$37

Komatsu Galeo PC270LL-7L Logging Excavator Shop Manual CEBM014600 – PDF DOWNLOAD

Komatsu Galeo PC270LL-7L Logging Excavator Shop Manual CEBM014600 – PDF DOWNLOAD

FILE DETAILS:

Komatsu Galeo PC270LL-7L Logging Excavator Shop Manual CEBM014600 – PDF DOWNLOAD

Language : English

Pages : 694

Downloadable : Yes

File Type : PDF

Size: 30.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu Galeo PC270LL-7L Logging Excavator Shop Manual CEBM014600 – PDF DOWNLOAD

SERIAL NUMBERS PC270LL-7L A85001 and UP

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.PREPARATIONS FOR WORK:

1. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

2. Before starting work, lower outrigger, bucket or any other work equipment to the ground. If this is not possible,

use blocks to prevent the work equipment from falling down. In addition, be sure to lock all the control levers and hang warning sign on them.

3. When disassembling or assembling, support the machine with blocks, jacks or stands before starting

work.

4. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

TABLE OF CONTENTS:

Komatsu Galeo PC270LL-7L Logging Excavator Shop Manual CEBM014600 – PDF DOWNLOAD

MAIN MENU………………………………………………………………………. 0

COVER………………………………………………………………………….. 1

CONTENTS……………………………………………………………………….. 2

FOREWORD……………………………………………………………………….. 2

SAFETY……………………………………………………………………… 5

SAFETY NOTICE……………………………………………………………. 5

IMPORTANT SAFETY NOTICE…………………………………………………… 5

GENERAL PRECAUTIONS………………………………………………………. 5

PREPARATIONS FOR WORK…………………………………………………….. 5

PRECAUTIONS DURING WORK…………………………………………………… 5

GENERAL…………………………………………………………………….. 7

HOW TO READ THE SHOP MANUAL…………………………………………………… 8

VOLUMES…………………………………………………………………. 8

DISTRIBUTION AND UPDATING…………………………………………………. 8

FILING METHOD……………………………………………………………. 8

REVISED EDITION MARK……………………………………………………… 8

REVISIONS……………………………………………………………….. 8

SYMBOLS…………………………………………………………………. 8

HOISTING INSTRUCTIONS………………………………………………………… 9

HOISTING………………………………………………………………… 9

WIRE ROPES………………………………………………………………. 9

COATING MATERIALS……………………………………………………………. 10

STANDARD TIGHTENING TORQUE……………………………………………………. 12

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS………………………………… 12

TIGHTENING TORQUE OF HOSE NUTS…………………………………………….. 13

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS…………………………………….. 13

TIGHTENING TORQUE FOR FLARED NUTS………………………………………….. 13

ELECTRIC WIRE CODE…………………………………………………………… 14

CLASSIFICATION BY THICKNESS……………………………………………….. 14

CLASSIFICATION BY COLOR AND CODE…………………………………………… 14

CONVERSION TABLES……………………………………………………………. 15

METHOD OF USING THE CONVERSION TABLE……………………………………….. 15

01 GENERAL……………………………………………………………………… 21

SPECIFICATION DIMENSION DRAWINGS………………………………………………. 22

PC270LL-7L………………………………………………………………. 22

DIMENSIONS………………………………………………………………. 22

WORKING RANGES…………………………………………………………… 24

WEIGHT TABLE………………………………………………………………… 27

FUEL, COOLANT AND LUBRICANTS………………………………………………….. 29

PC270LL-7L………………………………………………………………. 29

10 STRUCTURE AND FUNCTION………………………………………………………… 31

ENGINE RELATED PARTS…………………………………………………………. 33

RADIATOR . OIL COOLER . AFTERCOOLER……………………………………………. 34

POWER TRAIN…………………………………………………………………. 35

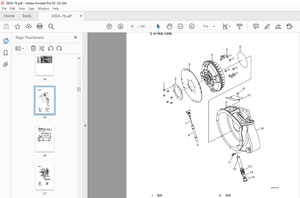

FINAL DRIVE…………………………………………………………………. 37

SWING CIRCLE………………………………………………………………… 41

TRACK FRAME . RECOIL SPRING…………………………………………………… 43

IDLER………………………………………………………………………. 45

TRACK ROLLER………………………………………………………………… 47

TRACK SHOE………………………………………………………………….. 48

TRIPLE GROUSER SHOE………………………………………………………….. 50

HYDRAULIC EQUIPMENT………………………………………………………….. 51

HYDRAULIC TANK………………………………………………………………. 53

HYDRAULIC PUMP………………………………………………………………. 55

HPV95 + 95………………………………………………………………. 55

LS VALVE………………………………………………………………… 60

PC VALVE………………………………………………………………… 60

LS(PC)-EPC VALVE…………………………………………………………. 73

CONTROL VALVE……………………………………………………………….. 77

SELF PRESSURE REDUCING VALVE………………………………………………….. 93

MAIN RELIEF VALVE………………………………………………………… 96

VARIABLE PRESSURE COMPENSATION VALVE……………………………………….. 97

CLSS……………………………………………………………………….. 99

SWING MOTOR………………………………………………………………….100

RELIEF VALVE PORTION………………………………………………………103

SWING LOCK……………………………………………………………….104

REVERSE PREVENTION VALVE………………………………………………………105

CENTER SWIVEL JOINT…………………………………………………………..108

TRAVEL MOTOR……………………………………………………………..110

PARKING BRAKE…………………………………………………………….115

TRAVEL JUNCTION VALVE……………………………………………………..121

VALVE CONTROL………………………………………………………………..123

CONNECTIONS………………………………………………………………123

LEVER POSITIONS…………………………………………………………..124

WORK EQUIPMENT . SWING PPC VALVE……………………………………………….125

TRAVEL PPC VALVE……………………………………………………………..130

SERVICE VALVE………………………………………………………………..139

SOLENOID VALVE……………………………………………………………….142

ATTACHMENT SOLENOID VALVE……………………………………………………..143

PPC ACCUMULATOR………………………………………………………………145

BOOM HYDRAULIC DRIFT PREVENTION VALVE…………………………………………..146

LIFT CHECK VALVE……………………………………………………………..149

HYDRAULIC CYLINDERS…………………………………………………………..150

BOOM CYLINDER…………………………………………………………….150

ARM CYLINDER……………………………………………………………..150

BUCKET CYLINDER…………………………………………………………..150

WORK EQUIPMENT……………………………………………………………….152

100 HOURS………………………………………………………………..153

500 HOURS………………………………………………………………..153

DIMENSION OF ARM………………………………………………………….154

DIMENSION OF BUCKET……………………………………………………….156

AIR CONDITIONER………………………………………………………………158

PIPING…………………………………………………………………..158

ENGINE CONTROL……………………………………………………………….159

FUEL CONTROL DIAL…………………………………………………………161

GOVERNOR MOTOR……………………………………………………………162

ENGINE THROTTLE AND PUMP CONTROLLER…………………………………………164

INPUT AND OUTPUT SIGNALS…………………………………………………..165

ELECTRONIC CONTROL SYSTEM……………………………………………………..167

MACHINE CONTROL SYSTEM DIAGRAM……………………………………………..168

ENGINE AND PUMP CONTROL FUNCTION……………………………………………170

SWING CONTROL FUNCTION WITH SOFT SWING………………………………………185

MULTI MONITOR SYSTEM………………………………………………………….193

MONITOR PANEL…………………………………………………………….194

MONITOR CONTROL, DISPLAY PORTION MONITOR PORTION……………………………..196

MONITOR ITEMS AND DISPLAY………………………………………………….197

MAINTENANCE FUNCTION………………………………………………………206

SENSORS……………………………………………………………………..211

ENGINE OIL LEVEL SENSOR……………………………………………………212

ENGINE OIL PRESSURE SENSOR (FOR LOW PRESSURE)………………………………..212

COOLANT TEMPERATURE SENSOR…………………………………………………212

HYDRAULIC OIL TEMPERATURE SENSOR……………………………………………212

FUEL LEVEL SENSOR…………………………………………………………213

AIR CLEANER CLOGGING SENSOR………………………………………………..213

CAB RISER AND RELATED PARTS……………………………………………………214

POWER CONTROL…………………………………………………………….215

CAB RISER HYDRAULIC SYSTEM…………………………………………………….216

20 TESTING, ADJUSTING AND TROUBLESHOOTING…………………………………………..231

STANDARD VALUE TABLES…………………………………………………………219

ENGINE…………………………………………………………………..219

CHASSIS………………………………………………………………….220

TESTING AND ADJUSTING…………………………………………………………231

SERVICE TOOLS…………………………………………………………….233

ENGINE…………………………………………………………………..234

COMPRESSION PRESSURE…………………………………………………..234

BLOW-BY PRESSURE………………………………………………………234

OIL PRESSURE………………………………………………………….234

RPM………………………………………………………………….234

SPEED SENSOR………………………………………………………….234

EXHAUST GAS COLOR……………………………………………………..234

FUEL INJECTION TIMING………………………………………………….234

VALVE CLEARANCE……………………………………………………….234

BELT TENSION – AIR COMPRESSOR………………………………………………235

EMERGENCY ESCAPE FROM ENGINE CONTROL FAILURE…………………………………236

SWING CIRCLE BEARINGS……………………………………………………..237

TRACK SHOE TENSION………………………………………………………..238

SPROCKET…………………………………………………………………238

OIL PRESSURE……………………………………………………………..239

WORK EQUIPMENT, SWING AND TRAVEL………………………………………..239

CONTROL CIRCUIT……………………………………………………….243

PUMP PC CONTROL CIRCUIT………………………………………………..244

PUMP LS CONTROL CIRCUIT………………………………………………..247

SOLENOID VALVE OUTPUT PRESSURE………………………………………….252

TABLE FOR FUNCTIONING CONDITIONS………………………………………..253

PPC LOCK SOLENOID VALVE………………………………………………..253

SWING AND PARKING BRAKE SOLENOID………………………………………..253

TRAVEL INTERCONNECTION SOLENOID VALVE……………………………………253

ATTACHMENT SOLENOID VALVE OUTPUT………………………………………..256

PPC VALVE OUTPUT PRESSURE………………………………………………….257

ATTACHMENT PPC VALVE OUTPUT…………………………………………….258

WORK EQUIPMENT AND SWING PPC VALVE………………………………………….259

WORK EQUIPMENT – HYDRAULIC DRIFT……………………………………………260

RELEASING PRESSURE IN HYDRAULIC CIRCUIT……………………………………..262

OIL LEAKAGE………………………………………………………………263

AIR BLEEDING OF VARIOUS PARTS………………………………………………266

SOFT SWING ADJUSTMENTS…………………………………………………….268

DIODE INSPECTION PROCEDURES………………………………………………..269

CAB DOOR STOP ADJUSTMENT…………………………………………………..271

MULTI-MONITOR PANEL……………………………………………………….272

TABLE FOR SERVICE AND FAILURE CODE NUMBERS……………………………….279

SERVICE MENU………………………………………………………….281

WAY OF SWITCHING TO SERVICE MENU………………………………………..281

ELECTRICAL SYSTEM TROUBLESHOOTING…………………………………………..297

PM TUNE UP SERVICE………………………………………………………..298

TROUBLESHOOTING………………………………………………………………303

TROUBLESHOOTING GENERAL……………………………………………………303

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………….305

SEQUENCE OF EVENTS IN TROUBLESHOOTING……………………………………307

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE………………………….308

CHECKS BEFORE TROUBLESHOOTING…………………………………………..316

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING……………………………..317

CLASSIFICATION OF TROUBLESHOOTING……………………………………317

STEPS FOR TROUBLESHOOTING…………………………………………..317

FAILURE-LOOKING PHENOMENON AND TROUBLESHOOTING NO……………………..318

CONNECTOR LOCATION CHART……………………………………………….321

CONNECTOR TABLE……………………………………………………321

CONNECTOR LOCATION DIAGRAM………………………………………….328

ELECTRICAL CIRCUIT DIAGRAMS…………………………………………….333

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS……………………………….334

CONNECTOR REPAIR PROCEDURES…………………………………………….357

CONTACT TERMINAL REMOVAL (HD30 TYPE)…………………………………357

STRIPPING INSULATION……………………………………………….358

CRIMPING CONTACT TERMINAL (HD30 TYPE)………………………………..359

INSERTION OF CONTACT TERMINAL (HD30 TYPE)…………………………….360

CONTACT TERMINAL REMOVAL (DT TYPE)…………………………………..361

STRIPPING INSULATION……………………………………………….362

CRIMPING CONTACT TERMINAL (DT TYPE)………………………………….363

INSERTION OF CONTACT TERMINAL (DT TYPE)………………………………364

TROUBLESHOOTING ELECTRICAL SYSTEM (E-MODE)…………………………………..365

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM……………………………369

POINTS TO REMEMBER IF ABNORMALITY RETURNS TO NORMAL BY ITSELF…………..369

USER CODE MEMORY RETENTION FUNCTION………………………………….369

INFORMATION CONTAINED IN TESTING PROCEDURES………………………………370

(E101)……………………………………………………………….372

ABNORMAL DATA IN ERROR HISTORY………………………………………372

(E112)……………………………………………………………….374

SHORT IN WINDSHIELD WIPER MOTOR DRIVE FORWARD ROTATION…………………374

SHORT IN GUARD WIPER MOTOR DRIVE FORWARD ROTATION……………………..375

(E113)……………………………………………………………….377

SHORT IN WINDSHIELD WIPER MOTOR DRIVE REVERSE ROTATION…………………377

SHORT IN GUARD WIPER MOTOR DRIVE REVERSE ROTATION……………………..378

(E114)……………………………………………………………….380

SHORT OR OPEN IN WINDOW WASHER SYSTEM………………………………..380

SHORT OR OPEN IN GUARD WASHER SYSTEM…………………………………381

(E115)……………………………………………………………….383

ABNORMAL WINDSHIELD WIPER MOTION…………………………………….383

ABNORMAL GUARD WIPER MOTION…………………………………………384

(E116)……………………………………………………………….386

ABNORMALITY IN PARKING WIPER ARM…………………………………….386

ABNORMALITY IN PARKING WIPER ARM (GUARD)……………………………..387

(E201)……………………………………………………………….390

SHORT OR OPEN IN TRAVEL INTERLOCKING SOLENOID…………………………390

(E203)……………………………………………………………….392

SHORT IN SWING AND PARKING SOLENOID GOVERNOR SYSTEM……………………392

SHORT IN SWING AND PARKING SOLENOID CONTROLLER SYSTEM (WITH SOFT SWING)….394

(E204)……………………………………………………………….396

SHORT IN MERGE/DIVIDE SOLENOID………………………………………396

(E205)……………………………………………………………….398

SHORT IN 2 STAGE RELIEF SOLENOID…………………………………….398

(E206)……………………………………………………………….400

SHORT IN TRAVEL SPEED SHIFT SOLENOID…………………………………400

(E211)……………………………………………………………….402

OPEN IN TRAVEL INTERLOCKING SOLENOID…………………………………402

(E213)……………………………………………………………….404

OPEN IN SWING PARKING BRAKE SOLENOID…………………………………404

OPEN IN SWING PARKING BRAKE SOLENOID (WITH SOFT SWING)…………………406

NO CODE………………………………………………………………408

SHORT OR OPEN IN SOFT SWING SOLENOID SYSTEM…………………………..408

(E214)……………………………………………………………….412

OPEN OF MERGE/DIVIDE SOLENOID……………………………………….412

(E215)……………………………………………………………….414

OPEN IN 2 STAGE RELIEF SOLENOID……………………………………..414

(E216)……………………………………………………………….416

OPEN IN TRAVEL SPEED SOLENOID……………………………………….416

(E217)……………………………………………………………….418

ABNORMAL INPUT FOR MODEL CODE……………………………………….418

(E218)……………………………………………………………….420

OPEN IN S-NET SIGNAL……………………………………………….420

(E222)……………………………………………………………….422

SHORT IN LS-EPC SOLENOID……………………………………………422

(E223)……………………………………………………………….424

OPEN IN LS-EPC SOLENOID SYSTEM………………………………………424

(E224)……………………………………………………………….426

ABNORMAL F-PUMP PRESSURE SENSOR SIGNAL……………………………….426

(E225)……………………………………………………………….428

ABNORMAL R-PUMP PRESSURE SENSOR SIGNAL……………………………….428

(E226)……………………………………………………………….430

ABNORMAL PRESSURE SENSOR POWER SUPPLY………………………………..430

(E227)……………………………………………………………….432

ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER…………………432

(E228)……………………………………………………………….434

SHORT IN ATTACHMENT RETURN SWITCHING RELAY……………………………434

NO CODE………………………………………………………………436

SHORT OR OPEN IN ATTACHMENT SOLENOID SYSTEM…………………………..436

NO CODE………………………………………………………………440

OPEN IN CAB TILT SYSTEM…………………………………………….440

(E232)……………………………………………………………….442

SHORT IN PC-EPC SOLENOID……………………………………………442

(E233)……………………………………………………………….444

OPEN IN PC-EPC SOLENOID SYSTEM………………………………………444

(E238)……………………………………………………………….446

OPEN IN ATTACHMENT RETURN SWITCH RELAY……………………………….446

(E245)……………………………………………………………….448

SHORT IN ATTACHMENT OIL FLOW RATE EPC SYSTEM………………………….448

(E246)……………………………………………………………….450

OPEN IN ATTACHMENT OIL FLOW RATE EPC SYSTEM…………………………..450

(E256)……………………………………………………………….452

INCORRECT NON-VOLATILE MEMORY DATA…………………………………..452

(E306)……………………………………………………………….454

ABNORMAL GOVERNOR POTENTIOMETER SIGNALS………………………………454

(E308)……………………………………………………………….456

ABNORMAL FUEL DIAL SIGNALS………………………………………….456

(E315)……………………………………………………………….458

SHORT IN BATTERY RELAY SYSTEM……………………………………….458

(E316)……………………………………………………………….460

STEP OUT IN GOVERNOR MOTOR………………………………………….460

(E317)……………………………………………………………….462

OPEN IN GOVERNOR MOTOR PHASE “A” AND “B”……………………………..462

(E318)……………………………………………………………….464

SHORT IN GOVERNOR MOTOR PHASE “A” AND “B”…………………………….464

(E501)……………………………………………………………….466

MODEL SELECTION FUNCTION NOT PROVIDED………………………………..466

(E502)……………………………………………………………….467

MODEL SELECTING SIGNAL FAULT………………………………………..467

(A000N1)……………………………………………………………..468

ENGINE SPEED OUT OF RANGE AT HIGH IDLE……………………………….468

(A000N2)……………………………………………………………..469

ENGINE SPEED OUT OF RANGE AT LOW IDLE………………………………..469

(AA10NX)……………………………………………………………..470

AIR CLEANER CLOG INDICATOR FAILURE…………………………………..470

(AB00KE)……………………………………………………………..472

LOW CHARGING VOLTAGE INDICATED………………………………………472

(B@BAZG)……………………………………………………………..474

ABNORMAL ENGINE OIL PRESSURE………………………………………..474

(B@BAZK)……………………………………………………………..476

ABNORMAL ENGINE OIL LEVEL…………………………………………..476

(B@BCNS)……………………………………………………………..478

ENGINE COOLANT INDICATING OVERHEAT CONDITION………………………….478

(B@BCZK)……………………………………………………………..480

ABNORMAL COOLANT LEVEL INDICATION……………………………………480

(B@HANS)……………………………………………………………..482

HYDRAULIC OIL OVERHEAT INDICATION……………………………………482

TROUBLESHOOTING MONITOR ELECTRICAL (E-MODE)………………………………….485

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM……………………………487

POINTS TO REMEMBER IF ABNORMALITY RETURNS TO NORMAL BY ITSELF…………..487

USER CODE MEMORY RETENTION FUNCTION………………………………….487

INFORMATION CONTAINED IN TESTING PROCEDURES………………………………488

(E-1)………………………………………………………………..490

ENGINE WILL NOT CRANK………………………………………………490

(E-2)………………………………………………………………..492

ENGINE STOPS WHILE IN OPERATION……………………………………..492

(E-3)………………………………………………………………..494

ENGINE SPEED IRREGULAR, OR HUNTING…………………………………..494

(E-4)………………………………………………………………..496

ENGINE DOES NOT STOP……………………………………………….496

(E-5)………………………………………………………………..498

AUTO DECELERATOR DOES NOT WORK………………………………………498

(E-6)………………………………………………………………..499

AUTO ENGINE WARM UP DEVICE DOES NOT WORK……………………………..499

(E-7)………………………………………………………………..500

COLD START PREHEATER DOES NOT WORK…………………………………..500

(E-8)………………………………………………………………..502

ALL WORK EQUIPMENT, SWING AND TRAVEL DO NOT OPERATE……………………502

(E-9)………………………………………………………………..504

ONE TOUCH POWER MAX SWITCH DOES NOT OPERATE…………………………..504

(E-10)……………………………………………………………….506

NO DISPLAY ON MONITOR PANEL…………………………………………506

(E-11)……………………………………………………………….508

PART OF DISPLAY ON MONITOR PANEL IS MISSING…………………………..508

(E-12)……………………………………………………………….509

MONITOR PANEL DISPLAYS CONTENTS IRRELEVANT TO THE MODEL………………..509

(E-13)……………………………………………………………….510

FUEL LEVEL INDICATOR LAMP LIGHTS UP WHEN FUEL TANK IS FULL……………..510

(E-14)……………………………………………………………….512

ENGINE COOLANT TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY……………512

(E-15)……………………………………………………………….514

HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT DISPLAY CORRECTLY……………..514

(E-16)……………………………………………………………….516

FUEL GAUGE DOES NOT DISPLAY CORRECTLY………………………………..516

(E-17)……………………………………………………………….518

SWING LOCK MONITOR DOES NOT DISPLAY CORRECTLY…………………………518

(E-18)……………………………………………………………….520

WHEN THE MONITOR SWITCH IS OPERATED, NO DISPLAY APPEARS………………..520

(E-19)……………………………………………………………….522

WINDSHIELD WIPER DOES NOT WORK………………………………………522

GUARD WIPER DOES NOT WORK…………………………………………..523

(E-20)……………………………………………………………….526

ALARM BUZZER CANNOT BE CANCELLED…………………………………….526

(E-21)……………………………………………………………….528

BOOM RAISE NOT CORRECTLY DISPLAYED ON MONITOR…………………………528

(E-22)……………………………………………………………….530

BOOM LOWER NOT CORRECTLY DISPLAYED ON MONITOR…………………………530

(E-23)……………………………………………………………….532

ARM EXTEND NOT CORRECTLY DISPLAYED ON MONITOR…………………………532

(E-24)……………………………………………………………….534

ARM RETRACT NOT CORRECTLY DISPLAYED ON MONITOR………………………..534

(E-25)……………………………………………………………….536

BUCKET CURL NOT CORRECTLY DISPLAYED ON MONITOR………………………..536

(E-26)……………………………………………………………….538

BUCKET DUMP NOT CORRECTLY DISPLAYED ON MONITOR………………………..538

(E-27)……………………………………………………………….540

SWING NOT CORRECTLY DISPLAYED ON MONITOR……………………………..540

(E-28)……………………………………………………………….542

TRAVEL NOT CORRECTLY DISPLAYED ON MONITOR…………………………….542

(E-29)……………………………………………………………….544

TRAVEL DIFFERENTIAL PRESSURE NOT CORRECTLY DISPLAYED ON MONITOR…………544

(E-30)……………………………………………………………….546

SERVICE NOT CORRECTLY DISPLAYED ON MONITOR……………………………546

(E-31)……………………………………………………………….548

AIR CONDITIONER SYSTEM DOES NOT WORK…………………………………548

(E-32)……………………………………………………………….552

TRAVEL ALARM DOES NOT SOUND…………………………………………552

30 DISASSEMBLY AND ASSEMBLY……………………………………………………….555

METHOD OF USING MANUAL………………………………………………………..559

PRECAUTIONS DURING OPERATION…………………………………………………..560

PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK…………………………………..560

PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK………………………………561

PRECAUTIONS WHEN COMPLETING THE OPERATIONS…………………………………..562

OTHER PRECAUTIONS…………………………………………………………562

SPECIAL TOOL LIST…………………………………………………………….563

SKETCHES OF SPECIAL TOOLS……………………………………………………..567

ENGINE………………………………………………………………………568

ALTERNATOR……………………………………………………………….568

CYLINDER HEAD…………………………………………………………….568

ENGINE FRONT SEAL…………………………………………………………568

ENGINE OIL COOLER…………………………………………………………568

ENGINE REAR SEAL………………………………………………………….568

FUEL INJECTION PUMP……………………………………………………….568

NOZZLE HOLDER…………………………………………………………….568

STARTING MOTOR……………………………………………………………568

THERMOSTAT……………………………………………………………….568

TURBOCHARGER……………………………………………………………..568

WATER PUMP……………………………………………………………….568

RADIATOR…………………………………………………………………….569

REMOVAL………………………………………………………………….569

INSTALLATION……………………………………………………………..570

HYDRAULIC OIL COOLER………………………………………………………….571

REMOVAL………………………………………………………………….571

INSTALLATION……………………………………………………………..572

ENGINE AND HYDRAULIC PUMPS…………………………………………………….573

REMOVAL………………………………………………………………….573

INSTALLATION……………………………………………………………..578

TRAVEL MOTOR AND FINAL DRIVE…………………………………………………..580

REMOVAL………………………………………………………………….580

INSTALLATION……………………………………………………………..580

FINAL DRIVE………………………………………………………………….581

DISASSEMBLY………………………………………………………………581

ASSEMBLY…………………………………………………………………586

REMOVAL………………………………………………………………….591

INSTALLATION……………………………………………………………..592

DISASSEMBLY………………………………………………………………593

ASSEMBLY…………………………………………………………………596

TRACK AND CARRIER ROLLER………………………………………………………602

REMOVAL………………………………………………………………….602

INSTALLATION……………………………………………………………..602

DISASSEMBLY………………………………………………………………603

ASSEMBLY…………………………………………………………………604

IDLER AND RECOIL SPRING……………………………………………………….607

REMOVAL………………………………………………………………….607

INSTALLATION……………………………………………………………..607

IDLER……………………………………………………………………608

DISASSEMBLY………………………………………………………………608

ASSEMBLY…………………………………………………………………609

RECOIL SPRING…………………………………………………………….612

DISASSEMBLY………………………………………………………………612

ASSEMBLY…………………………………………………………………613

TRACK ROLLER…………………………………………………………………614

REMOVAL………………………………………………………………….614

INSTALLATION……………………………………………………………..614

DISASSEMBLY………………………………………………………………615

ASSEMBLY…………………………………………………………………616

SPROCKET…………………………………………………………………….619

REMOVAL………………………………………………………………….619

INSTALLATION……………………………………………………………..619

TRACK SHOE…………………………………………………………………..620

EXPANSION OF TRACK SHOE……………………………………………………620

ASSEMBLY…………………………………………………………………621

SWING CIRCLE…………………………………………………………………622

REMOVAL………………………………………………………………….622

INSTALLATION……………………………………………………………..622

REVOLVING FRAME………………………………………………………………623

REMOVAL………………………………………………………………….623

INSTALLATION……………………………………………………………..625

CENTER SWIVEL JOINT…………………………………………………………..626

REMOVAL………………………………………………………………….626

INSTALLATION……………………………………………………………..627

DISASSEMBLY………………………………………………………………628

ASSEMBLY…………………………………………………………………629

HYDRAULIC TANK……………………………………………………………….630

REMOVAL………………………………………………………………….630

INSTALLATION……………………………………………………………..632

CONTROL VALVE………………………………………………………………..633

REMOVAL………………………………………………………………….633

INSTALLATION……………………………………………………………..636

DISASSEMBLY………………………………………………………………637

ASSEMBLY…………………………………………………………………638

HYDRAULIC PUMP……………………………………………………………….639

REMOVAL………………………………………………………………….639

INSTALLATION……………………………………………………………..641

HYDRAULIC PUMP INPUT SHAFT – OIL SEAL…………………………………………..642

REMOVAL………………………………………………………………….642

INSTALLATION……………………………………………………………..642

PPC VALVE……………………………………………………………………643

WORK EQUIPMENT……………………………………………………………643

ASSEMBLY…………………………………………………………………643

TRAVEL…………………………………………………………………..644

ASSEMBLY…………………………………………………………………644

HYDRAULIC CYLINDER……………………………………………………………645

DISASSEMBLY………………………………………………………………645

ASSEMBLY…………………………………………………………………647

WORK EQUIPMENT……………………………………………………………….651

REMOVAL………………………………………………………………….651

INSTALLATION……………………………………………………………..653

AIR CONDITIONER………………………………………………………………654

REMOVAL………………………………………………………………….654

INSTALLATION……………………………………………………………..657

COUNTERWEIGHT………………………………………………………………..658

REMOVAL………………………………………………………………….658

INSTALLATION……………………………………………………………..658

CAB…………………………………………………………………………659

REMOVAL………………………………………………………………….659

INSTALLATION……………………………………………………………..661

MONITOR……………………………………………………………………..662

REMOVAL………………………………………………………………….662

INSTALLATION……………………………………………………………..662

GOVERNOR PUMP CONTROLLER………………………………………………………663

REMOVAL………………………………………………………………….663

INSTALLATION……………………………………………………………..663

90 OTHERS……………………………………………………………………….665

ELECTRICAL…………………………………………………………………..667

CIRCUIT DIAGRAM SHEET 1 (PART 1 OF 3)……………………………………….667

CIRCUIT DIAGRAM SHEET 1 (PART 2 OF 3)……………………………………….669

CIRCUIT DIAGRAM SHEET 1 (PART 3 OF 3)……………………………………….671

CIRCUIT DIAGRAM SHEET 2 (PART 1 OF 1)……………………………………….673

CIRCUIT DIAGRAM SHEET 3 (PART 1 OF 2)……………………………………….675

CIRCUIT DIAGRAM SHEET 3 (PART 2 OF 2)……………………………………….677

CIRCUIT DIAGRAM SHEET 4 (PART 1 OF 2)……………………………………….679

CIRCUIT DIAGRAM SHEET 4 (PART 2 OF 2)……………………………………….681

HYDRAULIC……………………………………………………………………685

HYDRAULIC DIAGRAM (SHEET 1 OF 4) – FOLDOUT 11………………………………..685

HYDRAULIC DIAGRAM (SHEET 2 OF 4) – FOLDOUT 12………………………………..687

HYDRAULIC DIAGRAM (SHEET 3 OF 4) – FOLDOUT 13………………………………..689