$34

Komatsu D155CX-8 Base Tractor Operation & Maintenance Manual TEN00922-02 – PDF DOWNLOAD

Komatsu D155CX-8 Base Tractor Operation & Maintenance Manual TEN00922-02 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D155CX-8 Base Tractor Operation & Maintenance Manual TEN00922-02 – PDF DOWNLOAD

Language : English

Pages : 444

Downloadable : Yes

File Type : PDF

Size: 16.3 MB

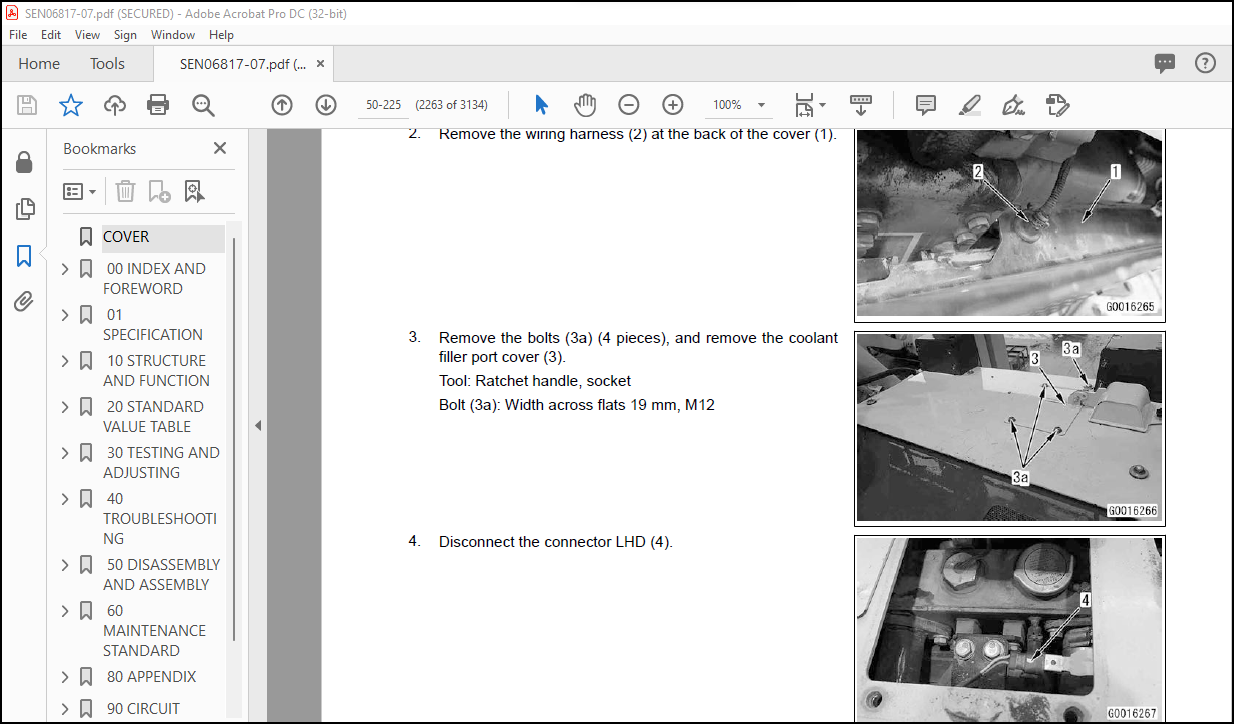

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu D155CX-8 Base Tractor Operation & Maintenance Manual TEN00922-02 – PDF DOWNLOAD

SERIAL NUMBERS 150001 and up

READ THIS MANUAL:

When you install the pipelayer attachments to this machine, you can use it for the pipelayer operation.

To handle the attachments, see the instruction manual of the attachment.

This manual gives details of the operation and methods of inspection and maintenance for this machine that

must be obeyed to use the machine safely. Most accidents are caused by the failure to follow fundamental safety

rules for the operation and maintenance of machines.

Read, understand and follow all precautions and warnings in this manual and on the machine before you do the

operation and maintenance. Failure to do so can cause serious injury or death.

Komatsu cannot predict every situation when the machine is used. Therefore, the safety messages in this manual

and on the machine cannot include all possible safety precautions.

If you do the operation, inspection, or maintenance in the situations that are not written in this manual, understand

that it is your responsibility to take the necessary precautions for the safety. Also in that case, you must

not do the operations which are prohibited in this manual. Incorrect operation, inspection and maintenance of

the machine is dangerous. It can cause serious personal injury or death.

If you sell the machine, be sure to give this manual to the new owner together with the machine.

Be sure to keep this Operation and Maintenance Manual in the shown storage to let all the personnel read it.

Storage location for the Operation and Maintenance Manual

It is provided on the back of the backrest of operator’s seat.

TABLE OF CONTENTS:

Komatsu D155CX-8 Base Tractor Operation & Maintenance Manual TEN00922-02 – PDF DOWNLOAD

FOREWORD…………………………………………………………………………………………………………………………………. 1-1

READ THIS MANUAL ………………………………………………………………………………………………………………. 1-5

SAFETY INFORMATION ………………………………………………………………………………………………………….. 1-6

INTRODUCTION …………………………………………………………………………………………………………………….. 1-7

MAIN APPLICATION OF MACHINE……………………………………………………………………………………… 1-7

DIRECTIONS OF MACHINE……………………………………………………………………………………………….. 1-7

VISIBILITY FROM OPERATOR’S SEAT ……………………………………………………………………………….. 1-8

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION …………………………………………… 1-10

PRODUCT INFORMATION……………………………………………………………………………………………………….1-11

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE …….1-11

LOCATION OF ENGINE NUMBER PLATE ……………………………………………………………………………1-11

LOCATION OF ROPS PLATE ……………………………………………………………………………………………. 1-12

SERVICE METER LOCATION …………………………………………………………………………………………… 1-12

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR…………………………………………………… 1-12

ABBREVIATION LIST …………………………………………………………………………………………………………….. 1-13

SAFETY……………………………………………………………………………………………………………………………………….. 2-1

SAFETY…………………………………………………………………………………………………………………………………. 2-2

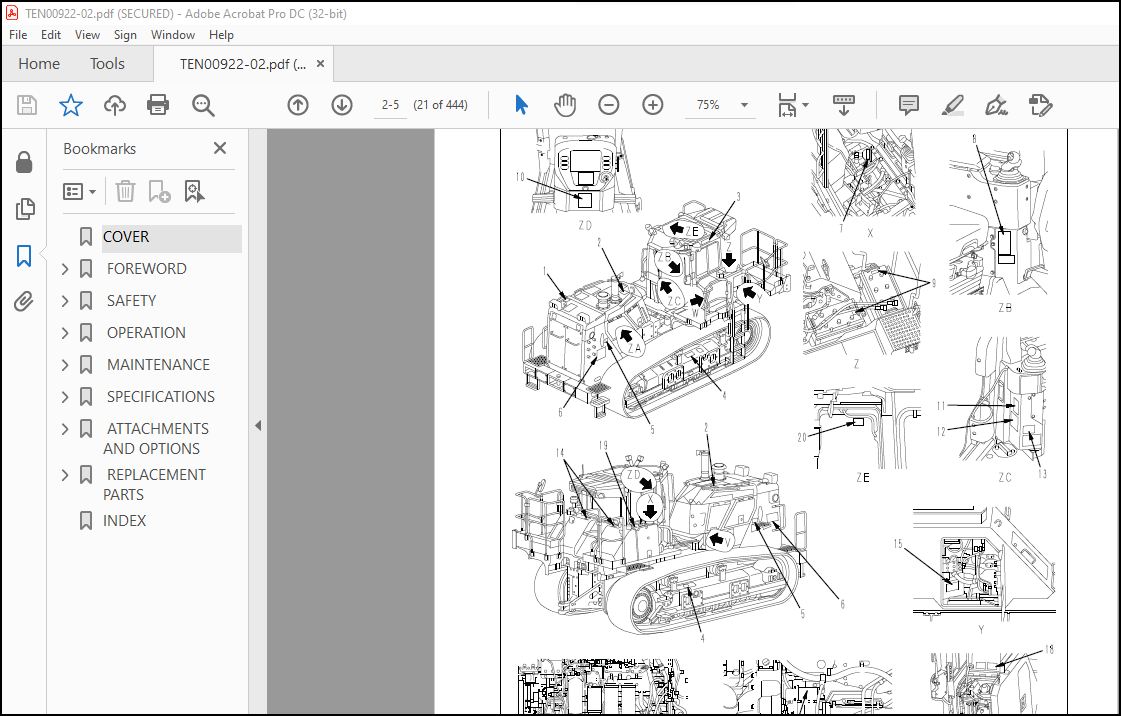

SAFETY LABELS ……………………………………………………………………………………………………………………. 2-4

LOCATION OF SAFETY LABELS………………………………………………………………………………………… 2-5

CONTENTS OF SAFETY LABELS ………………………………………………………………………………………. 2-7

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE ……………………………… 2-12

PRECAUTIONS BEFORE STARTING OPERATION……………………………………………………………… 2-12

PREPARATIONS FOR SAFE OPERATION …………………………………………………………………………. 2-12

PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………….. 2-14

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE……………………………………………………. 2-16

DO NOT GET CAUGHT IN WORK EQUIPMENT …………………………………………………………………. 2-17

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES……………………………………………….. 2-17

UNAUTHORIZED MODIFICATION …………………………………………………………………………………….. 2-18

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS ……………………………………………. 2-18

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING …………………………………………….. 2-18

PRECAUTIONS FOR OPERATION ………………………………………………………………………………………….. 2-19

PRECAUTIONS FOR JOBSITE …………………………………………………………………………………………. 2-19

START ENGINE………………………………………………………………………………………………………………. 2-22

PRECAUTIONS FOR OPERATION ……………………………………………………………………………………. 2-25

PRECAUTIONS FOR TRANSPORTATION………………………………………………………………………….. 2-29

TOWING AND BEING TOWED………………………………………………………………………………………….. 2-30

PRECAUTIONS FOR MAINTENANCE ……………………………………………………………………………………… 2-31

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE …………………………….. 2-31

PRECAUTIONS FOR CHECK AND MAINTENANCE ……………………………………………………………. 2-34

PRECAUTIONS FOR DEF………………………………………………………………………………………………………. 2-40

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING ………………………………………….. 2-40

PRECAUTIONS FOR ADDING………………………………………………………………………………………….. 2-40

PRECAUTIONS FOR STORING………………………………………………………………………………………… 2-40

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE ………………………………………………………….. 2-40

OTHER PRECAUTIONS…………………………………………………………………………………………………… 2-40

OPERATION …………………………………………………………………………………………………………………………………. 3-1

GENERAL VIEW……………………………………………………………………………………………………………………… 3-2

MACHINE EQUIPMENT NAME …………………………………………………………………………………………… 3-2

CONTROLS AND GAUGES NAMES……………………………………………………………………………………. 3-3

EXPLANATION OF COMPONENTS …………………………………………………………………………………………… 3-6

EXPLANATION OF MACHINE MONITOR EQUIPMENT …………………………………………………………. 3-6

SWITCHES…………………………………………………………………………………………………………………….. 3-91

CONTROL LEVERS AND PEDALS ……………………………………………………………………………………. 3-97

OTHER EQUIPMENT …………………………………………………………………………………………………….. 3-103

MACHINE OPERATIONS AND CONTROLS ……………………………………………………………………………. 3-145

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE ……………………………………………… 3-145

CONTENTS FOREWORD

1-2

METHOD FOR STARTING ENGINE…………………………………………………………………………………. 3-179

METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE …………………………… 3-185

METHOD FOR STOPPING ENGINE ………………………………………………………………………………… 3-188

METHOD FOR STARTING MACHINE (TRAVEL FORWARD AND REVERSE) AND STOPPING MACHINE

………………………………………………………………………………………………………………………. 3-190

SHIFT GEARS ………………………………………………………………………………………………………………. 3-193

METHOD FOR SWITCHING BETWEEN FORWARD AND REVERSE …………………………………… 3-197

METHOD FOR STEERING MACHINE………………………………………………………………………………. 3-198

PRECAUTIONS FOR OPERATION ………………………………………………………………………………….. 3-200

PRECAUTIONS WHEN OPERATING ON SLOPE………………………………………………………………. 3-201

PRECAUTIONS FOR USING BRAKE ………………………………………………………………………………. 3-201

DO NOT OPEN DOOR WHILE OPERATING MACHINE ……………………………………………………… 3-201

DO NOT MODIFY CAB GLASS IN ANY WAY THAT WILL OBSTRUCT THE VIEW …………………. 3-201

PRECAUTIONS FOR BLIND SPOTS CAUSED BY CAB AND ROPS STRUCTURES ……………… 3-202

TIPS FOR LONGER UNDERCARRIAGE LIFE …………………………………………………………………… 3-203

PARK MACHINE ……………………………………………………………………………………………………………. 3-206

METHOD FOR CHECKING AFTER FINISHING WORK………………………………………………………. 3-208

LOCK…………………………………………………………………………………………………………………………… 3-208

HANDLE AIR CONDITIONER………………………………………………………………………………………………… 3-212

EXPLANATION OF AIR CONDITIONER EQUIPMENT………………………………………………………… 3-213

METHOD FOR OPERATING AIR CONDITIONER………………………………………………………………. 3-218

HANDLE RADIO ………………………………………………………………………………………………………………….. 3-226

EXPLANATION OF RADIO EQUIPMENT ………………………………………………………………………….. 3-226

METHOD FOR CONTROLLING RADIO ……………………………………………………………………………. 3-229

ANTENNA…………………………………………………………………………………………………………………….. 3-231

TRANSPORTATION……………………………………………………………………………………………………………… 3-232

PRECAUTIONS FOR TRANSPORTATION………………………………………………………………………… 3-232

TRAVEL ON ROAD………………………………………………………………………………………………………… 3-232

PRECAUTIONS FOR TRANSPORTING MACHINE ……………………………………………………………. 3-232

TRANSPORTATION……………………………………………………………………………………………………….. 3-232

LOADING AND UNLOADING WITH TRAILER …………………………………………………………………… 3-233

LIFT MACHINE ……………………………………………………………………………………………………………… 3-237

COLD WEATHER OPERATION……………………………………………………………………………………………… 3-239

COLD WEATHER OPERATION INFORMATION ………………………………………………………………… 3-239

PRECAUTIONS AFTER DAILY WORK COMPLETION IN COLD WEATHER………………………….. 3-241

AFTER COLD WEATHER SEASON …………………………………………………………………………………. 3-241

PRECAUTIONS FOR LONG-TERM STORAGE ……………………………………………………………………….. 3-242

PREPARATION FOR LONG-TERM STORAGE ………………………………………………………………….. 3-242

MAINTENANCE DURING LONG-TERM STORAGE……………………………………………………………. 3-242

STARTING MACHINE AFTER LONG-TERM STORAGE……………………………………………………… 3-243

TROUBLES AND ACTIONS ………………………………………………………………………………………………….. 3-244

ACTIONS WHEN RUNNING OUT OF FUEL ……………………………………………………………………… 3-244

PRECAUTIONS FOR TOWING MACHINE ………………………………………………………………………… 3-244

PRECAUTIONS FOR DISCHARGED BATTERY ………………………………………………………………… 3-246

OTHER TROUBLE…………………………………………………………………………………………………………. 3-251

MAINTENANCE…………………………………………………………………………………………………………………………….. 4-1

PRECAUTIONS FOR MAINTENANCE ……………………………………………………………………………………….. 4-2

CHECK SERVICE METER READING ………………………………………………………………………………….. 4-2

KOMATSU GENUINE REPLACEMENT PARTS …………………………………………………………………….. 4-2

KOMATSU GENUINE LUBRICANTS ……………………………………………………………………………………. 4-2

ALWAYS USE CLEAN WASHER FLUID ……………………………………………………………………………….. 4-2

FRESH AND CLEAN LUBRICANTS …………………………………………………………………………………….. 4-2

CHECK DRAINED OIL AND USED FILTER…………………………………………………………………………… 4-2

PRECAUTIONS FOR REFILLING OIL OR FUEL …………………………………………………………………… 4-2

PRECAUTIONS FOR ADDING DEF ……………………………………………………………………………………. 4-2

PRECAUTIONS FOR WELDING …………………………………………………………………………………………. 4-2

DO NOT DROP THINGS INSIDE MACHINE …………………………………………………………………………. 4-2

PRECAUTIONS FOR KDPF ……………………………………………………………………………………………….. 4-3

FOREWORD CONTENTS

1-3

PRECAUTIONS FOR SCR ASSEMBLY ……………………………………………………………………………….. 4-3

DUSTY JOBSITES…………………………………………………………………………………………………………….. 4-3

AVOID MIXING OIL……………………………………………………………………………………………………………. 4-3

LOCK INSPECTION COVERS ……………………………………………………………………………………………. 4-3

PRECAUTIONS FOR OPENING AND CLOSING ENGINE SIDE COVER………………………………….. 4-3

BLEED AIR FROM HYDRAULIC CIRCUIT ……………………………………………………………………………. 4-3

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES ……………………………………………………. 4-3

CHECKS AFTER INSPECTION AND MAINTENANCE……………………………………………………………. 4-4

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE……………………………………. 4-4

OUTLINE OF MAINTENANCE…………………………………………………………………………………………………… 4-5

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC ………………………………………….. 4-5

HANDLE ELECTRICAL COMPONENTS ………………………………………………………………………………4-11

HYDRAULIC COMPONENTS……………………………………………………………………………………………. 4-13

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS…………………………………………………….. 4-14

MAINTENANCE SCHEDULE…………………………………………………………………………………………………… 4-16

MAINTENANCE SCHEDULE TABLE………………………………………………………………………………….. 4-16

MAINTENANCE PROCEDURE ……………………………………………………………………………………………….. 4-18

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS) ………………………. 4-18

WHEN REQUIRED ………………………………………………………………………………………………………….. 4-19

CHECKS BEFORE STARTING………………………………………………………………………………………….. 4-52

EVERY 250 HOURS MAINTENANCE ………………………………………………………………………………… 4-53

EVERY 500 HOURS MAINTENANCE ………………………………………………………………………………… 4-58

EVERY 1000 HOURS MAINTENANCE ………………………………………………………………………………. 4-64

EVERY 2000 HOURS MAINTENANCE ………………………………………………………………………………. 4-76

EVERY 4000 HOURS MAINTENANCE ………………………………………………………………………………. 4-89

EVERY 4500 HOURS MAINTENANCE ………………………………………………………………………………. 4-95

EVERY 8000 HOURS MAINTENANCE ………………………………………………………………………………. 4-96

EVERY 9000 HOURS MAINTENANCE ………………………………………………………………………………. 4-97

SPECIFICATIONS …………………………………………………………………………………………………………………………. 5-1

SPECIFICATIONS …………………………………………………………………………………………………………………… 5-2

SPECIFICATIONS: D155CX-8 BASE TRACTOR……………………………………………………………………. 5-2

ATTACHMENTS AND OPTIONS ……………………………………………………………………………………………………… 6-1

GENERAL PRECAUTIONS ………………………………………………………………………………………………………. 6-2

PRECAUTIONS FOR SAFETY……………………………………………………………………………………………. 6-2

ATTACHMENTS AND OPTIONS ……………………………………………………………………………………………….. 6-3

HANDLE HEADREST ………………………………………………………………………………………………………………. 6-4

HANDLE EXTERNAL POWER SUPPLY ENGINE PREHEATER…………………………………………………….. 6-5

INSTALLATION PROCEDURES FOR EXTERNAL POWER SUPPLY SYSTEM FOR EXTERNAL

POWER SUPPLY ENGINE PREHEATER ………………………………………………………………………….. 6-6

FABRICATE EXTERNAL POWER SUPPLY CABLE ……………………………………………………………….. 6-7

INSTALL EXTERNAL POWER SUPPLY SYSTEM …………………………………………………………………. 6-9

CHECK OPERATION AFTER COMPLETION OF ASSEMBLING ……………………………………………..6-11

METHOD FOR STARTING ENGINE IN COLD WEATHER …………………………………………………….. 6-12

REPLACEMENT PARTS…………………………………………………………………………………………………………………. 7-1

DEFINED LIFE PARTS …………………………………………………………………………………………………………….. 7-2

DEFINED LIFE PARTS LIST……………………………………………………………………………………………….. 7-2

CONSUMABLE PARTS ……………………………………………………………………………………………………………. 7-3

CONSUMABLE PARTS LIST ………………………………………………………………………………………………. 7-3

RECOMMENDED FUEL, COOLANT, AND LUBRICANT ……………………………………………………………….. 7-4

LUBRICATION CHART ………………………………………………………………………………………………………. 7-7

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ………….. 7-8

RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS ………….. 7-9