$34

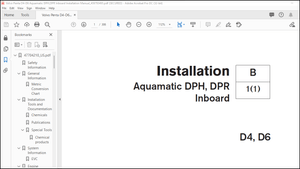

Komatsu D85C-21 PIPELAYER Operation & Maintenance Manual PEN00333-00 – PDF DOWNLOAD

Komatsu D85C-21 PIPELAYER Operation & Maintenance Manual PEN00333-00 – PDF DOWNLOAD

FILE DETAILS:

Komatsu D85C-21 PIPELAYER Operation & Maintenance Manual PEN00333-00 – PDF DOWNLOAD

Language : English

Pages : 225

Downloadable : Yes

File Type : PDF

Size: 5.17 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu D85C-21 PIPELAYER Operation & Maintenance Manual PEN00333-00 – PDF DOWNLOAD

SERIAL NUMBERS 36551 and up

FOREWORD:

This manual provides rules and guidelines which will help you use this machine safely and effectively. The

precautions in this manual must be followed at all times when performing operation and maintenance. Most

accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of

machines. Accidents can be prevented by knowing beforehand conditions that may cause a hazard when

performing operation and maintenance.

SAFETY LABELS:

The following warning signs and safety labels are used on this machine.

Be sure that you fully understand the correct position and content of labels.

To ensure that the content of labels can be read properly, be sure that they are in the correct place and always

keep them clean. When cleaning them, do not use organic solvents or gasoline. These may cause the labels to

peel off.

There are also other labels in addition to the warning signs and safety labels. Handle those labels in the same

way.

If the labels are damaged, lost, or cannot be read properly, replace them with new ones. For details of the part

numbers for the labels, see this manual or the actual label, and place an order with Komatsu distributor.

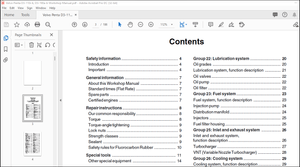

TABLE OF CONTENTS:

Komatsu D85C-21 PIPELAYER Operation & Maintenance Manual PEN00333-00 – PDF DOWNLOAD

FOREWORD 1- 1

FOREWORD 1- 2

SAFETY INFORMATION 1- 5

INTRODUCTION 1- 7

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE 1- 7

BREAKING IN THE MACHINE 1- 7

NECESSARY INFORMATION 1- 8

MACHINE SERIAL NO. PLATE AND POSITION 1- 8

ENGINE SERIAL NO. PLATE AND POSITION 1- 8

WINCH NUMBER PLATE POSITION 1- 8

POSITION OF SERVICE METER 1- 9

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR 1- 9

SAFETY 2- 1

SAFETY 2- 2

SAFETY LABELS 2- 4

POSITIONS OF SAFETY PICTOGRAMS 2- 4

SAFETY LABELS 2- 5

GENERAL PRECAUTIONS 2- 7

PRECAUTIONS FOR OPERATION 2- 15

BEFORE STARTING ENGINE 2- 15

OPERATION 2- 17

TRANSPORTATION 2- 20

BATTERY 2- 21

TOWING 2- 23

PRECAUTIONS FOR MAINTENANCE 2- 24

OPERATION 3- 1

GENERAL VIEW 3- 2

GENERAL VIEW OF MACHINE 3- 2

GENERAL VIEW OF CONTROLS AND GAUGES 3- 3

EXPLANATION OF COMPONENTS 3- 7

MACHINE INSTRUMENT PANEL 3- 7

CAB INSTRUMENT PANEL 3- 13

CONTROL LEVERS, PEDALS, HORN SWITCH 3- 17

FUSE BOX 3- 27

ASHTRAY 3- 28

HEATER, HANDLING 3- 29

AIR CONDITIONER, HANDLING 3- 30

OPERATION 3- 34

CHECK BEFORE STARTING ENGINE, ADJUST 3- 34

STARTING ENGINE (NORMAL, IN COLD WEATHER) 3- 52

OPERATIONS AND CHECKS AFTER STARTING ENGINE (NORMAL, IN COLD WEATHER) 3- 56

STOPPING ENGINE 3- 60

MOVING MACHINE 3- 61

STOPPING MACHINE 3- 63

SHIFTING GEAR 3- 63

SHIFTING BETWEEN FORWARD AND REVERSE 3- 64

STEERING MACHINE 3- 65

PRECAUTIONS FOR OPERATION 3- 69

PARKING MACHINE 3- 71

1 – 10

.

FOREWORD CONTENTS

CHECK AFTER FINISHING WORK 3- 73

LOCKING 3- 74

TIPS FOR LONGER UNDERCARRIAGE LIFE 3- 75

TRANSPORTATION 3- 77

TRANSPORTATION PROCEDURE 3- 77

LOADING, UNLOADING WORK 3- 77

PRECAUTIONS FOR LOADING 3- 77

METHOD OF LIFTING MACHINE 3- 78

PRECAUTIONS FOR TRANSPORTATION 3- 79

TRAVELING ON ROADS 3- 80

PROCEDURE FOR REMOVAL AND INSTALLATION OF BOOM 3- 80

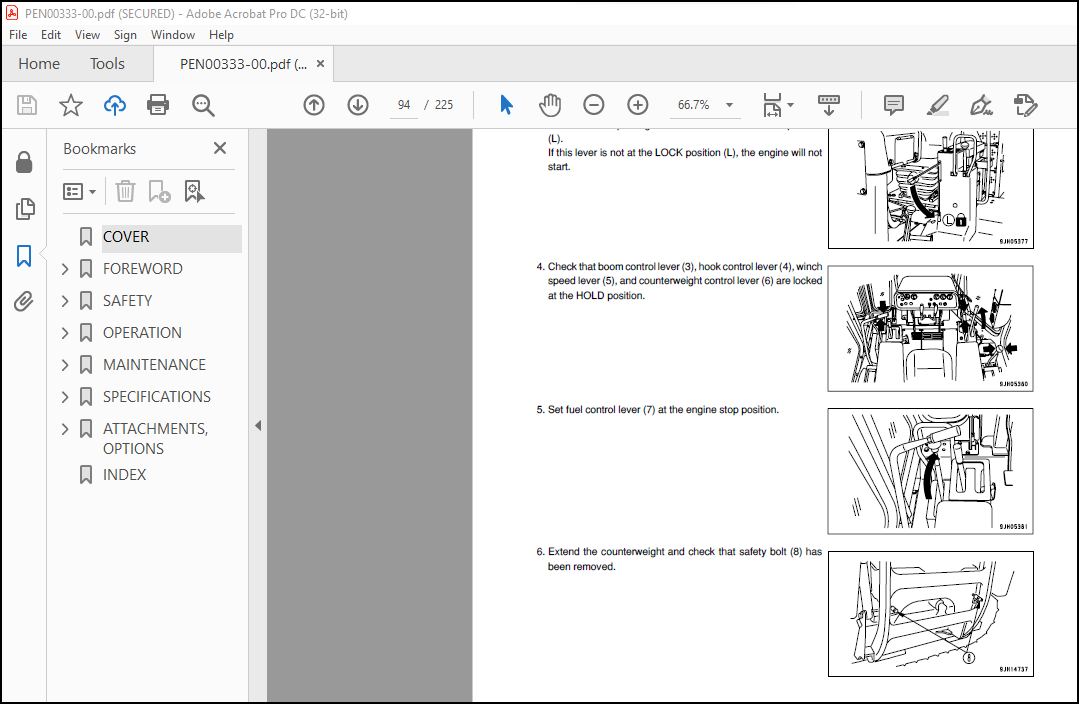

PROCEDURE FOR REMOVAL AND INSTALLATION OF COUNTERWEIGHT 3- 82

PROCEDURE FOR REMOVAL AND INSTALLATION OF CAB 3- 84

COLD WEATHER OPERATION 3- 87

PRECAUTIONS FOR LOW TEMPERATURE 3- 87

AFTER COMPLETION OF WORK 3- 89

AFTER COLD WEATHER 3- 89

LONG-TERM STORAGE 3- 90

BEFORE STORAGE 3- 90

DURING STORAGE 3- 90

AFTER STORAGE 3- 90

TROUBLESHOOTING 3- 91

AFTER RUNNING OUT OF FUEL 3- 91

METHOD OF TOWING MACHINE 3- 91

IF BATTERY IS DISCHARGED 3- 92

OTHER TROUBLE 3- 95

MAINTENANCE 4- 1

GUIDES TO MAINTENANCE 4- 2

OUTLINES OF SERVICE 4- 4

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC 4- 4

OUTLINE OF ELECTRIC SYSTEM 4- 7

WEAR PARTS 4- 8

WEAR PARTS LIST 4- 8

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE 4- 9

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS 4- 9

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS 4- 14

TORQUE LIST 4- 14

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS 4- 15

SAFETY CRITICAL PARTS 4- 15

MAINTENANCE SCHEDULE CHART 4- 16

MAINTENANCE SCHEDULE CHART 4- 16

SERVICE PROCEDURE 4- 18

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS) 4- 18

WHEN REQUIRED 4- 19

CHECK BEFORE STARTING 4- 36

EVERY 250 HOURS SERVICE 4- 37

EVERY 500 HOURS SERVICE 4- 47

EVERY 1000 HOURS SERVICE 4- 49

EVERY 2000 HOURS SERVICE 4- 56

EVERY 4000 HOURS SERVICE 4- 62

CONTENTS FOREWORD

SPECIFICATIONS 5- 1

SPECIFICATIONS 5- 2

LIFTING LOAD CAPACITY CURVE 5- 3

ATTACHMENTS, OPTIONS 6- 1

GENERAL PRECAUTIONS 6- 2

PRECAUTIONS RELATED TO SAFETY 6- 2

USING SEAT BELT 6- 3

HANDLING SEAT BELT 6- 3

SELECTION OF TRACK SHOE 6- 4

SELECTION OF TRACK SHOES 6- 4

CAP WITH LOCK, HANDLING 6- 5

METHOD OF OPENING AND CLOSING CAP WITH LOCK 6- 5

REVERSIBLE FAN, HANDLING 6- 6

REVERSING REVERSIBLE FAN 6- 6

EXTERNAL POWER SOURCE ENGINE PREHEATING HEATER 6- 7

PROCEDURE FOR SETTING UP EXTERNAL POWER SOURCE 6- 8

PROCEDURE FOR HANDLING EXTERNAL POWER SUPPLY 6- 13

INDEX 7- 1