$44

Komatsu D475A-5 Bulldozer Shop Manual SEBM033713 – PDF DOWNLOAD

Komatsu D475A-5 Bulldozer Shop Manual SEBM033713 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D475A-5 Bulldozer Shop Manual SEBM033713 – PDF DOWNLOAD

Language : English

Pages : 1252

Downloadable : Yes

File Type : PDF

Size: 76.3 MB

DESCRIPTION:

Komatsu D475A-5 Bulldozer Shop Manual SEBM033713 – PDF DOWNLOAD

MACHINE MODEL SERIAL No.

D475A-5 20001 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1. Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.• Always wear safety glasses when hitting parts with a hammer.• Always wear safety glasses when grinding parts with a grinder, etc.3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, hand shield, cap and other clothes suited for welding work.4. When carrying out any operation with two or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK:

- 7. Before adding oil or making any repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the machine from moving.

- 8. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers and hang warning signs on them.

- 9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

- 10.Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further

divided into the each main group of components.

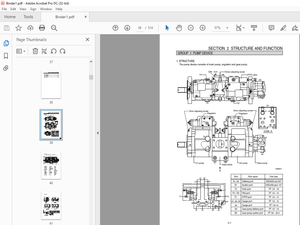

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding

of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to

be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component,

as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu D475A-5 Bulldozer Shop Manual SEBM033713 – PDF DOWNLOAD

COVER 1

CONTENTS 2

LIST OF REVISED PAGES 3

SAFETY 11

SAFETY NOTICE 11

FOREWORD 13

GENERAL 13

HOW TO READ THE SHOP MANUAL 14

HOISTING INSTRUCTIONS 15

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER 16

COATING MATERIALS 18

STANDARD TIGHTENING TORQUE 20

ELECTRIC WIRE CODE 23

CONVERSION TABLE 24

UNITS 30

01 GENERAL 31

SPECIFICATION DRAWINGS 32

SPECIFICATIONS 33

WEIGHT TABLE 42

FUEL, COOLANT AND LUBRICANTS 46

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD 49

RADIATOR AND OIL COOLER 52

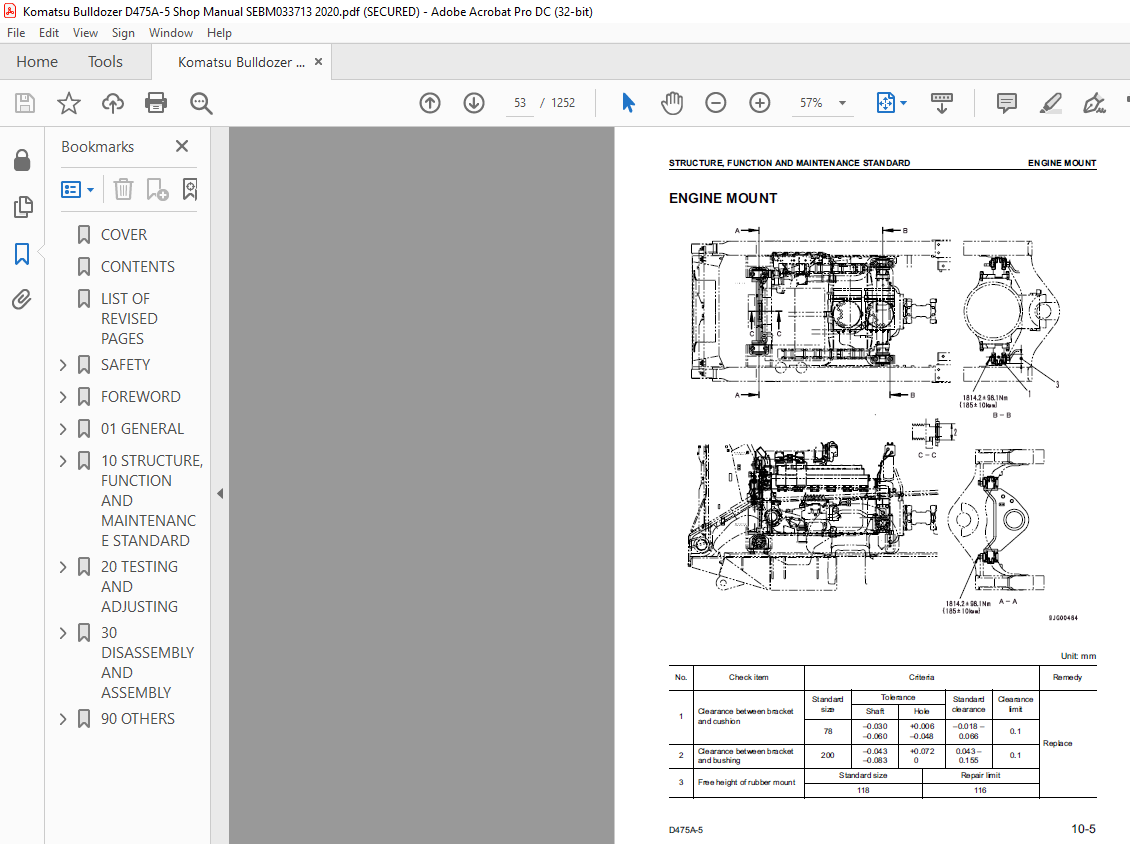

ENGINE MOUNT 53

POWER TRAIN 54

POWER TRAIN HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM 56

DAMPER AND UNIVERSAL JOINT 58

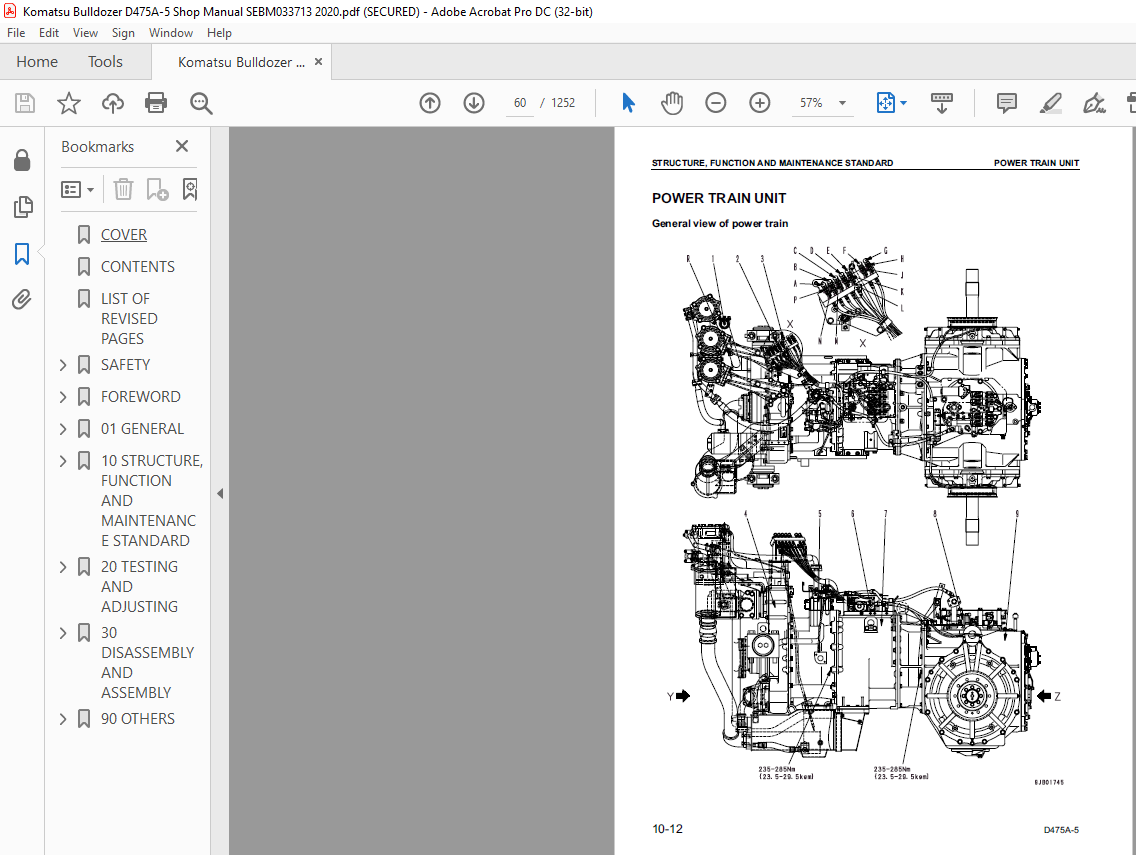

POWER TRAIN UNIT 60

TORQUE CONVERTER AND PTO 62

TORQUE CONVERTER VALVE 72

TORQUE CONVERTER LOCK-UP CONTROL SYSTEM 82

SCAVENGING PUMP 83

TRANSMISSION CONTROL 84

TRANSMISSION 86

TRANSMISSION ECMV 98

TRANSMISSION CLUTCH ECMV 100

PRIORITY VALVE 104

LUBRICATING OIL RELIEF VALVE 105

POWER TRAIN, LUBRICATION PUMP 106

STEERING, BRAKE CONTROL 108

FINAL DRIVE 111

STEERING UNIT 116

STEERING ECMV 128

STEERING CLUTCH ECMV, STEERING BRAKE ECMV 130

PARKING BRAKE VALVE 136

SUDDEN STOP PREVENTION VALVE 138

SPROCKET 140

TRACK FRAME 142

RECOIL SPRING 146

IDLER 148

TRACK ROLLER 150

CARRIER ROLLER 153

TRACK ROLLER BOGIE 154

TRACK SHOE 156

MAIN FRAME 160

SUSPENSION 163

WORK EQUIPMENT HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM 166

PPC CONTROL PIPING DIAGRAM 170

WORK EQUIPMENT CONTROL 172

WORK EQUIPMENT PUMP 174

COOLING FAN PUMP 191

COOLING FAN MOTOR 212

PPC VALVE 220

ELECTRIC LEVER (STEERING) 230

CONTROL VALVE 234

MAIN RELIEF VALVE 248

CLSS 249

UNLOAD VALVE 252

INTRODUCTION OF LS PRESSURE (LS SHUTTLE VALVE) 253

LS BYPASS PLUG 254

PRESSURE COMPENSATION VALVE 255

BLADE LIFT VALVE 258

MERGE DIVIDER VALVE 266

SELF PRESSURE REDUCING VALVE 268

PILOT SOLENOID VALVE 272

HYDRAULIC TANK 274

ACCUMULATOR 276

WORK EQUIPMENT CYLINDER 278

PISTON VALVE 280

QUICK DROP VALVE 281

BLADE CONTROL KNOB 284

PITCH AND DUAL SOLENOID VALVE 286

PIN PULLER HYDRAULIC CIRCUIT DIAGRAM 287

PIN PULLER SOLENOID VALVE 288

CYLINDER STAY 290

BLADE 292

RIPPER EQUIPMENT 296

CAB MOUNT 300

CAB 301

AIR CONDITIONER 304

ENGINE CONTROL 306

ENGINE CONTROL SYSTEM 307

DECELERATION POTENTIOMETER 308

ENGINE CONTROL SYSTEM WITH ELECTRONIC ENGINE THROTTLE CONTROLLER 309

FULE INJECTION PUMP WITH ELECTRONIC GOVERNOR 310

MONITOR SYSTEM 311

MONITOR PANEL 313

SENSORS 317

MODE SELECTION SYSTEM 321

ELECTRICAL EQUIPMENT 327

STEERING ELECTRONIC CONTROL SYSTEM 330

VHMS CONTROLLER 332

SENSORS 335

COMMUNICATION (ORB: ORBCOMM) CONTROLLER/ANTENNA 338

20 TESTING AND ADJUSTING 339

STANDARD VALUE TABLE FOR ENGINE 340

STANDARD VALUE TABLE FOR CHASSIS 341

TESTING AND ADJUSTING 353

TESTING, ADJUSTING, AND TROUBLESHOOTING DEVICES TABLE 355

MEASURING ENGINE SPEED 357

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE) 360

MEASURING EXHAUST TEMPERATURE 361

MEASURING EXHAUST GAS COLOR 363

ADJUSTING VALVE CLEARANCE 364

MEASURING COMPRESSION PRESSURE 365

MEASURING BLOW-BY PRESSURE 366

MEASURING ENGINE OIL PRESSURE 367

TESTING AND ADJUSTING FUEL INJECTION TIMING 368

TESTING AND ADJUSTING ALTERNATOR BELT TENSION 370

TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR 371

ADJUSTING ENGINE SPEED SENSOR 371

ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL 372

MEASURING POWER TRAIN OIL PRESSURE 374

ADJUSTING TRANSMISSION SPEED SENSOR 382

SIMPLE METHOD OF TESTING BRAKE PERFORMANCE 383

ADJUSTING BRAKE PEDAL AND PARKING BRAKE LEVER 384

ADJUSTING PCCS LEVER CONSOLE POSITION 387

EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE 388

ADJUSTING CLEARANCE OF IDLER 390

INSPECTING WEAR OF SPROCKET 390

TESTING AND ADJUSTING TRACK SHOE TENSION 391

TESTING AND ADJUSTING WORK EQUIPMENT OIL PRESSURE 392

TESTING AND ADJUSTING CONTROL CIRCUIT BASIC PRESSURE 401

MEASURING PPC VALVE OUTPUT PRESSURE AND SOLENOID VALVE OUTPUT PRESSURE 402

ADJUSTING PLAY OF PPC VALVE 409

MEASURING OUTLET PRESSURE OF RIPPER PIN PULLER SOLENOID VALVE 410

TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF BLADE AND RIPPER 411

MEASURING INTERNAL LEAKAGE OF WORK EQUIPMENT CYLINDER 412

RELEASING RESIDUAL PRESSURE FROM WORK EQUIPMENT CIRCUIT 413

BLEEDING AIR FROM WORK EQUIPMENT CYLINDER 413

ADJUSTING BLADE LEVER TILTING STROKE 414

ADJUSTING RIPPER LEVER POSITION 415

ADJUSTING LOCK LEVER 416

MEASURING FAN MOTOR SPEED 417

MEASURING FAN CIRCUIT OIL PRESSURE 418

BLEEDING AIR FROM FAN PUMP 419

MEASUREMENT PROCEDURE FOR BLADE TILT CONTROL ANGLE (DUAL TILTDOZER SPECIFICATION) 420

MEASUREMENT PROCEDURE FOR BLADE TILT CONTROL ANGLE (SUPERDOZER SPECIFICATION) 422

TESTING AND ADJUSTING OPERATOR’S CAB 424

ADJUSTING BLADE 428

SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS) 430

ADJUSTING METHOD OF REPLACED CONTROLLER 485

PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL EQUIPMENT SYSTEM 487

HANDLING OF OPTIONAL DEVICES 490

INITIALIZATION PROCEDURES FOR VHMS CONTROLLER 491

PROCEDURES FOR EXECUTING QUICK PM 496

PRECAUTIONS FOR REPLACING VHMS CONTROLLER 506

PM CLINIC SERVICE 507

TROUBLESHOOTING 517

POINTS TO REMEMBER WHEN TROUBLESHOOTING 518

SEQUENCE OF EVENTS IN TROUBLESHOOTING 519

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE 520

CHECKS BEFORE TROUBLESHOOTING 528

CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING 529

CONNECTOR ARRANGEMENT DRAWING AND ELECTRIC CIRCUIT DIAGRAM OF EACH SYSTEM 532

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 570

T-BRANCH BOX AND T-BRANCH TABLE 594

TROUBLESHOOTING WHEN SERVICE CODE “ELECTRICAL SYSTEM” AND FAILURE CODE “MECHANICAL SYSTEM” ARE INDICATED 597

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE 603

ERROR CODE [1500L0] (TRANSMISSION CLUTCH: SEE THE LIST (L0)) 605

ERROR CODE [15SAL1] (FORWARD CLUTCH: SEE THE LIST (L1)) 606

ERROR CODE [15SALH] (FORWARD CLUTCH: SEE THE LIST (LH)) 607

ERROR CODE [15SBL1] (REVERSE CLUTCH: SEE THE LIST (L1)) 608

ERROR CODE [15SBLH] (REVERSE CLUTCH: SEE THE LIST (LH)) 609

ERROR CODE [15SEL1] (1ST CLUTCH: SEE THE LIST (L1)) 610

ERROR CODE [15SELH] (1ST CLUTCH: SEE THE LIST (LH)) 611

ERROR CODE [15SFL1] (2ND CLUTCH: SEE THE LIST (L1)) 612

ERROR CODE [15SFLH] (2ND CLUTCH: SEE THE LIST (LH)) 613

ERROR CODE [15SGL1] (3RD CLUTCH: SEE THE LIST (L1)) 614

ERROR CODE [15SGLH] (3RD CLUTCH: SEE THE LIST (LH)) 615

ERROR CODE [1800MW] (POWER TRAIN CLUTCH: SLIP (MW)) 616

ERROR CODE [2201L1] (RIGHT CLUTCH: SEE THE LIST (L1)) 617

ERROR CODE [2201LH] (RIGHT CLUTCH: SEE THE LIST (LH)) 618

ERROR CODE [2202L1] (LEFT CLUTCH: SEE THE LIST (L1)) 619

ERROR CODE [2202LH] (LEFT CLUTCH: SEE THE LIST (LH)) 620

ERROR CODE [2300NR] (BRAKE THERMAL LOAD: ABNORMAL HEATING (NR)) 621

ERROR CODE [2301L1] (RIGHT BRAKE: SEE THE LIST (L1)) 622

ERROR CODE [2301LH] (RIGHT BRAKE: SEE THE LIST (LH)) 623

ERROR CODE [2301NR] (RIGHT STEERING BRAKE THERMAL LOAD: ABNORMAL HEATING (NR)) 624

ERROR CODE [2302L1] (LEFT BRAKE: SEE THE LIST (L1)) 625

ERROR CODE [2302LH] (LEFT BRAKE: SEE THE LIST (LH)) 626

ERROR CODE [2302NR] (LEFT STEERING BRAKE THERMAL LOAD: ABNORMAL HEATING (NR)) 627

ERROR CODE [A000N1] (OR VHMS_LED IS DISPLAYED “n2″ →”01”) ENGINE OVERRUN 627

ERROR CODE [A70XLK] (GOVERNOR SERVO SYSTEM RIGHT: *REFER TO TABLE (LK)) 628

ERROR CODE [A70YLK] (GOVERNOR SERVO SYSTEM LEFT: *REFER TO TABLE (LK)) 629

ERROR CODE [AA1ANX] (AIR CLEANER: CLOGGING (NX)) 630

ERROR CODE [AB00MA] (ALTERNATOR: MALFUNCTION (MA)) 630

ERROR CODE [B@BAZG] (ENGINE OIL: OIL PRESSURE REDUCTION (ZG)) 631

ERROR CODE [B@BAZK] (ENGINE OIL: OIL LEVEL REDUCTION (ZK)) 631

ERROR CODE [B@BCNS] (RADIATOR COOLANT: OVERHEAT (NS)) 632

ERROR CODE [B@BCZK] (RADIATOR COOLANT: LEVEL REDUCTION (ZK)) 632

ERROR CODE [B@CENS] (POWER TRAIN OIL: OVERHEAT (NS)) 633

ERROR CODE [B@HANS] (HYDRAULIC OIL: OVERHEAT (NS)) 633

ERROR CODE [B@HAZK] (HYDRAULIC OIL: LEVEL REDUCTION (ZK)) 634

ERROR CODE [D110KA] (BATTERY RELAY: DISCONNECTION (KA)) 635

ERROR CODE [D110KB] (BATTERY RELAY: SHORT CIRCUIT (KB)) 636

ERROR CODE [D130KA] (NEUTRAL SAFETY RELAY: DISCONNECTION (KA)) 637

ERROR CODE [D130KB] (NEUTRAL SAFETY RELAY: SHORT CIRCUIT (KB)) 639

ERROR CODE [D161KA] (BACK-UP ALARM RELAY: DISCONNECTION (KA)) 640

ERROR CODE [D161KB] (BACK-UP ALARM RELAY: SHORT CIRCUIT (KB)) 642

ERROR CODE [D182KZ] (PREHEATER RELAY: LOWERING OF LEVEL (KZ)) 644

ERROR CODE [D1D0KA] (GOVERNOR CUTOUT RELAY RIGHT: DISCONNECTION (KA)) 646

ERROR CODE [D1D0KB] (GOVERNOR CUTOUT RELAY RIGHT: SHORT CIRCUIT (KB)) 648

ERROR CODE [D1D1KA] (GOVERNOR CUTOUT RELAY LEFT: DISCONNECTION (KA)) 650

ERROR CODE [D1D1KB] (GOVERNOR CUTOUT RELAY LEFT: SHORT CIRCUIT (KB)) 652

ERROR CODE [D5ZFKA] (NEUTRAL SIGNAL 1: DISCONNECTION (KA)) 654

ERROR CODE [D5ZFKB] (NEUTRAL SIGNAL 1: SHORT CIRCUIT (KB)) 655

ERROR CODE [D5ZFL4] (ENGINE CONTROLLER NEUTRAL SIGNAL: ON AND OFF SIGNAL DO NOT AGREE (L4)) 656

ERROR CODE [D5ZGKA] (NEUTRAL SIGNAL 2: DISCONNECTION (KA)) 658

ERROR CODE [D5ZGKB] (NEUTRAL SIGNAL 2: SHORT CIRCUIT (KB)) 659

ERROR CODE [D5ZKKX] (CHASSIS THROTTLE SIGNAL: OUT OF INPUT SIGNAL RANGE (KX)) 660

ERROR CODE [D5ZRKA] (SNAP SHOT SWITCH: DISCONNECTION (KA)) 661

ERROR CODE [D5ZRKB] (SNAP SHOT SWITCH: SHORT CIRCUIT (KB)) 662

ERROR CODE [DAFRKR] (MONITOR PANEL CAN COMMUNICATION: DEFECTIVE COMMUNICATION (KR)) 664

ERROR CODE [DAQ0KK] (TRANSMISSION CONTROLLER: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 666

ERROR CODE [DAQ0KT] (TRANSMISSION CONTROLLER: ABNORMALITY IN CONTROLLER (KT)) 667

ERROR CODE [DAQ5KK] (TRANSMISSION CONTROLLER POTENTIOMETER POWER SUPPLY: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 668

ERROR CODE [DAQ6KK] (TRANSMISSION CONTROLLER SENSOR POWER SUPPLY: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 669

ERROR CODE [DAQ9KQ] (TRANSMISSION CONTROLLER TYPE COLLATION: TYPE SELECT SIGNAL INCONSISTENCY (KQ)) 670

ERROR CODE [DAQRKR] (TRANSMISSION CONTROLLER CAN COMMUNICATION: DEFECTIVE COMMUNICATION (ABNORMALITY IN OBJECTIVE COMPONENT SYSTEM) (KR)) 672

ERROR CODE [DAQSKR] (TRANSMISSION CONTROLLER S-NET COMMUNICATION: DEFECTIVE COMMUNICATION (ABNORMALITY IN OBJECTIVE COMPONENT SYSTEM) (KR)) 674

ERROR CODE [DB30KK] (STEERING CONTROLLER: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 676

ERROR CODE [DB30KT] (STEERING CONTROLLER: ABNORMALITY IN CONTROLLER (KT)) 677

ERROR CODE [DB35KK] (STEERING CONTROLLER POTENTIOMETER POWER SUPPLY: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 678

ERROR CODE [DB36KK] (STEERING CONTROLLER SENSOR POWER SUPPLY: SOURCE VOLTAGE REDUCTION (INPUT) (KK)) 680

ERROR CODE [DB39KQ] (STEERING CONTROLLER TYPE COLLATION: TYPE SELECT SIGNAL INCONSISTENCY (KQ)) 681

ERROR CODE [DB3RKR] (STEERING CONTROLLER CAN COMMUNICATION: DEFECTIVE COMMUNICATION (ABNORMALITY IN OBJECTIVE COMPONENT SYSTEM) (KR)) 682

ERROR CODE [DB3SKR] (STEERING CONTROLLER S-NET COMMUNICATION: DEFECTIVE COMMUNICATION (ABNORMALITY IN OBJECTIVE COMPONENT SYSTEM) (KR)) 684

ERROR CODE [DB40KK] (ENGINE CONTROLLER: LOWERING OF SOURCE VOLTAGE (KK)) 686

ERROR CODE [DB41KK] (SWITCH POWER SUPPLY: LOWERING OF SOURCE VOLTAGE (KK)) 686

ERROR CODE [DB42KK] (SOLENOID POWER SUPPLY 1: LOWERING OF SOURCE VOLTAGE (KK)) 688

ERROR CODE [DB43KK] (BACKUP POWER SUPPLY: LOWERING OF SOURCE VOLTAGE (KK)) 690

ERROR CODE [DB44KK] (SOLENOID POWER SUPPLY 2: LOWERING OF SOURCE VOLTAGE (KK)) 692

ERROR CODE [DB45KP] (RACK SENSOR POWER SUPPLY: LOWERING OF OUTPUT VOLTAGE (KP)) 694

ERROR CODE [DB49KM] (WRONG CONNECTION OF CONNECTOR: MISTAKE IN OPERATION OR SETTING (KM)) 696

ERROR CODE [DB49KQ] (ENGINE CONTROLLER SPECIFICATION: DISAGREEMENT OF MODEL SELECTION SIGNALS (KQ)) 697

ERROR CODE [DBB0KK] (OR LED OF VHMS CONTROLLER INDICATES “n9″”→01”) (VHMS CONTROLLER: LOWERING OF SOURCE VOLTAGE (KK)) 698

ERROR CODE [DBB0KQ] (OR LED OF VHMS CONTROLLER INDICATES “nF”→”11”) (CHECK OF VHMS CONTROLLER MODEL: DISAGREEMENT OF MODEL SELECTION SIGNALS (KQ)) 700

ERROR CODE [DBB3KK] (OR LED OF VHMS CONTROLLER INDICATES “n9″→”02”) (VHMS CONTROLLER: LOWERING OF BATTERY DIRECT SOURCE VOLTAGE (KK)) 701

ERROR CODE [DBB5KP] (OR LED OF VHMS CONTROLLER INDICATES “n9″→”04”) (SENSOR POWER SUPPLY (5V): LOWERING OF OUTPUT VOLTAGE (KP)) 702

ERROR CODE [DBB6KP] (OR LED OF VHMS CONTROLLER INDICATES “n9″→”02”) (SENSOR POWER SUPPLY (24V): LOWERING OF OUTPUT VOLTAGE (KP)) 703

ERROR CODE [DBB7KP] (OR LED OF VHMS CONTROLLER INDICATES “n9″→”03”) (SENSOR POWER SUPPLY (12V): LOWERING OF OUTPUT VOLTAGE (KP)) 704

ERROR CODE [DBBQKR] (OR LED OF VHMS CONTROLLER INDICATES “n8″→”02”) (VHMS KOM-NET: DEFECTIVE COMMUNICATION (KR)) 706

ERROR CODE [DD12KA] (SHIFT UP SWITCH: DISCONNECTION (KA)) 708

ERROR CODE [DD12KB] (SHIFT UP SWITCH: SHORT CIRCUIT (KB)) 710

ERROR CODE [DD13KA] (SHIFT DOWN SWITCH: DISCONNECTION (KA)) 712

ERROR CODE [DD13KB] (SHIFT DOWN SWITCH: SHORT CIRCUIT (KB)) 714

ERROR CODE [DD14KA] (PARKING LEVER SWITCH: DISCONNECTION (KA)) 716

ERROR CODE [DD14KB] (PARKING LEVER SWITCH: SHORT CIRCUIT (KB)) 718

ERROR CODE [DDN2LD] (BLADE TILT RIGHT OIL PRESSURE SWITCH SYSTEM: REFER TO TABLE (LD)) 720

ERROR CODE [DDN3LD] (BLADE TILT LEFT OIL PRESSURE SWITCH SYSTEM: REFER TO TABLE (LD)) 721

ERROR CODE [DDN7KA] (BLADE PITCH SWITCH: DISCONNECTION (KA)) 722

ERROR CODE [DDN7KB] (BLADE PITCH SWITCH: SHORT CIRCUIT (KB)) 724

ERROR CODE [DDN9KA] (BLADE TILT SWITCH: DISCONNECTION (KA)) 726

ERROR CODE [DDN9KB] (BLADE TILT SWITCH: SHORT CIRCUIT (KB)) 728

ERROR CODE [DDNALD] (BLADE LEFT RAISE FULL OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 730

ERROR CODE [DDNBLD] (RIPPER LEFT RAISE OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 731

ERROR CODE [DDNCLD] (RIPPER LEFT LOWER OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 732

ERROR CODE [DDNDLD] (RIPPER TILT IN OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 733

ERROR CODE [DDNELD] (RIPPER TILT BACK OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 734

ERROR CODE [DDNFLD] (BLADE LEFT LOWER FULL OIL PRESSURE SWITCH: REFER TO TABLE (LD)) 735

ERROR CODE [DDQ2KA] (PARKING LEVER SWITCH: DISCONNECTION (KA)) 736

ERROR CODE [DDQ2KB] (PARKING BRAKE LEVER SWITCH: SHORT CIRCUIT (KB)) 738

ERROR CODE [DDQ2L4] (PARKING BRAKE LEVER SWITCH: SEE TABLE (L4)) 740

ERROR CODE [DGE1KB] (OR LED OF VHMS CONTROLLER INDICATES “n2″→”42”) (ENGINE OIL TEMPERATURE SENSOR SYSTEM: SHORT CIRCUIT (KB)) (30 MINUTES AFTER ENGINE IS STARTED (ABOVE 500 RPM)) 741

ERROR CODE [DGE1KY] (OR LED OF VHMS CONTROLLER INDICATES “n2″→”41”) (ENGINE OIL TEMPERATURE SENSOR SYSTEM: DISCONNECTION (KY)) 742

ERROR CODE [DGE2KX] (COOLANT TEMPERATURE SENSOR: OUT OF INPUT SIGNAL RANGE (KX)) 744

ERROR CODE [DGE3KA] (ENGINE COOLANT TEMPERATURE SENSOR GAUGE) (FOR LOW TEMPERATURE): DISCONNECTION(KA)) 746

ERROR CODE [DGE5KB] (OR LED OF VHMS CONTROLLER INDICATES “n4″→”01”) (ATMOSPHEREIC TEMPERATURE SENSOR SYSTEM: DISCONNECTION OR SHORT CIRCUIT (KY OR KB)) 747

ERROR CODE [DGS1KX] (HYDRAULIC OIL TEMPERATURE SENSOR: INPUT SIGNAL IS OUT OF NORMAL RANGE (KX)) 748

ERROR CODE [DGT5KA] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”22”) (LEFT BANK EXHAUST TEMPERATURE SENSOR SYSTEM: DISCONNECTION (KA)) 750

ERROR CODE [DGT5KB] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”21”) (LEFT BANK EXHAUST TEMPERATURE SENSOR SYSTEM: SHORT CIRCUIT (KB)) 752

ERROR CODE [DGT6KA] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”12”) (RIGHT BANK EXHAUST TEMPERATURE SENSOR SYSTEM: DISCONNECTION (KA)) 754

ERROR CODE [DGT6KB] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”11”) (RIGHT BANK EXHAUST TEMPERATURE SENSOR SYSTEM: SHORT CIRCUIT (KB)) 756

ERROR CODE [DH22KA] (WORK EQUIPMENT PUMP OIL PRESSURE SENSOR (F): DISCONNECTION (KA)) 758

ERROR CODE [DH22KB] (WORK EQUIPMENT PUMP OIL PRESSURE SENSOR (F): SHORT CIRCUIT (KB)) 759

ERROR CODE [DH23KA] (WORK EQUIPMENT PUMP OIL PRESSURE SENSOR (R): DISCONNECTION (KA)) 760

ERROR CODE [DH23KB] (WORK EQUIPMENT PUMP OIL PRESSURE SENSOR (R): SHORT CIRCUIT (KB)) 761

ERROR CODE [DHE4KA] (ENGINE OIL PRESSURE SENSOR: DISCONNECTION (KA)) 762

ERROR CODE [DHE4KB] (ENGINE OIL PRESSURE SENSOR: SHORT CIRCUIT (KB)) 763

ERROR CODE [DHE5KB] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”32”) (ENGINE BLOW-BY PRESSURE SENSOR SYSTEM: DISCONNECTION (KB)) 764

ERROR CODE [DHE5KY] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”31”) (ENGINE BLOW-BY PRESSURE SENSOR SYSTEM: SHORT CIRCUIT WITH POWER SUPPLY LINE (KY)) 765

ERROR CODE [DHT3KX] (OR LED OF VHMS CONTROLLER INDICATES “n6″→”14”) (TRANSMISSION OIL PRESSURE SENSOR: OUT OF INPUT SIGNAL RANGE(KX)) 766

ERROR CODE [DK01KA] (LEFT YOKE ANGEL SENSOR: DISCONNECTION (KA)) 768

ERROR CODE [DK01KB] (LEFT YOKE ANGEL SENSOR: SHORT CIRCUIT (KB)) 770

ERROR CODE [DK03KA] (RIGHT YOKE ANGEL SENSOR: DISCONNECTION (KA)) 771

ERROR CODE [DK03KB] (RIGHT YOKE ANGEL SENSOR: SHORT CIRCUIT (KB)) 773

ERROR CODE [DK10KX] (FUEL DIAL: OUT OF NORMAL RANGE (KX)) 774

ERROR CODE [DK12KX] (DECELERATION POTENTIOMETER: OUT OF INPUT SIGNAL RANGE (KX)) 776

ERROR CODE [DK30KA] (STEERING POTENTIOMETER 1: DISCONNECTION (KA)) 778

ERROR CODE [DK30KB] (STEERING POTENTIOMETER 1: SHORT CIRCUIT (KB)) 779

ERROR CODE [DK30KX] (STEERING POTENTIOMETER 1: INPUT SIGNAL IS OUT OF NORMAL RANGE (KX)) 780

ERROR CODE [DK30KZ] (STEERING POTENTIOMETER 1: DISCONNECTION OR SHORT CIRCUIT (KZ)) 780

ERROR CODE [DK30L8] (STEERING POTENTIOMETER 1: SEE TABLE (L8)) 781

ERROR CODE [DK31KA] (STEERING POTENTIOMETER 2: DISCONNECTION (KA)) 782

ERROR CODE [DK31KB] (STEERING POTENTIOMETER 2: SHORT CIRCUIT (KB)) 783

ERROR CODE [DK40KA] (BRAKE POTENTIOMETER: DISCONNECTION (KA)) 784

ERROR CODE [DK40KB] (BRAKE POTENTIOMETER: SHORT CIRCUIT (KB)) 786

ERROR CODE [DK55KX] (FORWARD-REVERSE POTENTIOMETER: INPUT SIGNAL IS OUT OF NORMAL RANGE (KX)) 787

ERROR CODE [DK55KZ] (FORWARD-REVERSE POTENTIOMETER: DISCONNECTION OR SHORT CIRCUIT (KZ)) 787

ERROR CODE [DK55L8] (FORWARD-REVERSE POTENTIOMETER: SEE TABLE (L8)) 788

ERROR CODE [DK56KA] (FORWARD-REVERSE POTENTIOMETER 1: DISCONNECTION (KA)) 789

ERROR CODE [DK56KB] (FORWARD-REVERSE POTENTIOMETER 1: SHORT CIRCUIT (KB)) 790

ERROR CODE [DK57KA] (FORWARD-REVERSE POTENTIOMETER 2: DISCONNECTION (KA)) 791

ERROR CODE [DK57KB] (FORWARD-REVERSE POTENTIOMETER 2: SHORT CIRCUIT (KB)) 792

ERROR CODE [DK60KA] (ACCELERATION SENSOR: DISCONNECTION (KA)) 793

ERROR CODE [DK60KB] (ACCELERATION SENSOR: SHORT CIRCUIT (KB)) 794

ERROR CODE [DKFOKX] (OR LED OF VHMS CONTROLLER INDICATES “n2″→”62”) (INJECTION PUMP RACK SENSOR: OUT OF INPUT SIGNAL RANGE (KX)) 795

ERROR CODE [DKF1KX] (RACK SENSOR RIGHT: OUT OF INPUT SIGNAL RANGE (KX)) 796

ERROR CODE [DKF2KX] (RACK SENSOR LEFT: OUT OF INPUT SIGNAL RANGE (KX)) 798

ERROR CODE [DKH1KA] (PITCH ANGLE SENSOR: DISCONNECTION (KA)) 800

ERROR CODE [DKH1KB] (PITCH ANGLE SENSOR: SHORT CIRCUIT (KB)) 801

ERROR CODE [DLE1KA] (ENGINE SPEED SENSOR: DISCONNECTION (KA)) 802

ERROR CODE [DLE4LC] (ENGINE SPEED SENSOR A: *REFER TO TABLE (LC)) 804

ERROR CODE [DLE5LC] (ENGINE SPEED SENSOR B: *REFER TO TABLE (LC)) 806

ERROR CODE [DLF1KA] (TORQUE CONVERTER OUTPUT SPEED SENSOR: DISCONNECTION (KA)) 808

ERROR CODE [DLT3KA] (TRANSMISSION OUTPUT SPEED SENSOR: DISCONNECTION (KA)) 809

ERROR CODE [DV00KB] (CAUTION BUZZER: SHORT CIRCUIT (KB)) 810

ERROR CODE [DW55KA] (BLADE PITCH BACK SOLENOID: DISCONNECTION (KA)) 811

ERROR CODE [DW55KB] (BLADE PITCH BACK SOLENOID: SHORT CIRCUIT (KB)) 812

ERROR CODE [DW56KA] (BLADE PITCH DUMP SOLENOID: DISCONNECTION (KA)) 813

ERROR CODE [DW56KB] (BLADE PITCH DUMP SOLENOID: SHORT CIRCUIT (KB)) 814

ERROR CODE [DW57KA] (LEFT TILT LIMT SOLENOID: DISCONNECTION (KA)) 815

ERROR CODE [DW57KB] (LEFT TILT LIMT SOLENOID: SHORT CIRCUIT (KB)) 816

ERROR CODE [DW58KA] (RIGHT TILT LIMT SOLENOID: DISCONNECTION (KA)) 817

ERROR CODE [DW58KB] (RIGHT TILT LIMT SOLENOID: SHORT CIRCUIT (KB)) 818

ERROR CODE [DW59KA] (BLADE DUAL SELECTOR SOLENOID: DISCONNECTION (KA)) 819

ERROR CODE [DW59KB] (BLADE DUAL SELECTOR SOLENOID: SHORT CIRCUIT (KB)) 820

ERROR CODE [DW5AKA] (BLADE PITCH SELECTOR SOLENOID: DISCONNECTION (KA)) 821

ERROR CODE [DW5AKB] (BLADE PITCH SELECTOR SOLENOID: SHORT CIRCUIT (KB)) 822

ERROR CODE [DW5DKA] (BLADE PITCH DUMP SOLENOID (SUPERDOZER SPECIFICATION): DISCONNECTION (KA)) 823

ERROR CODE [DW5DKB] (BLADE PITCH DUMP SOLENOID (SUPERDOZER SPECIFICATION): SHORT CIRCUIT (KB)) 824

ERROR CODE [DW7BKA] (FAN REVERSE SOLENOID: DISCONNECTION (KA)) 825

ERROR CODE [DW7BKB] (FAN REVERSE SOLENOID: SHORT CIRCUIT (KB)) 826

ERROR CODE [DWJ0KA] (PUMP MERGE-DIVIDER SOLENOID: DISCONNECTION (KA)) 827

ERROR CODE [DWJ0KB] (PUMP MERGE-DIVIDER SOLENOID: SHORT CIRCUIT (KB)) 828

ERROR CODE [DWN3KA] (SUDDEN STOP PREVENTION SOLENOID: DISCONNECTION (KA)) 829

ERROR CODE [DWN3KB] (SUDDEN STOP PREVENTION SOLENOID: SHORT CIRCUIT (KB)) 830

ERROR CODE [DWN5KA] (FAN PUMP SOLENOID 1: DISCONNECTION (KA)) 831

ERROR CODE [DWN5KB] (FAN PUMP SOLENOID 1: SHORT CIRCUIT (KB)) 832

ERROR CODE [DWNCKA] (FAN PUMP SOLENOID 2: DISCONNECTION (KA)) 833

ERROR CODE [DWNCKB] (FAN PUMP SOLENOID 2: SHORT CIRCUIT (KB)) 834

ERROR CODE [DXE0KA] (LS SET SOLENOID: DISCONNECTION (KA)) 835

ERROR CODE [DXE0KB] (LS SET SOLENOID: SHORT CIRCUIT (KB)) 836

ERROR CODE [DXH1KA] (LOCK-UP SOLENOID: DISCONNECTION (KA)) 837

ERROR CODE [DXH1KB] (LOCK-UP SOLENOID: SHORT CIRCUIT (KB)) 838

ERROR CODE [DXH4KA] (1ST CLUTCH ECMV: DISCONNECTION (KA)) 839

ERROR CODE [DXH4KB] (1ST CLUTCH ECMV: SHORT CIRCUIT (KB)) 840

ERROR CODE [DXH5KA] (2ND CLUTCH ECMV: DISCONNECTION (KA)) 841

ERROR CODE [DXH5KB] (2ND CLUTCH ECMV: SHORT CIRCUIT (KB)) 842

ERROR CODE [DXH6KA] (3RD CLUTCH ECMV: DISCONNECTION (KA)) 843

ERROR CODE [DXH6KB] (3RD CLUTCH ECMV: SHORT CIRCUIT (KB)) 844

ERROR CODE [DXH7KA] (REVERSE CLUTCH ECMV: DISCONNECTION (KA)) 845

ERROR CODE [DXH7KB] (REVERSE CLUTCH ECMV: SHORT CIRCUIT (KB)) 846

ERROR CODE [DXH8KA] (FORWARD CLUTCH ECMV: DISCONNECTION (KA)) 847

ERROR CODE [DXH8KB] (FORWARD CLUTCH ECMV: SHORT CIRCUIT (KB)) 848

ERROR CODE [DXH9KA] (RIGHT STEERING CLUTCH ECMV: DISCONNECTION (KA)) 849

ERROR CODE [DXH9KB] (RIGHT STEERING CLUTCH ECMV: SHORT CIRCUIT (KB)) 850

ERROR CODE [DXHAKA] (LEFT STEERING CLUTCH ECMV: DISCONNECTION (KA)) 851

ERROR CODE [DXHAKB] (LEFT STEERING CLUTCH ECMV: SHORT CIRCUIT (KB)) 852

ERROR CODE [DXHBKA] (RIGHT BRAKE ECMV: DISCONNECTION (KA)) 853

ERROR CODE [DXHBKB] (RIGHT BRAKE ECMV: SHORT CIRCUIT (KB)) 854

ERROR CODE [DXHCKA] (LEFT BRAKE ECMV: DISCONNECTION (KA)) 855

ERROR CODE [DXHCKB] (LEFT BRAKE ECMV: SHORT CIRCUIT (KB)) 856

ERROR CODE [DXHDKA] (GOVERNOR SOLNOID RIGHT: DISCONNECTION (KA)) 857

ERROR CODE [DXHDKB] (GOVERNOR SOLNOID RIGHT: SHORT CIRCUIT (KB)) 860

ERROR CODE [DXHEKA] (GOVERNOR SOLNOID LEFT: DISCONNECTION (KA)) 861

ERROR CODE [DXHEKB] (GOVERNOR SOLNOID LEFT: SHORT CIRCUIT (KB)) 864

ERROR CODE [DXHFKA] (PRE-STROKE SOLENOID RIGHT: DISCONNECTION (KA)) 865

ERROR CODE [DXHFKB] (PRE-STORKE SOLENOID RIGHT: SHORT CIRCUIT (KB)) 866

ERROR CODE [DXHGKA] (PRE-STROKE SOLENOID LEFT: DISCONNECTION (KA)) 867

ERROR CODE [DXHGKB] (PRE-STORKE SOLENOID LEFT: SHORT CIRCUIT (KB)) 868

ERROR CODE [F@BBZL] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”38”) (ENGINE BLOW-BY PRESSURE: OVERPRESSURE (ZL)) 869

ERROR CODE [F@BYNR] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”62”) (LEFT BANK EXHAUST TEMPERATURE (2): ABNORMAL HEATING (NR)) 870

ERROR CODE [F@BYNS] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”61”) (LEFT BANK EXHAUST TEMPERATURE (1): OVERHEATING (NS)) 871

ERROR CODE [F@BZNR] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”72”) (RIGHT BANK EXHAUST TEMPERATURE (2): ABNORMAL HEATING (NR)) 872

ERROR CODE [F@BZNS] (OR LED OF VHMS CONTROLLER INDICATES “n3″→”71”) (RIGHT BANK EXHAUST TEMPERATURE (1): OVERHEATING (NS)) 873

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE) 875

INFORMATION DESCRIBED IN TROUBLESHOOTING LIST 876

E-1 THE ENGINE DOES NOT START 877

E-2 THE PREHEATER DOES NOT OPERATE (MANUAL PREHEATING FUNCTION) 880

E-3 THE RIPPER PIN PULLER CYLINDER DOES NOT OPERATE 882

E-4 THE MONITOR PANEL DOES NOT COME ON AT ALL WHEN THE STARTING SWITCH IS TURNED ON 883

E-5 WHEN THE STARTING SWITCH IS TURNED ON, THE MONITOR PANEL COMPLETELY REMAINS LIGHTED AND DOES NOT GO OUT 884

E-6 WHEN THE STARTING SWITCH IS TURNED ON, THE BASIC CHECK ITEMS FLASH 885

E-7 WHILE THE ENGINE IS OPERATING, ANY CAUTION ITEM FLASHES 886

E-8 AN EMERGENCY CAUTION ITEM FLASHES WHILE ENGINE IS RUNNING 889

E-9 WHILE THE PREHEATER IS OPERATING, THE PREHEATING PILOT LAMP DOES NOT COME ON 893

E-10 AT THE SELECTING TIME OF DUAL TILT, THE DUAL/SINGLE TILT SELECTOR LAMP DOES NOT COME ON (DUAL TILT-MOUNTED MACHINE) 895

E-11 AT THE LOCKING-UP OF THE TORQUE CONVERTER, THE TORQUE CONVERTER LOCK-UP DISPLAY LAMP DOES NOT COME ON 895

E-12 THE ENGINE COOLANT TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY 896

E-13 INDICATION OF THE POWER TRAIN TEMPERATURE GAUGE IS ABNORMAL 897

E-14 THE HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY 898

E-15 INDICATION OF THE FUEL GAUGE IS ABNORMAL 899

E-16 INDICATIONS OF GEAR SPEED AND ENGINE SPEED ARE ABNORMAL 900

E-17 INDICATION OF THE SHIFT MODE SERVICE METER IS ABNORMAL 900

E-18 THE SWITCH MODULE CANNOT BE OPERATED 901

E-19 THE WARNING LAMP DOES NOT FLASH OR DOES NOT GO OUT 902

E-20 THE ALARM BUZZER DOES NOT SOUND OR DOES NOT STOP 903

E-21 AUTO SHIFT DOWN IS NOT POSSIBLE OR IS NOT RELEASED 904

E-22 THE AUTOMATIC PITCH BACK SYSTEM DOES NOT OPERATE (ONLY SUPERDOZER SPECIFICATION) 905

E-23 THE ALARM BUZZER CANNOT BE CANCELLED 906

E-24 THE OPERATOR MODE CANNOT BE OPERATED 907

E-25 THE SERVICE MODE CANNOT BE OPERATED 908

E-26 THE BACK-UP ALARM DOES NOT SOUND 910

E-27 THE NIGHT LIGHT, THE HEADLAMP, THE WORKING LAMP AND THE REAR LAMP ON THE PANEL DO NOT COME ON 911

E-28 TROUBLESHOOTING FOR AIR CONDITIONER SYSTEM 916

E-29 ORBCOMM TERMINAL DOES NOT OPERATE NORMALLY (DATA ARE NOT TRANSMITTED) 931

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE) 933

INFORMATION IN TROUBLESHOOTING TABLE 934

H-1 NO FORCE (NO DRAWBAR PULL) 935

H-2 NO TRAVEL (AT 2ND OR 3RD SPEED) 936

H-3 NO TRAVEL AT ALL GEAR SPEEDS 937

H-4 MACHINE TRAVELS ONLY IN ONE DIRECTION FORWARD OR IN REVERSE 938

H-5 LARGE TIME LAG AT GEAR SPEED SHIFTING OR FORWARD-REVERSE SHIFTING 939

H-6 STEERING IS NOT POSSIBLE 940

H-7 STEERING IS POSSIBLE ONLY ON ONE SIDE 940

H-8 STEERING OVERRUN OCCURS 941

H-9 BRAKE DOES NOT WORK 941

H-10 TORQUE CONVERTER IS NOT LOCK-UP 942

H-11 TORQUE CONVERTER OIL IS OVERHEATED 942

H-12 ALL WORK EQUIPMENT SPEEDS ARE SLOW 943

H-13 WORK EQUIPMENT DOES NOT MOVE 944

H-14 BLADE LIFT SPEED IS SLOW OR LACKS POWER 944

H-15 BLADE TILT SPEED IS SLOW OR LACKS POWER 945

H-16 RIPPER LIFT SPEED IS SLOW OR LACKS POWER 945

H-17 RIPPER TILT SPEED IS SLOW OR LACKS POWER 946

H-18 EXCESSIVE HYDRAULIC DRIFT OF BLADE LIFT 946

H-19 EXCESSIVE HYDRAULIC DRIFT OF BLADE TILT 947

H-20 EXCESSIVE HYDRAULIC DRIFT OF RIPPER LIFT 947

H-21 RIPPER PIN PULLER CYLINDER DOES NOT WORK (GIANT RIPPER ATTACHMENT MACHINE) 948

H-22 BLADE PITCH DOES NOT WORK (DUAL TILT ATTACHMENT MACHINE) 948

H-23 ABNORMAL SOUND COMES OUT FROM AROUND WORK EQUIPMENT PUMP 948

TROUBLESHOOTING OF ENGINE BODY (S MODE) 949

POINTS TO REMEMBER WHEN TROUBLESHOOTING 950

METHOD OF USING TROUBLESHOOTING CHARTS 951

S-1 STARTING PERFORMANCE IS POOR (STARTING ALAWYS TAKES TIME) 954

S-2 ENGING DOES NOT START 955

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR) 958

S-4 ENGINE STOPS DURING OPERATIONS 959

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING) 960

S-6 ENGINE LACKS OUTPUT (NO POWER) 961

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION) 962

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE) 963

S-9 OIL BECOMES CONTAMINATED QUICKLY 964

S-10 FUEL CONSUMPTION IS EXCESSIVE 965

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN 966

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE) 967

S-13 OIL LEVEL RISES 968

S-14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING) 969

S-15 ABNORMAL NOISE IS MADE 970

S-16 VIBRATION IS EXCESSIVE 971

30 DISASSEMBLY AND ASSEMBLY 973

METHOD OF USING MANUAL 975

PRECAUTIONS WHEN CARRYING OUT OPERATION 977

SPECIAL TOOL LIST 979

SKETCHES OF SPECIAL TOOLS 988

REMOVAL AND INSTALLATION OF ENGINE OIL COOLER ASSEMBLY 996

REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY 996

REMOVAL AND INSTALLATION OF AFTER-COOLER CORE ASSEMBLY 998

REMOVAL AND INSTALLATION OF NOZZLE HOLDER ASSEMBLY 1000

REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL 1001

REMOVAL AND INSTALLATION OF ENGINE REAR SEAL 1002

REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY 1004

REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY 1008

REMOVAL AND INSTALLATION OF MAIN RADIATOR ASSEMBLY 1009

REMOVAL AND INSTALLATION OF SUB RADIATOR ASSEMBLY 1010

REMOVAL AND INSTALLATION OF RADIATOR GUARD ASSEMBLY 1012

REMOVAL AND INSTALLATION OF FAN MOTOR PUMP 1015

REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY 1016

REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY 1019

DISASSEMBLY AND ASSEMBLY OF DAMPER ASSEMBLY 1020

REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY 1022

REMOVAL AND INSTALLATION OF PTO, TORQUE CONVERTER ASSEMBLY 1025

DISCONNECTION AND CONNECTION OF PTO, TORQUE CONVERTER ASSEMBLY 1027

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY 1029

DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY 1037

REMOVAL AND INSTALLATION OF TORQFLOW TRANSMISSION ASSEMBLY 1042

DISASSEMBLY AND ASSEMBLY OF TORQFLOW TRANSMISSION ASSEMBLY 1043

DISASSEMBLY AND ASSEMBLY OF STEERING CASE ASSEMBLY 1057

DISASSEMBLY AND ASSEMBLY OF STEERING CLUTCH, BRAKE ASSEMBLY 1070

DISASSEMBLY AND ASSEMBLY OF TRANSFER GEAR HOUSING ASSEMBLY 1077

REMOVAL AND INSTALLATION OF POWER TRAIN PUMP ASSEMBLY 1080

REMOVAL AND INSTALLATION OF SCAVENGING PUMP ASSEMBLY 1080

REMOVAL AND INSTALLATION OF TORQUE CONVERTER OIL COOLER 1081

REMOVAL AND INSTALLATION OF TORQUE CONVERTER VALVE ASSEMBLY 1082

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER VALVE ASSEMBLY 1083

REMOVAL AND INSTALLATION OF TRANSMISSION CONTROL VALVE ASSEMBLY 1087

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CONTROL VALVE ASSEMBLY (ECMV ASSEMBLY) 1088

REMOVAL AND INSTALLATION OF STEERING CONTROL VALVE ASSEMBLY 1091

DISASSEMBLY AND ASSEMBLY OF STEERING CONTROL VALVE ASSEMBLY 1092

REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY 1094

DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY 1095

REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY 1107

DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY 1109

REMOVAL AND INSTALLATION OF RECOIL SPRING ASSEMBLY 1112

DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY 1127

REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY 1129

DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY 1132

REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY 1134

DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY 1134

REMOVAL AND INSTALLATION OF BOGIE ASSEMBLY 1137

DISASSEMBLY AND ASSEMBLY OF BOGIE ASSEMBLY 1142

REMOVAL AND INSTALLATION OF NO 1 BOGIE ASSEMBLY 1144

EXPANSIO AND INSTALLATION OF TRACK SHOE ASSEMBLY 1153

OVERALL DISASSEMBLY AND OVERALL ASSEMBLY OF TRACK SHOE 1156

PRESS-FITTING JIG DIMENSION TABLE FOR LINK PRESS 1169

FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK 1170

DISASSEMBLY AND ASSEMBLY OF MASTER LINK 1174

REMOVAL AND INSTALLATION OF PIVOT SHAFT ASSEMBLY 1178

REMOVAL AND INSTALLATION OF EQUALIZER BAR 1180

DISASSEMBLY AND ASSEMBLY OF EQUALIZER BAR BUSHING 1183

REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY 1186

REMOVAL AND INSTALLATION OF HYDRAULIC VALVE ASSEMBLY 1187

DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE 1188

DISASSEMBLY AND ASSEMBLY OF MERGE DIVIDER VALVE AND SELF PRESSURE REDUCING VALVE ASSEMBLY 1192

REMOVAL AND INSTALLATION OF PPC RELIEF VALVE ASSEMBLY 1194

DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY 1195

DISASSEMBLY AND ASSEMBLY OF RIPPER PIN PULLER CYLINDER ASSEMBLY 1201

REMOVAL AND INSTALLATION OF BLADE ASSEMBLY 1204

DISASSEMBLY AND ASSEMBLY OF GIANT RIPPER ASSEMBLY 1206

REMOVAL AND INSTALLATION OF ROPS GUARD 1209

REMOVAL AND INSTALLATION OF OPERATOR’S CAB ASSEMBLY 1210

REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY 1211

REMOVAL AND INSTALLATION OF CONTROLLER ASSEMBLY 1214

REMOVAL AND INSTALLATION OF AIR CONDITIONER CONDENSER ASSEMBLY 1215

REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY 1216

REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT 1218

REMOVAL AND INSTALLATION OF HOOD ASSEMBLY 1220

REMOVAL AND INSTALLATION OF FAN DRIVE ASSEMBLY 1221

REMOVAL AND INSTALLATION OF FAN MOTOR ASSEMBLY 1222

90 OTHERS 1225

POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM 1227

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/3) 1229

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (2/3) 1231

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (3/3) 1233

ELECTRICAL CIRCUIT DIAGRAM (1/8) 1235

ELECTRICAL CIRCUIT DIAGRAM (2/8) 1237

ELECTRICAL CIRCUIT DIAGRAM (3/8) 1239

ELECTRICAL CIRCUIT DIAGRAM (4/8) 1241

ELECTRICAL CIRCUIT DIAGRAM (5/8) 1243

ELECTRICAL CIRCUIT DIAGRAM (6/8) 1245

ELECTRICAL CIRCUIT DIAGRAM (7/8) 1247

ELECTRICAL CIRCUIT DIAGRAM (8/8) 1249

ELECTRICAL CIRCUIT DIAGRAM OF INSIDE CAB 1251

IMAGES PREVIEW OF THE MANUAL: