$36

Komatsu D355C-3 Pipelayer Shop Manual SEBM029903 – PDF DOWNLOAD

Komatsu D355C-3 Pipelayer Shop Manual SEBM029903 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D355C-3 Pipelayer Shop Manual SEBM029903 – PDF DOWNLOAD

Language : English

Pages : 793

Downloadable : Yes

File Type : PDF

Size: 105.6 MB

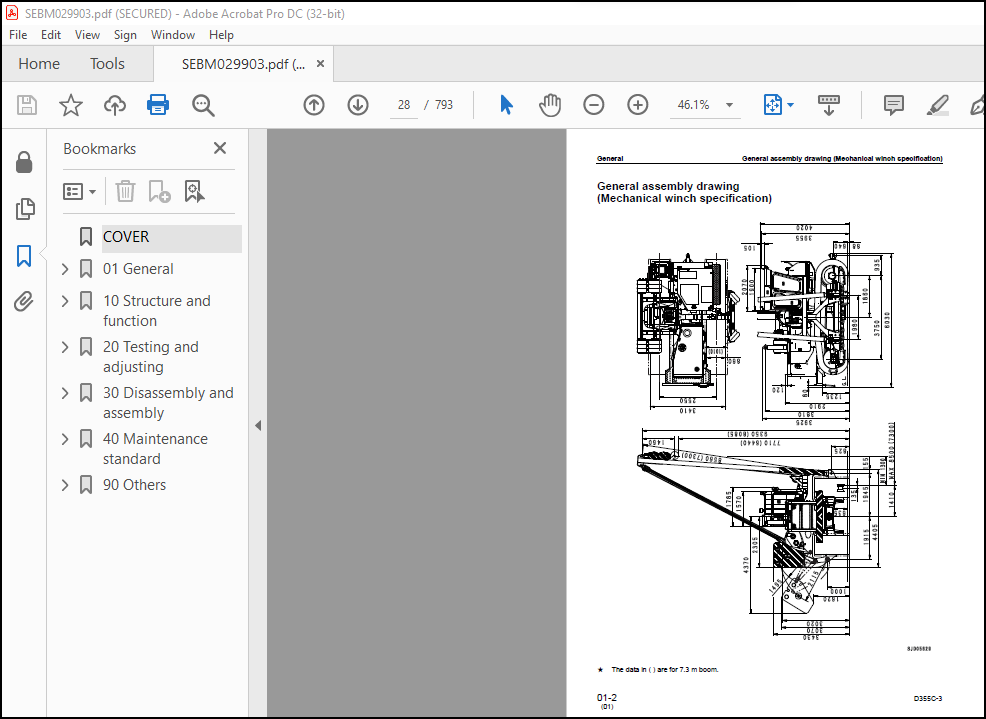

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu D355C-3 Pipelayer Shop Manual SEBM029903 – PDF DOWNLOAD

Machine model Serial number

D355C-3 14263 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.PREPARATIONS FOR WORK:

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any other work equipment to the ground. If this is not possible,

use blocks to prevent the work equipment from falling down. In addition, be sure to lock all the control levers and hang warning sign on them.

9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting

work.

10. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine.Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

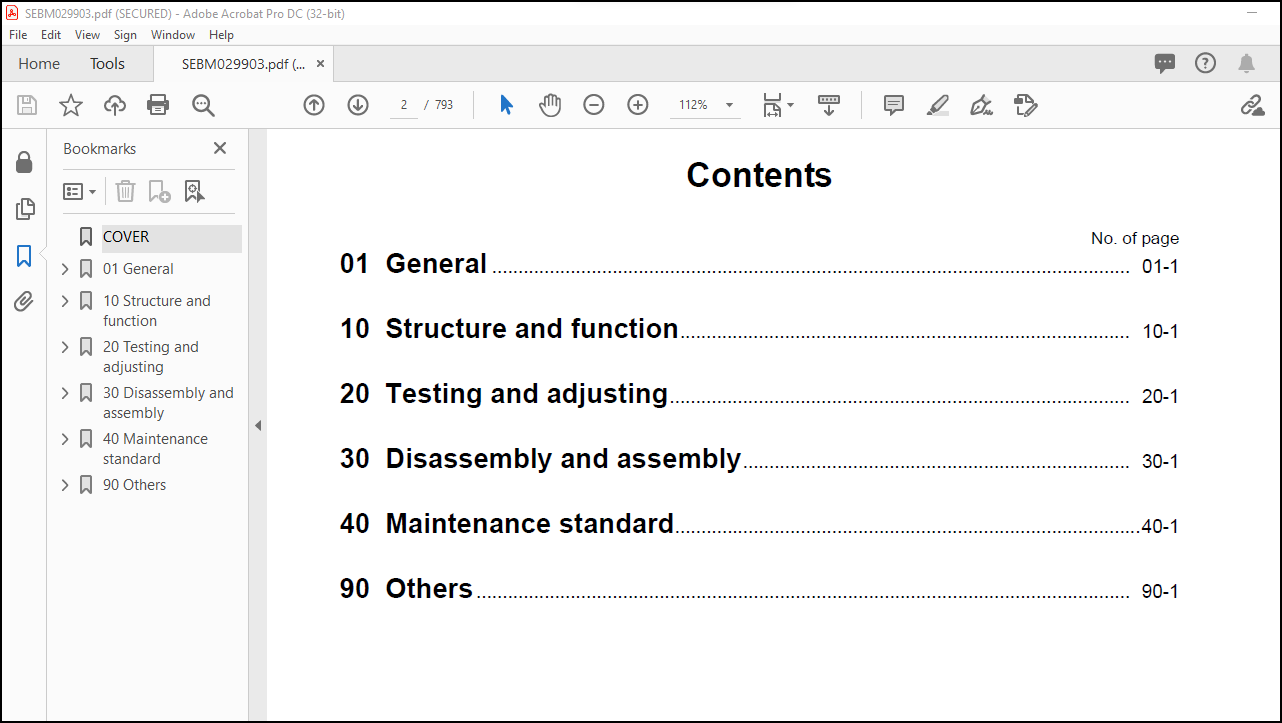

TABLE OF CONTENTS:

Komatsu D355C-3 Pipelayer Shop Manual SEBM029903 – PDF DOWNLOAD

COVER…………………………………………………………………………………………………………………….. 1

01 General………………………………………………………………………………………………………………… 27

General assembly drawing (Mechanical winch specification)…………………………………………………………………… 28

General assembly drawing (Hydraulic winch specification)……………………………………………………………………. 29

Specifications (Mechanical winch specification)……………………………………………………………………………. 30

Specifications (Hydraulic winch specification)…………………………………………………………………………….. 35

Weight table (Mechanical winch specification)……………………………………………………………………………… 40

Weight table (Hydraulic winch specification)………………………………………………………………………………. 42

Table of fuel, coolant and lubricants (Mechanical winch specification)……………………………………………………….. 44

Table of fuel, coolant and lubricants (Hydraulic winch specification)………………………………………………………… 47

10 Structure and function…………………………………………………………………………………………………… 49

Radiator fan…………………………………………………………………………………………………………… 50

Radiator shutter……………………………………………………………………………………………………….. 52

PTO (Power Take-Off) (Mechanical winch specification/Hydraulic winch specification)……………………………………………. 54

Oil cooler…………………………………………………………………………………………………………….. 56

Power train diagram…………………………………………………………………………………………………….. 58

TORQFLOW hydraulic circuit………………………………………………………………………………………………. 60

Power train hydraulic circuit diagram…………………………………………………………………………………….. 62

Torque converter……………………………………………………………………………………………………….. 64

Transmission control……………………………………………………………………………………………………. 67

TORQFLOW transmission…………………………………………………………………………………………………… 69

Transmission control valve………………………………………………………………………………………………. 76

Transmission lubrication valve…………………………………………………………………………………………… 81

Steering and brake control………………………………………………………………………………………………. 82

Bevel gear shaft and steering clutches……………………………………………………………………………………. 84

Steering and brake hydraulic piping………………………………………………………………………………………. 88

Steering and brake hydraulic circuit diagram………………………………………………………………………………. 90

Steering brakes………………………………………………………………………………………………………… 92

Steering control valve………………………………………………………………………………………………….. 96

Final drive…………………………………………………………………………………………………………….102

Track group…………………………………………………………………………………………………………….105

Recoil spring…………………………………………………………………………………………………………..106

Suspension……………………………………………………………………………………………………………..107

Winch control (Mechanical winch specification)……………………………………………………………………………..109

Hydraulic circuit diagram for winch (Mechanical winch specification)………………………………………………………….112

Winch (Mechanical winch specification)…………………………………………………………………………………….114

Detailed working circuit diagram for clutch and brake of winch (Mechanical winch specification)………………………………….119

Power train on winch (Mechanical winch specification)……………………………………………………………………….121

High-Low valve (Mechanical winch specification)…………………………………………………………………………….127

PPC valve (Mechanical winch specification)…………………………………………………………………………………128

Flow divider valve (Mechanical winch specification)…………………………………………………………………………131

Counterweight hydraulic tank (Mechanical winch specification)………………………………………………………………..133

Counterweight piping (Mechanical winch specification)……………………………………………………………………….134

Counterweight control (Mechanical winch specification)………………………………………………………………………135

Counterweight hydraulic circuit diagram (Mechanical winch specification)………………………………………………………136

Counterweight…………………………………………………………………………………………………………..137

Counterweight control valve (Mechanical winch specification)…………………………………………………………………138

Winch control (Hydraulic winch specification)………………………………………………………………………………139

Winch (Hydraulic winch specification)……………………………………………………………………………………..142

PPC valve for boom/counterweight (Hydraulic winch specification)……………………………………………………………..146

PPC valve for hook (Hydraulic winch specification)………………………………………………………………………….147

Hydraulic tank (Hydraulic winch specification)……………………………………………………………………………..151

Piping drawing of counterweight (Hydraulic winch specification)………………………………………………………………152

Counterweight control (Hydraulic winch specification)……………………………………………………………………….153

CLSS (Winch and counterweight control) (Hydraulic winch specification)………………………………………………………..155

Main pump (Hydraulic winch specification)………………………………………………………………………………….158

Control valve (Winch and counterweight control valve) (Hydraulic winch specification)…………………………………………..174

Winch (boom and hook) motor (Hydraulic winch specification)………………………………………………………………….197

Boom…………………………………………………………………………………………………………………..207

Safety device (Mechanical winch specification)……………………………………………………………………………..208

Safety device (Hydraulic winch specification)………………………………………………………………………………212

Cab……………………………………………………………………………………………………………………216

Heater…………………………………………………………………………………………………………………217

Actual electric wiring diagram (Mechanical winch specification)1……………………………………………………………..218

20 Testing and adjusting…………………………………………………………………………………………………….219

Standard value table for engine related parts………………………………………………………………………………220

Standard value table for chasss (Mechanical winch specification)……………………………………………………………..221

Standard value table for chassis (Hydraulic winch specification)……………………………………………………………..225

Testing and adjusting……………………………………………………………………………………………………229

Tools for testing, adjusting, and troubles……………………………………………………………………………..230

Adjusting valve clearance…………………………………………………………………………………………….231

Testing compression pressure………………………………………………………………………………………….232

Testing and adjusting fuel injection timing…………………………………………………………………………….233

Testing engine oil pressure…………………………………………………………………………………………..234

Testing exhaust color………………………………………………………………………………………………..235

Testing exhaust temperature…………………………………………………………………………………………..236

Testing and adjusting alternator belt tension…………………………………………………………………………..237

Testing blowby………………………………………………………………………………………………………238

Testing air supply pressure (boost pressure)……………………………………………………………………………239

Testing engine speed…………………………………………………………………………………………………240

Testing torque converter stall speed…………………………………………………………………………………..241

Bleeding air from counterweight cylinder……………………………………………………………………………….242

Adjusting winch control linkage (Mechanical winch specification)………………………………………………………….244

Adjusting winch control interlock mechanism (Mechanical winch specification)……………………………………………….246

Releasing procedure for winch drum…………………………………………………………………………………….247

Testing power train oil pressure………………………………………………………………………………………249

Testing counterweight oil pressure (Mechanical winch specification)……………………………………………………….251

Testing winch oil pressure (Mechanical winch specification)………………………………………………………………252

Hydraulic circuit diagram for winch (Mechanical winch specification)………………………………………………………253

Air bleeding procedure for hydraulic circuit (Hydraulic winch specification)……………………………………………….254

Testing and adjusting work equipment circuit oil pressure (Hydraulic winchspecification)…………………………………….256

Measuring source pressure of control circuit (Hydraulic winch specification)……………………………………………….259

Testing and adjusting oil pressure in pump PC control circuit (Hydraulic winch specification)………………………………..260

Testing and adjusting oil pressure in pump LS control circuit (Hydraulic winch specification)………………………………..263

Testing solenoid valve outlet pressure (Mechanical winch specification)……………………………………………………266

Testing PPC valve outlet pressure (Hydraulic winch specification)…………………………………………………………270

Testing leakage inside cylinder……………………………………………………………………………………….271

Reinstallation (if moment limiter was removed) and adjusting……………………………………………………………..272

Adjustment procedure for moment limiter performance……………………………………………………………………..273

Troubleshooting…………………………………………………………………………………………………………277

Points to remember when troubleshooting………………………………………………………………………………..278

Sequence of events in troubleshooting………………………………………………………………………………….279

Points to remember when carrying out maintenance………………………………………………………………………..280

Checks before troubleshooting…………………………………………………………………………………………288

Troubleshooting of engine system (S mode)………………………………………………………………………………289

Method of using troubleshooting charts……………………………………………………………………………..290

S-1 Starting performance is poor (starting always takes time)…………………………………………………………294

S-2 Engine does not start…………………………………………………………………………………………295

(1) Engine does not turn………………………………………………………………………………………295

(2) Engine turns but no exhaust smoke comes out (fuel is not being injected)………………………………………..296

(3) Exhaust smoke comes out but engine does not start (Fuel is being injected)………………………………………297

S-3 Engine does not pick up smoothly (follow-up is poor)……………………………………………………………..298

S-4 Engine stops during operations…………………………………………………………………………………299

S-5 Engine does not rotate smoothly (hunting)……………………………………………………………………….300

S-6 Engine lacks output (no power)…………………………………………………………………………………301

S-7 Exhaust smoke is black (incomplete combustion)…………………………………………………………………..302

S-8 Oil consumption is excessive (or exhaust smoke is blue)…………………………………………………………..303

S-9 Oil becomes contaminated quickly……………………………………………………………………………….304

S-10 Fuel consumption is excessive…………………………………………………………………………………305

S-11 Oil is in cooling water, or water spurts back, or water level goes down……………………………………………306

S-12 Oil pressure caution lamp lights up (drop in oil pressure)……………………………………………………….307

S-13 Oil level rises (water, fuel in oil)…………………………………………………………………………..308

S-14 Water temperature becomes too high (overheating)………………………………………………………………..309

S-15 Abnormal noise is made……………………………………………………………………………………….310

S-16 Vibration is excessive……………………………………………………………………………………….311

Troubleshooting of hydraulic, mechanical system (H mode)…………………………………………………………………313

Mechanical winch specification…………………………………………………………………………………….315

H-1 Torque converter oil temperature is too high (Mechanical winch specification)……………………………………315

H-2 Machine does not move (Mechanical winch specification)………………………………………………………..316

H-3 Machine lacks power or speed (Mechanical winch specification)………………………………………………….317

H-4 Machine moves when engine is started (Mechanical winch specification)…………………………………………..318

H-5 Excessive time lag when starting machine or shifting gear (Mechanical winch specification)………………………..318

H-6 Excessive shock when starting off or shifting gear (Mechanical winch specification)………………………………319

H-7 Machine moves in only one direction (FORWARD or REVERSE) (Mechanical winch specification)…………………………320

H-8 Steering clutch is not disengaged (Mechanical winch specification)……………………………………………..321

H-9 Steering clutch slips (Mechanical winch specification)………………………………………………………..322

H-10 Steering brake does not work (Mechanical winch specification)…………………………………………………323

H-11 Lack of power, speed when retract counterweight (Mechanical winch specification)………………………………..324

H-12 Impossible to retract counterweight (Mechanical winch specification)…………………………………………..325

H-13 Excessive hydraulic drift of counterweight cylinder (Mechanical winch specification)…………………………….326

H-14 Defective boom RAISE, LOWER (speed, raising force, lowering force) (Mechanical winch specification)……………….327

H-15 Defective hook RAISE, LOWER (speed, raising force, lowering force) (Mechanical winch specification)……………….328

H-16 Excessive hydraulic drift of boom (Mechanical winch specification)…………………………………………….329

H-17 Excessive hydraulic drift of hook (Mechanical winch specification)…………………………………………….330

H-18 Play when operating hook (Mechanical winch specification)…………………………………………………….331

H-19 Play when operating boom (Mechanical winch specification)…………………………………………………….332

H-20 Excessive time lag when operating hook (Mechanical winch specification)………………………………………..333

H-21 Excessive time lag when operating boom (Mechanical winch specification)………………………………………..334

H-22 Excessive inching amount (Mechanical winch specification)…………………………………………………….335

H-23 Winch free fall does not work (Mechanical winch specification)………………………………………………..336

H-24Winch overheats (Mechanical winch specification)……………………………………………………………..337

H-25 Excessive noise when operating winch clutch, brake (Mechanical winch specification)……………………………..338

H-26 Control lever is heavy (Mechanical winch specification)………………………………………………………339

H-27 Hook overwind horn does not sound (Mechanical winch specification)…………………………………………….340

Hydraulic winch specifications…………………………………………………………………………………….342

Hydraulic and mechanical system diagram (Hydraulic winch specifications)……………………………………………342

Information described in troubleshooting table…………………………………………………………………..344

H-28 Work equipment operates slowly or lacks power (Hydraulic winch specifications)………………………………….345

H-29 Engine speed drops significantly or engine stalls (Hydraulic winch specifications)………………………………346

H-30 Work equipment does not operate. (Hydraulic winch specifications)……………………………………………..347

H-31 Unusual noise is heard from around hydraulic pump (Hydraulic winch specifications)………………………………347

H-32 Fine control performance or response is poor (Hydraulic winch specifications)…………………………………..348

H-33 Boom speed or power is low (Hydraulic winch specifications)…………………………………………………..349

H-34 Hook speed or power is low (Hydraulic winch specifications)…………………………………………………..350

H-35 Counterweight speed or power is low (Hydraulic winch specifications)…………………………………………..351

H-36 Work equipment does not move in single operation (Hydraulic winch specifications)……………………………….351

H-37 Hydraulic drift of counterweight is large (Hydraulic winch specifications)……………………………………..352

H-38 Time lag of work equipment is large (Hydraulic winch specifications)…………………………………………..353

H-39 When certain work equipment is relieved hydraulically, other work equipment moves (Hydraulic winch specifications)….353

30 Disassembly and assembly………………………………………………………………………………………………….355

How to read this manual………………………………………………………………………………………………….357

Coating materials list…………………………………………………………………………………………………..359

Special tool list……………………………………………………………………………………………………….363

Sketches of special tools………………………………………………………………………………………………..368

Removal and installation of starting motor assembly…………………………………………………………………………376

Removal and installation of alternator assembly…………………………………………………………………………….377

Removal and installation of engine oil cooler core assembly………………………………………………………………….379

Removal and installation of fuel injection pump assembly…………………………………………………………………….381

Removal and installation of water pump assembly…………………………………………………………………………….383

Removal and installation of turbocharger assembly…………………………………………………………………………..386

Removal and installation of nozzle holder assembly………………………………………………………………………….388

Removal and installation of cylinder head assembly………………………………………………………………………….389

Removal and installation of thermostat assembly…………………………………………………………………………….401

Removal and installation of radiator assembly………………………………………………………………………………402

Removal and installation of fuel tank assembly (Mechanical winch specification)………………………………………………..413

Removal and installation of fuel tank assembly (Hydraulic winch specification)…………………………………………………415

Removal and installation of torque converter and winch cooler assembly………………………………………………………..417

Removal and installation of engine assembly………………………………………………………………………………..419

Removal and installation of transmission pump assembly………………………………………………………………………428

Removal and installation of floor frame assembly (Mechanical winch specification)………………………………………………429

Removal and installation of floor frame assembly (Hydraulic winch specification)……………………………………………….436

Removal and installation of torque converter assembly……………………………………………………………………….442

Disassembly and assembly of torque converter assembly……………………………………………………………………….447

Removal and installation of torque converter relief valve assembly……………………………………………………………462

Removal and installation of torque converter regulating valve assembly………………………………………………………..463

Removal and installation of transmission control valve assembly………………………………………………………………464

Removal and installation of TORQFLOW transmission assembly…………………………………………………………………..467

Disassembly and assembly of TORQFLOW transmission assembly…………………………………………………………………..485

Removal and installation of steering control valve assembly………………………………………………………………….511

Disassembly and assembly of steering control valve assembly………………………………………………………………….513

Removal and installation of brake safety valve assembly……………………………………………………………………..517

Disassembly and assembly of brake safety valve assembly……………………………………………………………………..518

Removal and installation of transmission lubrication valve assembly…………………………………………………………..519

Removal and installation of steering pump assembly………………………………………………………………………….520

Removal and installation of steering clutch assembly………………………………………………………………………..521

Disassembly and assembly of steering clutch assembly………………………………………………………………………..529

Removal and installation of bevel gear and bevel gear shaft………………………………………………………………….534

Disassembly and assembly of final drive assembly……………………………………………………………………………542

Removal and installation of track assembly…………………………………………………………………………………561

Removal and installation of carrier roller assembly…………………………………………………………………………564

Removal and installation of track roller assembly…………………………………………………………………………..566

Removal and installation of idler assembly…………………………………………………………………………………568

Disassembly and assembly of recoil spring assembly………………………………………………………………………….570

Removal and installation of track frame assembly……………………………………………………………………………574

Removal and installation of hydraulic tank assembly (Hydraulic winch specification)…………………………………………….578

Removal and installation of winch control valve assembly (Mechanical winch specification)……………………………………….582

Disassembly and assembly of winch control valve assembly (Mechanical winch specification)……………………………………….583

Removal and installation of high/low speed selector valve assembly (Mechanical winch specification)………………………………588

Disassembly and assembly of high/low speed selector valve assembly (Mechanical winch specification)………………………………589

Removal and installation of towing winch pump assembly (Mechanical winch specification)…………………………………………593

Removal and installation of counterweight pump assembly (Mechanical winch specification)………………………………………..594

Removal and installation of winch and counterweight control valve assembly (Hydraulic winch specification)………………………..595

Removal and installation of main pump assembly (Hydraulic winch specification)…………………………………………………599

Removal and installation of winch motor assembly (Hydraulic winch specification)……………………………………………….603

Removal and installation of counterweight cylinder assembly………………………………………………………………….607

Removal and installation of counterweight control valve assembly (Mechanical winch specification)………………………………..608

Disassembly and assembly of counterweight control valve assembly (Mechanical winch specification)………………………………..609

Disassembly and assembly of winch hook PPC valve assembly (Hydraulic winch specification)……………………………………….613

Disassembly and assembly of winch boom and counterweight PPC valve assembly (Hydraulic winch specification)……………………….615

Removal and installation of gate frame assembly…………………………………………………………………………….617

Removal and installation of counterweight/frame…………………………………………………………………………….620

Removal and installation of boom/frame…………………………………………………………………………………….624

Removal and installation of towing winch assembly (Mechanical winch specification)……………………………………………..625

Disassembly and assembly of towing winch assembly (Mechanical winch specification)……………………………………………..629

Removal and installation of winch assembly (Hydraulic winch specification)…………………………………………………….664

Disassembly and assembly of winch assembly (Hydraulic winch specification)…………………………………………………….670

Removal and installation of heater assembly………………………………………………………………………………..702

Removal and installation of operator’s cab assembly…………………………………………………………………………703

Removal and installation of operator’s seat assembly………………………………………………………………………..705

40 Maintenance standard……………………………………………………………………………………………………..707

Engine mount……………………………………………………………………………………………………………708

PTO……………………………………………………………………………………………………………………709

TORQFLOW transmission……………………………………………………………………………………………………710

(1) Torque converter…………………………………………………………………………………………………710

(2) Relief valve and regulator valve…………………………………………………………………………………..712

(3) Transmission…………………………………………………………………………………………………….714

(4) Transmission control valve………………………………………………………………………………………..716

(5) Transmission lubrication valve…………………………………………………………………………………….718

Transmission pump……………………………………………………………………………………………………….719

Bevel gear shaft and steering system………………………………………………………………………………………720

Steering pump…………………………………………………………………………………………………………..728

Final drive (1/3)……………………………………………………………………………………………………….729

Final drive (2/3)……………………………………………………………………………………………………….730

Final drive (3/3)……………………………………………………………………………………………………….732

Track frame…………………………………………………………………………………………………………….733

Recoil spring…………………………………………………………………………………………………………..734

Track………………………………………………………………………………………………………………….736

Idler………………………………………………………………………………………………………………….738

Track roller……………………………………………………………………………………………………………740

Carrier roller………………………………………………………………………………………………………….742

Suspension……………………………………………………………………………………………………………..743

Winch pump (Mechanical winch specification)………………………………………………………………………………..744

Counterweight pump (Mechanical winch specification)…………………………………………………………………………745

Hi-Lo valve (Mechanical winch specification)……………………………………………………………………………….746

PPC valve (Mechanical winch specification)…………………………………………………………………………………747

PPC valve for boom/counterweight (Hydraulic winch specification)……………………………………………………………..748

PPC valve for hook (Hydraulic winch specification)………………………………………………………………………….750

Flow divider valve (Mechanical winch specification)…………………………………………………………………………752

Winch (Mechanical winch specification)…………………………………………………………………………………….754

Lower clutch (Mechanical winch specification)………………………………………………………………………………756

Raise clutch (Mechanical winch specification)………………………………………………………………………………758

Winch brake (Mechanical winch specification)……………………………………………………………………………….760

Winch (Hydraulic winch specification)……………………………………………………………………………………..762

Control valve (for counterweight) (Mechanical winch specification)……………………………………………………………766

Control valve (Hydraulic winch specification)………………………………………………………………………………768

Winch (boom, hook) motor (Hydraulic winch specification)…………………………………………………………………….777

Counterweight cylinder…………………………………………………………………………………………………..780

Slow return valve……………………………………………………………………………………………………….781

Counterweight…………………………………………………………………………………………………………..782

Boom…………………………………………………………………………………………………………………..784

90 Others………………………………………………………………………………………………………………….787

Hydraulic circuit diagram (Hydraulic winch specification)……………………………………………………………………789

Electric circuit diagram (STD) (Mechanical winch specification)………………………………………………………………790

Electric circuit diagram (–50°C spec.) (Mechanical winch specification)……………………………………………………….791

Electric circuit diagram (–50°C spec.) (Hydraulic winch specification)………………………………………………………..792

Cab electric circuit diagram……………………………………………………………………………………………..793