$40

Komatsu D65EX-15E0, D65PX-15E0, D65WX-15E0 Galeo Bulldozer (69001 and up) Shop Manual PDF DOWNLOA

Komatsu D65EX-15E0, D65PX-15E0, D65WX-15E0 Galeo Bulldozer (69001 and up) Shop Manual

FILE DETAILS:

Komatsu D65EX-15E0, D65PX-15E0, D65WX-15E0 Galeo Bulldozer (69001 and up) Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : SEN00046-02

Total Pages : 1106

DESCRIPTION:

Komatsu D65EX-15E0, D65PX-15E0, D65WX-15E0 Galeo Bulldozer (69001 and up) Shop Manual

HOW TO READ THE SHOP MANUAL:

1. Composition of shop manual:

This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword:

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification:

This section explains the specifications of the machine.

10. Structure, function and maintenance standard:

This section explains the structure, function, and maintenance standard values of each component. The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

20. Standard value table:

This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

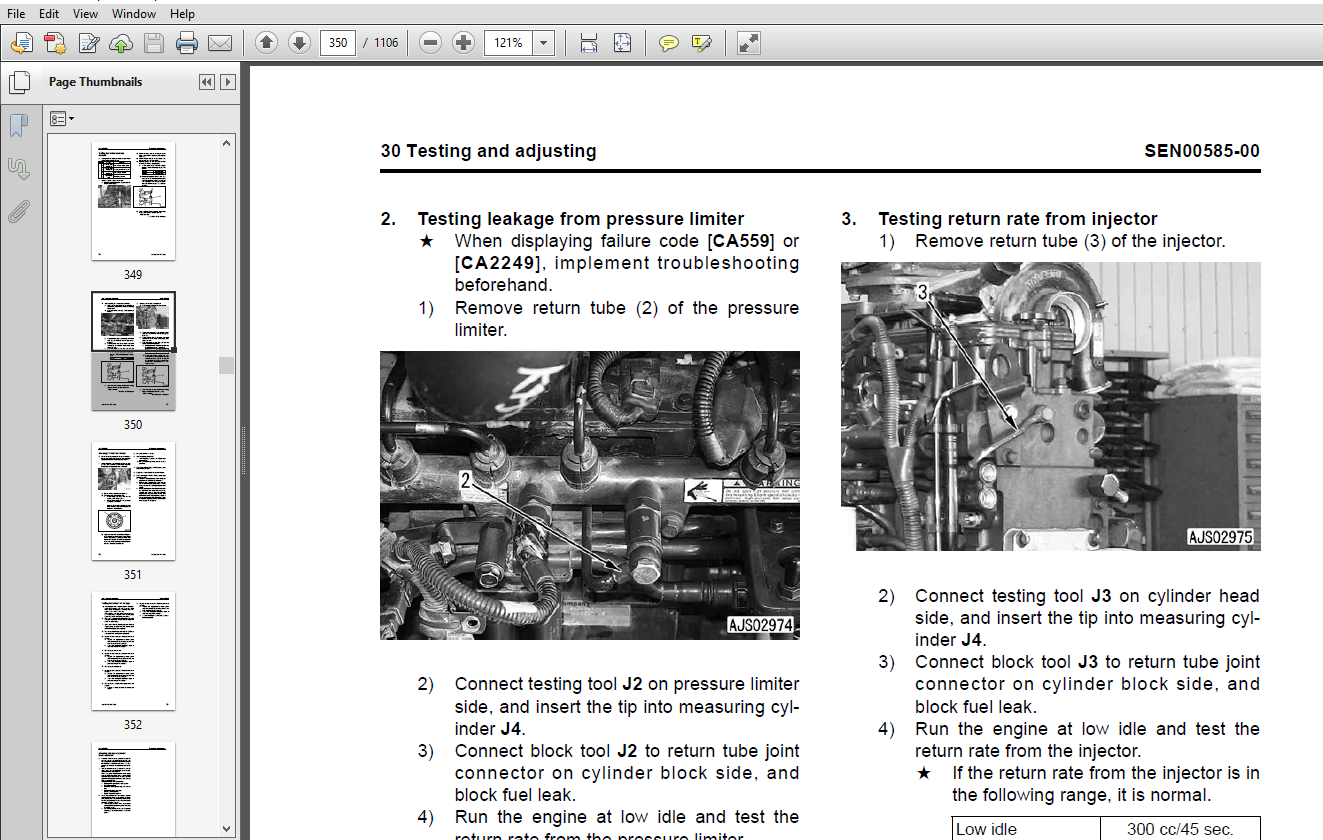

30. Testing and adjusting:

This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

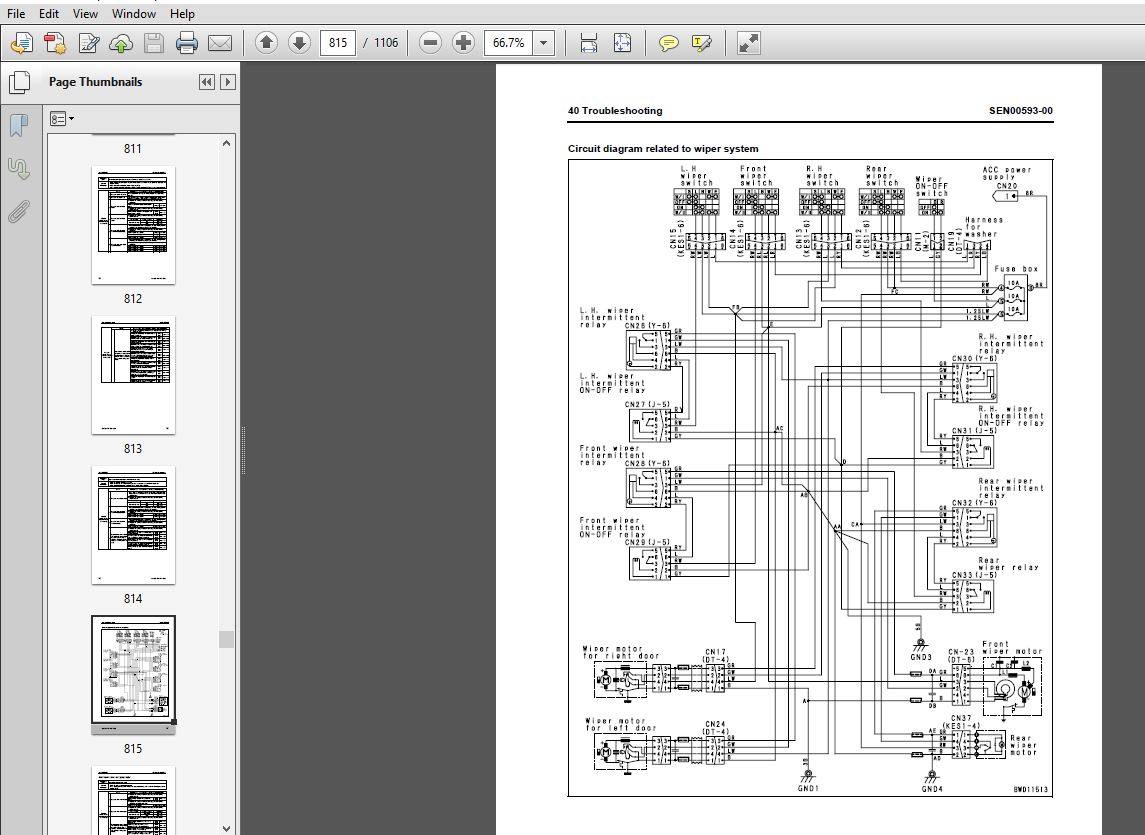

40. Troubleshooting:

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly:

This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume):

- Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams. - Engine volume

This section explains the method of reproducing, repairing, and replacing parts.

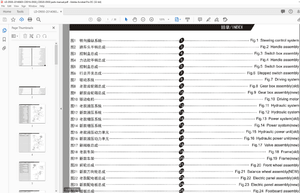

TABLE OF CONTENTS:

Komatsu D65EX-15E0, D65PX-15E0, D65WX-15E0 Galeo Bulldozer (69001 and up) Shop Manual

COVER........................................................................................................................................ 1 00 INDEX AND FOREWORD........................................................................................................................ 0 INDEX.................................................................................................................................... 2 ORGANIZATION LIST OF THE SHOP MANUAL................................................................................................. 3 TABLE OF CONTENTS.................................................................................................................... 5 FOREWORD AND GENERAL INFORMATION......................................................................................................... 16 SAFETY NOTICE........................................................................................................................ 17 HOW TO READ THE SHOP MANUAL.......................................................................................................... 21 EXPLANATION OF TERMS FOR MAINTENANCE STANDARD........................................................................................ 23 HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENT.................................................................................. 25 HOW TO READ ELECTRIC WIRE CODE....................................................................................................... 33 METHOD OF DISASSEMBLING AND CONNECTING PUSH-PULL TYPE COUPLER........................................................................ 36 STANDARD TIGHTERING TORQUE TABLE..................................................................................................... 39 CONVERSION TABLE..................................................................................................................... 43 01 SPECIFICATION............................................................................................................................. 0 SPECIFIICATION AND TECHNICAL DATA........................................................................................................ 49 SPECIFICATION DIMENSIONS............................................................................................................. 50 SPECIFICATIONS....................................................................................................................... 51 WEIGHT TABLE......................................................................................................................... 56 TABLE OF FUEL, COOLANT AND LUBRICANTS................................................................................................ 58 10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD.............................................................................................. 0 ENGINE AND COOLING SYSTEM................................................................................................................ 62 COOLING SYSTEM....................................................................................................................... 62 COOLING FAN PUMP..................................................................................................................... 64 COOLING FAN MOTOR.................................................................................................................... 72 POWER TRAIN, PART 1...................................................................................................................... 79 POWER TRAIN.......................................................................................................................... 80 HSS SYSTEM........................................................................................................................... 82 GENERAL VIEW OF POWER TRAIN UNIT..................................................................................................... 84 POWER TRAIN HYDRAULIC PIPING DRAWING................................................................................................. 86 TRANSMISSION, STEERING AND BRAKE CONTROL............................................................................................. 87 DAMPER AND UNIVERSAL JOINT........................................................................................................... 89 TORQUE CONVERTER AND PTO............................................................................................................. 91 TRANSMISSION......................................................................................................................... 96 TRANSMISSION CLUTCH ECMV............................................................................................................. 107 MAIN RELIEF VALVE AND TORQUE CONVERTER RELIEF VALVE.................................................................................. 113 LUBRICATION RELIEF VALVE............................................................................................................. 115 POWER TRAIN, PART 2...................................................................................................................... 117 BEVEL GEAR SHAFT, HASS AND BRAKE..................................................................................................... 118 BRAKE VALVE.......................................................................................................................... 133 FINAL DRIVE.......................................................................................................................... 138 UNDERCARRIAGE AND FRAME.................................................................................................................. 144 MAIN FRAME........................................................................................................................... 145 SUSPENSION........................................................................................................................... 147 TRACK FRAME AND IDLER CUSHION........................................................................................................ 153 IDLER................................................................................................................................ 157 TRACK ROLLER......................................................................................................................... 159 CARRIER ROLLER....................................................................................................................... 160 SPROCKET............................................................................................................................. 161 TRACK SHOE........................................................................................................................... 163 HYDRAULIC SYSTEM, PART 1................................................................................................................. 167 WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM.............................................................................................. 168 WORK EQUIPMENT CONTROL............................................................................................................... 170 HYDRAULIC TANK AND FILTER............................................................................................................ 172 SCAVENGING PUMP...................................................................................................................... 174 POWER TRAIN AND STEERING LUBRICATION PUMP............................................................................................ 175 HSS PUMP............................................................................................................................. 176 HSS MOTOR............................................................................................................................ 194 HYDRAULIC SYSTEM, PART 2................................................................................................................. 202 CONTROL VALVE........................................................................................................................ 203 SELF PRESSURE REDUCING VALVE......................................................................................................... 235 HYDRAULIC SYSTEM, PART 3................................................................................................................. 243 PPC VALVE (BLADE LIFT, BLADE TILT)................................................................................................... 244 PPC VALVE (RIPPER)................................................................................................................... 250 ELECTRIC LEVER (STEERING)............................................................................................................ 254 QUICK DROP VALVE..................................................................................................................... 257 PPC LOCK VALVE....................................................................................................................... 259 ACCUMULATOR.......................................................................................................................... 260 WORK EQUIPMENT........................................................................................................................... 262 BLADE................................................................................................................................ 263 CUTTING EDGE AND END BIT............................................................................................................. 267 RIPPER............................................................................................................................... 268 HYDRAULIC CYLINDER................................................................................................................... 269 PISTON VALVE......................................................................................................................... 272 CAB AND ITS ATTACHMENTS.................................................................................................................. 274 CAB MOUNT............................................................................................................................ 275 CAB.................................................................................................................................. 276 AIR CONDITIONER...................................................................................................................... 278 ELECTRICAL SYSTEM........................................................................................................................ 280 MONITOR SYSTEM....................................................................................................................... 281 MONITOR PANEL........................................................................................................................ 283 ENGINE CONTROL....................................................................................................................... 287 ENGINE CONTROL SYSTEM ............................................................................................................... 288 COOLING SYSTEM CONTROL SYSTEM........................................................................................................ 290 SYSTEM COMPONENTS.................................................................................................................... 292 PALM COMMAND CONTROL SYSTEM.......................................................................................................... 301 KOMTRAX TERMINAL SYSTEM.............................................................................................................. 303 KOMTRAX TERMINAL..................................................................................................................... 304 SENSOR .............................................................................................................................. 305 20 STANDARD VALUE TABLE...................................................................................................................... 0 STANDARD SERVICE VALUE TABLE............................................................................................................ 309 STANDARD SERVICE VALUE TABLE FOR ENGINE.............................................................................................. 310 STANDARD SERVICE VALUE TABLE FOR CHASSIS............................................................................................. 311 30 TESTING AND ADJUSTING .................................................................................................................... 0 TESTING AND ADJUSTING, PART 1............................................................................................................ 324 TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING ................................................................................... 326 MEASURING ENGINE SPEED............................................................................................................... 328 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)....................................................................................... 330 MEASURING EXHAUST TEMPERATURE........................................................................................................ 332 MEASURING EXHAUST GAS COLOR.......................................................................................................... 334 ADJUSTING VALVE CLEARANCE............................................................................................................ 335 MEASURING COMPRESSION PRESSURE....................................................................................................... 338 MEASURING BLOW-BY PRESSURE........................................................................................................... 342 MEASURING ENGINE OIL PRESSURE........................................................................................................ 343 HANDLING OF FUEL SYSTEM DEVICES...................................................................................................... 344 RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM......................................................................................... 344 TESTING FUEL PRESSURE................................................................................................................ 345 TESTING FUEL RETURN AND LEAK AMOUNT.................................................................................................. 349 BLEEDING AIR FROM FUEL CIRCUIT....................................................................................................... 351 TESTING FUEL CIRCUIT FOR LEAKAGE..................................................................................................... 352 HANDLING OF REDUCED CYLINDER MODE OPERATION.......................................................................................... 353 TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION........................................................................ 354 ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL.................................................................................... 355 MEASURING POWER TRAIN OIL PRESSURE................................................................................................... 357 ADJUSTING TRANSMISSION SPEED SENSOR (REPLACEMENT PROCEDURE).......................................................................... 361 SIMPLE METHOD TO TEST BRAKE PERFORMANCE.............................................................................................. 362 ADJUSTING BRAKE PEDAL................................................................................................................ 363 ADJUSTING PARKING BRAKE LEVER........................................................................................................ 365 EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE................................................................................. 366 ADJUSTING CLEARANCE OF IDLER......................................................................................................... 369 INSPECTING WEAR OF SPROCKET.......................................................................................................... 370 TESTING AND ADJUSTING TRACK SHOE TENSION............................................................................................. 370 TESTING AND ADJUSTING WORK EQUIPMENT AND HSS OIL PRESSURE............................................................................ 371 TESTING CONTROL CIRCUIT BASIC PRESSURE............................................................................................... 374 MEASURING PPC VALVE OUTPUT PRESSURE.................................................................................................. 375 ADJUSTING PLAY OF WORK EQUIPMENT PPC VALVE........................................................................................... 377 MEASURING INTERNAL LEAKAGE OF WORK EQUIPMENT CYLINDER................................................................................ 378 BLEEDING AIR FROM WORK EQUIPMENT CYLINDER............................................................................................ 378 RELEASING RESIDUAL PRESSURE IN WORK EQUIPMENT CYLINDER............................................................................... 379 CHECKING PARTS WHICH CAUSED HYDRAULIC DRIFT OF BLADE OR RIPPER....................................................................... 380 ADJUSTING WORK EQUIPMENT LOCK LEVEL.................................................................................................. 381 MEASURING FAN MOTOR SPEED............................................................................................................ 382 MEASURING FAN PUMP CIRCUIT PRESSURE.................................................................................................. 383 BLEEDING AIR FROM FAN PUMP........................................................................................................... 384 ADJUSTING STRAIGHT TILTDOZER......................................................................................................... 385 TESTING AND ADJUSTING OPERATOR CAB................................................................................................... 387 TESTING AND ADJUSTING, PART 2............................................................................................................ 392 SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS)............................................................................................ 393 TESTING AND ADJUSTING, PART 3............................................................................................................ 436 HANDLING OF VOLTAGE CIRCUIT OF ENGINE CONTROLLER..................................................................................... 437 ADJUSTMENT METHOD WHEN CONTROLLER HAS BEEN REPLACED.................................................................................. 437 PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM............................................................................. 439 INSPECTION PROCEDURE OF DIODE........................................................................................................ 444 PM-CLINIC SERVICE.................................................................................................................... 445 HOW TO START OPERATION OF KOMTRAX TERMINAL........................................................................................... 455 LAMP DISPLAY OF KOMTRAX TERMINAL..................................................................................................... 459 40 TROUBLESHOOTING........................................................................................................................... 0 GENERAL INFORMATION ON TROUBLESHOOTING................................................................................................... 463 POINTS TO REMEMBER WHEN TROUBLESHOOTING ............................................................................................. 464 HOW TO PROCEED TROUBLESHOOTING....................................................................................................... 465 CHECKS BEFORE TROUBLESHOOTING........................................................................................................ 466 CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING..................................................................................... 467 HOW TO DISTINGUISH WIRE CODE......................................................................................................... 470 WIRING TABLE FOR CONNECTOR PIN NUMBERS............................................................................................... 474 T-ADAPTER BOX AND T-ADAPTER TABLE.................................................................................................... 497 TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE), PART 1................................................................................ 502 FAILURE CODE TABLE................................................................................................................... 504 BEFORE TROUBLESHOOTING BY FAILURE CODES.............................................................................................. 511 CONTENTS OF TROUBLESHOOTING TABLE.................................................................................................... 513 FAILURE CODE [1500L0] TRANSMISSION CLUTCH: DUAL ENGAGEMENT........................................................................... 515 FAILURE CODE [15SAL1] FORWARD CLUTCH: FILL SIGNAL IS ON WHEN COMMAND CURRENT IS OFF.................................................. 516 FAILURE CODE [15SALH] FORWARD CLUTCH: FILL SIGNAL IS OFF WHEN COMMAND CURRENT IS ON.................................................. 518 FAILURE CODE [15SBL1] REVERSE CLUTCH: FILL SIGNAL IS ON WHEN COMMAND CURRENT IS OFF.................................................. 520 FAILURE CODE [15SBLH] REVERSE CLUTCH: FILL SIGNAL IS OFF WHEN COMMAND CURRENT IS ON.................................................. 522 FAILURE CODE [15SEL1] 1ST CLUTCH: FILL SIGNAL IS ON WHEN COMMAND CURRENT IS OFF...................................................... 524 FAILURE CODE [15SELH] 1ST CLUTCH: FILL SIGNAL IS OFF WHEN COMMAND CURRENT IS ON...................................................... 525 FAILURE CODE [15SFL1] 2ND CLUTCH: FILL SIGNAL IS ON WHEN COMMAND CURRENT IS OFF...................................................... 526 FAILURE CODE [15SFLH] 2ND CLUTCH: FILL SIGNAL IS OFF WHEN COMMAND CURRENT IS ON...................................................... 528 FAILURE CODE [15SGL1] 3RD CLUTCH: FILL SIGNAL IS ON WHEN COMMAND CURRENT IS OFF...................................................... 530 FAILURE CODE [15SGLH] 3RD CLUTCH: FILL SIGNAL IS OFF WHEN COMMAND CURRENT IS ON...................................................... 532 FAILURE CODE [AB00MA] ALTERNATOR: MALFUNCTION ....................................................................................... 534 FAILURE CODE [B@BAZG] ENGINE OIL: OIL PRESSURE TOO LOW............................................................................... 534 FAILURE CODE [B@BCNS] RADIATOR COOLANT: OVERHEAT..................................................................................... 535 FAILURE CODE [B@CENS] POWER TRAIN OIL: OVERHEAT...................................................................................... 535 FAILURE CODE [B@HANS] HYDRAULIC OIL: OVERHEAT........................................................................................ 536 FAILURE CODE [CA111] ENGINE CONTROLLER: ABNORMALITY IN CONTROLLER.................................................................... 537 FAILURE CODE [CA115] ABNORMAL ENGINE NE AND BKUP SPEED SENSORS: ABNORMAL SPEED SENSOR SIGNAL......................................... 537 FAILURE CODE [CA122] CHARGE PRESSURE SENSOR TOOL HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED............................................. 538 FAILURE CODE [CA123] CHARGE PRSSURE SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED................................................. 540 FAILURE CODE [CA131] DECELERATOR PEDAL SENSOR TOOL HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED........................................... 542 FAILURE CODE [CA132] DECELERATOR PEDAL SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED.............................................. 544 FAILURE CODE [CA144] COOLANT TEMPERATURE SENSOR TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED.......................................... 546 FAILURE CODE [CA145] COOLANT TEMPERATURE SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED............................................ 548 FAILURE CODE [CA153] CHARGE TEMPERATURE SENSOR TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED........................................... 550 FAILURE CODE [CA154] CHARGE TEMPERATURE SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED............................................. 552 FAILURE CODE [CA155] CHARGE TEMPERATURE SENSOR TOO HIGH AND ENGINE SPEED DERATED: EXCEEDED UPPER CONTROL LIMIT OF TEMPERATURE........ 554 FAILURE CODE [CA187] SENSOR POWER SOURCE 2 TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED................................................. 555 FAILURE CODE [CA221] ATMOSPHERIC PRESSURE SENSOR TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED......................................... 557 FAILURE CODE [CA222] ATMOSPHERIC PRESSURE SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED........................................... 559 FAILURE CODE [CA227] SENSOR POWER SOURCE 2 TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED............................................... 561 FAILURE CODE [CA234] ENGINE OVER SPEED: EXCESSIVELY HIGH SPEED....................................................................... 563 FAILURE CODE [CA238] ABNORMAL POWER SOURCE FOR NE SPEED SENSOR: EXCESSIVELY LOW VOLTAGE DETECTED..................................... 564 FAILURE CODE [CA271] IMV/PCV1 SHORT CIRCUIT: SHORT CIRCUIT........................................................................... 565 FAILURE CODE [CA272] IMV/PCV1 DISCONNECTION: DISCONNECTION........................................................................... 567 FAILURE CODE [CA281] ABNORMAL SUPPLY PUMP PRESSURE BALANCE: ABNORMAL PRESSURE FEED OF FUEL........................................... 569 TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE), PART 2................................................................................ 571 FAILURE CODE [CA322] INJECTOR NO.1 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 573 FAILURE CODE [CA323] INJECTOR NO.5 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 575 FAILURE CODE [CA324] INJECTOR NO.3 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 577 FAILURE CODE [CA325] INJECTOR NO.6 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 579 FAILURE CODE [CA331] INJECTOR NO.2 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 581 FAILURE CODE [CA332] INJECTOR NO.4 SYSTEM DISCONNECTION OR SHORT CIRCUIT: DISCONNECTION, SHORT CIRCUIT............................... 583 FAILURE CODE [CA342] ENGINE CONTROLLER DATA MATCHING ERROR: MATCHING ERROR........................................................... 585 FAILURE CODE [CA352] SENSOR POWER SOURCE 1 TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED................................................. 586 FAILURE CODE [CA386] SENSOR POWER SOURCE 1 TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED............................................... 588 FAILURE CODE [CA428] WATER DETECTION SENSOR TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED.............................................. 589 FAILURE CODE [CA429] WATER DETECTION SENSOR TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED................................................ 591 FAILURE CODE [CA435] ABNORMAL ENGINE OIL PRESSURE SWITCH: ABNORMAL SIGNAL CIRCUIT.................................................... 593 FAILURE CODE [CA441] POWER SOURCE VOLTAGE TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED.................................................. 595 FAILURE CODE [CA442] POWER SOURCE VOLTAGE TOO HIGH: EXCESSIVELY HIGH VOLTAGE HAS OCCURRED IN THE CONTROLLER POWER SOURCE CIRCUIT..... 597 FAILURE CODE [CA449] COMMON RAIL PRESSURE TOO HIGH (2): EXCESSIVELY HIGH PRESSURE TROUBLE OCCURRED................................... 599 FAILURE CODE [CA451] COMMON RAIL PRESSURE TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED................................................ 602 FAILURE CODE [CA452] COMMON RAIL PRESSURE TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED.................................................. 604 FAILURE CODE [CA488] CHARGE TEMPERATURE TOO HIGH AND TORQUE DERATED: EXCEEDED UPPER CONTROL LIMIT OF TEMPERATURE..................... 606 FAILURE CODE [CA553] COMMON RAIL PRESSURE TOO HIGH (1): EXCESSIVELY HIGH PRESSURE DETECTED........................................... 607 FAILURE CODE [CA559] LOSS OF PRESSURE FEED FROM SUPPLY PUMP (1): LOSS OF PRESSURE FEED DETECTED...................................... 608 FAILURE CODE [CA689] ABNORMAL ENGINE NE SPEED SENSOR: ABNORMAL SIGNAL ............................................................... 610 FAILURE CODE [CA731] ABNORMAL ENGINE BKUP SPEED SENSOR PHASE: ABNORMAL PHASE......................................................... 612 FAILURE CODE [CA757] LOSS OF ALL ENGINE CONTROLLER DATA: LOSS OF ALL DATA............................................................ 613 FAILURE CODE [CA778] ABNORMAL ENGINE BKUP SPEED SENSOR: ABNORMAL BKUP SIGNAL......................................................... 615 FAILURE CODE [CA1633] ABNORMAL KOMNET: ABNORMAL COMMUNICATION........................................................................ 617 FAILURE CODE [CA2185] DECELERATOR PEDAL SENSOR POWER SOURCE TOO HIGH: EXCESSIVELY HIGH VOLTAGE DETECTED.............................. 619 FAILURE CODE [CA2186] DECELERATOR PEDAL SENSOR POWER SOURCE TOO LOW: EXCESSIVELY LOW VOLTAGE DETECTED................................ 620 FAILURE CODE [CA2249] LOSS OF PRESSURE FEED FROM SUPPLY PUMP (2): LOSS OF PRESSURE FEED DETECTED..................................... 621 FAILURE CODE [CA2265] ELECTRIC LIFT PUMP DISCONNECTION: DISCONNECTION ............................................................... 622 FAILURE CODE [CA2266] ELECTRIC LIFT PUMP SHORT CIRCUIT: SHORT CIRCUIT................................................................ 624 FAILURE CODE [CA2311] ABNORMAL IMV SOLENOID: ABNORMAL RESISTANCE..................................................................... 626 FAILURE CODE [CA2555] AIR INTAKE HEATER RELAY DISCONNECTION: DISCONNECTION........................................................... 628 FAILURE CODE [CA2556] AIR INTAKE HEATER RELAY SHORT CIRCUIT: SHORT CIRCUIT........................................................... 630 TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE), PART 3................................................................................ 633 FAILURE CODE [D110KA] BATTERY RELAY: SHORT CIRCUIT................................................................................... 635 FAILURE CODE [D110KB] BATTERY RELAY: DISCONNECTION................................................................................... 637 FAILURE CODE [D130KA] NEUTRAL SAFELY RELAY: DISCONNECTION............................................................................ 639 FAILURE CODE [D130KB] NEUTRAL SAFELY RELAY: SHORT CIRCUIT............................................................................ 641 FAILURE CODE [D161KA] BACK-UP ALARM RELAY: DISCONNECTION............................................................................. 643 FAILURE CODE [D161KB] BACK-UP ALARM RELAY: SHORT CIRCUIT............................................................................. 645 FAILURE CODE [DAFRKR] MONITOR PANEL CAN COMMUNICATION: DEFECTIVE COMMUNICATION....................................................... 647 FAILURE CODE [DAQ1KT] [DB30KT] STEERING AND TRANSMISSION CONTROLLER: ABNORMALITY IN CONTROLLER....................................... 649 FAILURE CODE [DAQ1KK] [DB31KK] MAIN POWER SOURCE OF STEERING AND TRANSMISSION CONTROLLER: POWER SOURCE VOLTAGE DROP AND INPUT........ 650 FAILURE CODE [DAQ2KK] [DB32KK] LOAD POWER SOURCE OF STEERING AND TRANSMISSION CONTROLLER: POWER SOURCE VOLTAGE DROP AND INPUT........ 652 FAILURE CODE [DAQ5KK] [DB35KK] STEERING AND TRANSMISSION CONTROLLER SENSOR 5 V POWER SOURCE: POWER SOURCE VOLTAGE DROP AND INPUT..... 654 FAILURE CODE [DAQ6KK] [DB36KK] STEERING AND TRANSMISSION CONTROLLER SENSOR 24V POWER SOURCE: POWER SOURCE VOLTAGE DROP AND INPUT..... 656 FAILURE CODE [DAQ9KQ] [DB39KQ] STEERING AND TRANSMISSION CONTROLLER MODEL SELECTION: INCONSISTENCY IN MODEL SELECT SIGNAL............ 658 FAILURE CODE [DB2RKR] STEERING AND TRANSMISSION CONTROLLER CAN COMMUNICATION: DEFECTIVE COMMUNICATION................................ 660 FAILURE CODE [DB30KT] [DAQ0KT] STEERING AND TRANSMISSION CONTROLLER: ABNOTMALITY IN CONTROLLER....................................... 662 FAILURE CODE [DB31KK] [DAQ1KK] MAIN POWER SOURCE OF STEERING AND TRANSMISSION CONTROLLER: POWER SOURCE VOLTAGE DROP AND INPUT........ 662 FAILURE CODE [DAB32KK] [DAQ2KK] LOAD POWER SOURCE OF STEERING AND TRANSMISSION CONTROLLER: POWER SOURCE VOLTAGE DROP AND INPUT....... 662 FAILURE CODE [DB35KK] [DAQ5KK] STEERING AND TRANSMISSION CONTROLLER SENSOR 5 V POWER SOURCE: POWER SOURCE VOLTAGE DROP AND INPUT..... 662 FAILURE CODE [DB36KK] [DAQ6KK] STEERING AND TRANSMISSION CONTROLLER SENSOR 24 V POWER SOURCE: POWER SOURCE VOLTAGE DROP AND INPUT.... 662 FAILURE CODE [DB39KQ] [DAQ9KQ] STEERING AND TRANSMISSION CONTROLLER MODEL SELECTION: INCONSISTENCY IN MODEL SELECT SIGNAL............ 662 FAILURE CODE [DD12KA] SHIFT UP SWITCH: DISCONNECTION................................................................................. 663 FAILURE CODE [DD12KB] SHIFT UP SWITCH: SHORT CIRCUIT................................................................................. 665 FAILURE CODE [DD13KA] SHIFT DOWM SWITCH: DISCONNECTION............................................................................... 667 FAILURE CODE [DD13KB] SHIFT DOWN SWITCH: SHORT CIRCUIT............................................................................... 669 FAILURE CODE [DD14KA] [DDQ2KA] PARKING BRAKE LEVER SWITCH: DISCONNECTION............................................................. 671 FAILURE CODE [DD14KB] [DDQ2KB] PARKING BRAKE LEVER SWITCH: SHORT CIRCUIT............................................................. 673 FAILURE CODE [DDN7KA] PITCH CONTROL SWITCH: DISCONNECTION............................................................................ 675 FAILURE CODE [DDN7KB] PITCH CONTROL SWITCH: SHORT CIRCUIT............................................................................ 677 FAILURE CODE [DDQ2KA] [DD14KA] PARKING BRAKE LEVER SWITCH: DISCONNECTION............................................................. 679 FAILURE CODE [DDQ2KB] [DD14KB] PARKING BRAKE LEVER SWITCH: SHORT CIRCUIT............................................................. 679 FAILURE CODE [DGS1KX] HYDRAULIC OIL TEMPERATURE SENSOR: INPUT SIGNAL IS OUT OF NORMAL RANGE.......................................... 680 FAILURE CODE [DGT1KA] POWER TRAIN OIL TEMPERATURE SENSOR: DISCONNECTION.............................................................. 682 FAILURE CODE [DGT1KX] POWER TRAIN OIL TEMPERATURE SENSOR: INPUT SIGNAL IS OUT OF NORMAL RANGE........................................ 683 FAILURE CODE [DK10KA] FUEL DIAL: DISCONNECTION....................................................................................... 684 FAILURE CODE [DK10KB] FUEL DIAL: SHORT CIRCUIT....................................................................................... 686 FAILURE CODE [DK30KA] STEERING POTENTIOMETER (1): DISCONNECTION...................................................................... 688 FAILURE CODE [DK30KB] STEERING POTENTIOMETER (1): SHORT CIRCUIT...................................................................... 690 FAILURE CODE [DK30KX] STEERING POTENTIOMETER: INPUT SIGNAL IS OUT OF NORMAL RANGE ................................................... 692 FAILURE CODE [DK30KZ] STEERING POTENTIOMETER: DISCONNECTION OF SHORT CIRCUIT (DOUBLE FAILURE)........................................ 693 FAILURE CODE [DK30L8] STEERING POTENTIOMETER: INCONSISTENT ANALOG SIGNAL............................................................. 693 FAILURE CODE [DK31KA] STEERING POTENTIOMETER (2): DISCONNECTION...................................................................... 694 FAILURE CODE [DK31KB] STEERING POTENTIOMETER (2): SHORT CIRCUIT...................................................................... 696 FAILURE CODE [DK40KA] BRAKE POTENTIOMETER: DISCONNECTION............................................................................. 698 FAILURE CODE [DK40KB] BRAKE POTENTIOMETER: SHORT CIRCUIT............................................................................. 699 FAILURE CODE [DK55KX] FORWARD-REVERSE POTENTIOMETER: INPUT SIGNAL IS OUT OF NORMAL RANGE............................................. 700 FAILURE CODE [DK55KZ] FORWARD-REVERSE POTENTIOMETER: DISCONNECTION OF SHORT CIRCUIT (DOUBLE FAILURE)................................. 701 FAILURE CODE [DK55L8] FORWARD-REVERSE POTENTIOMETER: INCONSISTENT ANALOG SIGNAL...................................................... 702 FAILURE CODE [DK56KA] FORWARD-REVERSE POTENTIOMETER (1): SHORT CIRCUIT............................................................... 703 FAILURE CODE [DK56KB] FORWARD-REVERSE POTENTIOMETER (1): DISCONNECTION............................................................... 705 FAILURE CODE [DK57KA] FORWARD-REVERSE POTENTIOMETER (2): DISCONNECTION............................................................... 707 FAILURE CODE [DK57KB] FORWARD-REVERSE POTENTIOMETER (2): SHORT CIRCUIT............................................................... 709 TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE), PART 4................................................................................ 712 FAILURE CODE [DKH1KA] [DKH1KX] PITCH ANGLE SENSOR: SHORT CIRCUIT..................................................................... 714 FAILURE CODE [DKH1KB] [DKH1KX] PITCH ANGLE SENSOR: DISCONNECTION..................................................................... 715 FAILURE CODE [DLT3KA] TRANSMISSION OUTPUT SPEED SENSOR: DISCONNECTION................................................................ 717 FAILURE CODE [DLT3KB] TRANSMISSION OUTPUT SPEED SENSOR: SHORT CIRCUTI................................................................ 718 FAILURE CODE [DV00KB] ALARM BUZZER: SHORT CIRCUIT.................................................................................... 719 FAILURE CODE [DW5AKA] PITCH CONTROL SOLENOID: DISCONNECTION.......................................................................... 720 FAILURE CODE [DW5AKB] PITCH CONTROL SOLENOID: SHORT CIRCUIT.......................................................................... 721 FAILURE CODE [DW5AKY] PITCH CONTROL SOLENOID: SHORT CIRCUIT TO POWER SOURCE LINE..................................................... 722 FAILURE CODE [DW7BKA] FAN REVERSE SOLENOID: DISCONNECTION............................................................................ 723 FAILURE CODE [DW7BKB] FAN REVERSE SOLENOID: SHORT CIRCUIT............................................................................ 724 FAILURE CODE [DWN1KA] HSS EPC SOLENOID RIGHT: DISCONNECTION.......................................................................... 725 FAILURE CODE [DWN1KB] HSS EPC SOLENOID RIGHT: SHORT CIRCUIT.......................................................................... 726 FAILURE CODE [DWN1KY] HSS EPC SOLENOID RIGHT: SHORT CIRCUIT TO POWER SOURCE LINE..................................................... 727 FAILURE CODE [DWN2KA] HSS EPC SOLENOID LEFT: DISCONNECTION........................................................................... 728 FAILURE CODE [DWN2KB] HSS EPC SOLENOID LEFT: SHORT CIRCUIT........................................................................... 729 FAILURE CODE [DWN2KY] HSS EPC SOLENOID LEFT: SHORT CIRCUIT TO POWER SOURCE LINE...................................................... 730 FAILURE CODE [DWN5KA] FAN PUMP TVC SOLENOID: DISCONNECTION........................................................................... 731 FAILURE CODE [DWN5KB] FAN PUMP TVC SOLENOID: SHORT CIRCUIT........................................................................... 732 FAILURE CODE [DWN5KY] FAN PUMP TVC SOLENOID: SHORT CIRCUIT TO POWER SOURCE LINE .................................................... 733 FAILURE CODE [DXA0KA] HSS PUMP TVC SOLENOID: DISCONNECTION........................................................................... 734 FAILURE CODE [DXA0KB] HSS PUMP TVC SOLENOID: SHORT CIRCUIT........................................................................... 735 FAILURE CODE [DXA0KY] HSS PUMP TVC SOLENOID: SHORT CIRCUIT TO POWER SOURCE LINE .................................................... 736 FAILURE CODE [DXH4KA] 1ST CLUTCH ECMV: DISCONNECTION ............................................................................... 737 FAILURE CODE [DXH4KB] 1ST CLUTCH ECMV: SHORT CIRCUIT................................................................................. 738 FAILURE CODE [DXH4KY] 1ST CLUTCH ECMV: SHORT CIRCUIT TO POWER SOURCE LINE .......................................................... 739 FAILURE CODE [DXH5KA] 2ND CLUTCH ECMV: DISCONNECTION ............................................................................... 740 FAILURE CODE [DXH5KB] 2ND CLUTCH ECMV: SHORT CIRCUIT................................................................................. 741 FAILURE CODE [DXH5KY] 2ND CLUTCH ECMV: SHORT CIRCUIT TO POWER SOURCE LINE .......................................................... 742 FAILURE CODE [DXH6KA] 3RD CLUTCH ECMV: DISCONNECTION ............................................................................... 743 FAILURE CODE [DXH6KB] 3RD CLUTCH ECMV: SHORT CIRCUIT................................................................................. 744 FAILURE CODE [DXH6KY] 3RD CLUTCH ECMV: SHORT CIRCUIT TO POWER SOURCE LINE .......................................................... 745 FAILURE CODE [DXH7KA] REVERSE CLUTCH ECMV: DISCONNECTION ........................................................................... 746 FAILURE CODE [DXH7KB] REVERSE CLUTCH ECMV: SHORT CIRCUIT............................................................................. 747 FAILURE CODE [DXH7KY] REVERSE CLUTCH ECMV: SHORT CIRCUIT TO POWER SOURCE LINE ...................................................... 748 FAILURE CODE [DXH8KA] FORWARD CLUTCH ECMV: DISCONNECTION ........................................................................... 749 FAILURE CODE [DXH8KB] FORWARD CLUTCH ECMV: SHORT CIRCUIT............................................................................. 750 FAILURE CODE [DXH8KY] FORWARD CLUTCH ECMV: SHORT CIRCUIT TO POWER SOURCE LINE ...................................................... 751 TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE)............................................................................................ 753 BEFORE TROUBLESHOOTING OF ELECTRICAL SYSTEM.......................................................................................... 755 CONTENTS OF TROUBLESHOOTING TABLE.................................................................................................... 757 E-1 THE ENGINE DOES NOT START (THE STARTING MOTOR DOES NOT TURN)..................................................................... 758 E-2 THE PREHEATER DOES NOT OPERATE................................................................................................... 761 E-3 THE MONITOR PANEL DOES NOT LIGHT UP AT ALL WHEN THE STARTING SWITCH IS TURNED ON................................................. 764 E-4 WHEN THE STARTING SWITCH IS TURNED ON, THE MONITOR PANEL COMPLETELY REMAINS LIGHTED AND DOES NOT GO OUT.......................... 765 E-5 WHILE THE ENGINE IS RUNNING, THE BATTERY CHARGE LEVEL CAUTION LAMP FLASHES....................................................... 766 E-6 WHILE THE ENGINE IS RUNNING, THE EMERGENCY WARNING ITEM FLASHES.................................................................. 768 E-7 WHILE THE PREHEATER IS OPERATING, THE PREHEATING PILOT LAMP DOES NOT LIGHT UP.................................................... 771 E-8 THE COOLANT TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY........................................................................ 773 E-9 THE POWER TRAIN OIL TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY................................................................ 774 E-10 HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT INDICATE PROPERLY...................................................................... 776 E-11 FUEL GAUGE DOES NOT INDICATE PROPERLY........................................................................................... 778 E-12 GEAR SPEED AND ENGINE SPEED ARE NOT INDICATE PROPERLY........................................................................... 779 E-13 THE PRESET MODE SERVICE METER DOES NOT INDICATE NORMALLY........................................................................ 779 E-14 THE WARNING LAMP DOES NOT FLASH OR DOES NOT GO OUT.............................................................................. 779 E-15 THE ALARM BUZZER DOES NOT SOUND OR DOES NOT STOP................................................................................ 780 E-16 AUTO SHIFT DOWN IS NOT POSSIBLE OR IS NOT RELEASED.............................................................................. 782 E-17 THE BUZZER CANCEL SWITCH DOES NOT WORK.......................................................................................... 784 E-18 THE INFORMATION SWITCH DOES NOT WORK............................................................................................ 786 E-19 THE FAN CLEANING DOES NOT OPERATE OR CANNOT BE RESET............................................................................ 788 E-20 THE PRESET MODE DOES NOT OPERATE OR CANNOT BE RESET............................................................................. 790 E-21 THE MONITOR PANEL CANNOT BE SET IN THE SERVICE MODE OR CANNOT BE SET OUT OF THE SERVICE MODE.................................... 792 E-22 THE BACK-UP ALARM DOES NOT SOUND................................................................................................ 794 E-23 THE HEAD LAMP AND REAR LAMP DO NOT LIGHT UP..................................................................................... 796 E-24 THE HORN DOES NOT SOUND OR DOES NOT STOP........................................................................................ 799 E-25 MALFUNCTION OF WIPERS........................................................................................................... 800 E-26 WASHER DOES NOT SPRAY WATER..................................................................................................... 816 E-27 THE AIR CONDITIONER DOES NOT OPERATE............................................................................................ 821 E-28 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY........................................................................................ 825 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).............................................................................. 828 CONTENTS OF TROUBLESHOOTING TABLE.................................................................................................... 830 H-1 THERE IS NO TRAVEL POWER (NO DRAWBAR PULL)....................................................................................... 831 H-2 MACHINE DOES NOT MOVE (AT 2ND OR 3RD SPEED)...................................................................................... 832 H-3 MACHINE DOES NOT MOVE AT ANY GEAR SPEED.......................................................................................... 833 H-4 MACHINE TRAVELS ONLY IN ONE DIRECTION, FORWARD OR IN REVERSE..................................................................... 834 H-5 WHEN GEAR IS SHIFTED OR TRAVEL DIRECTION IS CHANGED, LARGE TIME LAG IS MADE...................................................... 835 H-6 MACHINE CANNOT BE STEERED (MACHINE DOES NOT TURN LEFTWARD OR RIGHTWARD).......................................................... 836 H-7 STEERING SPEED OR POWER IS LOW................................................................................................... 836 H-8 BRAKE DOES NOT WORK.............................................................................................................. 837 H-9 OVERHEAT OF POWER TRAIN OIL...................................................................................................... 838 H-10 ABNORMAL SOUND COMES OUT FROM AROUND HSS AND WORK EQUIPMENT PUMP OR HSS MOTOR................................................... 839 H-11 ALL WORK EQUIPMENT SPEEDS ARE SLOW.............................................................................................. 839 H-12 WORK EQUIPMENT DOES NOT MOVE.................................................................................................... 840 H-13 BLADE LIFT SPEED IS SLOW OR LACKS POWER......................................................................................... 840 H-14 BLADE TILT SPEED IS SLOW OR LACKS POWER......................................................................................... 841 H-15 RIPPER LIFT SPEED IS SLOW OR LACKS POWER........................................................................................ 841 H-16 EXCESSIVE HYDRAULIC DRIFT OF BLADE LIFT......................................................................................... 842 H-17 EXCESSIVE HYDRAULIC DRIFT OF BLADE TILT......................................................................................... 842 H-18 EXCESSIVE HYDRAULIC DRIFT OF RIPPER LIFT........................................................................................ 843 TROUBLESHOOTING OF ENGINE (S-MODE)....................................................................................................... 845 METHOD OF USING TROUBLESHOOTING CHARTS............................................................................................... 847 S-1 STARTING PERFORMANCE IS POOR..................................................................................................... 850 S-2 ENGINE DOES NOT START............................................................................................................ 851 S-3 ENGINE DOES NOT PICK UP SMOOTHLY................................................................................................. 854 S-4 ENGINE STOPS DURING OPERATIONS................................................................................................... 855 S-5 ENGINE DOES NOT ROTATE SMOOTHLY.................................................................................................. 856 S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)............................................................................................. 857 S-7 EXHAUST SMOKE IS BLACK (IMCOMPLETE COMBUSTION)................................................................................... 858 S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE).......................................................................... 859 S-9 OIL BECOMES CONTAMINATED QUICKLY................................................................................................. 860 S-10 FUEL CONSUMPTION IS EXCESSIVE................................................................................................... 861 S-11 OIL IS IN COOLANT (OR COOLANT SPURTS BACK, OR COOLANT LEVEL GOES DOWN).......................................................... 862 S-12 OIL PRESSURE DROPS.............................................................................................................. 863 S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)............................................................................................ 864 S-14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING).............................................................................. 865 S-15 ABNORMAL NOISE IS MADE.......................................................................................................... 866 S-16 VIBRATION IS EXCESSIVE.......................................................................................................... 867 50 IDSASSEMBLY AND ASSEMBLY.................................................................................................................. 0 GENERAL INFORMATION ON DISASSEMBLY AND ASSEMBLY.......................................................................................... 869 HOW TO READ THIS MANUAL ............................................................................................................. 870 COATING MATERIALS LIST............................................................................................................... 872 SPECIAL TOOL LIST.................................................................................................................... 875 SKETCHES OF SPECIAL TOOLS............................................................................................................ 880 ENGINE AND COOLING SYSTEM, PART 1........................................................................................................ 882 REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY................................................................................ 883 REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY................................................................................... 887 REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY................................................................................... 899 REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL........................................................................................ 901 REMOVAL AND INSTALLATION OF ENGINE REAR SEAL......................................................................................... 904 ENGINE AND COOLING SYSTEM, PART 2........................................................................................................ 909 REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY.......................................................................................... 910 REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY........................................................................................ 917 REMOVAL AND INSTALLATION OF AIR AFTERCOOLER ASSEMBLY................................................................................. 921 REMOVAL AND INSTALLATION OF FAN DRIVE ASSEMBLY....................................................................................... 922 REMOVAL AND INSTALLATION OF FAN MOTOR ASSEMBLY....................................................................................... 923 REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY....................................................................................... 924 REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY.......................................................................................... 926 REMOVAL AND INSTALLATION OF ENGINE HOOD ASSEMBLY..................................................................................... 927 POWER TRAIN, PART 1...................................................................................................................... 929 REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY................................................................................ 930 DISCONNECTION AND CONNECTION OF POWER TRAIN UNIT ASSEMBLY............................................................................ 933 DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY............................................................................................. 937 DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY................................................................................ 943 DISASSEMBLY AND ASSEMBLY OF TRQFLOW TRANSMISSION ASSEMBLY............................................................................ 948 POWER TRAIN, PART 2...................................................................................................................... 967 DISASSEMBLY AND ASSEMBLY OF HSS ASSEMBLY............................................................................................. 968 REMOVAL AND INSTALLATION OF FINAL DIRVE ASSEMBLY..................................................................................... 986 DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY..................................................................................... 988 UNDERCARRIAGE AND FRAME, PART 1.......................................................................................................... 996 REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY..................................................................................... 997 REMOVAL AND INSTALLATION OF IDLER ASSEMBLY........................................................................................... 999 DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY...........................................................................................1000 REMOVAL AND INSTALLATION OF RECOIL SPRING ASSEMBLY...................................................................................1004 DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY...................................................................................1005 REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY....................................................................................1009 DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY....................................................................................1010 REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY..................................................................................1014 DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY..................................................................................1015 UNDERCARRIAGE AND FRAME, PART 2..........................................................................................................1019 EXPANSION AND INSTALLATION OF TRACK SHOE ASSEMBLY....................................................................................1020 WHOLE DISASSEMBLY AND WHOLE ASSEMBLY OF TRACK SHOE ASSEMBLY..........................................................................1023 FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK...........................................................................................1038 REMOVAL AND INSTALLATION OF PIVOT SHAFT ASSEMBLY.....................................................................................1045 REMOVAL AND INSTALLATION OF EQUALIZER BAR ASSEMBLY...................................................................................1046 DISASSEMBLY AND ASSEMBLY OF EQUALIZER BAR SIDE BUSHING...............................................................................1048 HYDRAULIC SYSTEM.........................................................................................................................1050 REMOVAL AND INTALLATION OF CONTROL VALVE ASSEMBLY....................................................................................1051 DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY...................................................................................1053 REMOVAL AND INSTALLATION OF HSS PUMP ASSEMBLY........................................................................................1054 REMOVAL AND INSTALLATION OF POWER TRAIN AND LUBRICATING OIL PUMP ASSEMBLY............................................................1055 REMOVAL AND INSTALLATION OF COOLING FAN PUMP ASSEMBLY................................................................................1056 REMOVAL AND INSTALLATION OF SCAVENGING PUMP ASSEMBLY.................................................................................1058 REMOVAL AND INSTALLATION OF HSS MOTOR ASSEMBLY.......................................................................................1059 DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY..............................................................................1060 WORK EQUIPMENT...........................................................................................................................1067 REMOVAL AND INSTALLTION OF BLADE ASSEMBLY............................................................................................1068 CAB AND ITS ATTACHMENTS..................................................................................................................1071 REMOVAL AND INSTALLATION OF ROPS GUARD...............................................................................................1072 REMOVAL AND INSTALLATION OF OPERATOR'S CAB ASSEMBLY..................................................................................1073 REMOVAL AND INSTALLATION OF OPERATOR'S CAB GLASS (STUCK GLASS).......................................................................1079 REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY.....................................................................................1087 ELECTRICAL SYSTEM........................................................................................................................1094 REMOVAL AND INSTALLATION OF ENGINE CONTROLLER........................................................................................1095 REMOVAL AND INSTALLATION OF STEERING AND TRANSMISSION CONTROLLER ASSEMBLY............................................................1097 REMOVAL AND INSTALLATION OF KOMTRAX TERMINAL.........................................................................................1098 90 DIAGRAMS AND DRAWINGS..................................................................................................................... 0 HYDRAULIC DIAGRAMS AND DRAWINGS..........................................................................................................1100 POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM................................................................................................1101 HYDRAULIC CIRCUIT DIAGRAM............................................................................................................1102 ELECTRICAL DIAGRAMS AND DRAWINGS.........................................................................................................1103 ELECTRICAL CIRCUIT DIAGRAM...........................................................................................................1104 CONNECTOR ARRANGEMENT DIAGRAM........................................................................................................1105

IMAGES PREVIEW OF THE MANUAL: