$45

Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21 Bulldozer Workshop Service Repair Manual PDF DOWNLOAD

Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21 Bulldozer Workshop Service Repair Manual

FILE DETAILS:

Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21 Bulldozer Workshop Service Repair Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : SEBM025607

Total Pages : 407

DESCRIPTION:

Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21 Bulldozer Workshop Service Repair Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

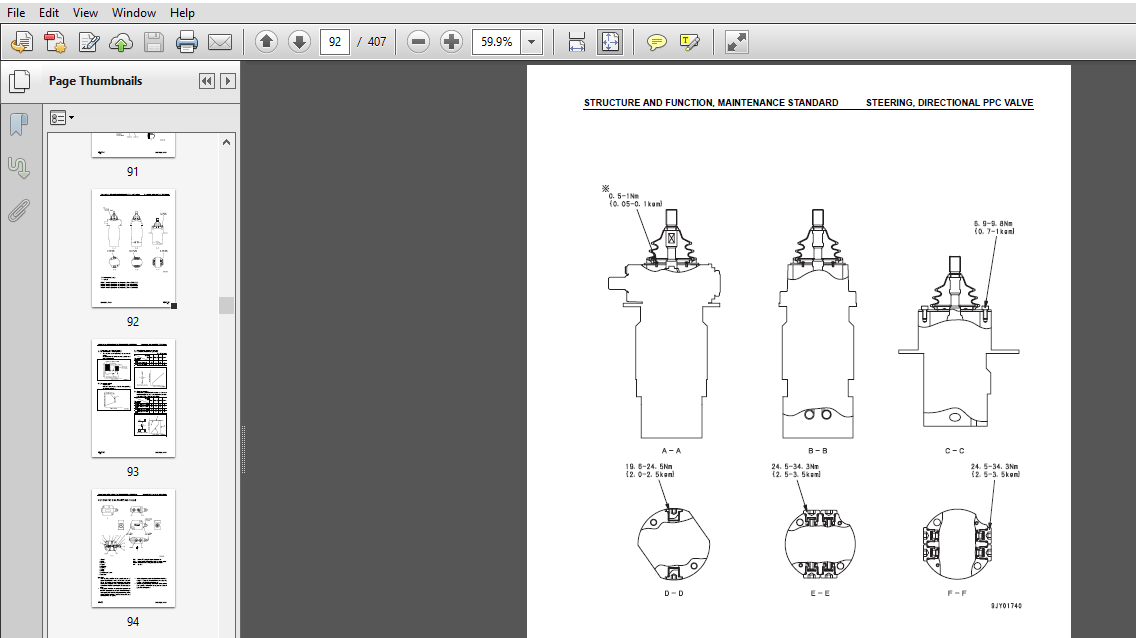

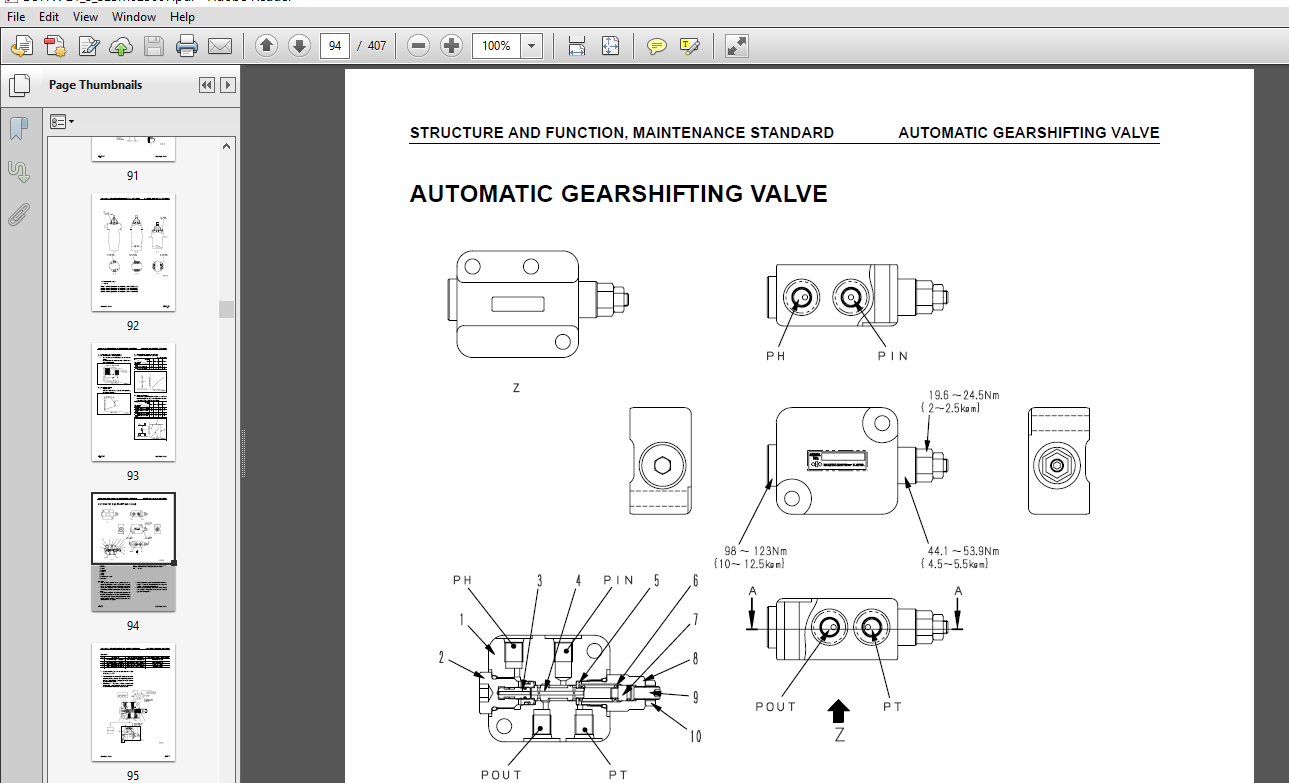

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD:

This section gives the judgment standards for inspection of disassembled parts. The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS:

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams. In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21 Bulldozer Workshop Service Repair Manual

COVER................................................................................................................................................................. 1 CONTENTS.............................................................................................................................................................. 2 01 GENERAL............................................................................................................................................................ 26 SPECIFICATION DRAWING............................................................................................................................................. 27 SPECIFICATIONS.................................................................................................................................................... 29 WEIGHT TABLE...................................................................................................................................................... 37 TABLE OF FUEL, COOLANT AND LUBRICANTS............................................................................................................................. 39 10 STRUCTURE AND FUNCTION, MAINTENANCE STANDARD....................................................................................................................... 40 COOLING SYSTEM.................................................................................................................................................... 41 ENGINE CONTROL.................................................................................................................................................... 42 POWER TRAIN....................................................................................................................................................... 43 POWER TRAIN SYSTEM................................................................................................................................................ 44 HST HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM....................................................................................................................... 45 STEERING, BRAKE CONTROL........................................................................................................................................... 46 DAMPER............................................................................................................................................................ 50 SOLENOID VALVE.................................................................................................................................................... 51 FINAL DRIVE....................................................................................................................................................... 53 HST PUMP.......................................................................................................................................................... 56 SAFETY-SUCTION VALVE.............................................................................................................................................. 61 CUT-OFF VALVE..................................................................................................................................................... 64 CHARGE SAFETY VALVE............................................................................................................................................... 65 CHARGE PUMP....................................................................................................................................................... 67 HST BRAKE QUICK RETURN CIRCUIT.................................................................................................................................... 68 TOWING VALVE...................................................................................................................................................... 69 PARKING BRAKE VALVE............................................................................................................................................... 70 AS VALVE.......................................................................................................................................................... 72 HST MOTOR......................................................................................................................................................... 74 STEERING, DIRECTIONAL PPC VALVE................................................................................................................................... 85 AUTOMATIC GEARSHIFTING VALVE...................................................................................................................................... 94 INCHING VALVE..................................................................................................................................................... 99 FRAME ASSEMBLY....................................................................................................................................................100 TRACK FRAME, RECOIL SPRING........................................................................................................................................101 IDLER.............................................................................................................................................................103 TRACK ROLLER......................................................................................................................................................105 CARRIER ROLLER....................................................................................................................................................107 SPROCKET..........................................................................................................................................................108 TRACK SHOE........................................................................................................................................................110 ARRANGEMENT OF HYDRAULIC EQUIPMENT FOR WORK EQUIPMENT.............................................................................................................114 WORK EQUIPMENT CONTROL............................................................................................................................................115 HYDRAULIC TANK, FILTER............................................................................................................................................117 HYDRAULIC PUMP....................................................................................................................................................118 WORK EQUIPMENT CYLINDER...........................................................................................................................................119 CONTROL VALVE.....................................................................................................................................................121 CLSS..............................................................................................................................................................129 WORK EQUIPMENT PPC VALVE..........................................................................................................................................139 WORK EQUIPMENT ...................................................................................................................................................146 CUTTING EDGE, END BIT.............................................................................................................................................149 CAB RELATED.......................................................................................................................................................150 SAFETY MECHANISM WHEN STARTING ENGINE.............................................................................................................................151 GEARSHIFT CONTROL SYSTEM..........................................................................................................................................152 PARKING BRAKE CONTROL SYSTEM......................................................................................................................................153 COMPONENT EQUIPMENT OF SYSTEM.....................................................................................................................................154 MONITOR SYSTEM....................................................................................................................................................156 SENSORS...........................................................................................................................................................160 20 TESTING AND ADJUSTING..............................................................................................................................................163 STANDARD VALUE TABLE FOR ENGINE...................................................................................................................................164 STANDARD VALUE TABLE FOR CHASSIS..................................................................................................................................166 STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM........................................................................................................................171 TESTING AND ADJUSTING.............................................................................................................................................173 TOOLS LIST FOR TESTING AND ADJUSTING..........................................................................................................................174 MEASURING ENGINE SPEED........................................................................................................................................175 MEASURING EXHAUST COLOR.......................................................................................................................................176 MEASURING BLOW-BY PRESSURE....................................................................................................................................177 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)................................................................................................................178 ADJUSTING VALVE CLEARANCE.....................................................................................................................................179 TESTING ADJUSTING FUEL INJECTION TIMING.......................................................................................................................181 MEASURING COMPRESSION PRESSURE................................................................................................................................182 ADJUSTING ENGINE STOP SOLENOIDE LINKAGE.......................................................................................................................183 MEASURING ENGINE OIL PRESSURE.................................................................................................................................184 BLEEDING AIR FROM FUEL CIRCUIT................................................................................................................................185 TESTING AND ADJUSTING TENSION OF AIR CONDITIONER COMPRESSOR BELT..............................................................................................186 MEASURING AND ADJUSTING HST OIL PRESSURE......................................................................................................................187 MEASURING SOLENOID VALVE OUTPUT PRESSURE......................................................................................................................193 MEASURING AND ADJUSTING WORK EQUIPMENT MAIN RELIEF PRESSURE...................................................................................................194 MEASURING PPC VALVE OUTPUT PRESSURE...........................................................................................................................196 MEASURING LEAKAGE INSIED CYLINDER.............................................................................................................................197 BLEEDING AIR FROM HYDRAULIC CYLINDERS.........................................................................................................................197 TESTING AND ADJUSTING TRACK SHOE TENSION......................................................................................................................198 TESTING AND ADJUSTING TRAVEL DEVIATION........................................................................................................................199 ADJUSTING FUEL CONTROL LINKAGE................................................................................................................................202 ADJUSTING DECELERATOR PEDAL LINKAGE...........................................................................................................................204 ADJUSTING BRAKE PEDAL LINKAGE.................................................................................................................................205 ADJUSTING STEERING/DIRECTIONAL/GEAR SHIFT LEVER AND LOCK LEVER................................................................................................206 ADJUSTING BLADE CONTROL LEVER AND LOCK LEVER..................................................................................................................209 ADJUSTING WORK EQUIPMENT PPC VALVE............................................................................................................................210 PROCEDURE FOR RELEASING PARKING BRAKE.........................................................................................................................211 PROCEDURE FOR INSPECTING DIODE................................................................................................................................213 TROUBLESHOOTING...................................................................................................................................................214 POINTS TO REMEMBER WHEN TROUBLESHOOTING.......................................................................................................................215 SEQUENCE OF EVENTS IN TROUBLESHOOTING.........................................................................................................................216 POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE..............................................................................................................217 CHECKS BEFORE TROUBLESHOOTING.................................................................................................................................225 METHOD OF USING TROUBLESHOOTING CHARTS........................................................................................................................226 TYPES AND LOCATIONS OF CONNECTORS.............................................................................................................................227 CONNECTOR ARRANGEMENT DIAGRAM.................................................................................................................................229 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS....................................................................................................................231 TROUBLESHOOTING FOR ELECTRICAL SYSTEM (E-MODE)................................................................................................................253 TABLE OF FAILURE MODES AND CAUSES (ELECTRICAL SYSTEM).....................................................................................................254 ELECTRICAL CIRCUIT DIAGRAM FOR EACH SYSTEM................................................................................................................256 E-1. WHEN STARTING SWITCH IS TURNED ON, STARTING MOTOR DOES NOT ROTATE....................................................................................258 E-2. ENGINE DOES NOT START (ENGINE STOP SOLENOID DOES NOT OPERATE NORMALLY)...............................................................................260 E-3. HEADLAMP DOES NOT LIGHT UP...........................................................................................................................261 E-4. WHEN STARTING SWITCH IS TURNED TO HEAT POSITION, ENGINE IS NOT HEATED................................................................................263 E-5. WINDSHIELD WIPER DOES NOT OPERATE....................................................................................................................264 E-6. WASHING WATER DOES NOT SPOUT.........................................................................................................................266 E-7. AIR CONDITIONER DOES NOT WORK........................................................................................................................268 a) AIR DOES NOT BLOW OUT..............................................................................................................................268 b) AIR IS NOT COOLED..................................................................................................................................271 E-8. PARKING BRAKE CANNOT BE RELEASED (PARKING BRAKE SOLENOID DOES NOT OPERATE)...........................................................................275 E-9. TRAVEL SPEED CONTROL IS ABNORMAL.....................................................................................................................276 a) WHEN GEAR SHIFT SWITCH IS PRESSED,GEAR SPEED DOES NOT CHANGE OR GEAR SPEED CHANGES BY ITSELF (GEAR SHIFT SWITCH OR CONTROLLER IS ABNORMAL).........276 b) GEAR SPEED CANNOT BE SELECTED NORMALLY (TRAVEL SPEED CHANGEOVER SOLENOID IS ABNORMAL)..............................................................277 E-10. BACKUP ALARM DOES NOT SOUND DURING REVERSE TRAVEL...................................................................................................279 E-11. HORN DOES NOT SOUND.................................................................................................................................281 TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)..................................................................................................282 TABLE OF FAILURE MODES AND CAUSES (HYDRAULIC AND MECHANICAL SYSTEMS)......................................................................................283 H-1. MACHINE DOES NOT TRAVEL IN EITHER DIRECTION OR IT STOPS SUDDENLY.....................................................................................285 H-2. MACHINE DOES NOT TRAVEL IN ONE DIRECTION.............................................................................................................286 H-3. MACHINE TRAVELS WHILE TRAVEL LEVER IS IN NEUTRAL.....................................................................................................286 H-5. MACHINE DEVIATES WHILE TRAVEL LEVER IS IN PARTIAL POSITION...........................................................................................286 H-7. MACHINE SWHINGS MOMENTARILY WHEN IT STARTS ON FLAT GROUND............................................................................................286 H-11. TURNING TIME LAG IS LARGE...........................................................................................................................286 H-12. WHEN OPERATOR INTENDS TO TURN GARDUALLY, MACHINE TURNS SHARPLY......................................................................................286 H-13. MACHINE DOES NOT RETURN QUICKLY TO STRAIGHT TRAVEL POSITION.........................................................................................286 H-14. MACHINE IS NOT DECELERATED SMOOTHLY OR TRAVEL SPEED CANNOT BE CONTROLLED ON DOWNHILL GROUND.........................................................286 H-15. MACHINE DEVIATES WHEN IT IS DECELERATED.............................................................................................................286 H-4. MACHINE DEVIATES WHEN TRAVEL LEVER IS MOVED TO STROKE END............................................................................................287 H-6. MACHINE MOVES BACK WHEN OPERATOR STARTS ON UPHILL GROUND.............................................................................................287 H-8. MACHINE STARTS SHARPLY...............................................................................................................................287 H-9. MACHINE SWINGS MOMENTARLLY WHEN IT STARTS............................................................................................................288 H-10. STARTING TIME LAG IS LARGE..........................................................................................................................289 H-16. MAXIMUM TRAVEL SPEED IS LOW OR OUTPUT POWER IS INSUFFICIENT OR ACCELERATION IS LOW..................................................................290 H-17. ENGINE STALLS.......................................................................................................................................291 H-18. HST NOISE IS LARGE..................................................................................................................................292 H-19. HST OIL TEMPERATURE RISES TOO HIGH..................................................................................................................293 H-20. GEAR SPEED DOES NOT CHANGE..........................................................................................................................293 H-21. ABNORMAL SOUND IS HEARD FROM AROUND WORK EQUIPMENT PUMP OR HST PUMP.................................................................................294 H-22. ANY WORK EQUIPMENT DOES NOT MOVE....................................................................................................................294 H-23. SPEED OR POWER OF EACH WORK EQUIPMENT IS LOW........................................................................................................295 H-24. SPEED OR POWER OF BLADE LIFT OF BLADE TILT CYLINDER IS LOW..........................................................................................295 H-25. SPEED OR POWER OF BLADE ANGLE CYLINDER IS LOW.......................................................................................................296 H-26. HYDRAULIC DRIFT OF BLADE LIFT CYLINDER IS LARGE.....................................................................................................297 H-27. HYDRAULIC DRIFT OF BLADE TILT CYLINDER IS LARGE.....................................................................................................297 H-28. HYDRAULIC DRIFT OF BLADE ANGLE CYLINDER IS LARGE....................................................................................................298 TROUBLESHOOTING FOR MACHINE MONITOR SYSTEM (M-MODE)...........................................................................................................299 TABLE OF FAILURE MODES AND CAUSES (MACHINE MONITOR SYSTEM)................................................................................................300 ELECTRIC CIRCUIT DIAGRAM FOR EACH SYSTEM..................................................................................................................301 M-1. WHEN STARTING SWITCH IS TURNED ON , MONITOR PANEL IS NOT TURNED ON...................................................................................303 M-2. TROUBLE IN PREHEATING CAUTION LAMP...................................................................................................................304 a) PREHEATING MONITOR DOES NOT LIGHT UP...............................................................................................................304 b) PREHEATING MONITOR KEEPS LIGHTING UP...............................................................................................................304 M-3. CAUTION ITEM LIGHTS UP...............................................................................................................................305 a) CHARGE CAUTION LAMP LIGHTS UP WHILE ENGINE IS RUNNING..............................................................................................305 b) OIL PRESSURE CAUTION LAMP LIGHTS UP WHILE ENGINE IS RUNNING........................................................................................306 c) HST FILTER CLOGGING CAUTION LAMP LIGHTS UP (WHILE FILTER IS NOT CLOGGED)...........................................................................306 M-4. TROUBLE IN HST OIL TEMPERATURE GAUGE.................................................................................................................307 a) GAUGE DOES NOT RISE ABOVE C (LOWEST POINT).........................................................................................................307 b) GAUGE DOES NOT LOWER BELOW H (HIGHEST POINT).......................................................................................................307 c) HST OIL TEMPERATURE INDICATED BY GAUGE IS DIFFERENT FROM ACTUAL TEMPERATURE........................................................................308 M-5. TROUBLE IN ENGINE WATER TEMPERATURE GAUGE............................................................................................................309 a) GAUGE DOES NOT RISE ABOVE C (LOWEST POINT).........................................................................................................309 b) GAUGE DOES NOT LOWER BELOW H (HIGHEST POINT).......................................................................................................309 c) ENGINE WATER TEMPERATURE INDICATED BY GAUGE IS DIFFERENT FROM ACTUAL TEMPERATURE...................................................................310 M-6. TROUBLE IN FUEL LEVEL GAUGE..........................................................................................................................311 a) GAUGE DOES NOT RISE ABOVE E (LOWEST POINT).........................................................................................................311 b) GAUGE DOES NOT LOWER BELOW F (HIGHEST POINT).......................................................................................................311 c) FUEL LEVEL INDICATED BY GAUGE IS DIFFERENT FROM ACTUAL LEVEL.......................................................................................312 M-7. SERVICE METER DOES NOT OPERATE AFTER ENGINE IS STARTED...............................................................................................313 M-8. MONITOR PANEL LAMP DOES NOT LIGHT UP (WHILE HEADLAMP IS NORMAL)......................................................................................314 M-9. TROUBLE IN DISPLAY OF TRAVEL SPEED (WHILE ACTUAL TRAVEL SPEED IS NORMAL).............................................................................315 a) TRAVEL SPEED IS NOT DISPLAYED......................................................................................................................315 b) DISPLAYED SPEED IS DIFFERENT FROM ACTUAL TRAVEL SPEED..............................................................................................315 30 DISASSEMBLY AND ASSEMBLY...........................................................................................................................................317 METHOD OF USING MANUAL............................................................................................................................................318 PRECAUTIONS WHEN CARRYING OUT OPERATION...........................................................................................................................319 SPECIAL TOOL LIST.................................................................................................................................................321 SKETCHES OF SPECIAL TOOLS.........................................................................................................................................323 REMOVAL OF FUEL INJECTION PUMP ASSEMBLY...........................................................................................................................324 INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY......................................................................................................................326 REMOVAL OF CYLINDER HEAD ASSEMBLY.................................................................................................................................328 INSTALLATION OF CYLINDER HEAD ASSEMBLY............................................................................................................................333 REMOVAL OF ENGINE FRONT SEAL......................................................................................................................................335 INSTALLATION OF ENGINE FRONT SEAL.................................................................................................................................336 REMOVAL OF ENGINE REAR SEAL.......................................................................................................................................337 INSTALLATION OF ENGINE REAR SEAL..................................................................................................................................338 REMOVAL OF RADIATOR GUARD ASSEMBLY................................................................................................................................339 INSTALLATION OF RADIATOR GUARD ASSEMBLY...........................................................................................................................341 DISASSEMBLY OF RADIATOR, OIL COOLER, AND CHARGE AIR COOLER ASSEMBLIES.............................................................................................342 ASSEMBLY OF RADIATOR, OIL COOLER, AND CHARGE AIR COOLER ASSEMBLIES................................................................................................344 REMOVAL OF ENGINE ASSEMBLY........................................................................................................................................346 INSTALLATION OF ENGINE ASSEMBLY...................................................................................................................................348 REMOVAL OF DAMPER.................................................................................................................................................349 INSTALLATION OF DAMPER............................................................................................................................................349 REMOVAL OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY..................................................................................................................350 INSTALLATION OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY.............................................................................................................351 DISASSEMBLY OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY..............................................................................................................352 ASSEMBLY OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY.................................................................................................................356 REMOVAL OF IDLER AND RECOIL SPRING ASSEMBLY.......................................................................................................................361 INSTALLATION OF IDLER AND RECOIL SPRING ASSEMBLY..................................................................................................................361 DISASSEMBLY OF RECOIL SPRING ASSEMBLY.............................................................................................................................362 ASSEMBLY OF RECOIL SPRING ASSEMBLY................................................................................................................................363 DISASSEMBLY OF IDLER ASSEMBLY.....................................................................................................................................365 ASSEMBLY OF IDLER ASSEMBLY........................................................................................................................................366 DISASSEMBLY OF TRACK ROLLER ASSEMBLY..............................................................................................................................368 ASSEMBLY OF TRACK ROLLER ASSEMBLY.................................................................................................................................369 DISASSEMBLY OF CARRIER ROLLER ASSEMBLY............................................................................................................................372 ASSEMBLY OF CARRIER ROLLER ASSEMBLY...............................................................................................................................373 SPREADING TRACK SHOE ASSEMBLY.....................................................................................................................................374 INSTALLATION OF TRACK SHOE ASSEMBLY...............................................................................................................................375 REMOVAL OF HST PUMP ASSEMBLY......................................................................................................................................376 INSTALLATION OF HST PUMP ASSEMBLY.................................................................................................................................377 REMOVAL OF MAIN CONTROL VALVE ASSEMBLY............................................................................................................................378 INSTALLATION OF MAIN CONTROL VALVE ASSEMBLY.......................................................................................................................379 DISASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY........................................................................................................................380 ASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY...........................................................................................................................384 DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLIES......................................................................................................................388 ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLIES.........................................................................................................................389 REMOVAL OF BLADE ASSEMBLY.........................................................................................................................................391 INSTALLATION OF BLADE ASSEMBLY....................................................................................................................................392 REMOVAL OF OPERATOR'S SEAT TRAME ASSEMBLY.........................................................................................................................393 INSTALLATION OF OPERATOR'S SEAT FRAME ASSEMBLY....................................................................................................................396 REMOVAL OF FUEL TANK ASSEMBLY.....................................................................................................................................397 INSTALLATION OF FUEL TANK ASSEMBLY................................................................................................................................397 REMOVAL OF HYDRAULIC TANK ASSEMBLY................................................................................................................................398 INSTALLATION OF HYDRAULIC TANK ASSEMBLY...........................................................................................................................399 90 OTHERS.............................................................................................................................................................400 HYDRAULIC CIRCUIT DIAGRAM (1/2)(D31EX-21 SERIAL NO.50001-50097 D31PX-21 SERIAL NO.50001-50181 D37EX-21 SERIAL NO. 5001-5104 D37PX-21 SERIAL NO. 5001-5090)........401 HYDRAULIC CIRCUIT DIAGRAM (1/2)(D31EX-21 SERIAL NO.50098 AND UP D31PX-21 SERIAL NO.50182 AND UP D37EX-21 SERIAL NO.5105 AND UP D37PX-21 SERIAL NO.5091 AND UP)....402 HYDRAULIC CIRCUIT DIAGRAM (2/2)...................................................................................................................................403 HYDRAULIC CIRCUIT DIAGRAM (2/2) (FOR D37EX, PX-21 EU SPEC.).......................................................................................................404 ELECTRICAL CIRCUIT DIAGRAM (1/2)..................................................................................................................................405 ELECTRICAL CIRCUIT DIAGRAM (2/2)..................................................................................................................................406 ELECTRICAL CIRCUIT DIAGRAM FOR AIR CONDITIONER....................................................................................................................407

IMAGES PREVIEW OF THE MANUAL: