$38

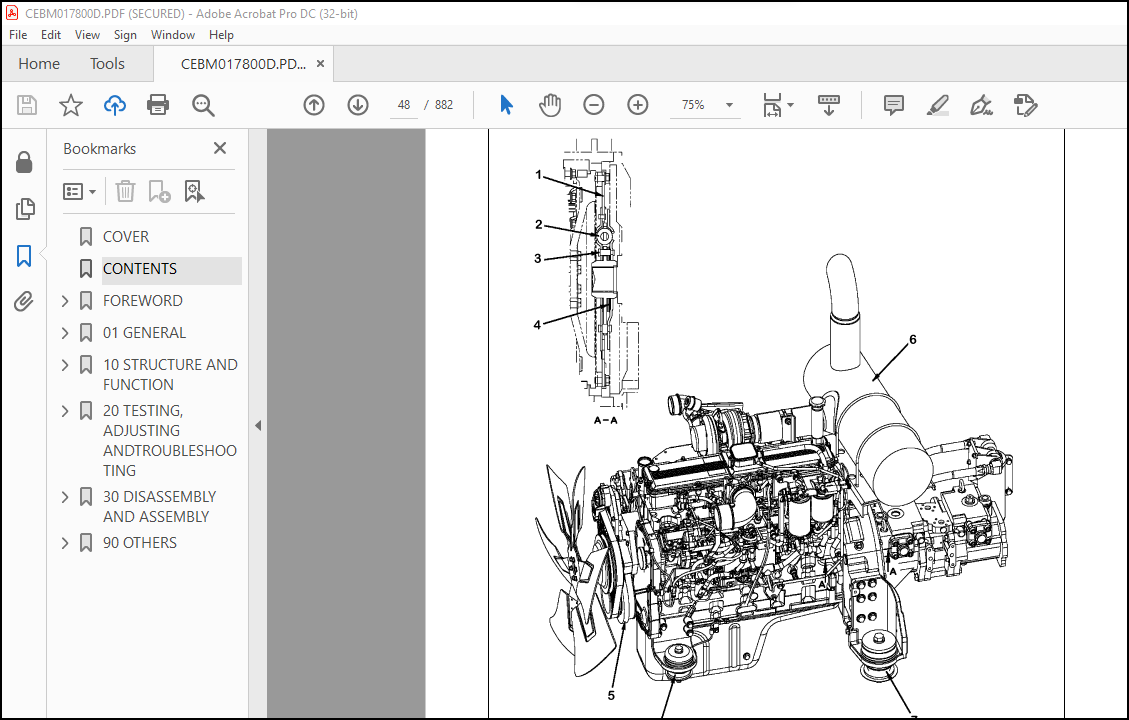

Komatsu Galeo PC300LL-7E0 Logging Road Builder Excavator Shop Manual CEBM017800 – PDF DOWNLOAD

Komatsu Galeo PC300LL-7E0 Logging Road Builder Excavator Shop Manual CEBM017800 – PDF DOWNLOAD

FILE DETAILS:

Komatsu Galeo PC300LL-7E0 Logging Road Builder Excavator Shop Manual CEBM017800 – PDF DOWNLOAD

Language : English

Pages : 882

Downloadable : Yes

File Type : PDF

Size: 18.1 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu Galeo PC300LL-7E0 Logging Road Builder Excavator Shop Manual CEBM017800 – PDF DOWNLOAD

SERIAL NUMBERS PC300LL-7E0 A86001 and UP

GENERAL PRECAUTIONS 00

Mistakes in operation are extremely dangerous. Read the OPERATION & MAINTENANCE MANUAL carefully BEFORE

operating the machine.

1. Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with

buttons missing.

• Always wear safety glasses when hitting parts with a hammer.

• Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding

work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.

4. When carrying out any operation with two or more workers, always agree on the operating procedure before starting.

Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER

REPAIR signs on the controls in the operator’s compartment.

5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct

places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas

provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK 00

1. Before adding oil or making repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the

machine from moving.

2. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert

the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers

and hang warning signs on them.

3. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

4. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders

or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails,

ladders or steps, use a stand to provide safe footing.

TABLE OF CONTENTS:

Komatsu Galeo PC300LL-7E0 Logging Road Builder Excavator Shop Manual CEBM017800 – PDF DOWNLOAD

COVER…………………………………………………………………………………….. 1

CONTENTS………………………………………………………………………………….. 3

FOREWORD………………………………………………………………………………….. 2

SAFETY………………………………………………………………………………… 4

SAFETY NOTICE………………………………………………………………………. 4

IMPORTANT SAFETY NOTICE………………………………………………………….. 4

GENERAL PRECAUTIONS……………………………………………………………… 4

PREPARATIONS FOR WORK……………………………………………………………. 4

PRECAUTIONS DURING WORK………………………………………………………….. 5

01 GENERAL………………………………………………………………………………… 6

HOW TO READ THE SHOP MANUAL……………………………………………………………… 9

VOLUMES……………………………………………………………………………. 9

DISTRIBUTION AND UPDATING……………………………………………………………. 9

FILING METHOD………………………………………………………………………. 9

REVISED EDITION MARK………………………………………………………………… 9

REVISIONS………………………………………………………………………….. 9

SYMBOLS……………………………………………………………………………. 10

HOISTING INSTRUCTIONS…………………………………………………………………… 11

HOISTING…………………………………………………………………………… 11

WIRE ROPES…………………………………………………………………………. 11

PUSH PULL COUPLER………………………………………………………………………. 13

TYPE 1…………………………………………………………………………….. 13

DISCONNECTION…………………………………………………………………… 13

CONNECTION……………………………………………………………………… 13

TYPE 2…………………………………………………………………………….. 14

DISCONNECTION…………………………………………………………………… 14

CONNECTION……………………………………………………………………… 14

TYPE 3…………………………………………………………………………….. 15

DISCONNECTION…………………………………………………………………… 15

CONNECTION……………………………………………………………………… 15

EXPLANATION OF MAINTENANCE STANDARD TERMS…………………………………………………. 16

STANDARD TIGHTENING TORQUE………………………………………………………………. 18

BOLTS AND NUTS……………………………………………………………………… 18

TIGHTENING TORQUE OF HOSE NUTS……………………………………………………….. 19

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS……………………………………………….. 19

TIGHTENING TORQUE FOR FLARED NUTS…………………………………………………….. 19

TIGHTENING TORQUES FOR O-RING BOSS PIPING JOINTS……………………………………….. 20

TABLE OF TIGHTENING TORQUES FOR O-RING BOSS PLUGS………………………………………. 20

TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE)……………………………… 20

ELECTRIC WIRE CODE……………………………………………………………………… 8

CLASSIFICATION BY THICKNESS………………………………………………………….. 8

CLASSIFICATION BY COLOR AND CODE……………………………………………………… 8

HOW TO READ ELECTRIC WIRE CODE……………………………………………………….. 21

CONVERSION TABLES………………………………………………………………………. 24

METHOD OF USING THE CONVERSION TABLE………………………………………………….. 24

COATING MATERIALS………………………………………………………………………. 30

SPECIFICATIONS…………………………………………………………………………. 32

DIMENSIONS…………………………………………………………………………. 32

ROAD BUILDER……………………………………………………………………. 32

LOG LOADER – 42 FT KOMATSU FOREST FRONT……………………………………………. 32

WORKING RANGES……………………………………………………………………… 34

ROAD BUILDER……………………………………………………………………. 34

LOG LOADER – 42 FT KOMATSU FOREST FRONT……………………………………………. 36

WEIGHT TABLE…………………………………………………………………………… 41

FUEL, COOLANT, AND LUBRICANTS……………………………………………………………. 43

10 STRUCTURE AND FUNCTION…………………………………………………………………… 45

ENGINE RELATED PARTS……………………………………………………………………. 48

RADIATOR . OIL COOLER . AFTERCOOLER………………………………………………………. 49

POWER TRAIN……………………………………………………………………………. 50

FINAL DRIVE……………………………………………………………………………. 51

SPROCKET………………………………………………………………………………. 55

SPROCKET TOOL………………………………………………………………………. 56

SWING MACHINERY………………………………………………………………………… 57

SWING CIRCLE……………………………………………………………………….. 61

TRACK FRAME . RECOIL SPRING……………………………………………………………… 62

IDLER…………………………………………………………………………………. 64

TRACK ROLLER/CARRIER ROLLER……………………………………………………………… 66

TRACK SHOE…………………………………………………………………………….. 68

TRIPLE GROUSER SHOE…………………………………………………………………….. 71

DOUBLE GROUSER SHOE…………………………………………………………………….. 72

HYDRAULIC EQUIPMENT…………………………………………………………………….. 73

HYDRAULIC TANK AND FILTER……………………………………………………………….. 75

HYDRAULIC PUMP…………………………………………………………………………. 76

HPV125 + 125……………………………………………………………………….. 76

LS VALVE…………………………………………………………………………… 82

PC VALVE…………………………………………………………………………… 87

LS(PC)-EPC VALVE……………………………………………………………………. 94

VARIABLE VOLUME VALVE……………………………………………………………….. 98

CONTROL VALVE…………………………………………………………………………..100

CLSS…………………………………………………………………………………..112

VALVE FUNCTIONS AND OPERATION…………………………………………………………….116

UNLOADER VALVE………………………………………………………………………….118

INTRODUCTION OF LS PRESSURE………………………………………………………………120

LS BYPASS VALVE…………………………………………………………………………121

PRESSURE COMPENSATION VALVE………………………………………………………………122

PRESSURE COMPENSATION VALVE INNER SHUTTLE………………………………………………125

BOOM REGENERATION CIRCUIT…………………………………………………………….127

ARM REGENERATION CIRCUIT……………………………………………………………..129

MERGE-DIVIDER VALVE……………………………………………………………………..131

LS SELECT VALVE…………………………………………………………………………133

SELF PRESSURE REDUCING VALVE……………………………………………………………..134

TRAVEL JUNCTION VALVE……………………………………………………………………137

TRAVEL PPC SHUTTLE VALVE…………………………………………………………………139

BOOM DRIFT PREVENTION VALVE………………………………………………………………141

ARM DRIFT PREVENTION VALVE……………………………………………………………….144

QUICK RETURN VALVE………………………………………………………………………148

LIFT CHECK VALVE………………………………………………………………………..150

MAIN RELIEF VALVE……………………………………………………………………….151

2-STAGE SAFETY-SUCTION VALVE……………………………………………………………..152

VARIABLE PRESSURE COMPENSATION VALVE………………………………………………………154

CONTROL VALVE…………………………………………………………………………..156

PPC VALVE………………………………………………………………………………157

WORK EQUIPMENT AND SWING PPC VALVE…………………………………………………….157

TRAVEL PPC VALVE…………………………………………………………………….163

PRESSURE REDUCING VALVE………………………………………………………………….166

STRAIGHT TRAVEL PPC VALVE…………………………………………………………….172

PPC ACCUMULATOR……………………………………………………………………..174

SOLENOID VALVE………………………………………………………………………….175

ATTACHMENT SOLENOID VALVE………………………………………………………………..176

CENTER SWIVEL JOINT……………………………………………………………………..178

TRAVEL MOTOR……………………………………………………………………………179

TYPE: KMV200ADT-2……………………………………………………………………179

OPERATION OF MOTOR…………………………………………………………………..182

PARKING BRAKE…………………………………………………………………………..184

BRAKE VALVE OPERATION………………………………………………………………..186

SAFETY VALVE……………………………………………………………………………188

SWING MOTOR…………………………………………………………………………….191

TYPE: KMF230ABE-5……………………………………………………………………191

SWING HOLDING BRAKE………………………………………………………………….194

RELIEF VALVE PORTION…………………………………………………………………195

REVERSE PREVENTION VALVE…………………………………………………………………196

EXPLANATORY DRAWING OF EFFECTS………………………………………………………..197

HYDRAULIC CYLINDERS – EXCAVATOR WORK EQUIPMENT……………………………………………..200

BOOM CYLINDER……………………………………………………………………….200

ARM CYLINDER………………………………………………………………………..200

BUCKET CYLINDER……………………………………………………………………..201

WORK EQUIPMENT PIVOT POINT MEASUREMENTS……………………………………………………202

BOSS BUSHING/PINS – EXCAVATOR WORK EQUIPMENT……………………………………………202

DIMENSION OF ARM – EXCAVATOR WORK EQUIPMENT…………………………………………….204

DIMENSION OF BUCKET………………………………………………………………….206

CAB AND ATTACHMENTS……………………………………………………………………..208

AIR CONDITIONER PIPING……………………………………………………………….208

ELECTRICAL SYSTEM……………………………………………………………………….209

ENGINE CONTROL………………………………………………………………………209

ELECTRONIC COMPONENTS……………………………………………………………………211

FUEL CONTROL DIAL……………………………………………………………………211

ENGINE CONTROLLER……………………………………………………………………212

COOLANT TEMPERATURE SENSOR……………………………………………………………216

OIL PRESSURE SWITCH………………………………………………………………….216

ENGINE SPEED SENSOR………………………………………………………………….217

BOOST PRESSURE AND TEMPERATURE SENSOR………………………………………………….217

WIF (WATER-IN-FUEL DETECTION) SENSOR…………………………………………………..218

ENGINE OIL LEVEL SENSOR………………………………………………………………218

ELECTRONIC CONTROL SYSTEM………………………………………………………………..219

CONTROL FUNCTION…………………………………………………………………….219

SYSTEM DIAGRAM…………………………………………………………………..220

ENGINE AND PUMP CONTROL FUNCTION………………………………………………………222

PUMP AND VALVE CONTROL……………………………………………………………….226

LS CONTROL FUNCTION………………………………………………………………227

CUT-OFF FUNCTION…………………………………………………………………227

2-STAGE RELIEF FUNCTION…………………………………………………………..227

POWER MAXIMIZING AND MACHINE PUSH-UP…………………………………………………..228

AUTO-DECELERATION……………………………………………………………………230

AUTO-WARM-UP AND OVERHEAT PREVENTION…………………………………………………..231

SWING CONTROL……………………………………………………………………….233

TRAVEL CONTROL………………………………………………………………………235

ATTACHMENT FLOW CONTROL AND CIRCUIT SELECTOR (IF EQUIPPED)……………………………….237

SYSTEM COMPONENTS……………………………………………………………………….238

PPC OIL PRESSURE SWITCH………………………………………………………………238

OIL PRESSURE SENSOR………………………………………………………………….239

PUMP PRESSURE SENSOR (HIGH PRESSURE)…………………………………………………..240

PUMP CONTROLLER……………………………………………………………………..241

MONITOR SYSTEM………………………………………………………………………….245

MACHINE MONITOR……………………………………………………………………..246

MONITOR CONTROL AND DISPLAY………………………………………………………………249

MONITOR…………………………………………………………………………….249

DISPLAY…………………………………………………………………………….250

SWITCHES……………………………………………………………………………….254

BRIGHTNESS, CONTRAST ADJUSTMENT……………………………………………………….262

SERVICE METER CHECK FUNCTION………………………………………………………….263

DISPLAY LCD CHECK FUNCTION……………………………………………………………263

USER CODE DISPLAY FUNCTION……………………………………………………………264

SENSOR…………………………………………………………………………………266

HYDRAULIC OIL LEVEL SENSOR……………………………………………………………266

HYDRAULIC OIL AND COOLANT TEMPERATURE SENSOR……………………………………………266

FUEL LEVEL SENSOR……………………………………………………………………267

AIR CLEANER CLOGGING SENSOR…………………………………………………………..268

KOMTRAX TERMINAL SYSTEM………………………………………………………………….269

KOMTRAX TERMINAL…………………………………………………………………….270

20 TESTING, ADJUSTING ANDTROUBLESHOOTING………………………………………………………273

TESTING AND ADJUSTING……………………………………………………………………274

STANDARD VALUE TABLES………………………………………………………………..277

ENGINE RELATED…………………………………………………………………..277

CHASSIS RELATED………………………………………………………………….278

SERVICE TOOLS……………………………………………………………………….286

ENGINE SERVICE TOOLS……………………………………………………………..286

CHASSIS SERVICE TOOLS…………………………………………………………….287

ENGINE……………………………………………………………………………..288

AIR BOOST PRESSURE……………………………………………………………….288

AIR COMPRESSOR BELT TENSION……………………………………………………….288

BLOW-BY PRESSURE…………………………………………………………………288

COMPRESSION PRESSURE……………………………………………………………..288

ENGINE OIL PRESSURE………………………………………………………………288

ENGINE SPEED…………………………………………………………………….288

EXHAUST GAS COLOR………………………………………………………………..288

FUEL CIRCUIT FOR LEAKAGE………………………………………………………….288

FUEL CIRCUIT FOR BLEEDING AIR……………………………………………………..288

FUEL PRESSURE……………………………………………………………………288

FUEL RETURN RATE…………………………………………………………………288

FUEL INJECTION TIMING…………………………………………………………….288

VALVE CLEARANCE………………………………………………………………….288

ENGINE FUNCTIONS…………………………………………………………………….289

MEASURE ENGINE SPEED WITH MACHINE MONITOR…………………………………………..289

PREPARATION………………………………………………………………….289

MEASURING LOW IDLE SPEED………………………………………………………289

MEASURING HIGH IDLE SPEED……………………………………………………..289

MEASURING THE ENGINE SPEED WHEN 2-PUMPS ARE RELIEVED……………………………..289

MEASURING THE ENGINE SPEED AT 2-PUMP RELIEF AND POWER MAXIMIZING (NEAR RATED SPEED)….289

MEASURING THE SPEED WHEN AUTO-DECELERATION SPEED IS IN OPERATION…………………..289

CYLINDER CUT-OUT OPERATION………………………………………………………..290

NO INJECTION CRANKING OPERATION……………………………………………………290

REFRIGERANT COMPRESSOR BELT…………………………………………………………..291

INSPECTION………………………………………………………………………291

ADJUSTMENT………………………………………………………………………291

SWING CIRCLE BEARING CLEARANCE………………………………………………………..292

TRACK SHOE TENSION…………………………………………………………………..293

INSPECTION………………………………………………………………………293

ADJUSTMENT………………………………………………………………………293

OIL PRESSURE IN WORK EQUIPMENT………………………………………………………..294

OIL PRESSURE IN SWING………………………………………………………………..294

OIL PRESSURE IN TRAVEL CIRCUIT………………………………………………………..294

MEASURING……………………………………………………………………….294

ADJUSTING……………………………………………………………………….296

CONTROL CIRCUIT OIL PRESSURE………………………………………………………….299

MEASURING……………………………………………………………………….299

PUMP PC CONTROL CIRCUIT OIL PRESSURE…………………………………………………..300

MEASURING……………………………………………………………………….300

ADJUSTING……………………………………………………………………….302

PUMP LS CONTROL CIRCUIT OIL PRESSURE…………………………………………………..303

MEASURING……………………………………………………………………….303

ADJUSTING……………………………………………………………………….307

SOLENOID VALVE OUTPUT PRESSURE………………………………………………………..308

ATTACHMENT SOLENOID VALVE OUTPUT………………………………………………………311

PPC VALVE OUTPUT…………………………………………………………………….313

ATTACHMENT PPC VALVE OUTPUT…………………………………………………………..314

WORK EQUIPMENT AND SWING PPC VALVES……………………………………………………315

HYDRAULIC DRIFT IN WORK EQUIPMENT……………………………………………………..316

BOOM AND BUCKET CYLINDERS INSPECTION……………………………………………….316

ARM CYLINDER INSPECTION…………………………………………………………..316

BOOM LOCK VALVE INSPECTION………………………………………………………..317

PPC VALVE INSPECTION……………………………………………………………..317

RELEASE REMAINING PRESSURE IN HYDRAULIC CIRCUIT…………………………………………318

OIL LEAKAGE AMOUNT……………………………………………………………….318

BLEEDING AIR FROM VARIOUS SYSTEMS……………………………………………………..321

DIODE INSPECTION PROCEDURES…………………………………………………………..323

MACHINE MONITOR – SPECIAL FUNCTIONS……………………………………………………324

ORDINARY AND SPECIAL FUNCTIONS…………………………………………………….325

OPERATORS MENU AND DISPLAY (OUTLINE)……………………………………………….326

SERVICE MENU OPERATION AND DISPLAY…………………………………………………….334

SWITCHING TO SERVICE MENU…………………………………………………………334

MONITORING [01] FUNCTION………………………………………………………….335

FUNCTION OF ABNORMALITY RECORD [02]………………………………………………..340

FUNCTION OF MAINTENANCE RECORD [03]………………………………………………..342

FUNCTION OF MAINTENANCE MODE CHANGE [04]……………………………………………343

FUNCTION OF PHONE NUMBER ENTRY [05]………………………………………………..345

FUNCTION OF DEFAULT [06]………………………………………………………….346

FUNCTION OF ADJUSTMENT [07]……………………………………………………….348

FUNCTION OF CYLINDER CUT OUT OPERATION [08]…………………………………………349

FUNCTION OF NO INJECTION CRANKING [09]……………………………………………..351

HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER…………………………………………..353

PROCEDURE FOR TURNING ON KOMTRAX TERMINAL………………………………………………354

KOMTRAX TERMINAL LAMP INDICATIONS……………………………………………………..357

TROUBLESHOOTING ELECTRICAL SYSTEM……………………………………………………..360

PM-CLINIC INSPECTION TABLE……………………………………………………………363

TROUBLESHOOTING (GENERAL)………………………………………………………………..369

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………..370

SEQUENCE OF EVENTS IN TROUBLESHOOTING………………………………………………….372

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE………………………………………………373

PRECAUTIONS WHEN HANDLING ELECTRICAL EQUIPMENT………………………………………373

HANDLING ELECTRONIC CONTROL UNIT…………………………………………………..378

POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRICAL CIRCUITS…………………………..379

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT…………………………………381

CATEGORIES AND METHOD OF USING TROUBLESHOOTING CHARTS………………………………..384

TROUBLESHOOTING INDIVIDUAL ELECTRICAL CIRCUITS………………………………………385

TROUBLESHOOTING INDIVIDUAL HYDRAULIC CIRCUITS……………………………………….387

POSSIBLE PROBLEMS WHEN TROUBLESHOOTING A MODE…………………………………………..389

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS……………………………………………..392

T-ADAPTER TABLE……………………………………………………………………..414

TROUBLESHOOTING OF ELECTRICALSYSTEM (E-MODE)……………………………………………….417

CONNECTOR TYPES AND LOCATIONS…………………………………………………………420

CONNECTOR LAYOUT DRAWINGS…………………………………………………………….426

TROUBLESHOOTING BY FAILURE CODE……………………………………………………….432

BEFORE CARRYING OUT TROUBLESHOOTING WHEN FAILURE CODE IS DISPLAYED…………………….435

LOCATION OF FUSE BOX AND FUSE NUMBERS………………………………………………436

INFORMATION CONTAINED IN TESTING PROCEDURES…………………………………………….438

A000N1 – ENGINE OVER SPEED……………………………………………………………441

AA10NX – AIR CLEANER CLOG SENSOR SYSTEM………………………………………………..442

AB00KE – CHARGE VOLTAGE IS LOW………………………………………………………..444

B@BAZG – ENGINE OIL PRESSURE DROP……………………………………………………..446

B@BAZK – ENGINE OIL LEVEL DROP………………………………………………………..448

B@BCNS – COOLANT HIGH TEMPERATURE SENSOR SHOWING OVERHEAT (NS)……………………………450

B@BCZK – ENGINE COOLANT LEVEL DROP…………………………………………………….452

B@HANS – HYDRAULIC OIL OVERHEAT CONDITION………………………………………………453

CA111 – CRITICAL INTERNAL FAILURE……………………………………………………..454

CA115 – ENGINE NE AND BACKUP SPEED SENSOR ERROR…………………………………………455

CA122 – CHARGE AIR PRESSURE SENSOR HIGH ERROR…………………………………………..456

CA123 – CHARGE AIR PRESSURE SENSOR LOW ERROR……………………………………………458

CA131 – THROTTLE SENSOR HIGH ERROR…………………………………………………….460

CA132 – THROTTLE SENSOR LOW ERROR……………………………………………………..461

CA144 – COOLANT TEMPERATURE (HIGH) SENSOR OUT OF RANGE (KX)………………………………462

CA145 – COOLANT TEMPERATURE (LOW) SENSOR OUT OF RANGE (KX)……………………………….464

CA153 – CHARGE AIR PRESSURE SENSOR HIGH ERROR…………………………………………..466

CA154 – CHARGE AIR PRESSURE SENSOR LOW ERROR……………………………………………468

CA187 – SENSOR SUPPLY 2 VOLT LOW ERROR…………………………………………………470

CA221 – AMBIENT PRESSURE SENSOR HIGH ERROR……………………………………………..472

CA222 – AMBIENT PRESSURE SENSOR LOW ERROR………………………………………………474

CA227 – SENSOR SUPPLY 2 VOLT HIGH ERROR………………………………………………..476

CA234 – ENGINE OVER SPEED…………………………………………………………….478

CA238 – SPEED SENSOR SUPPLY VOLT ERROR…………………………………………………479

CA271 – UMV/PCV1 SHORT ERROR………………………………………………………….480

CA272 – UMV/PCV1 OPEN ERROR…………………………………………………………..481

CA322 – OPEN IN NO. 1 INJECTOR SOLENOID VALVE…………………………………………..482

CA323 – OPEN IN NO. 5 INJECTOR SOLENOID VALVE…………………………………………..484

CA324 – OPEN IN NO. 3 INJECTOR SOLENOID VALVE…………………………………………..486

CA325 – OPEN IN NO. 6 INJECTOR SOLENOID VALVE…………………………………………..488

CA331 – OPEN IN NO. 2 INJECTOR SOLENOID VALVE…………………………………………..490

CA332 – OPEN IN NO. 4 INJECTOR SOLENOID VALVE…………………………………………..492

CA342 – CALIBRATION CODE INCOMPATIBILITY……………………………………………….494

CA351 – INJECTOR DRIVE CIRCUIT ERROR…………………………………………………..496

CA352 – AMBIENT PRESSURE SENSOR 1 VOLT LOW ERROR………………………………………..498

CA386 – AMBIENT PRESSURE SENSOR 1 VOLT HIGH ERROR……………………………………….500

CA428 – WATER IN FUEL SENSOR HIGH ERROR………………………………………………..502

CA429 – WATER IN FUEL SENSOR LOW ERROR…………………………………………………504

CA441 – BATTERY VOLTAGE LOW ERROR……………………………………………………..506

CA442 – BATTERY VOLTAGE HIGH ERROR…………………………………………………….508

CA449 – RAIL PRESSURE VERY HIGH……………………………………………………….510

CA451 – RAIL PRESSURE SENSOR HIGH ERROR………………………………………………..514

CA452 – RAIL PRESSURE SENSOR LOW ERROR…………………………………………………516

CA553 – RAIL PRESSURE ERROR…………………………………………………………..518

CA559 – RAIL PRESSURE VERY LOW………………………………………………………..520

CA689 – ENGINE NE SPEED SENSOR ERROR…………………………………………………..522

CA731 – ENGINE BACK-UP SPEED SENSOR PHASE ERROR…………………………………………524

CA757 – PERSISTENT DATA LOSS ERROR…………………………………………………….526

CA778 – ENGINE BKUP SPEED SENSOR ERROR…………………………………………………528

CA1633 – (KOMNET) DATALINK HAS TIME-OUT ERROR…………………………………………..530

CA2185 – THROTTLE SENSOR HIGH ERROR……………………………………………………532

CA2186 – THROTTLE SENSOR LOW ERROR…………………………………………………….533

CA2249 – RAIL PRESSURE VERY LOW……………………………………………………….534

CA2265 – ELECTRIC LIFT PUMP HIGH ERROR…………………………………………………536

CA2266 – ELECTRIC LIFT PUMP LOW ERROR………………………………………………….537

CA2556 – GRID HEATER RELAY VOLT LOW ERROR………………………………………………538

CA2555 – GRID HEATER RELAY VOLT HIGH ERROR……………………………………………..540

D110KB – BATTERY RELAY DRIVE S/C………………………………………………………542

D196KA – SERVICE RETURN RELAY ERROR……………………………………………………544

D196KB – SERVICE RETURN RELAY ERROR……………………………………………………546

DA25KP – SENSOR POWER ERROR…………………………………………………………..548

DA2RMC – PUMP COMMUNICATION ERROR……………………………………………………..550

DA2SKQ – MODEL SELECTION ERROR………………………………………………………..552

DAFRMC – MONITOR COMMUNICATION ERROR…………………………………………………..554

DHPAMA – F PUMP PRESSURE SENSOR ERROR………………………………………………….556

DHPBMA – R PUMP PRESSURE SENSOR ERROR………………………………………………….558

DHS3MA – ARM CURL PRESSURE SENSOR ERROR………………………………………………..560

DHS4MA – CURL PPC PRESSURE SENSOR ERROR………………………………………………..562

DW43KA – TRAVEL SPEED SOLENOID ERROR…………………………………………………..564

DW43KB – TRAVEL SPEED SOLENOID ERROR…………………………………………………..566

DW45KA – SWING BRAKE SOLENOID ERROR……………………………………………………568

DW45KB – SWING BRAKE SOLENOID ERROR……………………………………………………571

DW91KA – TRAVEL JUNCTION SOLENOID ERROR………………………………………………..574

DW91KB – TRAVEL JUNCTION SOLENOID ERROR………………………………………………..576

DWJ0KA – MERGE-DIVIDER SOLENOID ERROR………………………………………………….578

DWJ0KB – MERGE-DIVIDER SOLENOID ERROR………………………………………………….580

DWK0KA – 2-STAGE RELIEF SOLENOID ERROR…………………………………………………582

DWK0KB – 2-STAGE RELIEF SOLENOID ERROR…………………………………………………584

DXA0KA – PC-EPC SOLENOID ERROR………………………………………………………..586

DXA0KB – PC-EPC SOLENOID ERROR………………………………………………………..588

DXE0KA – LS-EPC SOLENOID ERROR………………………………………………………..590

DXE0KB – LS-EPC SOLENOID ERROR………………………………………………………..592

DXE4KA – SERVICE CURRENT EPC ERROR…………………………………………………….594

DXE4KB – SERVICE CURRENT EPC ERROR…………………………………………………….596

DY20KA – WINDSHIELD WIPER MOTOR DRIVE ERROR…………………………………………….598

DY20MA – WINDSHIELD WIPER MOTOR DRIVE ERROR…………………………………………….600

DY2CKB – WINDSHIELD WASHER DRIVE ERROR…………………………………………………602

DY2DKB – WINDSHIELD WIPER DRIVE ERROR………………………………………………….604

DY2EKB – WINDSHIELD WIPER DRIVE ERROR………………………………………………….606

E-1 – ENGINE WILL NOT CRANK…………………………………………………………..608

E-2 – AUTO DECELERATOR DOES NOT WORK…………………………………………………..610

E-3 – AUTO ENGINE WARM UP DEVICE DOES NOT WORK………………………………………….611

E-4 – COLD START PRE-HEATER DOES NOT WORK………………………………………………612

E-5 – ALL WORK EQUIPMENT, SWING AND TRAVEL DO NOT OPERATE………………………………..614

E-6 – POWER MAXIMIZING FUNCTION DOES NOT OPERATE………………………………………..616

E-7 – MACHINE MONITOR DOES NOT OPERATE…………………………………………………618

E-8 – MACHINE MONITOR DOES NOT DISPLAY SOME ITEMS……………………………………….620

E-9 – MACHINE MONITOR DOES NOT DISPLAY ITEMS CORRECTLY…………………………………..621

E-10 – MONITOR FUEL LEVEL WAS INDICATING RED WHILE ENGINE IS RUNNING………………………622

E-11 – COOLANT HIGH TEMPERATURE SENSOR SHOWING OVERHEAT………………………………….624

E-12 – HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT DISPLAY CORRECTLY…………………………626

E-13 – MONITOR FUEL LEVEL WAS INDICATING RED WHILE ENGINE IS RUNNING………………………628

E-14 – SWING LOCK MONITOR DOES NOT DISPLAY CORRECTLY…………………………………….630

E-15 – WHEN THE MONITOR SWITCH IS OPERATED, NO DISPLAY APPEARS……………………………632

E-16 – WINDSHIELD WIPER AND WASHER DO NOT OPERATE……………………………………….634

WINDSHIELD WASHER DRIVE ERROR……………………………………………………..636

E-17 – MACHINE PUSH-UP FUNCTION DOES NOT OPERATE………………………………………..638

E-18 – BOOM RAISE NOT CORRECTLY DISPLAYED ON MONITOR…………………………………….640

E-19 – BOOM LOWER NOT CORRECTLY DISPLAYED ON MONITOR…………………………………….642

E-20 – ARM IN NOT CORRECTLY DISPLAYED ON MONITOR………………………………………..644

E-21 – ARM OUT NOT CORRECTLY DISPLAYED ON MONITOR……………………………………….646

E-22 – BUCKET CURL NOT CORRECTLY DISPLAYED ON MONITOR……………………………………648

E-23 – BUCKET DUMP NOT CORRECTLY DISPLAYED ON MONITOR……………………………………650

E-24 – SWING NOT CORRECTLY DISPLAYED ON MONITOR…………………………………………652

E-25 – TRAVEL NOT CORRECTLY DISPLAYED ON MONITOR………………………………………..654

E-26 – TRAVEL DIFFERENTIAL NOT CORRECTLY DISPLAYED ON MONITOR…………………………….656

E-27 – SERVICE NOT CORRECTLY DISPLAYED ON MONITOR……………………………………….658

E-28 – KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY…………………………………………660

E-29 – AIR CONDITIONER SYSTEM DOES NOT WORK…………………………………………….662

E-30 – TRAVEL ALARM DOES NOT SOUND…………………………………………………….664

E-31 – HORN DOES NOT SOUND……………………………………………………………666

TROUBLESHOOTING HYDRAULIC ANDMECHANICAL SYSTEM (H-MODE)……………………………………..669

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS……………………………………….670

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE………………………………………….672

H-1 – WORK EQUIPMENT, TRAVEL AND SWING SPEEDS ARE SLOW…………………………………..673

H-2 – ENGINE SPEED DROPS SHARPLY OR ENGINE STALLS……………………………………….674

H-3 – NO WORK EQUIPMENT, TRAVEL OR SWING MOVEMENT……………………………………….675

H-4 – ABNORMAL NOISE IS HEARD FROM HYDRAULIC PUMP……………………………………….675

H-5 – AUTO-DECELERATOR DOES NOT WORK…………………………………………………..676

H-6 – FINE CONTROL MODE DOES NOT FUNCTION………………………………………………676

H-7 – BOOM MOVES SLOWLY OR LACKS POWER…………………………………………………677

H-8 – WORK EQUIPMENT MOVES SLOWLY OR LACKS POWER………………………………………..678

H-9 – BUCKET MOVES SLOWLY OR LACKS POWER……………………………………………….679

H-10 – WORK EQUIPMENT DOES NOT MOVE IN A INDEPENDENT OPERATION……………………………679

H-11 – WORK EQUIPMENT HAS EXCESSIVE HYDRAULIC DRIFT……………………………………..680

H-12 – WORK EQUIPMENT HAS EXCESSIVE LAG TIME……………………………………………681

H-13 – OTHER WORK EQUIPMENT MOVES WHEN RELIEVING A SINGLE CIRCUIT…………………………681

H-14 – ONE-TOUCH POWER MAX. SWITCH DOES NOT OPERATE……………………………………..682

H-15 – IN A COMPOUND OPERATION, WORK EQUIPMENT WITH LARGER LOADS MOVES SLOWLY………………682

H-16 – IN SWING AND BOOM RAISE OPERATION, BOOM MOVES SLOWLY………………………………682

H-17 – IN SWING + TRAVEL, TRAVEL SPEED DROPS SHARPLY…………………………………….683

H-18 – MACHINE SWERVES WHEN TRAVELING………………………………………………….684

H-19 – MACHINE TRAVELS SLOWLY…………………………………………………………685

H-20 – MACHINE CANNOT BE STEERED EASILY OR LACKS POWER…………………………………..686

H-21 – TRAVEL SPEED DOES NOT SHIFT, OR IT IS TOO SLOW OR FAST DURING SHIFTING………………687

H-22 – TRACK SHOES DO NOT TURN (ON ONE SIDE ONLY)……………………………………….687

H-23 – MACHINE DOES NOT SWING…………………………………………………………688

H-25 – EXCESSIVE OVERRUN WHEN STOPPING SWING……………………………………………690

H-24 – SWING ACCELERATION IS POOR, OR SWING SPEED IS SLOW………………………………..689

H-26 – THERE IS A SUDDEN SHOCK WHEN STOPPING SWING………………………………………691

H-27 – ABNORMAL NOISE CAUSED WHEN STOPPING SWING………………………………………..691

H-28 – SWING NATURAL DRIFT IS EXCESSIVE………………………………………………..692

30 DISASSEMBLY AND ASSEMBLY………………………………………………………………….693

ENGINE COMPONENTS……………………………………………………………………….696

CYLINDER HEAD……………………………………………………………………….696

ENGINE FRONT SEAL……………………………………………………………………696

ENGINE REAR SEAL…………………………………………………………………….696

FUEL SUPPLY PUMP…………………………………………………………………….696

VALVES……………………………………………………………………………..696

SPECIAL TOOLS LIST…………………………………………………………………..697

CONNECTOR REPAIR PROCEDURES………………………………………………………………700

CONTACT TERMINAL REMOVAL (HD30 TYPE)…………………………………………………..700

STRIPPING INSULATION…………………………………………………………………701

CRIMPING CONTACT TERMINAL (HD30 TYPE)………………………………………………….702

INSERTION OF CONTACT TERMINAL (HD30 TYPE)………………………………………………703

CONTACT TERMINAL REMOVAL (DT TYPE)…………………………………………………….704

STRIPPING INSULATION…………………………………………………………………705

CRIMPING CONTACT TERMINAL (DT TYPE)……………………………………………………706

INSERTION OF CONTACT TERMINAL (DT TYPE)………………………………………………..707

ENGINE AND COOLING SYSTEM………………………………………………………………..708

RADIATOR ASSEMBLY……………………………………………………………………708

REMOVAL…………………………………………………………………………708

INSTALLATION…………………………………………………………………….709

HYDRAULIC OIL COOLER ASSEMBLY…………………………………………………………710

REMOVAL…………………………………………………………………………710

INSTALLATION…………………………………………………………………….711

AFTERCOOLER ASSEMBLY…………………………………………………………………712

REMOVAL…………………………………………………………………………712

INSTALLATION…………………………………………………………………….712

ENGINE AND HYDRAULIC PUMP ASSEMBLY…………………………………………………….713

REMOVAL…………………………………………………………………………713

INSTALLATION…………………………………………………………………….717

POWER TRAIN…………………………………………………………………………….719

FINAL DRIVE ASSEMBLY…………………………………………………………………719

REMOVAL…………………………………………………………………………719

INSTALLATION…………………………………………………………………….720

DISASSEMBLY……………………………………………………………………..720

ASSEMBLY………………………………………………………………………..725

SWING MOTOR AND SWING MACHINERY ASSEMBLY……………………………………………….731

REMOVAL…………………………………………………………………………731

INSTALLATION…………………………………………………………………….732

DISASSEMBLY……………………………………………………………………..733

ASSEMBLY………………………………………………………………………..736

SWING CIRCLE ASSEMBLY………………………………………………………………..742

REMOVAL…………………………………………………………………………742

INSTALLATION…………………………………………………………………….742

UNDERCARRIAGE AND FRAME………………………………………………………………….743

TRACK ROLLER ASSEMBLY AND CARRIER ROLLER ASSEMBLY……………………………………….743

DISASSEMBLY……………………………………………………………………..743

ASSEMBLY………………………………………………………………………..743

IDLER ASSEMBLY………………………………………………………………………745

DISASSEMBLY……………………………………………………………………..745

ASSEMBLY………………………………………………………………………..746

RECOIL SPRING……………………………………………………………………….749

DISASSEMBLY……………………………………………………………………..749

ASSEMBLY………………………………………………………………………..750

SPROCKET……………………………………………………………………………752

REMOVAL…………………………………………………………………………752

INSTALLATION…………………………………………………………………….752

TRACK SHOE ASSEMBLY………………………………………………………………….753

EXPANSION OF TRACK SHOE…………………………………………………………..753

INSTALLATION OF TRACK SHOE………………………………………………………..754

REVOLVING FRAME ASSEMBLY……………………………………………………………..755

REMOVAL…………………………………………………………………………755

INSTALLATION…………………………………………………………………….757

COUNTERWEIGHT ASSEMBLY……………………………………………………………….758

REMOVAL…………………………………………………………………………758

INSTALLATION…………………………………………………………………….758

HYDRAULIC SYSTEM………………………………………………………………………..759

CENTER SWIVEL JOINT ASSEMBLY………………………………………………………….759

REMOVAL…………………………………………………………………………759

INSTALLATION…………………………………………………………………….760

DISASSEMBLY……………………………………………………………………..761

ASSEMBLY………………………………………………………………………..761

HYDRAULIC TANK ASSEMBLY………………………………………………………………762

REMOVAL…………………………………………………………………………762

INSTALLATION…………………………………………………………………….764

CONTROL VALVE ASSEMBLY……………………………………………………………….765

REMOVAL…………………………………………………………………………765

INSTALLATION…………………………………………………………………….768

ASSEMBLY………………………………………………………………………..770

MAIN RELIEF VALVE ASSEMBLY………………………………………………………..771

HYDRAULIC PUMP ASSEMBLY………………………………………………………………772

REMOVAL…………………………………………………………………………772

INSTALLATION…………………………………………………………………….774

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT…………………………………………………775

REMOVAL…………………………………………………………………………775

INSTALLATION…………………………………………………………………….775

WORK EQUIPMENT PPC VALVE ASSEMBLY……………………………………………………..776

DISASSEMBLY……………………………………………………………………..776

ASSEMBLY………………………………………………………………………..776

TRAVEL PPC VALVE ASSEMBLY…………………………………………………………….777

DISASSEMBLY……………………………………………………………………..777

ASSEMBLY………………………………………………………………………..777

HYDRAULIC CYLINDER ASSEMBLY…………………………………………………………..778

DISASSEMBLY……………………………………………………………………..778

ASSEMBLY………………………………………………………………………..780

WORK EQUIPMENT………………………………………………………………………….784

WORK EQUIPMENT ASSEMBLY………………………………………………………………784

REMOVAL…………………………………………………………………………784

INSTALLATION…………………………………………………………………….785

CAB AND ITS ATTACHMENTS………………………………………………………………….787

OPERATOR’S CAB ASSEMBLY………………………………………………………………787

REMOVAL…………………………………………………………………………787

INSTALLATION…………………………………………………………………….789

OPERATOR’S CAB GLASS (STUCK GLASS)…………………………………………………….790

REMOVAL…………………………………………………………………………791

INSTALLATION…………………………………………………………………….792

FRONT WINDOW ASSEMBLY………………………………………………………………..801

REMOVAL…………………………………………………………………………801

INSTALLATION…………………………………………………………………….804

ELECTRICAL SYSTEM……………………………………………………………………….809

WORK EQUIPMENT ASSEMBLY………………………………………………………………809

REMOVAL…………………………………………………………………………809

INSTALLATION…………………………………………………………………….810

MACHINE MONITOR……………………………………………………………………..811

REMOVAL…………………………………………………………………………811

INSTALLATION…………………………………………………………………….811

PUMP CONTROLLER……………………………………………………………………..812

REMOVAL…………………………………………………………………………812

INSTALLATION…………………………………………………………………….812

KOMTRAX TERMINAL…………………………………………………………………….813

REMOVAL…………………………………………………………………………813

INSTALLATION…………………………………………………………………….813

ENGINE CONTROLLER……………………………………………………………………814

REMOVAL…………………………………………………………………………814

INSTALLATION…………………………………………………………………….814

90 OTHERS………………………………………………………………………………….815

ELECTRICAL CIRCUIT DIAGRAMS………………………………………………………………817

TO CABIN HARNESS…………………………………………………………………….817

CABIN HARNESS VIEW 1…………………………………………………………………819

CABIN HARNESS VIEW 2…………………………………………………………………821

CONTROLLER (CR700) VIEW………………………………………………………………823

FLOOR HARNESS VIEW…………………………………………………………………..825

MONITOR AND RADIO HARNESS VIEW………………………………………………………..827

LEFT CONSOLE, FUSE PANEL AND KOMTRAX CONTROLLER…………………………………………829

WARNING AND INDICATOR LAMPS…………………………………………………………..831

ENGINE AND DRIVE SYSTEM SENSORS AND CONTROLLERS…………………………………………833

ENGINE SENSORS AND CONTROLLERS………………………………………………………..835

FUEL INJECTOR SYSTEM VIEW…………………………………………………………….837

ELECTRICAL DIAGRAM – 1 OF 9…………………………………………………………..839

ELECTRICAL DIAGRAM – 2 OF 9…………………………………………………………..841

ELECTRICAL DIAGRAM – 3 OF 9…………………………………………………………..843

ELECTRICAL DIAGRAM – 4 OF 9…………………………………………………………..845

ELECTRICAL DIAGRAM – 5 OF 9…………………………………………………………..847

ELECTRICAL DIAGRAM – 6 OF 9…………………………………………………………..849

ELECTRICAL DIAGRAM – 7 OF 9…………………………………………………………..851

ELECTRICAL DIAGRAM – 8 OF 9…………………………………………………………..853

ELECTRICAL DIAGRAM – 9 OF 9…………………………………………………………..855

HYDRAULIC CIRCUIT DIAGRAMS……………………………………………………………….857

VIEW “A” – 1 OF 11…………………………………………………………………..857

VIEW “A” – 2 OF 11…………………………………………………………………..859

VIEW “A” – 3 OF 11…………………………………………………………………..861

VIEW “A” – 4 OF 11…………………………………………………………………..863

VIEW “A” – 5 OF 11…………………………………………………………………..865

VIEW “A” – 6 OF 11…………………………………………………………………..867

VIEW “A” – 7 OF 11…………………………………………………………………..869

VIEW “A” – 8 OF 11…………………………………………………………………..871

VIEW “A” – 9 OF 11…………………………………………………………………..873

VIEW “A” – 10 OF 11………………………………………………………………….875

VIEW “A” – 11 OF 11………………………………………………………………….877

VIEW “B” – 1 OF 1……………………………………………………………………879