$36

Komatsu Diesel Engine Shop Manual DE-BE3 – PDF DOWNLOAD

Komatsu Diesel Engine Shop Manual DE-BE3 – PDF DOWNLOAD

FILE DETAILS:

Komatsu Diesel Engine Shop Manual DE-BE3 – PDF DOWNLOAD

Language : English

Pages : 152

Downloadable : Yes

File Type : PDF

Size: 17.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu Diesel Engine Shop Manual DE-BE3 – PDF DOWNLOAD

FOREWORD:

This shop manual is published for the information and guidance of the

service personnel who repair or rebuild KOMATSU engines and units used

thereon. The manual contains information on the overhauling procedure

as well as description of adjusting and testing methods necessitated

during overhaul operation. All the KOMATSU engine models are included

in this manual because the operational procedures are the same of very

similar, and because the various KOMATSU machines equipped with these

engines are often handled in the same workshop.

It is hoped that the descriptions in this manual are useful to ensure the

right and economical service operation.

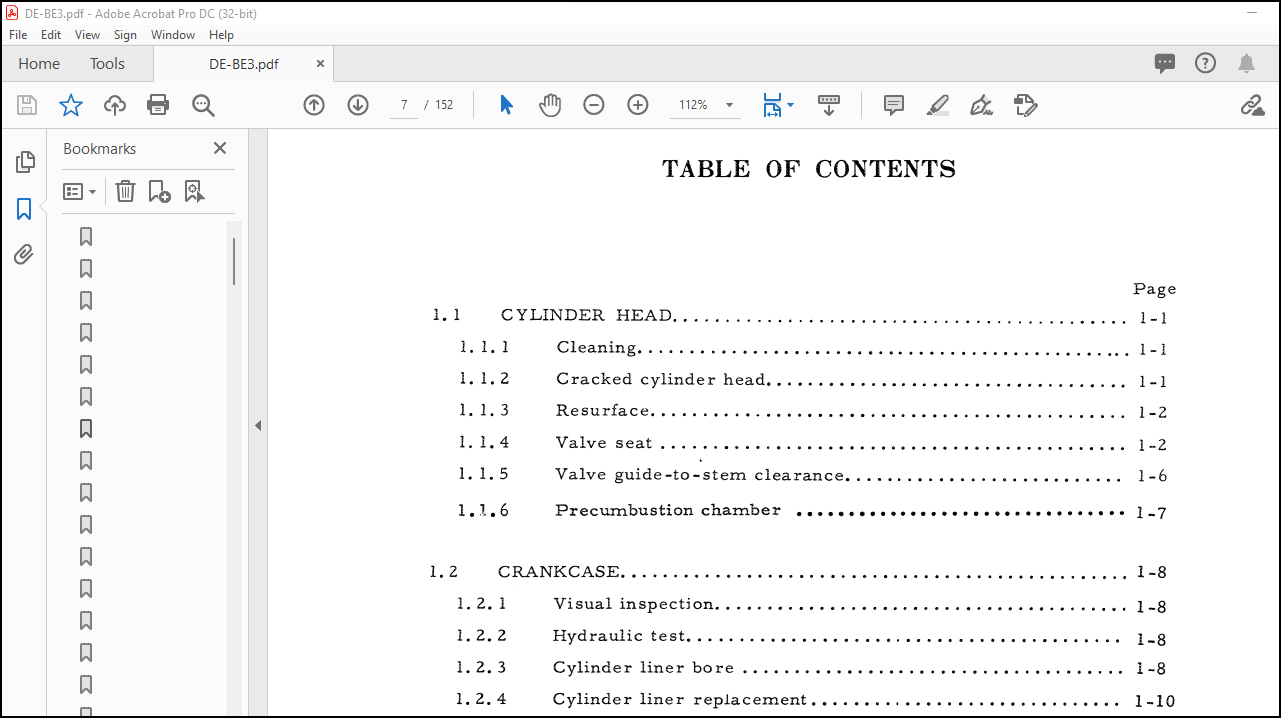

TABLE OF CONTENTS:

Komatsu Diesel Engine Shop Manual DE-BE3 – PDF DOWNLOAD

1 1 CYLINDER HEAD 1-1

Cleaning l -1

Cracked cylinder head 1-1

Resurface 1-2

Valve seat 1-2

Valve guide-to-stem clearance, 1-6

Precumbustion chamber I – 7

1 2 CRANKCASE 1-8

Visual inspection 1-8

Hydraulic test 1-8

Cylinder liner bore 1-8

Cylinder liner replacement 1-10

Resurface 1-11

1 3 CRANKSHAFT AND MAIN BEARING 1-11

1 3 l Crankshaft journal and crankpin 1-11

1 3 2 Crankshaft run-out 1-12

Fillet 1-13

Main bearing-to-journal clearance 1-14

Main bearing crush 1-14

Crankshaft end play 1-15

Magnaflux test of crank shaft 1-16

Main bearing cap replacement 1-16

I 4 FLYWHEEL 1-1 7

Flywheel-to-clutch shaft bearing fitting 1-17

Ring gear teeth 1-18

Flywheel replacement 1-18

Flywheel · , , , · · · · · · · · · · 1-18

1 5 PISTONS, PISTON PINS, PISTON RINGS AND Page

CONNECTING RODS, , · · ·, · 1-19

Visual inspection of piston ,, , ,, 1-19

Cylinder liner-to-piston clearance , 1-19

Piston pin-to -pin hole clearance , 1-22

Piston ring-to-groove clearance 1-22

Piston ring gap , , , , 1-24

Piston pin -to-connecting rod end bushing clearance 1 _24

Crank pin-to-bearing clearance 1-25

Crank pin metal crush , , : , · · 1-27

Rod bore alignment and rod twist 1- 27

1-6 ATTENTION FOR INSTALLATING PISTON

AND CONNECTING ROD , · ·, · · · · · · · · l-27

1 7 CAMSHAFT 1-28

1 7 1 Visualinspection 1-28

l 7 2 Camshatt-to-bushing clearance 1-28

1 7,3 Camheight 1-30

1 7 4 Camshaft runout 1-30

Camshaft end play 1-30

Key and keyway , 1-31

l 8 VALVES AND VALVE MECHANISM 1-31

Visual inspection 1-31

Valve face 1-31

Valve stem 1-32

Stem runout 1-3 2

Sinking of valve 1-33

1 8 4 2 Valve guide-to stem clearance · 1-33

Squareness of valve spring

Load of valve spring , ,

Rocker shaft ,

Rocker arm-to-bushing clearance

Push rods ,

Tappet-to-guide clearance

Re-facing tappet : 1-38

Attention for installing valves 1-38

1 9 TIMING GEARS · , · · 1-38

1 9 l Visual inspection , , , , , 1-38

1 9 2 Gear backlash 1-38

1 9 3 Gear shaft end play and shaft-to-bushing clearance 1-40

1 10 MANIFOLDS 1-42

Exhaust manifold 1-42

Intake manifold , l-4 2

Water manifold 1-43

l 11 MAIN ENGINE TUNE- UP 1-43

Valve clearance adjustment 1-43

Injection timing gear adjustment 1-44

Bleeding of fuel system 1-45

Lubricating oil pressure adjustment 1-46

1 12 ENGINE TESTS1-46

1 12 l “Run-in” operation , 1-46

Observation during run-in operation , , , ,_ 1-49

Servicing after completing run-in operation 1-49

Engine performance test s 1-49