$45

Komatsu D85EX-15, D85PX-15 Bulldozer Shop Manual - PDF DOWNLOAD

Komatsu D85EX-15, D85PX-15 Bulldozer Shop Manual

FILE DETAILS:

Komatsu D85EX-15, D85PX-15 Bulldozer Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : SEBM029105

Total Pages : 924

DESCRIPTION:

Komatsu D85EX-15, D85PX-15 Bulldozer Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD:

This section gives the judgment standards for inspection of disassembled parts. The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS:

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams. In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu D85EX-15, D85PX-15 Bulldozer Shop Manual

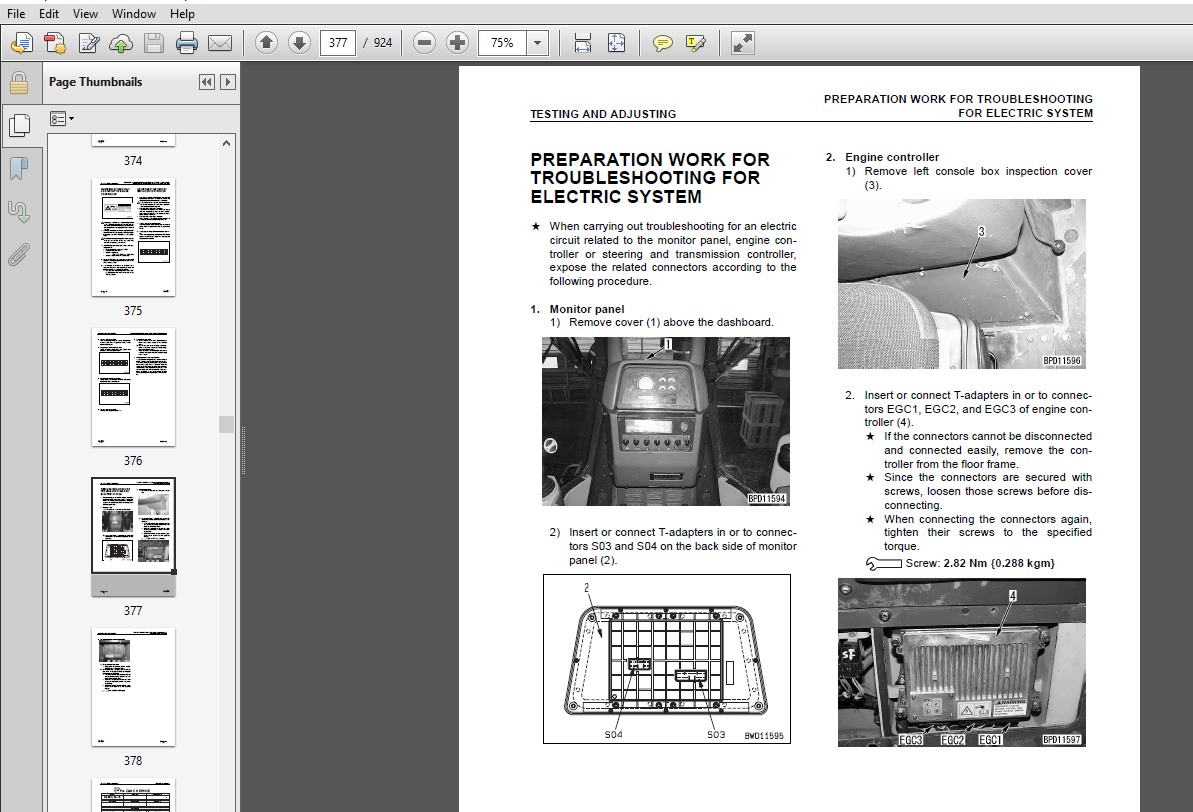

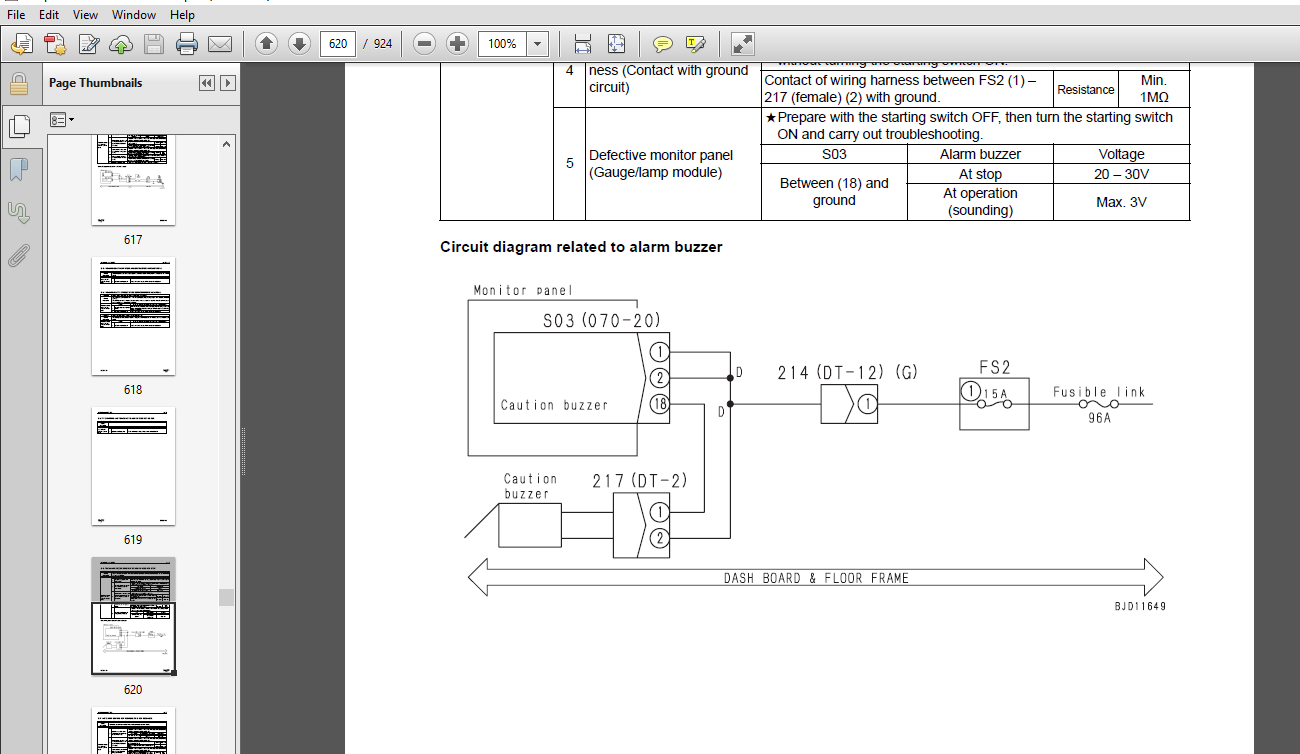

COVER......................................................................................................................................... 1 CONTENTS...................................................................................................................................... 2 01 GENERAL.................................................................................................................................... 27 SPECIFICATION DRAWING..................................................................................................................... 28 SPECIFICATIONS............................................................................................................................ 29 WEIGHT TABLE.............................................................................................................................. 39 TABLE OF FULE, COOLANT AND LUBRICANT...................................................................................................... 41 10 STRUCTURE,FUNCTION AND MAINTENANCE STANDARD................................................................................................ 43 POWER TRAIN............................................................................................................................... 44 OVERALL DRAWING OF POWER TRAIN UNIT....................................................................................................... 46 HYDRAULIC PIPING OF POWER TRAIN .......................................................................................................... 48 DAMPER,UNIVERSAL JOINT ................................................................................................................... 49 TORQUE CONVERTER,PTO...................................................................................................................... 51 SCAVENGING PUMP........................................................................................................................... 57 TRANSMISSION CONTROL...................................................................................................................... 58 TRANSMISSION.............................................................................................................................. 59 TRANSMISSION ECMV......................................................................................................................... 71 MAIN RELIEF VALVE......................................................................................................................... 76 LUBRICATION RELIEF VALVE ................................................................................................................. 78 POWER TRAIN PUMP, LUBRICATION PUMP........................................................................................................ 79 HSS SYSTEM................................................................................................................................ 80 HYDRAULIC,HSS PUMP........................................................................................................................ 82 HSS MOTOR.................................................................................................................................100 HSS OIL COOLER BYPASS VALVE ..............................................................................................................107 STEERING,BRAKE CONTROL....................................................................................................................108 BEVEL GEAR SHAFT,HSS,BRAKE................................................................................................................110 BRAKE VALVE...............................................................................................................................124 FINAL DRIVE...............................................................................................................................129 SPROCKET..................................................................................................................................136 TRACK FRAME...............................................................................................................................138 RECOIL SPRING.............................................................................................................................140 IDLER.....................................................................................................................................142 TRACK ROLLER..............................................................................................................................144 CARRIER ROLLER............................................................................................................................146 TRACK SHOE................................................................................................................................148 MAIN FRAME................................................................................................................................151 SUSPENSION................................................................................................................................153 WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM...................................................................................................156 PPC CONTROL PIPING DIAGRAM................................................................................................................159 WORK EQUIPMENT CONTROL....................................................................................................................160 COOLING FAN PUMP .........................................................................................................................162 COOLING FAN MOTOR.........................................................................................................................170 HYDRAULIC TANK............................................................................................................................176 ACCUMULATOR...............................................................................................................................178 PPC LOCK VALVE............................................................................................................................179 HYDRAULIC CYLINDER........................................................................................................................180 PISTON VALVE..............................................................................................................................182 QUICK DROP VALVE..........................................................................................................................183 PPC VALVE.................................................................................................................................184 PCCS LEVER................................................................................................................................198 CONTROL VALVE.............................................................................................................................201 SELF PRESSURE REDUCING VALVE..............................................................................................................233 CYLINDER STAY.............................................................................................................................240 BLADE.....................................................................................................................................241 RIPPER....................................................................................................................................244 CAB MOUNT.................................................................................................................................246 CAB.......................................................................................................................................247 AIR CONDITIONER...........................................................................................................................249 ENGING CONTROL............................................................................................................................250 ENGING CONTROL SYSTEM ....................................................................................................................251 DECELERATION POTENTIOMETER................................................................................................................252 CRI ENGING CONTROL SYSTEM.................................................................................................................253 MONITOR SYSTEM............................................................................................................................255 MONITOR PANEL.............................................................................................................................258 SENSORS...................................................................................................................................261 PALM COMMAND CONTROL SYSTEM...............................................................................................................265 20 TESTING AND ADJUSTING......................................................................................................................267 STANDARD VALUE TABLE FOR ENGING...........................................................................................................268 STANDARD VALUE TABLE FOR CHASSIS..........................................................................................................269 TESTING AND ADJUSTING.....................................................................................................................275 TOOLS FOR TESTING, ADJUSTING,AND TROUBLESHOOTING......................................................................................277 MEASURING ENGINE SPEED ...............................................................................................................279 MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)........................................................................................282 MEASURING EXHAUST TEMPERATURE.........................................................................................................284 MEASURING EXHAUST GAS COLOR ..........................................................................................................285 ADJUSTING VALVE CLEARANCE.............................................................................................................287 MEASURING COMPRESSION PRESSURE........................................................................................................289 MEASURING BLOW-BY PRESSURE............................................................................................................291 MEASURING ENGINE OIL PRESSURE ........................................................................................................292 HANDLING OF FUEL SYSTEM DEVICES.......................................................................................................293 RELEASING RESIDUAL PRESSURE FORM FUEL SYSTEM..........................................................................................293 MEASURING FUEL PRESSURE...............................................................................................................294 BLEEDING AIR FROM FUEL CIRCUIT........................................................................................................295 REDUCED CYLINDER MODE OPERATION FOR ENGINE............................................................................................298 TESTING AND ADJUSTING ALTERNATOR BELT TENSION.........................................................................................299 TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION.........................................................................299 ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL.....................................................................................300 MEASURING POWER TRAIN OIL PRESSURE....................................................................................................302 ADJUSTING TRANSMISSION SPEED SENSOR...................................................................................................308 SIMPLE METHOD OF TESTING BRAKE PERFORMANCE............................................................................................309 ADJUSTING BRAKE PEDAL.................................................................................................................310 EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE..................................................................................313 ADJUSTING CLEARANCE OF IDLER..........................................................................................................316 INSPECTING WEAR OF SPROCKET...........................................................................................................317 TESTING AND ADJUSTING TRACK SHOE TENSION..............................................................................................317 TESTING AND ADJUSTING WORK EQUIPMENT AND HSS OIL PRESSURE.............................................................................318 TESTING CONTROL CIRCUIT MAIN PRESSURE.................................................................................................321 MEASURING PPC VALVE OUTPUT PRESSURE...................................................................................................322 ADJUSTING PLAY OF WORK EQUIPMENT PPC VALVE............................................................................................324 TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF BLAND AND RIPPER.........................................................................325 MEASURING INTERNAL LEAKAGE OF WORK EQUIPMENT CYLINDER.................................................................................326 BLEEDING AIR FROM WORK EQUIPMENT CYLINDER.............................................................................................326 RELEASING RESIDUAL PRESSURE IN WORK EQUIPMENT CYLINDER................................................................................327 ADJUSTING SAFETY LOCK LEVER...........................................................................................................328 MEASURING FAN MOTOR SPEED.............................................................................................................329 MEASURING FAN PUMP CIRCUIT PRESSURE...................................................................................................330 BLEEDING AIR FORM FAN PUMP............................................................................................................331 ADJUSTING BLADE.......................................................................................................................332 TESTING AND ADJUSTING OF OPERATOR'S CAB...............................................................................................334 SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS).............................................................................................338 HANDLING OF HIGH-VOLTAGE CIRCUIT OF ENGINE CONTROLLER.................................................................................375 ADJUSTMENT METHOD OF REPLACED CONTROLLER..............................................................................................375 PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM..............................................................................377 PM CLINIC SERVICE.....................................................................................................................379 UNDERCARRIAGE CHECK SHEET.............................................................................................................385 TROUBLESHOOTING...........................................................................................................................388 POINTS TO REMEMBER WHEN TROUBLESHOOTING...............................................................................................389 SEQUENCE OF EVENTS IN TROUBLESHOOTING.................................................................................................390 POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE......................................................................................391 CHECKS BEFORE TROUBLESHOOTING.........................................................................................................399 CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING......................................................................................400 TYPES AND LOCATIONS OF CONNECTORS.....................................................................................................403 CONNECTOR ARRANGEMENT DRAWING.........................................................................................................409 CIRCUIT DRAWING FOR ENGINE CONTROLLER SYSTEM (E CIRCUIT)..............................................................................415 CIRCUIT DRAWING FOR STEERING AND TRANSMISSION CONTROLLER SYSTEM (ST・TM CIRCUIT).......................................................417 CIRCUIT DRAWING FOR MONITOR PANEL SYSTEM (M CIRCUIT)..................................................................................419 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS............................................................................................421 T-BRANCH BOX AND T-BRANCH TABLE.......................................................................................................444 TROUBLESHOOTING WHEN ERROR CODE IS DISPLAYED(ERROR CODE)..............................................................................446 INFORMATION DESCRIBED IN TROUBLESHOOTING LIST.....................................................................................449 TROUBLE CODE TABLE................................................................................................................450 ERROR CODE [1500LO] (TRANSMISSION CLUTCH:SEE THE LIST.(L1)).......................................................................451 ERROR CODE [15SAL1] (FORWARD CLUTCH:SEE THE LIST.(L1))............................................................................452 ERROR CODE [15SALH] (FORWARD CLUTCH:SEE THE LIST.(LH))............................................................................453 ERROR CODE [15SBL1] (REVERSE CLUTCH:SEE THE LIST.(L1))............................................................................454 ERROR CODE [15SBLH] (REVERSE CLUTCH:SEE THE LIST.(LH))............................................................................455 ERROR CODE [15SEL1] (1ST CLUTCH:SEE THE LIST.(L1))................................................................................456 ERROR CODE [15SELH] (1ST CLUTCH:SEE THE LIST.(LH))................................................................................457 ERROR CODE [15SFL1] (2ND CLUTCH:SEE THE LIST.(L1))................................................................................458 ERROR CODE [15SFLH] (2ND CLUTCH:SEE THE LIST.(LH))................................................................................459 ERROR CODE [15SGL1] (3RD CLUTCH:SEE THE LIST.(L1))................................................................................460 ERROR CODE [15SGLH] (3RD CLUTCH:SEE THE LIST.(LH))................................................................................461 ERROR CODE [A000N1] (ENGINE:OVERRUN (N1)).........................................................................................462 ERROR CODE [AB00MA] (ALTERNATOR:MALFUNCTION (MA)).................................................................................463 ERROR CODE [AD00L2] (COMMON RAIL:SEE THE LIST.(L2))...............................................................................463 ERROR CODE [AD00MA] (COMMON RAIL:DEFECTIVE FUNCTION(MA))..........................................................................464 ERROR CODE [AD10L3] (FUEL SUPPLY PUMP:SEE THE LIST.(L3))..........................................................................464 ERROR CODE [AD10MA] (FUEL SUPPLY PUMP:DEFECTIVE FUNCTION (MA))....................................................................467 ERROR CODE [AD10MB] (FUEL SUPPLY PUMP:FUNCTION REDUCTION (MB))....................................................................467 ERROR CODE [AD11KA] (FUEL SUPPLY PUMP SOLENOID 1:DISCONNECTION IN WIRING (KA))....................................................468 ERROR CODE [AD11KB] (FUEL SUPPLY PUMP SOLENOID 1:SHORT CIRCUIT (KB))..............................................................469 ERROR CODE [AD51KA] (FUEL SUPPLY PUMP SOLENOID 2:DISCONNECTION IN WIRING (KA))....................................................470 ERROR CODE [AD51KB] (FUEL SUPPLY PUMP SOLENOID 2:DISCONNECTION IN SHORT (KB)).....................................................471 ERROR CODE [ADA1KA] (NO.1 INJECTOR SOLENOID:DISCONNECTION IN WIRING (KA)).........................................................472 ERROR CODE [ADAZKB] (NO.1.2,AND 3 INJECTOR SOLENOIDS:SHORT(KB))...................................................................473 ERROR CODE [ADB1KA] (NO.2 INJECTOR SOLENOID:DISCONNECTION IN WIRING(KA))..........................................................475 ERROR CODE [ADC1KA] (NO.3 INJECTOR SOLENOID:DISCONNECTION IN WIRING(KA))..........................................................476 ERROR CODE [ADD1KA] (NO.4 INJECTOR SOLENOID:DISCONNECTION IN WIRING(KA))..........................................................477 ERROR CODE [ADDZKB] (NO.4.5,AND 6 INJECTOR SOLENOIDS:SHORT(KB))...................................................................478 ERROR CODE [ADE1KA] (NO.5 FUEL INJECTOR SOLENOID:DISCONNECTION(KA))...............................................................480 ERROR CODE [ADF1KA] (NO.6 FUEL INJECTOR SOLENOID:DISCONNECTION(KA))...............................................................481 ERROR CODE [B@BAZG] (ENGINE OIL: OIL PRESSURE REDUCTION (ZG)).....................................................................482 ERROR CODE [B@BCNS] (RADIATOR COOLANT: OVERHEAT (NS)).............................................................................482 ERROR CODE [B@BCZK] (RADIATOR COOLANT:LEVEL REDUCTION (ZK)).......................................................................483 ERROR CODE [B@CENS] (POWER TRAN OIL: OVERHEAT (NS))...............................................................................483 ERROR CODE [B@HANS] (HYDRAULIC OIL: OVERHEAT (NS))................................................................................484 ERROR CODE [D110KA] (BATTERY RELAY:DISCONNECTION(KA)).............................................................................485 ERROR CODE [D110KB] (BATTERY RELAY:SHORT CIRCUIT(KB)).............................................................................486 ERROR CODE [D13OKA] (NEUTRAL SAFETY RELAY: DISCONNECTION (KA))....................................................................487 ERROR CODE [D13OKB] (NEUTRAL SAFETY RELAY: SHORT CIRCUIT (KB))....................................................................489 ERROR CODE [D161KA] (BACK-UP ALARM RELAY: DISCONNECTION (KA)).....................................................................490 ERROR CODE [D161KB] (BACK-UP ALARM RELAY:SHORT CIRCUIT (KB))......................................................................492 ERROR CODE [D182KZ] (PREHEATER RELAY COIL: DISCONNECTION OR SHORT CIRCUIT (KZ))...................................................494 ERROR CODE [D1D0KB] (ENGINE CONTROLLER LOAD POWER SUPPLY RELAY : SHORT CIRCUIT (KB))..............................................496 ERROR CODE [D5ZFKA] (TRANSMISSION NEUTRAL SIGNAL: DISCONNECTION (KA)).............................................................498 ERROR CODE [D5ZFKB] (TRANSMISSION NEUTRAL SIGNAL:SHORT CIRCUIT(KB))...............................................................499 ERROR CODE [DAFRKR] (MONITOR PANEL CAN COMMUNICATION: DEFECTIVE COMMUNICATION (KR)................................................500 ERROR CODE [DAQ0KK] [DB30KK] (STEERING AND TRANSMISSION CONTROLLER:SOURCE VOLTAGE REDUCTION/INPUT (KK))...........................502 ERROR CODE [DAQ0KT] [DB30KT] (STEERING AND TRANSMISSION CONTROLLER:ABNORMALITY IN CONTROLLER(KT)).................................503 ERROR CODE [DAQ5KK] [DB35KK] (STEERING AND TRANSMISSION CONTROLLER SENSOR 5V POWER SUPPLY:SOURCE VOLTAGE REDUCTION/INPUT (KK))....504 ERROR CODE [DAQ6KK] [DB36KK] (STEERING AND TRANSMISSION CONTROLLER SENSOR POWER SUPPLY:SOURCE VOLTAGE REDUCTION/INPUT (KK)).......506 ERROR CODE [DAQ9KQ] [DB39KQ] (STEERING AND TRANSMISSION CONTROLLER TYPE COLLATION:TYPE SELECT SIGNAL INSISTENCY (KQ)).............507 ERROR CODE [DAQRKR] [DB3RKR] (STEERING AND TRANSMISSION CONTROLLER CAN COMMUNICATION:DEFECTIVE COMMUNICATION (KR))................508 ERROR COED [DB20KQ] (ENGINE CONTROLLER TYPE COLLATION:TYPE SELECT CODE INCONSISTENCY (KQ))........................................510 ERROR CODE [DB20KT] (ENGINE CONTROLLER :ABNORMALITY IN CONTROLLER (KT))...........................................................512 ERROR CODE [DB22KK] (ENGINE CONTROLLER LOAD POWER SUPPLY:SOURCE VOLTAGE REDUCTION/INPUT (KK)).....................................513 ERROR CODE [DB29KQ] (ENGINE CONTROLLER TYPE SELECT:TYPE SELECT SIGNAL INCONSISTENCY (KQ)).........................................515 ERROR CODE [DB2AMA] (FUEL INJECTION AMOUNT ADJUSTMENT SWITCH SIGNAL:MALFUNCTION (MA)).............................................516 ERROR CODE [DB2RKR] (ENGINE CONTROLLER CAN COMMUNICATION :DEFECTIVE COMMUNICATION (KR))...........................................517 ERROR CODE [DB2RMC] (STEERING AND TRANSMISSION CONTROLLER CAN COMMUNICATION:DEFECTIVE COMMUNICATION (MC)).........................519 ERROR CODE [DB30KK] [DAQ0KK] (STEERING AND TRANSMISSION CONTROLLER:SOURCE VOLTAGE REDUCTION/INPUT (KK)............................521 ERROR CODE [DB30KT] [DAQ0KT] (STEERING AND TRANSMISSION CONTROLLER:ABNORMALITY IN CONTROLLER (KT).................................521 ERROR CODE [DB35KK] [DAQ5KK] (STEERING AND TRANSMISSION CONTROLLER ENSOR 5V POWER SUPPLY:SOURCE VOLTAGE REDUCTION/INPUT (KK)......521 ERROR CODE [DB36KK] [DAQ6KK] (STEERING AND TRANSMISSION CONTROLLER SENSOR 24V POWER SUPPLY:SOURCE VOLTAGE REDUCTION/INPUT (KK)....521 ERROR CODE [DB39KQ] [DAQ9KQ] (STEERING AND TRANSMISSION CONTROLLER TYPE COLLATION: TYPE SELECT SIGNAL INCONSISTENCY (KQ)..........521 ERROR CODE [DB3RKR] [DAQRKR] (STEERING AND TRANSMISSION CONTROLLER CAN COMMUNICATION:DEFECTIVE COMMUNICATION (KR).................521 ERROR CODE [DD11KB] (STARTING SWITCH:SHORT CIRCUIT (KB))..........................................................................522 ERROR CODE [DD12KA] (SHIFT UP SWITCH:DISCONNECTION (KA))..........................................................................523 ERROR CODE [DD12KB] (SHIFT UP SWITCH:SHORT CIRCUIT (KB))..........................................................................525 ERROR CODE [DD13KA] (SHIFT DOWN SWITCH:DISCONNECTION (KA))........................................................................527 ERROR CODE [DD13KB] (SHIFT DOWN SWITCH:SHORT CIRCUIT (KB))........................................................................529 ERROR CODE [DD14KA] [DDQ2KA] (PARKING LEVER SWITCH:DISCONNECTION (KA))............................................................531 ERROR CODE [DD14KB] [DDQ2KB] (PARKING LEVER SWITCH:SHORT CIRCUIT(KB)).............................................................533 ERROR CODE [DDE2L6] (ENGINE OIL PRESSURE SWITCH:REFER TO TABLE (L6))..............................................................535 ERROR CODE [DDQ2KA] [DD14KA] (PARKING LEVER SWITCH:DISCONNECTION (KA))............................................................537 ERROR CODE [DDQ2KB] [DD14KB] (PARKING LEVER SWITCH:SHORT CIRCUIT (KB))............................................................537 ERROR CODE [DGE2KX] (ENGINE WATER TEMPERATURE SENSOR (FOR HIGH TEMPERATURE): INPUT SIGNAL IS OUT OF NORMAL RANGE (KX))............538 ERROR CODE [DGE3L6] (ENGINE WATER TEMPERATURE SENSOR (FOR LOW TEMPERATURE):SEE TABLE (L6))........................................539 ERROR CODE (DGE4KX] (FUEL TEMPERATURE SENSOR:INPUT SIGNAL IS OUT OF NORMAL RANGE (KX))............................................540 ERROR CODE [DGS1KX] (HYDRAULIC OIL TEMPERATURE SENSOR: INPUT SIGNAL IS OUT OF NORMAL RANGE(KX))...................................541 ERROR CODE [DH21KA] (HSS AND WORK EQUIPMENT PUMP OIL PRESSURE SENSOR:DISCONNECTION (KA))..........................................542 ERROR CODE [DH21KB] (HSS AND WORK EQUIPMENT PUMP OIL PRESSURE SENSOR:SHORT CIRCUIT (KB))..........................................543 ERROR CODE [DH30KX] (BOOST PRESSURE SENSOR:INPUT IS OUT OF NORMAL RANGE(KX))......................................................544 ERROR CODE [DH40KX] (COMMON RAIL PRESSURE SENSOR:INPUT IS OUT OF NORMAL RANGE(KX))................................................546 ERROR CODE [DK10KX] (FUEL CONTROL DIAL:INPUT IS OUT OF NORMAL RANGE (KX)).........................................................548 ERROR CODE [DK12KX] (DECELERATION POTENTIOMETER:INPUT IS OUT OF NORMAL RANGE (KX))................................................550 ERROR CODE [DK30KA] (STEERING POTENTIOMETER 1: DISCONNECTION (KA))................................................................552 ERROR CODE [DK30KB] (STEERING POTENTIOMETER 1: SHORT CIRCUIT (KB))................................................................554 ERROR CODE [DK30KX] (STEERING POTENTIOMETER :INPUT SIGNAL IS OUT OF NORMAL RANGE (KX))............................................555 ERROR CODE [DK30L8] (STEERING POTENTIOMETER 1 : SEE THE TABLE(L8))................................................................556 ERROR CODE [DK31KA] (STEERING POTENTIOMETER 2 : DISCONNECTION (KA))...............................................................557 ERROR CODE [DK31KB] (STEERING POTENTIOMETER 2 : SHORT CIRCUIT (KB))...............................................................559 ERROR CODE [DK40KA] (BRAKE POTENTIOMETER : DISCONNECTION(KA)).....................................................................560 ERROR CODE [DK40KB] (BRAKE POTENTIOMETER : SHORT CIRCUIT(KB)).....................................................................562 ERROR CODE [DK55KX] (FORWARD-REVERSE POTENTIOMETER: INPUT SIGNAL IS OUT OF NORMAL RANGE (KX)).....................................563 ERROR CODE [DK55KZ] (FORWARD-REVERSE POTENTIOMETER: DISCONNECTION OR SHORT CIRCUIT (KZ))..........................................563 ERROR CODE [DK55L8] (FORWARD-REVERSE POTENTIOMETER: SEE THE TABLE (L8))...........................................................564 ERROR CODE [DK56KA] (FORWARD-REVERSE POTENTIOMETER 1 :DISCONNECTION (KA)).........................................................565 ERROR CODE [DK56KB] (FORWARD-REVERSE POTENTIOMETER 1 :SHORT CIRCUIT (KB)).........................................................567 ERROR CODE [DK57KA] (FORWARD-REVERSE POTENTIOMETER 2 :DISCONNECTION (KA)).........................................................568 ERROR CODE [DK57KB] (FORWARD-REVERSE POTENTIOMETER 2 :SHORT CIRCUIT (KB)).........................................................570 ERROR CODE [DKH1KA] (PITCH ANGLE SENSOR : DISCONNECTION (KA)).....................................................................571 ERROR CODE [DKH1KB] (PITCH ANGLE SENSOR : SHORT CIRCUIT (KB)).....................................................................572 ERROR CODE [DLE3LC] (ENGINE NE SPEED SENSOR :SEE TABLE (LC))......................................................................573 ERROR CODE [DLF1KA] (TRANSMISSION BEVEL SPEED SENSOR :DISCONNECTION (KA)).........................................................575 ERROR CODE [DLH1LC] (ENGINE G SPEED SENSOR :SEE THE TABLE (LC))...................................................................576 ERROR CODE [DV00KB] (CAUTION BUZZER: SHORT CIRCUIT (KB))..........................................................................577 ERROR CODE [DW7BKA] (FAN REVERSE SOLENOID : DISCONNECTION (KA))...................................................................578 ERROR CODE [DW7BKB] (FAN REVERSE SOLENOID : SHORT CIRCUIT (KB))...................................................................579 ERROR CODE [DWN1KA] (HSS EPC SOLENOID LEFT : DISCONNECTION (KA))..................................................................580 ERROR CODE [DWN1KB] (HSS EPC SOLENOID LEFT : SHORT CIRCUIT (KB))..................................................................581 ERROR CODE [DWN2KA] (HSS EPC SOLENOID RIGHT : DISCONNECTION (KA)).................................................................582 ERROR CODE [DWN2KB] (HSS EPC SOLENOID RIGHT : SHORT CIRCUIT (KB)).................................................................583 ERROR CODE [DWN5KA] (FAN PUMP SOLENOID : DISCONNECTION (KA))......................................................................584 ERROR CODE [DWN5KB] (FAN PUMP SOLENOID :SHORT CIRCUIT (KB)).......................................................................585 ERROR CODE [DXA0KA] (HSS・HYDRAULIC PUMP TVC SOLENOID: DISCONNECTION (KA)).........................................................586 ERROR CODE [DXA0KB] (HSS・ HYDRAULIC PUMP TVC SOLENOID: SHORT CIRCUIT (KB))........................................................587 ERROR CODE [DXH4KA] (1ST CLUTCH ECMV: DISCONNECTION (KA)).........................................................................588 ERROR CODE [DXH4KB] (1ST CLUTCH ECMV: SHORT CIRCUIT (KB)).........................................................................589 ERROR CODE [DXH5KA] (2ND CLUTCH ECMV: DISCONNECTION (KA)).........................................................................590 ERROR CODE [DXH5KB] (2ND CLUTCH ECMV:SHORT CIRCUIT (KB))..........................................................................591 ERROR CODE [DXH6KA] (3RD CLUTCH ECMV: DISCONNECTION (KA)).........................................................................592 ERROR CODE [DXH6KB] (3RD CLUTCH ECMV:SHORT CIRCUIT (KB))..........................................................................593 ERROR CODE [DXH7KA] (REVERSE CLUTCH ECMV: DISCONNECTION (KA)).....................................................................594 ERROR CODE [DXH7KB] (REVERSE CLUTCH ECMV:SHORT CIRCUIT (KB))......................................................................595 ERROR CODE [DXH8KA] (FORWARD CLUTCH ECMV: DISCONNECTION (KA)).....................................................................596 ERROR CODE [DXH8KB] (FORWARD CLUTCH ECMV:SHORT CIRCUIT (KB))......................................................................597 TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE).........................................................................................598 INFORMATION DESCRIBED IN TROUBLESHOOTING LIST.....................................................................................599 E-1 THE ENGINE DOES NOT START.....................................................................................................600 E-2 THE PREHEATER DOES NOT OPERATE.(MANUAL PREHEATING FUNCTION)...................................................................602 E-3 THE MONITOR PANEL DOES NOT COME ON AT ALL WHEN THE STARTING SWITCH IS TURNED ON...............................................604 E-4 WHEN THE STARTING SWITCH IS TURNED ON,THE MONITOR PANEL COMPLETELY REMAINS LIGHTED AND DOES NOT GO OUT........................605 E-5 WHEN THE STARTING SWITCH IS TURNED OD,THE RADIATOR WATER LEVEL CAUTION LAMP FLASHES...........................................606 E-6 WHILE THE ENGINE IS OPERATING, THE BATTERY CHARGE LEVEL CAUTION LAMP FLASHES..................................................607 E-7 WHILE THE ENGINE IS OPERATING, THE EMERGENCY WARNING ITEM FLASHES.............................................................609 E-8 WHILE THE PREHEATER IS OPERATING , THE PREHEATING PILOT LAMP DOES NOT COME ON.................................................612 E-9 THE ENGINE WATER TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY.................................................................614 E-10 INDICATION OF THE POWER TRAIN TEMPERATURE GAUGS IS ABNORMAL..................................................................615 E-11 THE HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY...............................................................616 E-12 INDICATION OF THE FUEL GAUGES IS ABNORMAL....................................................................................617 E-13 INDICATIONS OF GAES SPEED AND ENGINE SPEED ARE ABNORMAL......................................................................618 E-14 INDICATION OF THE PRESET MODE SERVICE METER IS ABNORMAL......................................................................618 E-15 THE WARNING LAMP DOES NOT FLASH OR DOES NOT GO OUT ..........................................................................619 E-16 THE ALARM BUZZER DOES NOT SOUND OR DOES NOT STOP.............................................................................620 E-17 AUTO SHIFT DOWN IS NOT POSSIBLE OR IS NOT RELEASED...........................................................................621 E-18 THE BUZZER CANCEL SWITCH DOES NOT WORK.......................................................................................622 E-19 THE INFORMATION SWITCH DOES NOT WORK.........................................................................................623 E-20 THE MANUAL MODE DOES NOT OPERATE OR CANNOT BE RESET..........................................................................625 E-21 THE MONITOR PANEL CANNOT BE SET IN THE SERVICE MODE..........................................................................626 E-22 THE BACK-UP ALARM DOES NOT SOUND.............................................................................................628 E-23 THE HEAD LAMP, REAR LAMP, AND RIPPER POINT LAMP DO NOT LIGHT UP..............................................................629 E-24 MALFUNCTION OF WIPERS........................................................................................................632 E-25 WASHING WATER DOES NOT COME OUT..............................................................................................648 E-26 THE AIR CONDITIONER DOES NOT OPERATE.........................................................................................653 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)...........................................................................658 INFORMATION DESCRIBED IN TROUBLESHOOTING LIST.....................................................................................659 H-1 NO TRAVEL POWER (NO DRAWBAR PULL).............................................................................................660 H-2 MACHINE DOES NOT MOVE (AT 2ND OR 3RD SPEED)...................................................................................661 H-3 MACHINE DOES NOT MOVE IN ANY SPEED RANGE......................................................................................662 H-4 MACHINE TRAVELS ONLY IN ONE DIRECTION FORWARD OR IN REVERES...................................................................663 H-5 WHEN GEAR IS SHIFTED OR TRAVEL DIRECTION IS CHANGED, LARGE TIME LAG IS MADE...................................................664 H-6 MACHINE DOES NOT TURN (NOT TURNED RIGHTWARD OR LEFTWARD)......................................................................665 H-7 STEERING SPEED OR POWER IS LOW................................................................................................665 H-8 BRAKE DOES NOT WORK...........................................................................................................666 H-9 OVERHEAT OF POWER TRAIN OIL TEMPERATURE.......................................................................................666 H-10 ABNORMAL SOUND COMES OUT FROM AROUND HSS AND WORK EQUIPMENT PUMP OR HSS MOTOR................................................667 H-11 ALL WORK EQUIPMENT SPEEDS ARE SLOW...........................................................................................667 H-12 WORK EQUIPMENT DOES NOT MOVE.................................................................................................668 H-13 BLAND LIFT SPEED IS SLOW OR LACKS POWER......................................................................................668 H-14 BLAND TILT SPEED IS SLOW OR LACKS POWER......................................................................................669 H-15 RIPPER LIFT SPEED IS SLOW OR LACKS POWER.....................................................................................669 H-16 EXCESSIVE HYDRAULIC DRIFT OR BLADE LIFT......................................................................................670 H-17 EXCESSIVE HYDRAULIC DRIFT OR BLADE TILT......................................................................................670 H-18 EXCESSIVE HYDRAULIC DRIFT OF RIPPER LIFT.....................................................................................671 TROUBLESHOOTING OF ENGINE SYSTEM (S MODE).............................................................................................672 METHOD OF USING TROUBLESHOOTING CHARTS............................................................................................673 S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME).....................................................................677 S-2 ENGINE DOES NOT START.........................................................................................................678 S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)..........................................................................681 S-4 ENGINE STOPS DURING OPERATIONS................................................................................................682 S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING).....................................................................................683 S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)..........................................................................................684 S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)................................................................................685 S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE )......................................................................686 S-9 OIL BECOMES CONTAMINATED QUICKLY..............................................................................................687 S-10 FUEL CONSUMPTION IS EXCESSIVE................................................................................................688 S-11 OIL IS IN COOLING WATER (OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN)......................................................689 S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE) ..................................................................690 S-13 OIL LEVEL RISES (WATER,FUEL IN OIL)..........................................................................................691 S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING).............................................................................692 S-15 ABNORMAL NOISE IS MADE.......................................................................................................693 S-16 VIBRATION IS EXCESSIVE.......................................................................................................694 30 DISASSEMBLY AND ASSEMBLY...................................................................................................................695 HOW TO READ THIS MANUAL ..................................................................................................................697 PRECAUTIONS WHEN PERFORMING OPERATION.....................................................................................................699 SPECIAL TOOL LIST.........................................................................................................................701 SKETCH OF SPECIAL TOOL....................................................................................................................705 FUEL SUPPLY PUMP..........................................................................................................................709 SPECIAL TOOLS.........................................................................................................................709 REMOVAL...............................................................................................................................709 INSTALLATION..........................................................................................................................712 FUEL INJECTOR.............................................................................................................................715 REMOVAL...............................................................................................................................715 INSTALLATION..........................................................................................................................716 NOZZLE TIP................................................................................................................................719 SPECIAL TOOL..........................................................................................................................719 REMOVAL...............................................................................................................................719 INSTALLATION..........................................................................................................................720 ENGINE FRONT SEAL.........................................................................................................................721 SPECIAL TOOLS.........................................................................................................................721 REMOVAL ..............................................................................................................................721 INSTALLATION..........................................................................................................................722 ENGINE REAR SEAL..........................................................................................................................723 SPECIAL TOOLS.........................................................................................................................723 REMOVAL AND INSTALLATION..............................................................................................................723 ENGINE CYLINDER HEAD......................................................................................................................726 SPECIAL TOOLS.........................................................................................................................726 REMOVAL...............................................................................................................................726 INSTALLATION..........................................................................................................................731 ENGINE OIL PAN............................................................................................................................734 REMOVAL...............................................................................................................................734 INSTALLATION..........................................................................................................................736 FUEL TANK.................................................................................................................................737 REMOVAL...............................................................................................................................737 INSTALLATION..........................................................................................................................738 RADIATOR..................................................................................................................................739 REMOVAL...............................................................................................................................739 INSTALLATION..........................................................................................................................740 ENGINE....................................................................................................................................741 SPECIAL TOOLS.........................................................................................................................741 REMOVAL...............................................................................................................................741 INSTALLATION..........................................................................................................................744 DAMPER....................................................................................................................................745 REMOVAL...............................................................................................................................745 INSTALLATION..........................................................................................................................746 SPECIAL TOOLS.........................................................................................................................747 DISASSEMBLY...........................................................................................................................748 ASSEMBLY..............................................................................................................................750 POWER TRAIN UNIT..........................................................................................................................752 REMOVAL...............................................................................................................................752 INSTALLATION..........................................................................................................................755 DISCONNECTION.........................................................................................................................756 CONNECTION............................................................................................................................759 TORQFLOW TRANSMISSION.....................................................................................................................760 SPECIAL TOOLS.........................................................................................................................760 DISASSEMBLY...........................................................................................................................760 ASSEMBLY..............................................................................................................................766 HSS.......................................................................................................................................774 SPECIAL TOOLS.........................................................................................................................774 DISASSEMBLY...........................................................................................................................774 ASSEMBLY..............................................................................................................................781 PTO.......................................................................................................................................792 DISASSEMBLY...........................................................................................................................792 ASSEMBLY..............................................................................................................................794 TORQUE CONVERTER..........................................................................................................................798 DISASSEMBLY...........................................................................................................................798 ASSEMBLY..............................................................................................................................799 SCAVENGING PUMP...........................................................................................................................802 REMOVAL AND INSTALLATION..............................................................................................................802 HSS AND WORK EQUIPMENT PUMP...............................................................................................................803 REMOVAL...............................................................................................................................803 INSTALLATION..........................................................................................................................804 FAN PUMP..................................................................................................................................805 REMOVAL AND INSTALLATION..............................................................................................................805 POWER TRAIN AND LUBRICATING OIL PUMP......................................................................................................806 REMOVAL AND INSTALLATION..............................................................................................................806 HSS MOTOR.................................................................................................................................807 REMOVAL AND INSTALLATION..............................................................................................................807 FINAL DRIVE...............................................................................................................................808 SPECIAL TOOLS.........................................................................................................................808 REMOVAL...............................................................................................................................808 INSTALLATION..........................................................................................................................809 SPECIAL TOOLS.........................................................................................................................810 DISASSEMBLY...........................................................................................................................810 ASSEMBLY..............................................................................................................................815 TRACK FRAME...............................................................................................................................822 REMOVAL...............................................................................................................................822 INSTALLATION..........................................................................................................................824 IDLER.....................................................................................................................................825 REMOVAL AND INSTALLATION..............................................................................................................825 SPECIAL TOOLS.........................................................................................................................827 DISASSEMBLY...........................................................................................................................827 ASSEMBLY..............................................................................................................................828 RECOIL SPRING.............................................................................................................................831 REMOVAL...............................................................................................................................831 INSTALLATION..........................................................................................................................832 SPECIAL TOOLS.........................................................................................................................833 DISASSEMBLY...........................................................................................................................833 ASSEMBLY..............................................................................................................................835 TRACK ROLLER..............................................................................................................................837 REMOVAL AND INSTALLATION..............................................................................................................837 SPECIAL TOOLS.........................................................................................................................838 DISASSEMBLY...........................................................................................................................838 ASSEMBLY..............................................................................................................................839 CARRIER ROLLER............................................................................................................................841 REMOVAL AND INSTALLATION..............................................................................................................841 SPECIAL TOOLS.........................................................................................................................842 DISASSEMBLY...........................................................................................................................842 ASSEMBLY..............................................................................................................................843 TRACK SHOE................................................................................................................................845 CHECK BEFORE EXPANDING TRACK SHOE ASSEMBLY............................................................................................845 EXPANSION TRACK SHOE ASSEMBLY (ORDINARY)..............................................................................................845 EXPANSION TRACK SHOE ASSEMBLY (WHEN TRACK FRAME HAS INTERNAL TROUBLE).................................................................846 INSTALLATION..........................................................................................................................847 SPECIAL TOOLS.........................................................................................................................848 WHOLE DISASSEMBLY.....................................................................................................................848 WHOLE ASSEMBLY........................................................................................................................850 DIMENSIONS TABLE OF FITTING JIG OF LINK PRESS.........................................................................................861 DISASSEMBLY OF 1 LINK IN THE FIELD....................................................................................................862 DISASSEMBLY AND ASSEMBLY OF MASTER LINK...............................................................................................864 PIVOT SHAFT...............................................................................................................................867 REMOVAL AND INSTALLATION..............................................................................................................867 EQUALIZER BAR.............................................................................................................................868 REMOVAL...............................................................................................................................868 INSTALLATION..........................................................................................................................869 DISASSEMBLY AND ASSEMBLY..............................................................................................................870 WORK EQUIPMENT CONTROL VALVE..............................................................................................................872 REMOVAL...............................................................................................................................872 INSTALLATION..........................................................................................................................874 ASSEMBLY..............................................................................................................................875 HYDRAULIC CYLINDER........................................................................................................................876 SPECIAL TOOLS.........................................................................................................................876 DISASSEMBLY...........................................................................................................................876 ASSEMBLY..............................................................................................................................879 BLADE.....................................................................................................................................881 REMOVAL...............................................................................................................................881 INSTALLATION..........................................................................................................................882 RIPPER....................................................................................................................................883 DISASSEMBLY ..........................................................................................................................883 ASSEMBLY..............................................................................................................................885 ROPS GUARD................................................................................................................................887 REMOVAL AND INSTALLATION..............................................................................................................887 OPERATOR'S CAB............................................................................................................................888 REMOVAL...............................................................................................................................888 INSTALLATION..........................................................................................................................890 REMOVAL AND INSTALLATION OF OPERATOR'S CAB GLASS (STUCK GLASS)............................................................................893 SPECIAL TOOLS.........................................................................................................................894 REMOVAL...............................................................................................................................894 INSTALLATION..........................................................................................................................895 FLOOR FRAME...............................................................................................................................902 SPECIAL TOOLS.........................................................................................................................902 REMOVAL...............................................................................................................................902 INSTALLATION..........................................................................................................................905 ENGINE CONTROLLER.........................................................................................................................907 REMOVAL AND INSTALLATION..............................................................................................................907 STEERING AND TRANSMISSION CONTROLLER......................................................................................................908 REMOVAL AND INSTALLATION..............................................................................................................908 ENGINE HOOD...............................................................................................................................909 REMOVAL AND INSTALLATION..............................................................................................................909 FAN DRIVE.................................................................................................................................910 REMOVAL...............................................................................................................................910 INSTALLATION..........................................................................................................................911 FAN MOTOR.................................................................................................................................912 REMOVAL AND INSTALLATION..............................................................................................................912 90 OTHERS.....................................................................................................................................913 POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM.....................................................................................................914 WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/3)............................................................................................915 WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (2/3)............................................................................................916 WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (3/3)............................................................................................917 ELECTRICAL CIRCUIT DIAGRAM (1/6)..........................................................................................................918 ELECTRICAL CIRCUIT DIAGRAM (2/6)..........................................................................................................919 ELECTRICAL CIRCUIT DIAGRAM (3/6)..........................................................................................................920 ELECTRICAL CIRCUIT DIAGRAM (4/6)..........................................................................................................921 ELECTRICAL CIRCUIT DIAGRAM (5/6)..........................................................................................................922 ELECTRICAL CIRCUIT DIAGRAM (6/6)..........................................................................................................923 CAB ELECTRICAL CIRCUIT DIAGRAM............................................................................................................924

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: