$43

Komatsu D51EX-22 D51PX-22 Crawler Dozer Shop Manual CEBM019111 – PDF DOWNLOAD

Komatsu D51EX-22 D51PX-22 Crawler Dozer Shop Manual CEBM019111 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D51EX-22 D51PX-22 Crawler Dozer Shop Manual CEBM019111 – PDF DOWNLOAD

Language : English

Pages : 1266

Downloadable : Yes

File Type : PDF

Size: 77.6 MB

DESCRIPTION:

Komatsu D51EX-22 D51PX-22 Crawler Dozer Shop Manual CEBM019111 – PDF DOWNLOAD

SERIAL NUMBERS

D51EX-22 B10001 and up

D51PX-22 B10001 and up

ENGINE 6D107E-1

GENERAL;

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate

understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you

understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For

ease of understanding, the manual is divided into the following sections. These sections are further divided into each main

group of components.

GENERAL

This section lists the general machine dimensions, performance specifications, component weights, and fuel, coolant and

lubricant specification charts.

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

This section explains the structure and function of each component. It serves not only to give an understanding of the

structure, but also serves as reference material for troubleshooting. In addition, this section gives the judgement standards

when inspecting disassembled parts.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at

completion of the checks and repairs.

TROUBLESHOOTING

Troubleshooting charts correlating “Problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling each component,

as well as precautions to be taken for these operations.

OTHER

This section has the foldout drawings for the machine.

FOREWORD EXPLANATION OF MAINTENANCE STANDARD TERMS

412. Repair Limit And Allowable Value

• The size of a part changes because of wear and deformation while it is used. The limit of changed size is called the

“repair limit”.

• If a part is worn to the repair limit must be replaced or repaired.

• The performance and function of a product lowers while it is used. A value below which the product can be used

without causing a problem is called the “allowable value”.

• If a product is worn to the allowable value, it must be checked or repaired. Since the permissible value is estimated

from various tests or experiences in most cases, however, it must be judged after considering the operating condition

and customer’s requirement.

5. Clearance Limit

• Parts can be used until the clearance between them is increased to a certain limit. The limit at which those parts

cannot be used is called the “clearance limit”.

• If the clearance between the parts exceeds the clearance limit, they must be replaced or repaired.

6. Interference Limit

• The allowable maximum interference between the hole of a part and the shaft of another part to be assembled is called

the “interference limit”.

• The interference limit shows the repair limit of the part of smaller tolerance.

• If the interference between the parts exceeds the interference limit, they must be replaced or repaired.

TABLE OF CONTENTS:

Komatsu D51EX-22 D51PX-22 Crawler Dozer Shop Manual CEBM019111 – PDF DOWNLOAD

D51EX-22 SM Title Page rev11 pdf 0

CONTENTS 2

00 FOREWORD 0

CONTENTS 2

LIST OF REVISED PAGES 3

SAFETY 13

SAFETY NOTICE 13

IMPORTANT SAFETY NOTICE 13

GENERAL PRECAUTIONS 13

PREPARATIONS FOR WORK 13

PRECAUTIONS DURING WORK 13

GENERAL 15

HOW TO READ THE SHOP MANUAL 16

VOLUMES 16

DISTRIBUTION AND UPDATING 16

FILING METHOD 16

REVISED EDITION MARK 16

REVISIONS 16

SYMBOLS 16

HOISTING INSTRUCTIONS 17

HOISTING 17

WIRE ROPES 17

PUSH PULL COUPLER 18

TYPE 1 18

DISCONNECTION 18

CONNECTION 18

TYPE 2 19

DISCONNECTION 19

CONNECTION 19

TYPE 3 20

DISCONNECTION 20

CONNECTION 20

EXPLANATION OF MAINTENANCE STANDARD TERMS 21

STANDARD TIGHTENING TORQUE 23

BOLTS AND NUTS 23

TIGHTENING TORQUE OF HOSE NUTS 24

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS 24

TIGHTENING TORQUE FOR FLARED NUTS 24

TIGHTENING TORQUES FOR O-RING BOSS PIPING JOINTS 25

TABLE OF TIGHTENING TORQUES FOR O-RING BOSS PLUGS 25

TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE) 25

ELECTRIC WIRE CODE 26

CLASSIFICATION BY THICKNESS 26

CLASSIFICATION BY COLOR AND CODE 26

HOW TO READ ELECTRIC WIRE CODE 27

CONVERSION TABLES 30

METHOD OF USING THE CONVERSION TABLE 30

COATING MATERIALS 36

01 GENERAL 39

SPECIFICATION DRAWING 40

D51EX, PX-22 POWER ANGLE, POWER TILT DOZER WITH ROPS CAB 40

SPECIFICATION 41

WEIGHT TABLE 45

TABLE OF FUEL, COOLANT AND LUBRICANTS 48

RECOMMENDED PRODUCTS OTHER THAN KOMATSU GENUINE OILS 50

10 STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD 51

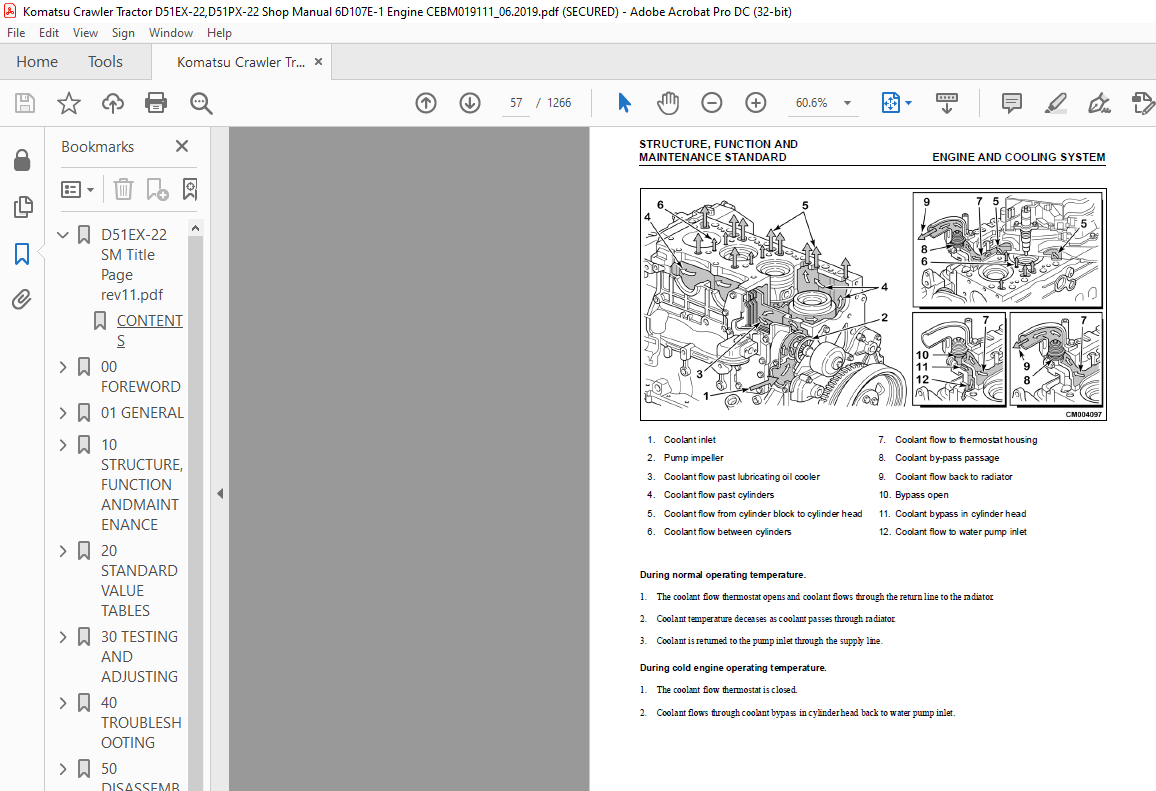

ENGINE AND COOLING SYSTEM 53

ENGINE RELATED PARTS 53

COOLING SYSTEM 55

COOLING FAN PUMP – SEE HYDRAULIC SYSTEM 2 (WORK EQUIPMENT AND FAN PUMP) 58

COOLING FAN MOTOR 59

OIL COOLER BYPASS VALVE 65

CHARGE SAFETY VALVE 68

POWER TRAIN 70

POWER TRAIN 70

POWER TRAIN SYSTEM 71

DAMPER 72

FINAL DRIVE 73

PATH OF POWER TRANSMISSION 76

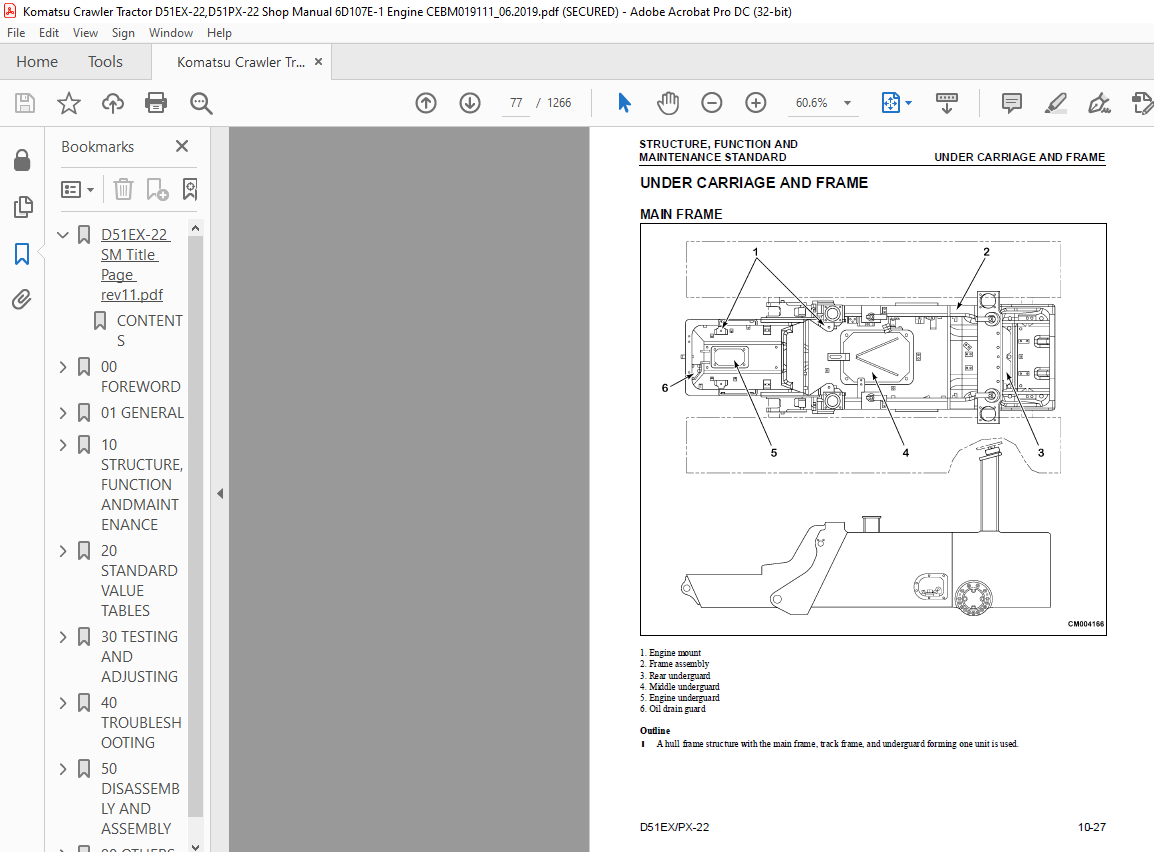

UNDER CARRIAGE AND FRAME 77

MAIN FRAME 77

TRACK FRAME AND RECOIL SPRING 78

SUSPENSION 80

IDLER 83

TRACK ROLLER 85

CARRIER ROLLER 89

TRACK SHOE 95

HYDRAULIC SYSTEM 1 (HST) 100

HST HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM 100

HST PUMP 101

SAFETY-SUCTION VALVE 109

TOWING VALVE 112

HST MOTOR 113

MOTOR CONTROL VALVE 125

SOLENOID VALVE (3-SPOOL), EPC VALVE (2-SPOOL) AND TOWING VALVE 125

SOLENOID VALVE 127

EPC VALVE 128

CHARGE PUMP 132

HYDRAULIC SYSTEM 2 (WORK EQUIPMENT) 134

CLSS (CLOSED CENTER LOAD SENSING SYSTEM) 134

UNLOAD VALVE 138

PRESSURE COMPENSATION VALVE 144

LS BYPASS VALVE 145

WORK EQUIPMENT HYDRAULIC ARRANGEMENT DIAGRAM 146

WORK EQUIPMENT AND FAN PUMP 147

SERVO VALVE 152

CONTROL VALVE 154

QUICK DROP VALVE 166

BLADE PPC VALVE 168

RIPPER/WINCH PPC VALVE 174

HYDRAULIC TANK, FILTER 178

ACCUMULATOR 179

WORK EQUIPMENT 180

WORK EQUIPMENT 180

CUTTING EDGE AND END BIT 185

RIPPER 186

WORK EQUIPMENT CYLINDER 187

LIFT CYLINDER 187

TILT CYLINDER 187

ANGLE CYLINDER 188

RIPPER CYLINDER 188

PISTON VALVE FOR ANGLE CYLINDER 190

CAB AND ITS ATTACHMENTS 191

ROPS CAB 191

STEERING AND BRAKE CONTROL 192

WORK EQUIPMENT CONTROL 194

CAB DAMPER MOUNT 196

AIR CONDITIONER 197

AIR CONDITIONER AND FLOOR HEATER 197

AIR CONDITIONER PIPING 198

ELECTRICAL SYSTEM 199

MONITOR SYSTEM 199

ENGINE CONTROL 201

ENGINE CONTROL SYSTEM 202

COOLING CONTROL SYSTEM 204

HST CONTROL SYSTEM 206

GEAR SHIFT CONTROL SYSTEM 207

GEAR SHIFTING BY OPERATOR 207

SET TRAVEL SPEEDS CORRESPONDING TO GEAR SPEEDS 208

CHANGING TRAVEL SPEED ACCORDING TO CHANGE OF ENGINE SPEED 210

STRAIGHT TRAVEL CORRECTION CONTROL SYSTEM 211

PARKING BRAKE CONTROL SYSTEM 212

KOMTRAX SYSTEM 214

SYSTEM COMPONENTS 216

MONITOR PANEL 216

ENGINE CONTROLLER 220

HST CONTROLLER 222

ELECTRIC LEVER (FOR TRAVEL) 224

KOMTRAX TERMINAL 226

SENSORS 227

BRAKE OIL PRESSURE SENSOR 228

HYDRAULIC OIL TEMPERATURE SENSOR 229

HST CIRCUIT OIL PRESSURE SENSOR 230

AIR CLEANER CLOGGING SENSOR 231

DECELERATOR PEDAL POTENTIOMETER 232

BRAKE PEDAL POTENTIOMETER 232

FUEL CONTROL DIAL 233

FUEL LEVEL SENSOR 234

CHARGE FILTER CLOGGING SENSOR 235

COOLANT TEMPERATURE SENSOR 235

ENGINE OIL PRESSURE SWITCH 236

ENGINE ROTATION SENSOR 236

BOOST PRESSURE AND TEMPERATURE SENSOR 237

WIF SENSOR 237

HST MOTOR SPEED SENSOR 238

20 STANDARD VALUE TABLES 239

STANDARD VALUE TABLE FOR ENGINE 240

STANDARD VALUE TABLE FOR CHASSIS 241

PERFORMANCE MEASURING POSTURE AND METHOD 246

30 TESTING AND ADJUSTING 249

LIST OF TOOLS 251

ENGINE 254

ENGINE SPEED 254

AIR INTAKE BOOST PRESSURE 255

EXHAUST TEMPERATURE 256

EXHAUST GAS COLOR 258

VALVE CLEARANCE 259

COMPRESSION PRESSURE 262

BLOW-BY PRESSURE 264

ENGINE OIL PRESSURE 265

HANDLING CONTROLLER HIGH-VOLTAGE CIRCUIT 266

FUEL SYSTEM 267

HANDLING FUEL SYSTEM PARTS 267

RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM 267

BLEEDING AIR FROM FUEL CIRCUIT 268

FUEL PRESSURE 270

FUEL RETURN RATE AND LEAKAGE 272

FUEL CIRCUIT FOR LEAKAGE 275

FAN (WORK EQUIPMENT) PUMP PRESSURE 276

FAN SPEED 276

FAN SPEED SENSOR 277

DECELERATOR PEDAL 279

HST OIL PRESSURE 281

MOTOR CONTROL VALVE OUTLET PRESSURE 286

TRAVEL DEVIATION 289

PARKING BRAKE LEVER 290

BRAKE PERFORMANCE 292

BRAKE PEDAL LINKAGE 293

EMERGENCY RELEASE OF PARKING BRAKE 295

IDLER CLEARANCE 298

TRACK SHOE TENSION 300

WORK EQUIPMENT 301

OIL PRESSURE 301

WORK EQUIPMENT PPC VALVE 303

OIL PRESSURE 303

PPC circuit connection diagram 304

ADJUSTING PLAY OF WORK EQUIPMENT PPC VALVE 1 305

LOCK LEVER ADJUSTMENT 306

CYLINDER LEAKAGE 307

HYDRAULIC CIRCUIT 309

RELEASING RESIDUAL PRESSURE 309

BLEEDING AIR 310

BLADE CENTER BALL ADJUSTMENT 311

BLADE PITCH BALL ADJUSTMENT 311

DIODES 312

PROCEDURE FOR TESTING 312

MONITOR PANEL (EMMS) – SPECIAL FUNCTIONS 314

PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL SYSTEM 375

ELECTRIC/HYDRAULIC DEVICES ARE ADJUSTED/REPLACED 377

ITEMS TO BE ADJUSTED 377

HST CONTROLLER ADJUSTMENT AFTER REPLACEMENT 378

MONITOR PANEL ADJUSTMENT AFTER REPLACEMENT 381

PM-CLINIC 383

PM-CLINIC SERVICE 383

PM-CLINIC INSPECTION SHEET (1/2) 386

PM-CLINIC INSPECTION SHEET (2/2) 387

PM-CLINIC UNDERCARRIAGE CHECK SHEET 388

UNDERCARRIAGE TROUBLESHOOTING REPORT (NORMAL) 389

UNDERCARRIAGE TROUBLESHOOTING REPORT (IMPACT) 390

PM-CLINIC UNDERCARRIAGE CHECK SHEET 391

UNDERCARRIAGE TROUBLESHOOTING REPORT (NORMAL) 392

UNDERCARRIAGE TROUBLESHOOTING REPORT (IMPACT) 393

40 TROUBLESHOOTING 395

TROUBLESHOOTING (GENERAL) 395

POINTS TO REMEMBER WHEN TROUBLESHOOTING 396

SEQUENCE OF EVENTS IN TROUBLESHOOTING 398

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE 399

PRECAUTIONS WHEN HANDLING ELECTRICAL EQUIPMENT 399

HANDLING ELECTRONIC CONTROL UNIT 404

POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRICAL CIRCUITS 405

ELECTRIC WIRE CODE 406

CLASSIFICATION BY THICKNESS 406

CLASSIFICATION BY COLOR AND CODE 406

HOW TO READ ELECTRIC WIRE CODE 407

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT 409

CHECKS BEFORE TROUBLESHOOTING 411

CATEGORIES AND METHOD OF USING TROUBLESHOOTING CHARTS 412

TROUBLESHOOTING INDIVIDUAL ELECTRICAL CIRCUITS 413

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 416

T-ADAPTER TABLE 440

MODE CHART 444

TROUBLESHOOTING (BY ERROR CODE) 447

TROUBLESHOOTING BY ERROR CODE 453

INFORMATION IN TROUBLESHOOTING TABLE 460

ERROR CODE [6091NX] 462

HST CHARGE FILTER ELEMENT CLOGGING 462

ERROR CODE [AA10NX] 464

AIR CLEANER CLOGGING 464

ERROR CODE [AB00MA] 466

ALTERNATOR MALFUNCTION 466

ERROR CODE [B@BAZG] 467

ENGINE OIL LOWERING OF OIL PRESSURE 467

ERROR CODE [B@BCNS] 468

COOLANT OVERHEAT 468

ERROR CODE [B@CRNS] 469

HST OIL OVERHEATING 469

ERROR CODE [B@CRZG] 470

HST OIL LOWERING OF OIL PRESSURE 470

ERROR CODE [CA111] 471

ABNORMALITY IN ENGINE CONTROLLER 471

ERROR CODE [CA115] 472

ABNORMALITY IN NE AND BKUP SPEED SENSOR SIGNAL 472

ERROR CODE [CA122] 474

CHARGE PRESSURE SENSOR TOO HIGH 474

ERROR CODE [CA123] 476

CHARGE PRESSURE SENSOR TOO LOW 476

ERROR CODE [CA131] 478

DECELERATOR PEDAL SENSOR TOO HIGH 478

ERROR CODE [CA132] 480

DECELERATOR PEDAL SENSOR TOO LOW 480

ERROR CODE [CA144] 482

COOLANT TEMPERATURE SENSOR TOO HIGH 482

ERROR CODE [CA145] 484

COOLANT TEMPERATURE SENSOR TOO LOW 484

ERROR CODE [CA153] 486

CHARGE TEMPERATURE SENSOR TOO HIGH 486

ERROR CODE [CA154] 488

CHARGE TEMPERATURE SENSOR TOO low 488

ERROR CODE [CA187] 490

SENSOR POWER SORCE EXCESSIVELY LOW 490

ERROR CODE [CA221] 492

ATMOSPHERIC PRESSURE SENSOR TOO HIGH 492

ERROR CODE [CA222] 494

ATMOSPHERIC PRESSURE SENSOR TOO LOW 494

ERROR CODE [CA227] 496

SENSOR POWER SORCE EXCESSIVELY HIGH 496

ERROR CODE [CA234] 498

ENGINE OVERSPEED 498

ERROR CODE [CA238] 499

ABNORMAL POWER SOURCE FOR NE SPEED SENSOR 499

ERROR CODE [CA271] 500

IMV/PCV1 SHORT CIRCUITED 500

ERROR CODE [CA272] 502

IMV/PCV1 OPEN 502

ERROR CODE [CA322] 504

NO 1 INJECTOR SHOWING OPEN OR SHORT 504

ERROR CODE [CA323] 506

NO 5 INJECTOR SHOWING OPEN OR SHORT 506

ERROR CODE [CA324] 508

NO 3 INJECTOR SHOWING OPEN OR SHORT 508

ERROR CODE [CA325] 510

NO 6 INJECTOR SHOWING OPEN OR SHORT 510

ERROR CODE [CA331] 512

NO 2 INJECTOR SHOWING OPEN OR SHORT 512

ERROR CODE [CA332] 514

NO 4 INJECTOR SHOWING OPEN OR SHORT 514

ERROR CODE [CA342] 516

ENGINE CONTROLLER DATA MATCHING ERROR 516

ERROR CODE [CA352] 517

SENSOR POWER SOURCE TOO LOW 517

ERROR CODE [CA386] 518

SENSOR POWER SOURCE TOO HIGH 518

ERROR CODE [CA428] 520

WATER IN FUEL SENSOR VOLTAGE TOO HIGH 520

ERROR CODE [CA429] 522

WATER IN FUEL SENSOR VOLTAGE TOO LOW 522

ERROR CODE [CA435] 524

ABNORMAL ENGINE OIL PRESSURE SWITCH 524

ERROR CODE [CA441] 526

POWER SOURCE VOLTAGE IS TOO LOW 526

ERROR CODE [CA442] 528

POWER SOURCE VOLTAGE TOO HIGH 528

ERROR CODE [CA449] 530

COMMON RAIL PRESSURE TOO HIGH 530

ERROR CODE [CA451] 532

COMMON RAIL PRESSURE TOO HIGH 532

ERROR CODE [CA452] 534

COMMON RAIL PRESSURE TOO LOW 534

ERROR CODE [CA488] 536

CHARGE TEMPERATURE TOO HIGH AND TORQUE DERATED 536

ERROR CODE [CA553] 537

COMMON RAIL PRESSURE TOO HIGH 537

ERROR CODE [CA559] 538

LOSS OF PRESSURE FEED FROM SUPPLY PUMP 538

ERROR CODE [CA689] 540

ABNORMAL ENGINE NE SPEED SENSOR 540

ERROR CODE [CA731] 542

ABNORMAL ENGINE BKUP SPEED SENSOR PHASE 542

ERROR CODE [CA757] 544

LOSS OF ALL ENGINE CONTROLLER DATA 544

ERROR CODE [CA778] 546

ABNORMAL ENGINE BKUP SPEED SENSOR 546

ERROR CODE [CA1633] 548

ABNORMAL KOMNET 548

ERROR CODE [CA2185] 550

DECELERATOR PEDAL SENSOR POWER SOURCE TOO HIGH 550

ERROR CODE [CA2186] 551

DECELERATOR PEDAL SENSOR POWER SOURCE TOO LOW 551

ERROR CODE [CA2249] 552

LOSS OF PRESSURE FEED FROM SUPPLY PUMP (2) 552

ERROR CODE [CA2311] 554

ABNORMAL IMV SOLENOID 554

ERROR CODE [CA2555] 556

AIR INTAKE HEATER RELAY DISCONNECTION 556

ERROR CODE [CA2556] 558

AIR INTAKE HEATER RELAY SHORT CIRCUIT 558

ERROR CODE [D130KA] 560

NEUTRAL SAFETY RELAY DISCONNECTION 560

ERROR CODE [D130KB] 562

NEUTRAL SAFETY RELAY SHORT CIRCUIT 562

ERROR CODE [DAFRKR] 564

CAN COMMUNICATION MONITOR PANEL – HST CONTROLLER 564

ERROR CODE [DAFRMC] 566

CAN COMMUNICATION MONITOR PANEL – ENGINE CONTROLLER 566

ERROR CODE [DAJ000] 568

HST CONTROLLER MEMORY ERROR 568

ERROR CODE [DAJ0KK] 570

HST CONTROLLER LOWERING OF SOURCE VOLTAGE 570

ERROR CODE [DAJ0KQ] 572

HST CONTROLLER MACHINE CODE ERROR 572

ERROR CODE [DAJ0KT] 573

HST CONTROLLER MEMORY ERROR 573

ERROR CODE [DAJ5KK] 574

HST CONTROLLER POWER SUPPLY LOWING 574

ERROR CODE [DAJ6KK] 576

HST POWER SUPPLY LOWING 576

ERROR CODE [DAJRKR] 578

CAN COMMUNICATION HST CONTROLLER DEFECTIVE 578

ERROR CODE [DB2RKR] 580

CAN COMMUNICATION HST CONTROLLER DEFECTIVE 580

ERROR CODE [DD12KA] 582

SHIFT UP SWITCH DISCONNECTION 582

ERROR CODE [DD12KB] 584

SHIFT UP SWITCH SHORT CIRCUIT 584

ERROR CODE [DD13KA] 586

SHIFT DOWN SWITCH DISCONNECTION 586

ERROR CODE [DD13KB] 588

SHIFT DOWN SWITCH SHORT CIRCUIT 588

ERROR CODE [DD14KB] 590

TRAVEL LOCK LIMIT SWITCH 1 SHORT CIRCUIT 590

ERROR CODE [DD1NL4] 592

FAN ROTATION SELECTOR SWITCH DISAGREEMENT 592

ERROR CODE [DDDCKB] 594

REVERSE TRAVEL SPEED SWITCH SHORT CIRCUIT 594

ERROR CODE [DDP6KA] 596

BRAKE OIL PRESSURE SENSOR DISCONNECTION 596

ERROR CODE [DDP6KB] 598

BRAKE OIL PRESSURE SENSOR SHORT CIRCUIT 598

ERROR CODE [DDP6MA] 600

BRAKE OIL PRESSURE SENSOR MALFUNCTION 600

ERROR CODE [DDQ2KA] 602

TRAVEL LOCK LIMIT SWITCH 1 DISCONNECTION 602

ERROR CODE [DDT0L4] 604

SHIFT MODE SWITCH DISAGREEMENT OF ON/ OFF SIGNALS 604

ERROR CODE [DDU1FS] 606

TRAVEL LOCK LIMIT SWITCHES 1 AND 2 FIXING 606

ERROR CODE [DDU1KA] 608

TRAVEL LOCK LIMIT SWITCH 2 DISCONNECTION 608

ERROR CODE [DDU1KY] 610

TRAVEL LOCK LIMIT SWITCH 2 SHORT WITH POWER SUPPLY LINE 610

ERROR CODE [DGS1KA] 612

HST OIL TEMPERATURE SENSOR DISCONNECTION 612

ERROR CODE [DGS1KX] 614

HST OIL TEMPERATURE SENSOR OUT OF INPUT SIGNAL RANGE 614

ERROR CODE [DHH5KA] 615

LEFT HST PUMP PRESSURE SENSOR DISCONNECTION 615

ERROR CODE [DHH5KB] 617

LEFT HST PUMP PRESSURE SENSOR SHORT CIRCUIT 617

ERROR CODE [DHH6KA] 619

RIGHT HST PUMP PRESSURE SENSOR DISCONNECTION 619

ERROR CODE [DHH6KB] 621

RIGHT HST PUMP PRESSURE SENSOR SHORT CIRCUIT 621

ERROR CODE [DK10KA] 623

FUEL DIAL SENSOR DISCONNECTION 623

ERROR CODE [DK10KB] 625

FUEL DIAL SENSOR SHORT CIRCUIT 625

ERROR CODE [DK30KA] 627

STEERING ANGLE SENSOR 1 DISCONNECTION 627

ERROR CODE [DK30KB] 629

STEERING ANGLE SENSOR 1 SHORT CIRCUIT 629

ERROR CODE [DK30KX] 631

STEERING ANGLE SENSOR OUT OF INPUT SIGNAL RANGE 631

ERROR CODE [DK30KZ] 632

STEERING ANGLE SENSOR DISCONNECTION OR SHORT CIRCUIT 632

ERROR CODE [DK30L8] 633

STEERING ANGLE SENSOR DISAGREEMENT OF ANALOG SIGNALS 633

ERROR CODE [DK31KA] 635

STEERING ANGLE SENSOR DISCONNECTION 635

ERROR CODE [DK31KB] 637

STEERING ANGLE SENSOR 2 SHORT CIRCUIT 637

ERROR CODE [DK40KA] 639

BRAKE PEDAL SENSOR DISCONNECTION 639

ERROR CODE [DK40KB] 641

BRAKE PEDAL SENSOR SHORT CIRCUIT 641

ERROR CODE [DK55KX] 643

DIRECTIONAL POTENTIOMETER OUT OF INPUT SIGNAL RANGE 643

ERROR CODE [DK55KZ] 644

DIRECTIONAL POTENTIOMETER DISCONNECTION OR SHORT CIRCUIT 644

ERROR CODE [DK55L8] 645

DIRECTIONAL POTENTIOMETER DISAGREEMENT OF ANALOG SIGNALS 645

ERROR CODE [DK56KA] 647

DIRECTIONAL POTENTIOMETER 1 DISCONNECTION 647

ERROR CODE [DK56KB] 649

DIRECTIONAL POTENTIOMETER 1 SHORT CIRCUIT 649

ERROR CODE [DK57KA] 651

DIRECTIONAL POTENTIOMETER 2 DISCONNECTION 651

ERROR CODE [DK57KB] 653

DIRECTIONAL POTENTIOMETER 2 SHORT CIRCUIT 653

ERROR CODE [DLM0KX] 655

HST MOTOR SPEED SENSORS OUT OF INPUT SIGNAL RANGE 655

ERROR CODE [DLM1KA] 657

LEFT HST MOTOR SPEED SENSOR DISCONNECTION 657

ERROR CODE [DLM1KB] 659

LEFT HST MOTOR SPEED SENSOR: SHORT CIRCUIT 659

ERROR CODE [DLM1MA] 661

LEFT HST MOTOR SPEED SENSOR: MALFUNCTION 661

ERROR CODE [DLM2KA] 663

RIGHT HST MOTOR SPEED SENSOR DISCONNECTION 663

ERROR CODE [DLM2KB] 665

RIGHT HST MOTOR SPEED SENSOR SHORT CIRCUIT 665

ERROR CODE [DLM2MA] 667

RIGHT HST MOTOR SPEED SENSOR MALFUNCTION 667

ERROR CODE [DLM3KA] 669

FAN SPEED SENSOR DISCONNECTION 669

ERROR CODE [DLM3KB] 671

FAN SPEED SENSOR: SHORT CIRCUIT 671

ERROR CODE [DN21FS] 673

BRAKE PEDAL AND PROXIMITY SWITCH FIXING 673

ERROR CODE [DV00KB] 675

CAUTION BUZZER SHORT CIRCUIT 675

ERROR CODE [DV20KB] 676

BACK ALARM BUZZER SHORT CIRCUIT 676

ERROR CODE [DW4BKA] 677

PARKING BRAKE SOLENOID VALVE DISCONNECTION 677

ERROR CODE [DW4BKB] 679

PARKING BRAKE SOLENOID VALVE SHORT CIRCUIT 679

ERROR CODE [DW4BKY] 681

PARKING BRAKE SOLENOID VALVE SHORTED 681

ERROR CODE [DW7BKA] 682

FAN REVERSE SOLENOID VALVE DISCONNECTION 682

ERROR CODE [DW7BKB] 682

FAN REVERSE SOLENOID VALVE SHORT CIRCUIT 683

ERROR CODE [DW7BKY] 684

FAN REVERSE SOLENOID VALVE SHORTED 684

ERROR CODE [DW7EKA] 685

SLOW BRAKE SOLENOID VALVE DISCONNECTION 685

ERROR CODE [DW7EKB] 689

SLOW BRAKE SOLENOID VALVE SHORT CIRCUIT 689

ERROR CODE [DW7EKY] 691

SLOW BRAKE SOLENOID VALVE SHORTED 691

ERROR CODE [DWN5KA] 693

FAN EPC SOLENOID VALVE DISCONNECTION 693

ERROR CODE [DWN5KB] 695

FAN EPC SOLENOID VALVE SHORT CIRCUIT 695

ERROR CODE [DWN5KY] 697

FAN EPC SOLENOID VALVE SHORTED 697

ERROR CODE [DXA4KA] 699

LF HST PUMP EPC SOLENOID VALVE DISCONNECTION 699

ERROR CODE [DXA4KB] 701

LF HST PUMP EPC SOLENOID VALVE SHORT CIRCUIT 701

ERROR CODE [DXA4KY] 702

LF HST PUMP EPC SOLENOID VALVE SHORTED 702

ERROR CODE [DXA5KA] 703

LR HST PUMP EPC SOLENOID VALVE DISCONNECTION 703

ERROR CODE [DXA5KB] 705

LR HST PUMP EPC SOLENOID VALVE SHORT CIRCUIT 705

ERROR CODE [DXA5KY] 706

LR HST PUMP EPC SOLENOID VALVE SHORTED 706

ERROR CODE [DXA6KA] 707

RF HST PUMP EPC SOLENOID VALVE DISCONNECTION 707

ERROR CODE [DXA6KB] 709

RF HST PUMP EPC SOLENOID VALVE SHORT CIRCUIT 709

ERROR CODE [DXA6KY] 710

RF HST PUMP EPC SOLENOID VALVE SHORTED 710

ERROR CODE [DXA7KA] 711

RR HST PUMP EPC SOLENOID VALVE DISCONNECTION 711

ERROR CODE [DXA7KB] 712

RR HST PUMP EPC SOLENOID VALVE SHORT CIRCUIT 712

ERROR CODE [DXA7KY] 713

RR HST PUMP EPC SOLENOID VALVE SHORTED 713

ERROR CODE [DXK1KA] 714

LEFT HST MOTOR EPC SOLENOID VALVE DISCONNECTION 714

ERROR CODE [DXK1KB] 715

LEFT HST MOTOR EPC SOLENOID VALVE SHORT CIRCUIT 715

ERROR CODE [DXK1KY] 716

LEFT HST MOTOR EPC SOLENOID VALVE SHORTED 716

ERROR CODE [DXK2KA] 717

RIGHT HST MOTOR EPC SOLENOID VALVE DISCONNECTION 717

ERROR CODE [DXK2KB] 718

RIGHT HST MOTOR EPC SOLENOID VALVE SHORT CIRCUIT 718

ERROR CODE [DXK2KY] 719

RIGHT HST MOTOR EPC SOLENOID VALVE SHORTED 719

TROUBLESHOOTING (E-MODE) 723

BEFORE CARRYING OUT TROUBLESHOOTING (E-MODE) 725

CONNECTION TABLE OF FUSE BOX 725

INFORMATION IN TROUBLESHOOTING TABLE 727

E-1 728

STARTING MOTOR DOES NOT ROTATE 728

E-2 732

ENGINE IS NOT PRE-HEATED 732

E-3 736

WHEN STARTING SWITCH IS TURNED ON, ANY ITEM DOES NOT LIGHT 736

E-4 738

CHARGE LEVEL CAUTION FLASHES WHILE ENGINE IS RUNNING 738

E-5 740

EMERGENCY WARNING ITEMS FLASH WHILE ENGINE IS RUNNING 740

E-6 744

PRE-HEAT LAMP DOES NOT LIGHT DURING PRE-HEATING OPERATION 744

E-7 746

COOLANT TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY 746

E-8 747

HST OIL TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY 747

E-9 748

FUEL LEVEL GAUGE DOES NOT INDICATE PROPERLY 748

E-10 750

TRAVEL INDICATOR DOES NOT DISPLAY NORMALLY 750

E-11 750

MULTI-INFORMATION UNIT DOES NOT DISPLAY NORMALLY 750

E-12 751

CAUTION LAMP DOES NOT FLASH OR DOES NOT GO OFF 751

E-13 752

CAUTION BUZZER DOES NOT SOUND OR DOES NOT STOP 752

E-14 754

REVERSE TRAVEL SPEED SETTING SWITCH DOES NOT FUNCTION 754

E-15 756

SHIFT MODE SWITCH DOES NOT FUNCTION 756

E-16 758

BUZZER CANCEL SWITCH DOES NOT FUNCTION 758

E-17 760

INFORMATION SWITCH DOES NOT FUNCTION 760

E-18 762

THE FAN CLEANING DOES NOT OPERATE OR CANNOT BE RESET 762

E-19 764

BACKUP ALARM DOES NOT SOUND 764

E-20 765

THE HORN DOES NOT SOUND OR DOES NOT STOP 765

E-21 766

WORK EQUIPMENT DOES NOT MOVE 766

E-22 768

HEAD LAMP OR REAR LAMP DOES NOT LIGHT UP 768

E-23 772

FOOT HEATER DOES NOT OPERATE 772

E-24 776

AIR CONDITIONER DOES NOT OPERATE [CAB SPECIFICATION] 776

E-25 781

WIPER AND WASHER DO NOT OPERATE [CAB SPECIFICATION] 781

E-26 794

KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY 794

TROUBLESHOOTING (H-MODE) 797

INFORMATION IN TROUBLESHOOTING TABLE 798

H-1 799

RIGHT AND LEFT TRAVEL SYSTEMS INOPERABLE 799

H-2 801

RIGHT OR LEFT TRAVEL SYSTEM DOES NOT OPERATE 801

H-3 802

RIGHT OR LEFT TRAVEL SYSTEM DOES NOT OPERATE 802

H-4 803

SPEED OR POWER OF TRAVEL IS LOW 803

H-5 804

GEAR IS NOT SHIFTED 804

H-6 805

LARGE SHOCKS ARE MADE WHEN MACHINE STARTS AND STOPS TRAVEl 805

H-7 806

MACHINE DEVIATES LARGELY DURING TRAVEL 806

H-8 807

HYDRAULIC DRIFT OF TRAVEL IS LARGE 807

H-9 808

ENGINE STALLS OR SPEED LOWERS EXTREMELY DURING TRAVEl 808

H-10 809

ABNORMAL SOUND COMES OUT FROM AROUND HST PUMP AND MOTOR 809

H-11 810

WORK EQUIPMENT DOSE NOT OPERATE AT ALL 810

H-12 811

SPEED OR POWER OF WHOLE WORK EQUIPMENT IS LOW 811

H-13 812

SPEED OR POWER OF LIFTING BLADE IS LOW 812

H-14 813

SPEED OR POWER OF TILTING BLADE IS LOW 813

H-15 814

SPEED OR POWER OF ANGLING BLADE IS LOW 814

H-16 815

TIME LAG IN LIFTING BLADE IS LARGE 815

H-17 816

HYDRAULIC DRIFT OF LIFTING BLADE IS LARGE 816

H-18 817

HYDRAULIC DRIFT OF TILTING BLADE IS LARGE 817

H-19 818

ABNORMAL SOUND COMES FROM WORK EQUIPMENT PUMP AND CONTROL VALVE 818

H-20 819

HST OIL TEMPERATURE RISES TOO HIGH 819

H-21 820

FAN SPEED IS ABNORMAL (HIGH, LOW, OR 0 RPM) 820

TROUBLESHOOTING (S-MODE) 821

METHOD OF USING TROUBLESHOOTING CHARTS 822

(S-1) ENGINE STARTING PERFORMANCE IS POOR 826

(S-2) ENGINE DOES NOT CRANK 827

ENGINE CRANKS BUT NO EXHAUST SMOKE COMES OUT OF STACK 828

SMOKE COMES OUT OF STACK BUT ENGINE DOES NOT START 829

(S-3) ENGINE DOES NOT RUN SMOOTHLY 830

(S-4) ENGINE STOPS DURING OPERATIONS 831

(S-5) ENGINE SPEED HUNTS 832

(S-6) ENGINE LACKS POWER 833

(S-7) EXHAUST SMOKE IS BLACK 835

(S-8) OIL CONSUMPTION IS EXCESSIVE OR EXHAUST SMOKE IS BLUE 836

(S-9) OIL BECOMES CONTAMINATED QUICKLY 837

(S-10) FUEL CONSUMPTION IS EXCESSIVE 838

(S-11) OIL FOUND IN COOLANT, OR COOLANT SPURTS FROM RADIATOR 839

(S-12) OIL PRESSURE CAUTION LAMP LIGHTS UP 840

(S-13) OIL LEVEL RISES (COOLANT OR FUEL FOUND IN OIL) 841

(S-14) COOLANT TEMPERATURE TOO HIGH (OVERHEATING) 842

(S-15) ABNORMAL NOISE IS HEARD WHEN ENGINE IS RUNNING 843

(S-16) EXCESSIVE VIBRATION WHEN ENGINE IS RUNNING 844

50 DISASSEMBLY AND ASSEMBLY 845

HOW TO USE THIS MANUAL 848

REMOVAL AND INSTALLATION OF COMPONENTS 848

Special Tools 848

OVERHAUL OF COMPONENTS 849

Special Tools 849

Disassembly Procedures 849

Assembly Procedures 849

PRECAUTIONS WHEN CARRYING OUT AN OPERATION 850

SPECIAL TOOL LIST 852

SKETCH OF SPECIAL TOOLS 859

CONNECTOR REPAIR PROCEDURES 874

CONTACT TERMINAL REMOVAL (HD30 TYPE) 874

STRIPPING INSULATION 875

CRIMPING CONTACT TERMINAL (HD30 TYPE) 876

INSERTION OF CONTACT TERMINAL (HD30 TYPE) 877

CONTACT TERMINAL REMOVAL (DT TYPE) 878

STRIPPING INSULATION 879

CRIMPING CONTACT TERMINAL (DT TYPE) 880

INSERTION OF CONTACT TERMINAL (DT TYPE) 881

NOSE GUARD (HOOD) 883

REMOVAL 883

OPENING FRONT GRILL 883

REMOVING SIDE PANELS 884

DISCONNECTING HOOD-RELATED COMPONENTS 884

REMOVAL OF HOOD 885

INSTALLATION 887

MUFFLER AND EXHAUST STACK 889

REMOVAL 889

INSTALLATION 890

CAB 891

REMOVAL 891

FLOOR ACCESS PLATE 894

LIFTING CAB OFF MACHINE 897

INSTALLATION 900

MONITOR PANEL AND HST CONTROLLER 905

REMOVAL 905

INSTALLATION 907

KOMTRAX CONTROLLER 908

REMOVAL 908

INSTALLATION 908

SEAT 909

REMOVAL 909

INSTALLATION 909

AIR CONDITIONER/HEATER 910

DISASSEMBLY OF AIR CONDITIONER 910

REMOVING CONDENSER 911

BLOWER MOTORS AND EVAPORATOR 913

ASSEMBLY OF AIR CONDITIONER 914

FOOT HEATER 915

REMOVAL 915

INSTALLATION 916

FOOT HEATER OVERHAUL PROCEDURES 917

OVERHAUL PROCEDURES 917

ASSEMBLY PROCEDURES 919

ENGINE AND HST PUMP 921

REMOVAL 921

BELLY PANS 921

DRAINING THE COOLING SYSTEM 921

DRAINING THE HYDRAULIC SYSTEM 922

DISCONNECTING COMPONENTS 923

LIFTING ENGINE AND HST PUMP ASSEMBLY 929

INSTALLATION 931

INSTALL ENGINE AND HST PUMP ASSEMBLY 931

REMOVAL FROM ENGINE 933

INSTALLATION TO ENGINE 936

DRIVE DAMPENER 937

REMOVAL 937

INSTALLATION 938

HST PUMP OVERHAUL PROCEDURES 939

DISASSEMBLY PROCEDURES 939

REMOVAL OF ACCESSORIES 939

REMOVAL OF REAR PUMP 940

REMOVAL OF END CAP 940

DISASSEMBLY OF CYLINDER BLOCK AND PISTONS 941

DISASSEMBLY OF ROCKER CAM 942

REMOVAL OF FRONT SHAFT 943

DISASSEMBLY OF SHAFT 944

DISASSEMBLY OF FRONT COVER 945

DISASSEMBLY FRONT SERVO PISTON 946

DISASSEMBLY OF END CAP 947

DISASSEMBLY OF REAR PUMP 947

DISASSEMBLY OF REAR SHAFT 947

ASSEMBLY PROCEDURES 948

INSTALLATION OF REAR SERVO PISTON 949

INSTALLATION OF REAR COVER 951

INSTALLATION OF REAR SHAFT 952

ASSEMBLY OF REAR ROCKER CAM 953

INSTALLATION OF REAR CYLINDER BLOCK AND PISTON 954

ASSEMBLY OF END CAP 955

ASSEMBLY OF FRONT COVER 957

INSTALLATION OF FRONT OIL SEAL 957

INSTALLATION OF END CAP 957

INSTALLATION OF REAR PUMP 958

INSTALLATION OF ACCESSORIES 959

WORK EQUIPMENT PUMP OVERHAUL PROCEDURES 960

DISASSEMBLY PROCEDURES 960

PUMP 960

(PC VALVE) 961

(LS VALVE) 961

REMOVAL OF END CAP 962

DISASSEMBLY OF CYLINDER BLOCK AND PISTON 962

DISASSEMBLY OF SHAFT ASSEMBLY 963

DISASSEMBLY OF ROCKER CAM 965

REMOVAL OF BALLS AND PISTON 965

ASSEMBLY PROCEDURES 967

INSTALLATION OF PUMP CASE 967

INSTALLATION OF ROCKER CAM 967

ASSEMBLY AND INSTALLATION OF SHAFT 968

INSTALLATION OF OIL SEAL 969

INSTALLATION OF CYLINDER BLOCK AND PISTON 970

INSTALLATION OF END CAP 971

ASSEMBLY OF SERVO VALVE 971

INSTALLATION OF SERVO VALVE ASSEMBLY 973

REMOVAL 974

INSTALL 975

CHARGE PUMP OVERHAUL PROCEDURES 976

TOOLS REQUIRED 976

DISASSEMBLY PROCEDURES 976

INSPECT PARTS FOR WEAR 980

ASSEMBLY PROCEDURES 982

GENERAL NOTES 982

PLACING PUMP BACK INTO SERVICE 987

DIESEL ENGINE OVERHAUL PROCEDURES 988

DISASSEMBLY OF EXTERNAL COMPONENTS 988

PREPARATION WORK 988

STARTING MOTOR 989

ENGINE SLING BRACKET ON REAR SIDE 989

FAN PULLEY 989

VIBRATION DAMPER AND CRANKSHAFT PULLEY 989

BELT TENSIONER 990

FAN HUB 990

ALTERNATOR 990

THERMOSTAT 991

WATER PUMP 991

TURBOCHARGER AND EXHAUST MANIFOLD 991

FUEL FILTER ASSEMBLY 992

WIRING HARNESS ASSEMBLY 992

FUEL PIPING AND COMMON RAIL 993

DISASSEMBLY OF ENGINE TOP END 994

INTAKE MANIFOLD 994

VALVE COVER HOUSING 994

ROCKER ARM ASSEMBLY AND CROSSHEAD 995

PUSH RODS 995

FUEL INJECTORS 995

CYLINDER HEAD 996

REMOVAL OF OIL COOLER, ENGINE CONTROLLER AND FUEL PUMP 998

OIL COOLER 998

ENGINE CONTROLLER 998

FUEL SUPPLY PUMP 999

DISASSEMBLY OF ENGINE LOWER END 1000

FLYWHEEL 1000

REAR OIL SEAL 1000

FLYWHEEL HOUSING 1001

OIL PAN 1001

FRONT COVER 1001

OIL PUMP 1002

CAMSHAFT 1002

GEAR HOUSING 1003

PISTONS AND CONNECTING RODS 1003

CRANKSHAFT 1004

PISTON COOLING NOZZLES 1006

TAPPETS 1006

CYLINDER BLOCK 1006

ASSEMBLY OF ENGINE LOWER END 1007

PREPARATION WORK 1007

TAPPETS 1007

PISTON COOLING NOZZLE 1007

CRANKSHAFT 1008

MAIN CAP MOUNTING BOLTS 1009

PISTON AND CONNECTING ROD ASSEMBLY 1010

GEAR HOUSING 1014

CAMSHAFT 1015

FLYWHEEL HOUSING 1016

REAR OIL SEAL 1017

FLYWHEEL 1018

OIL PUMP 1019

FRONT COVER 1020

OIL PAN 1021

VIBRATION DAMPER 1022

INSTALLATION OF OIL COOLER, ENGINE CONTROLLER AND FUEL PUMP 1023

FUEL SUPPLY PUMP 1023

ENGINE CONTROLLER 1023

OIL COOLER 1023

CYLINDER HEAD 1025

FUEL INJECTORS 1027

PUSH RODS 1028

ROCKER ARM ASSEMBLY 1028

ADJUSTING VALVE CLEARANCE 1028

VALVE COVER HOUSING 1029

AIR INTAKE MANIFOLD COVER 1030

ASSEMBLY OF EXTERNAL COMPONENTS 1032

PREPARATION WORK 1032

HARNESS ASSEMBLY 1032

FUEL FILTER ASSEMBLY 1032

EXHAUST MANIFOLD AND TURBOCHARGER 1032

WATER PUMP 1033

THERMOSTAT 1033

ALTERNATOR 1034

FAN HUB 1034

BELT TENSIONER 1035

FAN PULLEY 1035

ENGINE SLING BRACKET ON REAR SIDE 1035

STARTER MOTOR 1035

REFILLING WITH OIL 1036

TRACK SYSTEM 1038

SPREADING THE TRACK 1038

(CONVENTIONAL TYPE TRACK SHOE) 1038

Whole disassembly 1062

Whole assembly 1065

1 When recycling for lubricated track 1065

WHOLE DISASSEMBLY AND ASSEMBLY OF TRACK SHOE (PLUS TYPE TRACK SHOE) 1061

Special tools 1061

FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK (CONVENTIONAL TYPE TRACK SHOE) 1075

Special tools 1075

Disassembly 1075

Assembly 1077

FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK (PLUS TYPE TRACK SHOE) 1083

Special tools 1083

Disassembly 1084

Assembly 1088

TRACK FRAME 1091

REMOVAL OF TRACK FRAME 1091

REMOVING TRACKS 1091

TRACK FRAME REMOVAL PREPARATIONS 1094

LIFTING TRACK FRAME FROM MACHINE 1096

FRONT TRACK IDLER 1100

REMOVING FRONT IDLER 1100

PULLING IDLER FROM TRACK FRAME 1101

INSTALLING FRONT IDLER 1103

TRACK ROLLER 1104

REMOVAL 1104

INSTALLATION 1104

TRACK ROLLER OVERHAUL PROCEDURES 1105

DISASSEMBLY 1105

ASSEMBLY 1106

CARRIER ROLLER OVERHAUL PROCEDURES 1110

DISASSEMBLY 1110

ASSEMBLY 1111

FINAL DRIVE 1112

FINAL DRIVE REMOVAL 1112

INSTALLING THE FINAL DRIVE 1116

FINAL DRIVE OVERHAUL PROCEDURES 1118

DISASSEMBLY PROCEDURES 1118

DRAINING OIL 1118

COVER 1119

RING GEAR 1119

NO 1 PLANETARY CARRIER ASSEMBLY 1120

NO 1 SUN GEAR 1120

NO 2 SUN GEAR 1120

NO 2 PLANETARY CARRIER ASSEMBLY 1121

HUB ASSEMBLY 1122

NO 2 PLANETARY CARRIER (HST MOTOR ASSEMBLY) 1123

ASSEMBLY OF FINAL DRIVE 1124

NO 2 PLANETARY CARRIER (HST MOTOR ASSEMBLY) 1124

ASSEMBLY OF HUB 1124

NO 2 PLANETARY CARRIER ASSEMBLY 1127

NO 2 SUN GEAR 1128

NO 1 SUN GEAR 1128

NO 1 PLANETARY CARRIER ASSEMBLY 1128

RING GEAR 1129

COVER 1130

REFILLING WITH OIL 1130

TRAVEL MOTOR OVERHAUL PROCEDURES 1132

DISASSEMBLY PROCEDURES 1132

TRAVEL MOTOR 1132

REMOVAL OF END COVER 1132

DISASSEMBLY OF END COVER 1133

REMOVAL OF RELIEF VALVE 1133

DISASSEMBLY OF SHUTTLE VALVE 1134

REMOVAL OF CYLINDER BLOCK 1134

REMOVAL OF PISTONS 1134

DISASSEMBLY OF BRAKE AND PISTON 1135

REMOVAL AND DISASSEMBLY OF DRIVE SHAFT 1135

REMOVAL OF OIL SEAL 1136

ASSEMBLY PROCEDURES 1137

INSTALLATION OF MOTOR CASE 1137

Install of oil seal 1137

ASSEMBLY OF DRIVE SHAFT 1143

ASSEMBLY OF PISTONS 1144

INSTALLATION OF DRIVE SHAFT ASSEMBLY 1144

INSTALLATION OF DISCS AND PLATES 1145

INSTALLATION OF BRAKE PISTON 1145

ASSEMBLY OF END COVER 1145

ASSEMBLY OF SHUTTLE VALVE 1146

ASSEMBLY OF MAIN PISTON 1146

INSTALLATION OF MAIN VALVE 1147

INSTALLATION OF VALVE PLATE 1147

NSTALLATION OF END COVER 1148

CHECK OF SHAFT ROTATION TORQUE 1149

FAN MOTOR 1150

REMOVAL PROCEDURES 1150

DISCONNECTING THE GRILL FROM THE FAN 1150

DISCONNECTING HYDRAULIC FAN MOTOR 1151

REMOVING THE FAN GUARD 1152

REMOVING THE FAN MOTOR 1153

INSTALLATION PROCEDURES 1154

FAN MOTOR OVERHAUL PROCEDURES 1156

DISASSEMBLY PROCEDURES 1156

REMOVAL OF END COVER 1156

DISASSEMBLY OF END COVER 1156

DISASSEMBLY OF PILOT VALVE 1157

CYLINDER BLOCK, SHAFT AND PISTON 1158

DISASSEMBLY OF CYLINDER BLOCK AND PISTON 1158

DISASSEMBLY OF SHAFT 1159

DISASSEMBLY OF MOTOR CASE 1159

ASSEMBLY PROCEDURES 1160

INSTALLATION OF MOTOR CASE 1160

ASSEMBLY AND INSTALLATION OF SHAFT 1160

ASSEMBLY OF CYLINDER BLOCK AND PISTON 1161

INSTALLATION OF CYLINDER BLOCK AND PISTON 1162

INSTALLATION OF OIL SEAL 1163

ASSEMBLY OF END COVER 1163

INSTALLATION OF END COVER 1165

CHECK OF SHAFT ROTATION TORQUE 1166

DB 12 VALVE 1168

REMOVAL 1168

INSTALLATION 1171

COOLING PACKAGE 1172

REMOVING THE GRILL AND COOLING FAN ASSEMBLY 1172

REMOVING THE GRILL FRAME 1172

REMOVING THE COOLING FAN ASSEMBLY 1179

REMOVING THE COOLING PACKAGE 1183

REMOVING THE FAN SHROUD 1183

REMOVING THE RADIATOR 1186

REMOVING THE OIL COOLER 1188

REMOVING THE AIR CHARGE COOLER 1189

INSTALLING THE COOLING PACKAGE 1191

INSTALLING THE GRILL AND COOLING FAN ASSEMBLY 1192

FUEL TANK 1196

REMOVING THE FUEL TANK 1196

PREPARATIONS FOR REMOVAL 1196

LIFTING THE FUEL TANK OFF THE MACHINE 1199

INSTALLING THE FUEL TANK 1200

HYDRAULIC TANK 1201

REMOVING THE HYDRAULIC TANK 1201

PREPARATIONS FOR REMOVAL 1201

LIFTING THE HYDRAULIC TANK OFF THE MACHINE 1205

INSTALLING THE HYDRAULIC TANK 1207

WORK EQUIPMENT 1208

REMOVING OR INSTALLING PINS 1208

FRONT BLADE, TILT AND ANGLE CYLINDERS 1209

REMOVAL 1209

ADJUSTING BLADE CENTER BALL AND PITCH ROD PLAY 1214

PITCH ROD 1214

CENTER BALL 1215

INSTALLATION 1215

“C” FRAME 1216

REMOVAL 1216

INSTALLATION 1218

LIFT CYLINDERS 1219

REMOVAL 1219

INSTALLATION 1220

CYLINDER OVERHAUL PROCEDURES 1221

DISASSEMBLY PROCEDURES 1221

PISTON AND ROD 1221

PISTON AND HEAD ASSEMBLY 1222

DISASSEMBLY OF GLAND NUT 1222

ASSEMBLY PROCEDURES 1222

GLAND NUT ASSEMBLY AND PISTON ASSEMBLY 1222

DISASSEMBLY OF PISTON 1223

PISTON ROD ASSEMBLY 1224

EXPANSION AND INSTALLATION OF TRACK SHOE ASSEMBLY 1040

(PLUS TYPE TRACK SHOE) 1040

Expansion normal 1040

Installation 1040

WHOLE DISASSEMBLY AND ASSEMBLY OF TRACK SHOE ASSEMBLY (CONVENTIONAL TYPE TRACK SHOE) 1041

Special tools 1041

Whole disassembly 1041

Whole assembly 1046

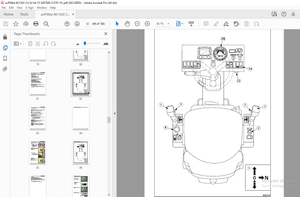

90 OTHERS 1225

CONNECTOR ARRANGEMENT DRAWING AND ELECTRICAL CIRCUIT DIAGRAM 1227

CONNECTOR LIST 1227

CONNECTOR LOCATION VIEW 1231

CAB ELECTRICAL ACCESSORIES 1245

AIR CONDITIONER AND HEATER UNIT 1247

HYDRAULIC SYSTEM 1249

VIEW (1 OF 2) 1249

VIEW (2 OF 2) 1251

ELECTRICAL DIAGRAMS 0

IN CAB SWITCHES, RELAYS AND CONNECTORS (VIEW 1 OF 5) 1253

CAB HARNESS AND CONTROLLER CONNECTIONS (VIEW 2 OF 5 ) 1255

ENGINE HARNESS AND CONTROLLER (VIEW 3 OF 5) 1257

MONITOR PANEL AND SWITCHES (VIEW 4 OF 5) 1259

KOMTRAX AND CONNECTORS (VIEW 5 OF 5) 1261

CONVENTIONAL iB WIRING DIAGRAM (1 OF 2) 1263

CONVENTIONAL iB WIRING DIAGRAM (2 OF 2) 1265

IMAGES PREVIEW OF THE MANUAL: