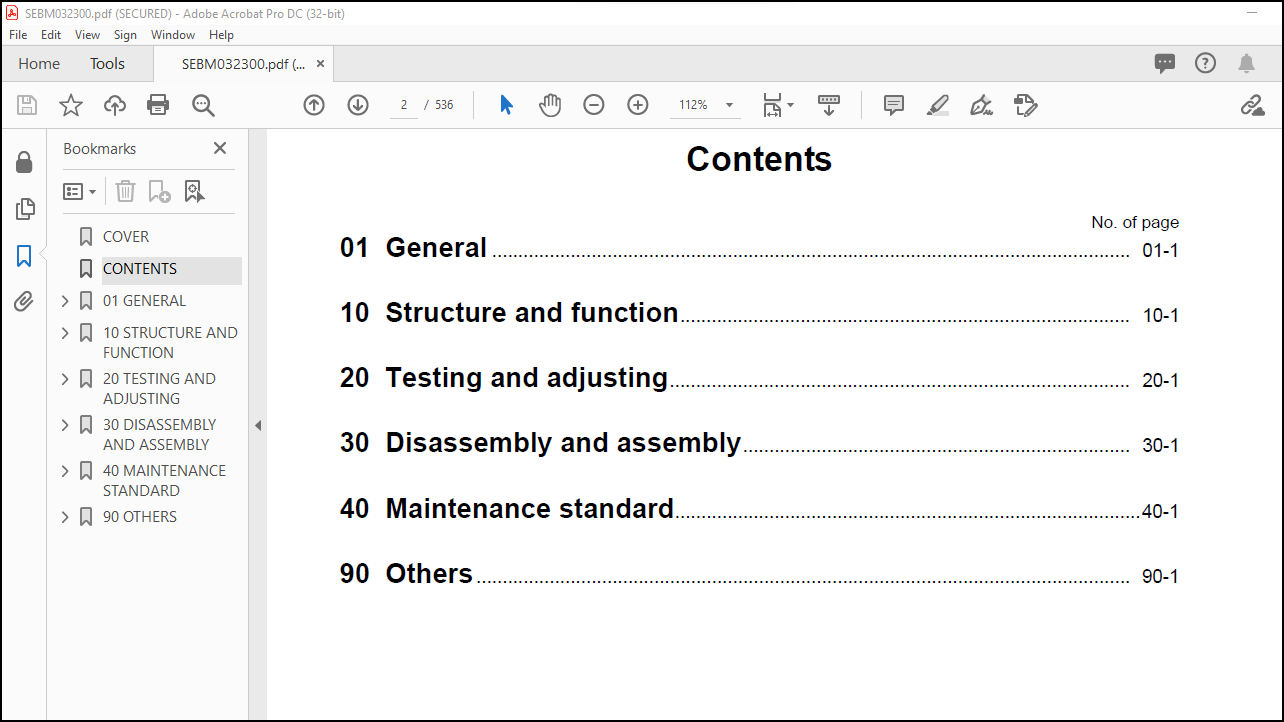

TABLE OF CONTENTS:

Komatsu D155C-1 PIPELAYER Shop Manual SEBM032300 – PDF DOWNLOAD

COVER………………………………………………………………………………… 1

CONTENTS……………………………………………………………………………… 2

01 GENERAL……………………………………………………………………………. 23

GENERAL ASSEMBLY DRAWING……………………………………………………………. 24

SPECIFICATIONS…………………………………………………………………….. 25

WEIGHT TABLE………………………………………………………………………. 29

TABLE OF FUEL,COOLANT AND LUBRICANTS…………………………………………………. 31

10 STRUCTURE AND FUNCTION………………………………………………………………. 34

RADIATOR FAN ……………………………………………………………………… 35

RADIATOR SHUTTER ………………………………………………………………….. 37

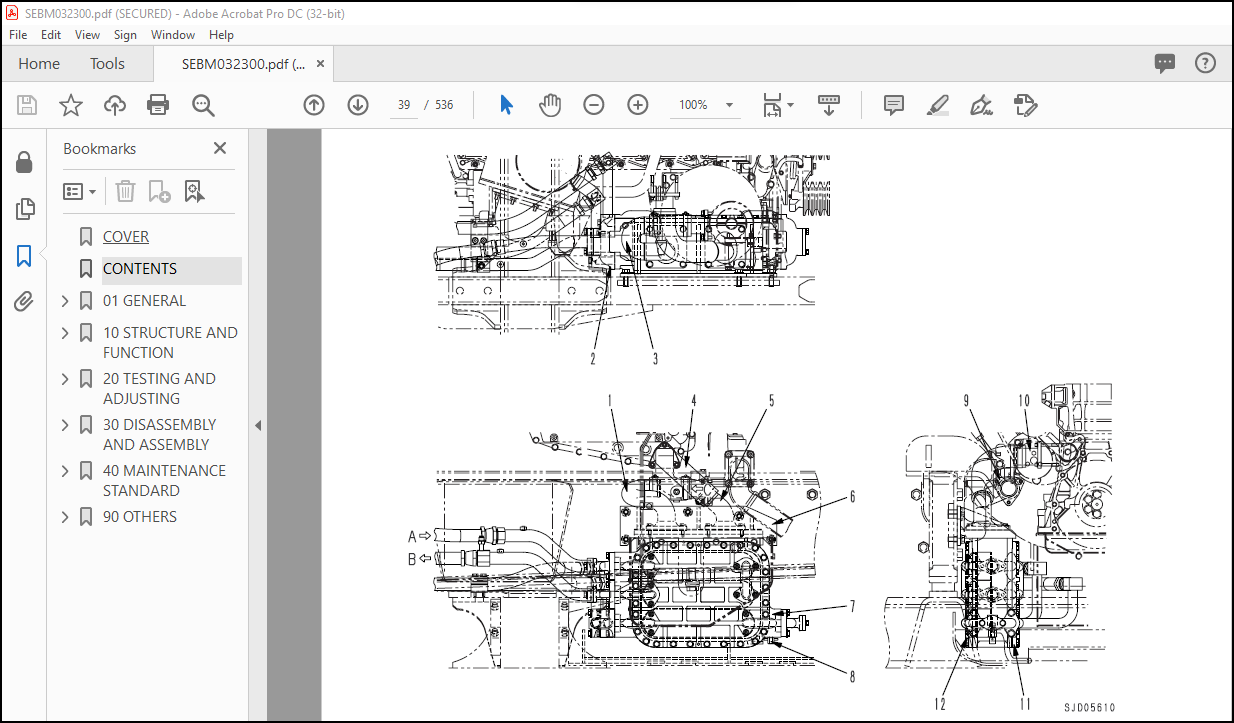

PTO (POWER TAKE-OFF)……………………………………………………………….. 38

OIL COOLER………………………………………………………………………… 39

POWER TRAIN DIAGRAM ……………………………………………………………….. 40

TORQFLOW HYDRAULIC CIRCUIT………………………………………………………….. 42

HYDRAULIC CIRCUIT DIAGRAM ………………………………………………………….. 43

TORQUE CONVERTER…………………………………………………………………… 44

TRANSMISSION CONTROL……………………………………………………………….. 49

TRANSMISSION………………………………………………………………………. 50

TRANSMISSION CONTROL VALVE………………………………………………………….. 58

TRANSMISSION LUBRICATION RELIEF VALVE………………………………………………… 65

STEERING AND BRAKE CONTROL …………………………………………………………. 66

AXLE,STEERING CLUTCH……………………………………………………………….. 67

STEERING BRAKE HYDRAULIC PIPING …………………………………………………….. 70

STEERING AND BRAKE HYDRAULIC CIRCUIT DIAGRAM………………………………………….. 71

STEERING BRAKE ……………………………………………………………………. 73

STEERING CONTROL VALVE …………………………………………………………….. 78

FINAL DRIVE ………………………………………………………………………. 83

TRACK GROUP ………………………………………………………………………. 85

RECOIL SPRING …………………………………………………………………….. 86

SUSPENSION………………………………………………………………………… 87

WINCH CONTROL……………………………………………………………………… 88

HYDRAULIC CIRCUIT DIAGRAM FOR WINCH………………………………………………….. 91

WINCH…………………………………………………………………………….. 92

DETAILED WORKING CIRCUIT DIAGRAM FOR CLUTCH AND BRAKE OF WINCH …………………………. 97

POWER TRAIN ON WINCH ………………………………………………………………. 99

HIGH-LOW VALVE……………………………………………………………………..105

PPC VALVE………………………………………………………………………….106

FLOW DIVIDER VALVE………………………………………………………………….108

COUNTERWEIGHT HYDRAULIC TANK ………………………………………………………..110

COUNTERWEIGHT PIPING………………………………………………………………..111

COUNTERWEIGHT CONTROL ………………………………………………………………112

COUNTERWEIGHT HYDRAULIC CIRCUIT DIAGRAM ………………………………………………113

COUNTERWEIGHT ……………………………………………………………………..114

COUNTERWEIGHT CONTROL VALVE………………………………………………………….117

BOOM………………………………………………………………………………118

SAFETY DEVICE………………………………………………………………………119

CAB……………………………………………………………………………….125

ACTUAL ELECTRIC WIRING DIAGRAM ………………………………………………………126

20 TESTING AND ADJUSTING………………………………………………………………..127

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS …………………………………………128

STANDARD VALUE TABLE FOR CHASSIS……………………………………………………..130

TESTING AND ADJUSTING ………………………………………………………………134

TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING ……………………………………135

ADJUSTING VALVE CLEARANCE ……………………………………………………….136

MEASURING COMPRESSION PRESSURE……………………………………………………137

TESTING AND ADJUSTING FUEL INJECTION TIMING ……………………………………….138

MEASURING ENGINE OIL PRESSURE…………………………………………………….139

MEASURING EXHAUST COLOR………………………………………………………….140

MEASURING EXHAUST TEMPERATURE ……………………………………………………141

TESTING AND ADJUSTING ALTERNATOR BELT TENSION………………………………………142

MEASURING BLOW-BY……………………………………………………………….143

MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)……………………………………..144

MEASURING ENGINE SPEED…………………………………………………………..145

NEASURING TORQUE CONVERTER STALL SPEED…………………………………………….146

BLEEDING AIR FROM COUNTERWEIGHT CYLINDER ………………………………………….147

ADJUSTING WINCH CONTROL INTERLOCK MECHANISM………………………………………..148

MEASURING OIL PRESSURE ………………………………………………………….149

MEASURING COUNTERWEIGHT OIL PRESSURE ……………………………………………..151

MEASURING WINCH OIL PRESSURE …………………………………………………….152

HYDRAULIC CIRCUIT DIAGRAM FOR WINCH ………………………………………………153

MEASURING LEAKAGE INSIDE CYLINDER…………………………………………………154

REINSTALLATION (IF MOMENT LIMITER WAS REMOVED) AND ADJUSTING ………………………..155

ADJUSTMENT PROCEDURE FOR MOMENT LIMITER PERFORMANCE…………………………………156

TROUBLESHOOTING ……………………………………………………………………159

POINTS TO REMEMBER WHEN TROUBLESHOOTING …………………………………………..160

SEQUENCE OF EVENTS IN TROUBLESHOOTING …………………………………………….161

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE……………………………………162

CHECKS BEFORE TROUBLESHOOTING ……………………………………………………170

TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)………………………………………….171

METHOD OF USING TROUBLESHOOTING CHARTS…………………………………………172

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………….176

S-2 ENGINE DOES NOT START…………………………………………………….177

(1) ENGINE DOES NOT TURN …………………………………………………177

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)……178

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….179

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)…………………………180

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………….181

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………..182

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………….183

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)………………………………..184

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)………………………..185

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………..186

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………….187

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN……….188

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)…………………..189

S-13 OIL LEVEL RISES (WATER,FUEL IN OIL)……………………………………….190

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)……………………………191

S-15 ABNORMAL NOISE IS MADE…………………………………………………..192

S-16 VIBRATION IS EXCESSIVE…………………………………………………..193

TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM (H MODE)……………………………..194

H-1 TORQUE CONVERTER OIL TEMPERATURE IS TOO HIGH ……………………………….195

H-2 MACHINE DOES NOT MOVE…………………………………………………….196

H-3 MACHINE LACKS POWER OR SPEED………………………………………………197

H-4 MACHINE MOVES WHEN ENGINE IS STARTED……………………………………….198

H-5 EXCESSIVE TIME LAG WHEN STARTING MACHINE OR SHIFTING GEAR…………………….198

H-6 EXCESSIVE SHOCK WHEN STARTING OFF OR SHIFTING GEAR…………………………..199

H-7 MACHINE MOVES IN ONLY ONE DIRECTION (FORWARD OR REVERSE)……………………..200

H-8 STEERING CLUTCH IS NOT DISENGAGED………………………………………….201

H-9 STEERING CLUTCH SLIPS…………………………………………………….202

H-10 STEERING BRAKE DOES NOT WORK …………………………………………….203

H-11 LACK OF POWER,SPEED WHEN RETRACT COUNTERWEIGHT …………………………….204

H-12 IMPOSSIBLE TO RETRACT COUNTERWEIGHT ………………………………………205

H-13 EXCESSIVE HYDRAULIC DRIFT OF COUNTERWEIGHT CYLINDER ………………………..206

H-14 DEFECTIVE BOOM RAISE,LOWER (SPEED,RAISING FORCE,LOWERING FORCE)………………207

H-15 DEFECTIVE HOOK RAISE,LOWER (SPEED,RAISING FORCE,LOWERING FORCE)………………208

H-16 EXCESSIVE HYDRAULIC DRIFT OF BOOM…………………………………………209

H-17 EXCESSIVE HYDRAULIC DRIFT OF HOOK ………………………………………..210

H-18 PLAY WHEN OPERATING HOOK ………………………………………………..211

H-19 PLAY WHEN OPERATING BOOM…………………………………………………212

H-20 EXCESSIVE TIME LAG WHEN OPERATING HOOK ……………………………………213

H-21 EXCESSIVE TIME LAG WHEN OPERATING BOOM…………………………………….214

H-22 EXCESSIVE INCHING AMOUNT…………………………………………………215

H-23 WINCH FREE FALL DOES NOT WORK ……………………………………………216

H-24 WINCH OVERHEATS…………………………………………………………217

H-25 EXCESSIVE NOISE WHEN OPERATING WINCH CLUTCH,BRAKE ………………………….218

H-26 CONTROL LEVER IS HEAVY…………………………………………………..219

H-27 HOOK OVERWIND HORN DOES NOT SOUND…………………………………………220

30 DISASSEMBLY AND ASSEMBLY …………………………………………………………….221

METHOD OF USING MANUAL ……………………………………………………………..223

PRECAUTIONS WHEN CARRYING OUT OPERATION……………………………………………….225

SPECIAL TOOL LIST…………………………………………………………………..227

REMOVAL AND INSTALLATION OF STARTING MOTOR ASSEMBLY…………………………………….230

REMOVAL AND INSTALLATION OF ALTERNATOR ASSEMBLY………………………………………..231

REMOVAL AND INSTALLATION OF ENGINE OIL COOLER CORE ASSEMBLY……………………………..233

REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY………………………………..235

REMOVAL AND INSTALLATION OF WATER PUMP ASSEMBLY ……………………………………….237

REMOVAL AND INSTALLATION OF TURBOCHARGER ASSEMBLY …………………………………….240

REMOVAL AND INSTALLATION OF NOZZLE HOLDER ASSEMBLY …………………………………….242

REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY……………………………………..243

REMOVAL AND INSTALLATION OF THERMOSTAT ASSEMBLY………………………………………..257

REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY …………………………………………258

REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY…………………………………………269

REMOVAL AND INSTALLATION OF TORQUE CONVERTER AND WINCH OIL COOLER ASSEMBLY………………..271

REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY……………………………………………273

REMOVAL AND INSTALLATION OF PTO ASSEMBLY ……………………………………………..282

DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY………………………………………………286

REMOVAL AND INSTALLATION OF TRANSMISSION PUMP ASSEMBLY………………………………….293

REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY……………………………………….294

REMOVAL AND INSTALLATION OF TORQUE CONVERTER ASSEMBLY…………………………………..301

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY…………………………………..306

REMOVAL AND INSTALLATION OF TORQUE CONVERTER RELIEF VALVE ASSEMBLY……………………….316

REMOVAL AND INSTALLATION OF TORQUE CONVERTER REGULATING VALVE ASSEMBLY……………………317

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER RELIEF VALVE ASSEMBLY……………………….318

REMOVAL AND INSTALLATION OF TRANSMISSION CONTROL VALVE ASSEMBLY………………………….319

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CONTROL VALVE ASSEMBLY………………………….322

REMOVAL AND INSTALLATION OF TRANSMISSION ASSEMBLY………………………………………326

DISASSEMBLY AND ASSEMBLY OF TORQFLOW TRANSMISSION ASSEMBLY………………………………328

REMOVAL AND INSTALLATION OF TRANSMISSION LUBRICATION VALVE ASSEMBLY………………………354

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION LUBRICATION VALVE ASSEMBLY………………………355

REMOVAL AND INSTALLATION OF STEERING CONTROL VALVE ASSEMBLY……………………………..356

DISASSEMBLY AND ASSEMBLY OF STEERING CONTROL VALVE ASSEMBLY …………………………….358

REMOVAL AND INSTALLATION OF BRAKE SAFETY VALVE ASSEMBLY…………………………………362

DISASSEMBLY AND ASSEMBLY OF BRAKE SAFETY VALVE ASSEMBLY ………………………………..363

REMOVAL AND INSTALLATION OF STEERING PUMP ASSEMBLY …………………………………….364

REMOVAL AND INSTALLATION OF STEERING CLUTCH ASSEMBLY……………………………………365

DISASSEMBLY AND ASSEMBLY OF BRAKE BOOSTER ASSEMBLY……………………………………..368

DISASSEMBLY AND ASSEMBLY OF STEERING RELIEF VALVE ASSEMBLY ……………………………..369

DISASSEMBLY AND ASSEMBLY OF STEERING CLUTCH ASSEMBLY …………………………………..370

DISASSEMBLY AND ASSEMBLY OF BEVEL GEAR SHAFT ASSEMBLY…………………………………..372

DISASSEMBLY AND ASSEMBLY OF FIRST PINION ASSEMBLY………………………………………379

DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY……………………………………….382

REMOVAL AND INSTALLATION OF TRACK ASSEMBLY…………………………………………….393

REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY…………………………………….396

REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY………………………………………398

DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY …………………………………….400

REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY……………………………………….402

REMOVAL AND INSTALLATION OF IDLER ASSEMBLY…………………………………………….406

REMOVAL AND INSTALLATION OF WINCH CONTROL VALVE ASSEMBLY ……………………………….407

DISASSEMBLY AND ASSEMBLY OF WINCH CONTROL VALVE ASSEMBLY ……………………………….408

REMOVAL AND INSTALLATION OF HIGH/LOW SPEED SELECTOR VALVE ASSEMBLY……………………….413

DISASSEMBLY AND ASSEMBLY OF HIGH/LOW SPEED SELECTOR VALVE ASSEMBLY……………………….414

REMOVAL AND INSTALLATION OF TOWING WINCH PUMP ASSEMBLY …………………………………418

REMOVAL AND INSTALLATION OF COUNTERWEIGHT PUMP ASSEMBLY ………………………………..419

REMOVAL AND INSTALLATION OF COUNTERWEIGHT CYLINDER ASSEMBLY……………………………..420

DISASSEMBLY AND ASSEMBLY OF COUNTERWEIGHT CYLINDER ASSEMBLY……………………………..421

REMOVAL AND INSTALLATION OF COUNTERWEIGHT CONTROL VALVE ASSEMBLY…………………………425

DISASSEMBLY AND ASSEMBLY OF COUNTERWEIGHT CONTROL VALVE ASSEMBLY…………………………426

REMOVAL AND INSTALLATION OF GATE FRAME ASSEMBLY………………………………………..430

REMOVAL AND INSTALLATION OF COUNTERWEIGHT/FRAME………………………………………..433

REMOVAL AND INSTALLATION OF BOOM/FRAME………………………………………………..437

REMOVAL AND INSTALLATION OF TOWING WINCH ASSEMBLY………………………………………438

DISASSEMBLY AND ASSEMBLY OF TOWING WINCH ASSEMBLY ……………………………………..442

REMOVAL AND INSTALLATION OF HEATER ASSEMBLY……………………………………………477

40 MAINTENANCE STANDARD…………………………………………………………………478

ENGINE MOUNT ………………………………………………………………………479

PTO……………………………………………………………………………….480

TORQFLOW TRANSMISSION ………………………………………………………………481

(1) TORQUE CONVERTER…………………………………………………………….481

(2) RELIEF VALVE AND REGULATOR VALVE………………………………………………483

TRANSMISSION ………………………………………………………………………484

TRANSMISSION CONTROL VALVE ………………………………………………………….486

TRANSMISSION PUMP ………………………………………………………………….488

BEVEL GEAR SHAFT AND STEERING CLUTCH …………………………………………………489

STEERING BRAKE …………………………………………………………………….493

STEERING CONTROL VALVE………………………………………………………………495

STEERING PUMP ……………………………………………………………………..497

FINAL DRIVE………………………………………………………………………..498

TRACK FRAME ……………………………………………………………………….502

RECOIL SPRING ……………………………………………………………………..503

TRACK …………………………………………………………………………….504

IDLER……………………………………………………………………………..506

TRACK ROLLER……………………………………………………………………….508

CARRIER ROLLER……………………………………………………………………..510

SUSPENSION ………………………………………………………………………..511

WINCH PUMP ………………………………………………………………………..512

COUNTERWEIGHT PUMP …………………………………………………………………513

HI-LO VALVE………………………………………………………………………..514

PPC VALVE………………………………………………………………………….515

FLOW DIVIDER VALVE………………………………………………………………….516

WINCH……………………………………………………………………………..517

LOWER CLUTCH……………………………………………………………………….519

RAISE CLUTCH……………………………………………………………………….521

WINCH BRAKE………………………………………………………………………..523

CONTROL VALVE (FOR COUNTERWEIGHT)…………………………………………………….525

COUNTERWEIGHT CYLINDER ……………………………………………………………..527

SLOW RETURN VALVE ………………………………………………………………….528

COUNTERWEIGHT ……………………………………………………………………..529

BOOM ……………………………………………………………………………..531

90 OTHERS …………………………………………………………………………….533

ELECTRIC CIRCUIT DIAGRAM (STD)……………………………………………………….534

ELECTRIC CIRCUIT DIAGRAM (-50℃ SPEC.)…………………………………………………535

CAB ELECTRIC CIRCUIT DIAGRAM…………………………………………………………536