$33

Komatsu Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Operator & Mantenance Manual PDF

Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Operator & Maintenance Manual – PDF DOWNLOAD

DESCRIPTION:

Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Operator & Maintenance Manual – PDF DOWNLOAD

SERIAL NUMBERS PC750-20072

PC800-40069 and up

FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. The

precautions in this manual must be followed at all times when performing operation and maintenance. Most

accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of

machines. Accidents can be prevented by knowing beforehand conditions that may cause a hazard when

performing operation and maintenance

WARNING

Operators and maintenance personnel must always do as follows before beginning operation or maintenance.

Always be sure to read and understand this manual thoroughly before performing operation and maintenance.

Read the safety messages given in this manual and the safety labels affixed to the machine thoroughly and be sure that you

understand them fully.

Keep this manual in the storage location for the operation and maintenance manual given below, and have all personnel read it

periodically.

If this manual has been lost or has become dirty and cannot be read, request a replacement manual immediately from Komatsu

or your Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners together with the machine.

Komatsu delivers machines that comply with all applicable regulations and standards of the country to which it has been shipped.

If this machine has been purchased in another country or purchased from someone in another country, it may lack certain safety

devices and specifications that are necessary for use in your country. If there is any question about whether your product

complies with the applicable standards and regulations of your country, consult Komatsu or your Komatsu distributor before

operating the machine.

TABLE OF CONTENTS:

Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Operator & Maintenance Manual – PDF DOWNLOAD

CONTENTS

FOREWORD 1- 1

FOREWORD 1- 2

SAFETY INFORMATION 1- 5

INTRODUCTION 1- 7

DIRECTIONS OF MACHINE 1- 7

BREAKING-IN THE NEW MACHINE 1- 7

PRODUCT INFORMATION 1- 8

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION 1- 8

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION 1- 8

SERVICE METER LOCATION 1- 9

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR 1- 9

SAFETY 2- 1

SAFETY 2- 2

SAFETY LABELS 2- 4

LOCATION OF SAFETY LABELS 2- 5

SAFETY LABELS 2- 6

GENERAL PRECAUTIONS 2- 12

SAFETY MACHINE OPERATION 2- 20

STARTING ENGINE 2- 20

OPERATION 2- 22

TRANSPORTATION 2- 28

BATTERY 2- 29

TOWING 2- 31

LIFTING OBJECTS WITH BUCKET 2- 32

SAFETY MAINTENANCE INFORMATION 2- 33

OPERATION 3- 1

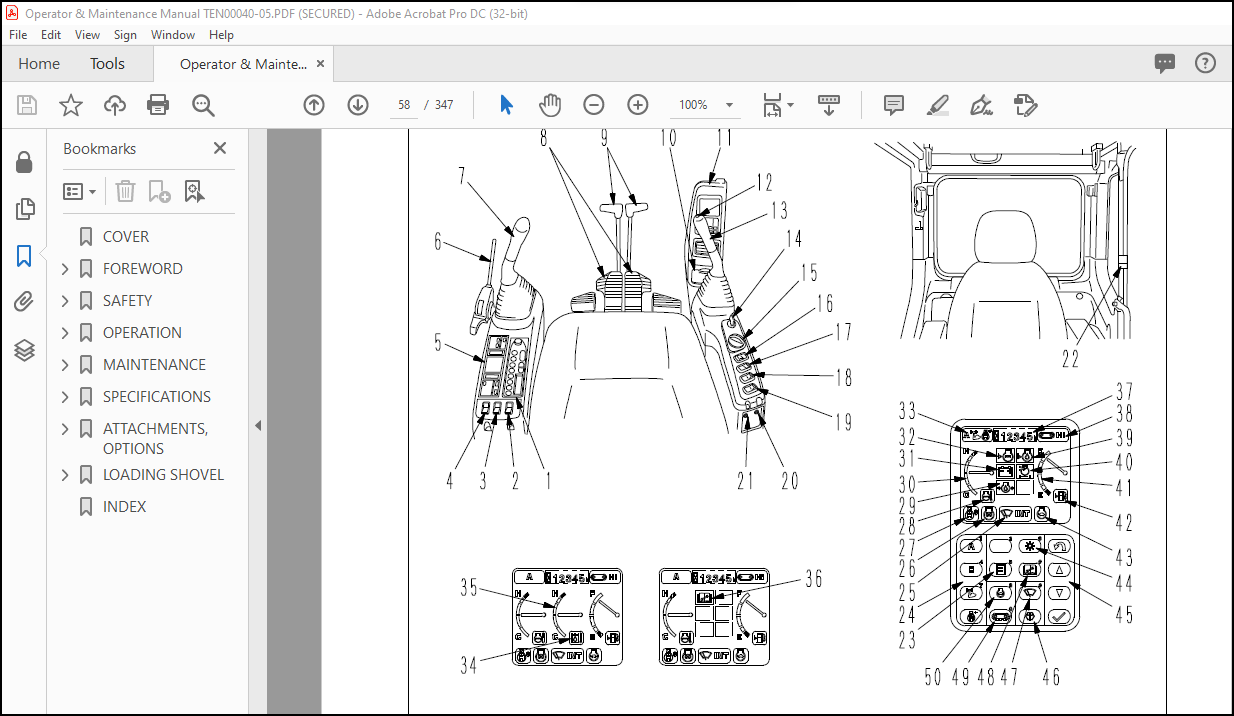

MACHINE VIEW ILLUSTRATIONS 3- 2

OVERALL MACHINE VIEW 3- 2

CONTROLS AND GAUGES 3- 3

DETAILED CONTROLS AND GAUGES 3- 5

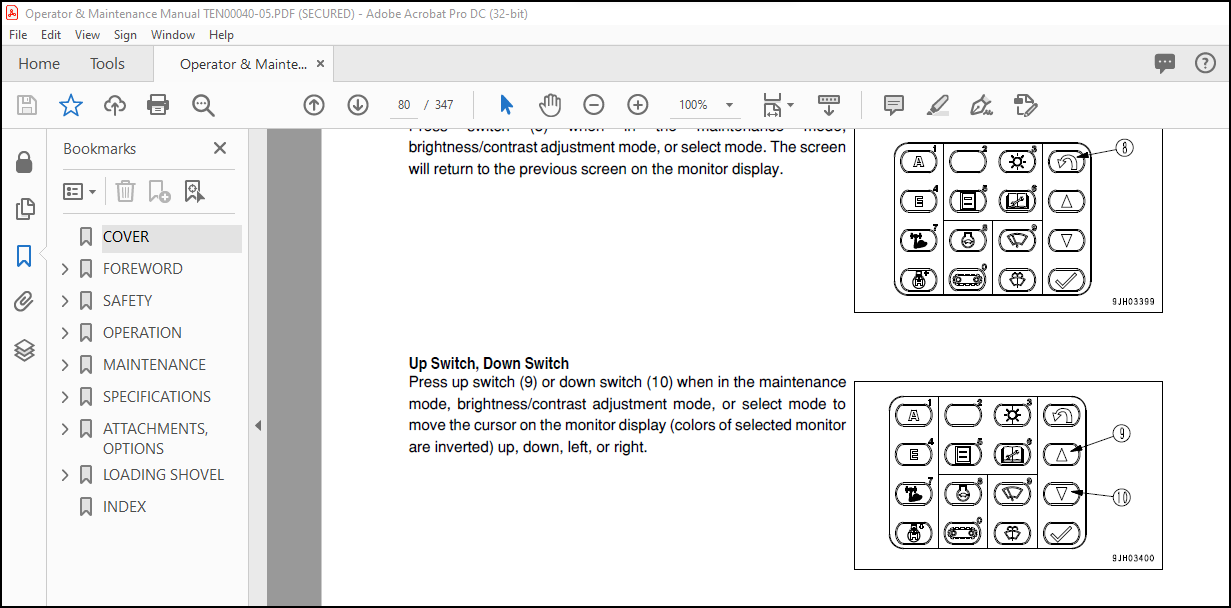

MONITORING SYSTEM 3- 5

SWITCHES 3- 28

CONTROL LEVERS AND PEDALS 3- 35

SUN ROOF 3- 38

WINDSHIELD 3- 39

EMERGENCY EXIT FROM OPERATOR’S CAB 3- 44

DOOR LOCK 3- 44

CAP WITH LOCK 3- 45

HOT AND COOL BOX 3- 46

MAGAZINE BOX 3- 46

ASHTRAY 3- 47

AIR CONDITIONER CONTROLS 3- 48

RADIO 3- 62

AUXILIARY ELECTRIC POWER 3- 71

FUSE 3- 72

CIRCUIT BREAKER 3- 73

CONTROLLER 3- 74

TOOL BOX 3- 74

GREASE PUMP 3- 75

ACCUMULATOR 3- 78

MACHINE OPERATIONS AND CONTROLS 3- 79

BEFORE STARTING ENGINE 3- 79

STARTING ENGINE 3- 99

AFTER STARTING ENGINE 3-104

STOPPING THE ENGINE 3-112

MACHINE OPERATION 3-113

STEERING THE MACHINE 3-117

SWINGING 3-119

WORK EQUIPMENT CONTROLS AND OPERATIONS 3-120

WORKING MODE 3-122

PROHIBITED OPERATIONS 3-123

GENERAL OPERATION INFORMATION 3-126

TRAVELING ON SLOPES 3-128

ESCAPE FROM MUD 3-130

RECOMMENDED APPLICATIONS 3-131

BUCKET REPLACEMENT 3-132

PARKING MACHINE 3-134

CHECK AFTER SHUT OFF ENGINE 3-135

LOCKING 3-136

TRANSPORTATION 3-137

PRECAUTIONS FOR TRANSPORTATION 3-137

LIFTING MACHINE 3-138

SHIPPING MACHINE INFORMATION 3-140

TRANSPORTATION POSTURE 3-141

PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE 3-147

COLD WEATHER OPERATION 3-149

COLD WEATHER OPERATION INFORMATION 3-149

AFTER DAILY WORK COMPLETION 3-152

AFTER COLD WEATHER SEASON 3-152

LONG TERM STORAGE 3-153

BEFORE STORAGE 3-153

DURING STORAGE 3-153

AFTER STORAGE 3-153

STARTING MACHINE AFTER LONG-TERM STORAGE 3-154

TROUBLES AND ACTIONS 3-155

RUNNING OUT OF FUEL 3-155

PHENOMENA THAT ARE NOT FAILURES 3-156

TOWING THE MACHINE 3-157

SEVERE JOB CONDITION 3-157

DISCHARGED BATTERY 3-158

OTHER TROUBLE 3-162

MAINTENANCE 4- 1

MAINTENANCE INFORMATION 4- 2

OUTLINE OF SERVICE 4- 4

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC 4- 4

ELECTRIC SYSTEM MAINTENANCE 4- 7

WEAR PARTS 4- 8

WEAR PARTS LIST 4- 9

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS 4- 10

PROPER SELECTION 4- 10

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN

KOMATSU GENUINE OIL 4- 11

TIGHTENING TORQUE SPECIFICATIONS 4- 12

TIGHTENING TORQUE LIST 4- 12

SAFETY CRITICAL PARTS 4- 13

SAFETY CRITICAL PARTS LIST 4- 14

MAINTENANCE SCHEDULE 4- 15

MAINTENANCE SCHEDULE CHART 4- 15

MAINTENANCE PROCEDURE 4- 17

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS) 4- 17

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS) 4- 17

WHEN REQUIRED 4- 18

CHECK BEFORE STARTING 4- 41

EVERY 10 HOURS MAINTENANCE 4- 42

EVERY 100 HOURS MAINTENANCE 4- 45

EVERY 250 HOURS MAINTENANCE 4- 46

EVERY 500 HOURS MAINTENANCE 4- 53

EVERY 1000 HOURS MAINTENANCE 4- 66

EVERY 2000 HOURS MAINTENANCE 4- 77

EVERY 4000 HOURS MAINTENANCE 4- 80

EVERY 5000 HOURS MAINTENANCE 4- 83

EVERY 8000 HOURS MAINTENANCE 4- 86

SPECIFICATIONS 5- 1

SPECIFICATIONS 5- 2

ATTACHMENTS AND OPTIONS 6- 1

GENERAL PRECAUTIONS FOR SAFETY 6- 2

PRECAUTIONS WHEN SELECTING 6- 2

READ THE INSTRUCTION MANUAL THOROUGHLY 6- 2

PRECAUTIONS WHEN REMOVING OR INSTALLING 6- 2

PRECAUTIONS WHEN USING 6- 2

ATTACHMENT GUIDE 6- 3

COMBINATIONS OF WORK EQUIPMENT 6- 4

LOADING SHOVEL 7- 1

EXPLANATION OF COMPONENTS 7- 2

SWITCHES 7- 2

FUSE 7- 5

OPERATIONS 7- 6

OPERATION OF WORK EQUIPMENT 7- 6

PRECAUTIONS DURING OPERATION 7- 8

LOADING SHOVEL WORK 7- 12

PRECAUTIONS WHEN DISASSEMBLING MACHINE 7- 13

RELEASING PRESSURE 7- 13

TRANSPORTATION 7- 14

MACHINE CONFIGURATION FOR TRANSPORT 7- 14

WEAR PARTS 7- 15

WEAR PARTS LIST 7- 15

MAINTENANCE 7- 16

CHECK BEFORE STARTING 7- 16

EVERY 10 HOURS MAINTENANCE 7- 18

EVERY 5000 HOURS MAINTENANCE 7- 19

SPECIFICATION 7- 21

COMBINATION OF WORK EQUIPMENT 7- 22

COMBINATION OF WORK EQUIPMENT 7- 22

INDEX 8- 1

IMAGES PREVIEW OF THE MANUAL: