$46

Komatsu HD1500-8E0 Dump Truck Shop Manual SEN06836-05 – PDF DOWNLOAD

Komatsu HD1500-8E0 Dump Truck Shop Manual SEN06836-05 – PDF DOWNLOAD

FILE DETAILS:

Komatsu HD1500-8E0 Dump Truck Shop Manual SEN06836-05 – PDF DOWNLOAD

Language : English

Pages : 3136

Downloadable : Yes

File Type : PDF

Size: 185 MB

TABLE OF CONTENTS:

Komatsu HD1500-8E0 Dump Truck Shop Manual SEN06836-05 – PDF DOWNLOAD

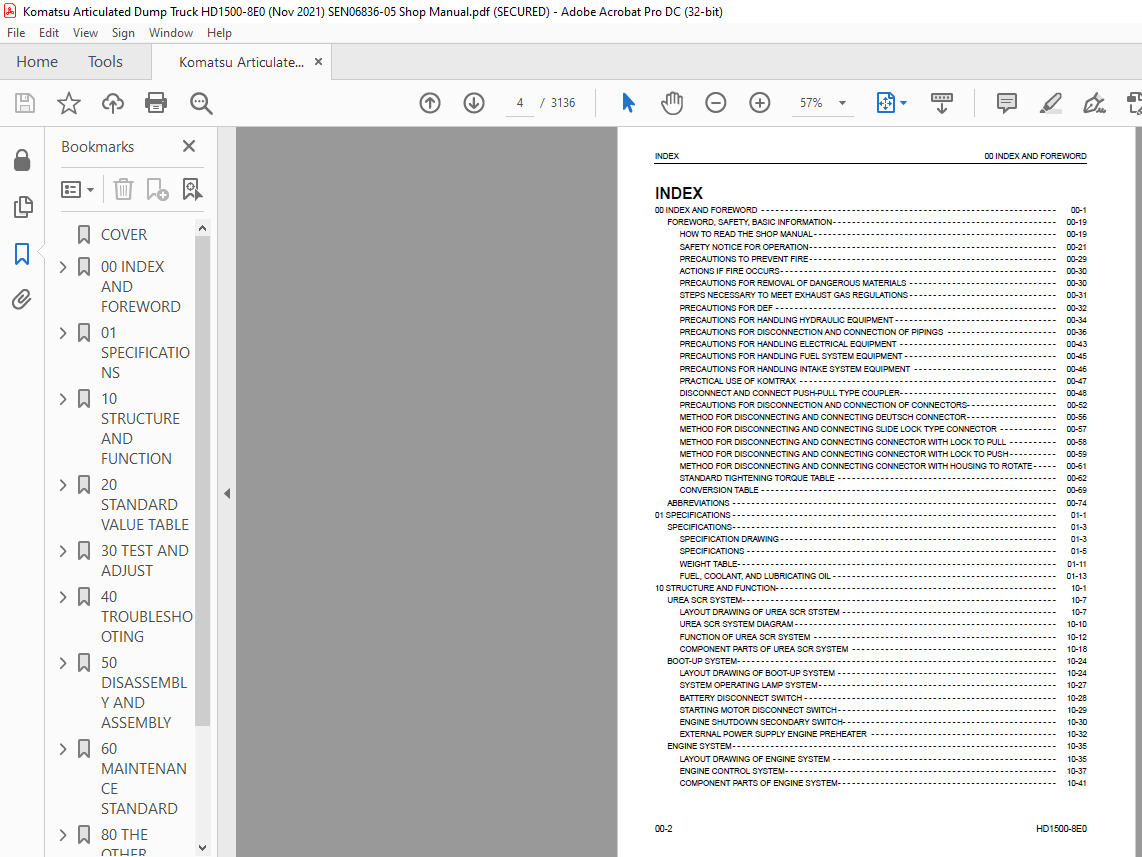

00 INDEX AND FOREWORD 00 1

FOREWORD, SAFETY, BASIC INFORMATION 00 19

HOW TO READ THE SHOP MANUAL 00 19

SAFETY NOTICE FOR OPERATION 00 21

PRECAUTIONS TO PREVENT FIRE 00 29

ACTIONS IF FIRE OCCURS 00 30

PRECAUTIONS FOR REMOVAL OF DANGEROUS MATERIALS 00 30

STEPS NECESSARY TO MEET EXHAUST GAS REGULATIONS 00 31

PRECAUTIONS FOR DEF 00 32

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT 00 34

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS 00 36

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT 00 43

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT 00 45

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT 00 46

PRACTICAL USE OF KOMTRAX 00 47

DISCONNECT AND CONNECT PUSH PULL TYPE COUPLER 00 48

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS 00 52

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR 00 56

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR 00 57

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL 00 58

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH 00 59

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE 00 61

STANDARD TIGHTENING TORQUE TABLE 00 62

CONVERSION TABLE 00 69

ABBREVIATIONS 00 74

01 SPECIFICATIONS 01 1

SPECIFICATIONS 01 3

SPECIFICATION DRAWING 01 3

SPECIFICATIONS 01 5

WEIGHT TABLE 01 11

FUEL, COOLANT, AND LUBRICATING OIL 01 13

10 STRUCTURE AND FUNCTION 10 1

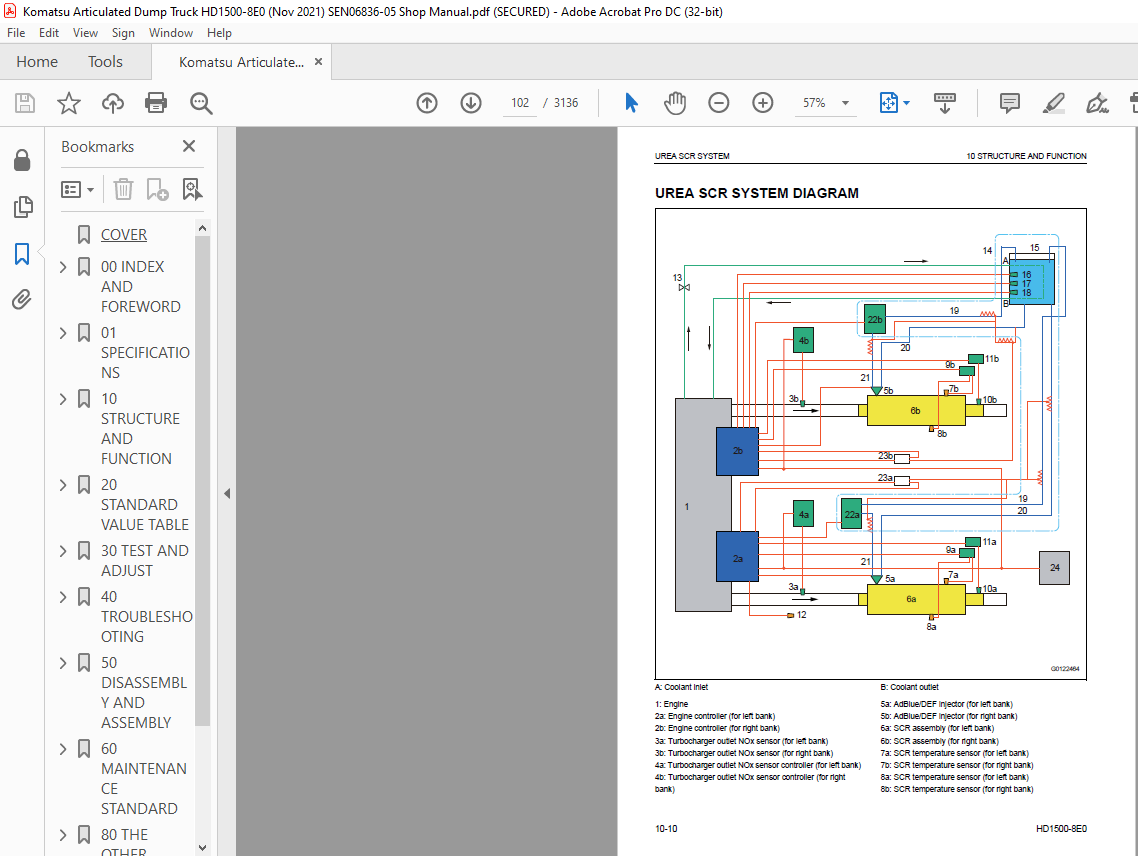

UREA SCR SYSTEM 10 7

LAYOUT DRAWING OF UREA SCR STSTEM 10 7

UREA SCR SYSTEM DIAGRAM 10 10

FUNCTION OF UREA SCR SYSTEM 10 12

COMPONENT PARTS OF UREA SCR SYSTEM 10 18

BOOT UP SYSTEM 10 24

LAYOUT DRAWING OF BOOT UP SYSTEM 10 24

SYSTEM OPERATING LAMP SYSTEM 10 27

BATTERY DISCONNECT SWITCH 10 28

STARTING MOTOR DISCONNECT SWITCH 10 29

ENGINE SHUTDOWN SECONDARY SWITCH 10 30

EXTERNAL POWER SUPPLY ENGINE PREHEATER 10 32

ENGINE SYSTEM 10 35

LAYOUT DRAWING OF ENGINE SYSTEM 10 35

ENGINE CONTROL SYSTEM 10 37

COMPONENT PARTS OF ENGINE SYSTEM 10 41

HD1500 8E0 00 3

00 INDEX AND FOREWORD INDEX

COOLING SYSTEM 10 42

LAYOUT DRAWING OF COOLING SYSTEM 10 42

FAN SPEED CONTROL SYSTEM OF FAN CLUTCH 10 44

COMPONENT PARTS OF COOLING SYSTEM 10 45

CONTROL SYSTEM 10 73

LAYOUT DRAWING OF CONTROL SYSTEM 10 73

RETARDER AND HOIST CONTROL SYSTEM 10 75

MACHINE MONITOR SYSTEM 10 77

REARVIEW MONITOR SYSTEM 10 79

KOMTRAX Plus SYSTEM 10 80

PAYLOAD METER SYSTEM 10 85

COMPONENT PARTS OF CONTROL SYSTEM 10 97

HYDRAULIC SYSTEM 10 145

LAYOUT DRAWING OF HYDRAULIC SYSTEM 10 145

COMPONENT PARTS OF HYDRAULIC SYSTEM 10 146

POWER TRAIN SYSTEM 10 181

LAYOUT DRAWING OF POWER TRAIN SYSTEM 10 181

TRANSMISSION CONTROL SYSTEM 10 184

GEAR SHIFT CONTROL SYSTEM 10 190

DIRECTION CONTROL SYSTEM 10 193

KOMATSU TRACTION CONTROL SYSTEM (KTCS) 10 194

TRAVEL SPEED LIMITATION SYSTEM 10 196

REAR AXLE OIL FILTRATION SYSTEM 10 200

COMPONENT PARTS OF POWER TRAIN SYSTEM 10 202

WORK EQUIPMENT SYSTEM 10 258

WORK EQUIPMENT CONTROL 10 258

HOIST CONTROL 10 259

BUDDY SYSTEM 10 261

COMPONENT PARTS OF WORK EQUIPMENT SYSTEM 10 263

STEERING SYSTEM 10 270

LAYOUT DRAWING OF STEERING SYSTEM 10 270

FUNCTION OF STEERING SYSTEM 10 271

STEERING COLUMN 10 272

STEERING CONTROL LINKAGE 10 273

COMPONENT PARTS OF STEERING SYSTEM 10 274

BRAKE SYSTEM 10 286

LAYOUT DRAWING OF BRAKE SYSTEM 10 286

RETARDER CONTROL 10 289

ARSC SYSTEM 10 291

COMPONENT PARTS OF BRAKE SYSTEM 10 292

AUTO GREASING SYSTEM 10 321

LAYOUT DRAWING OF AUTO GREASING SYSTEM 10 321

AUTO GREASING SYSTEM DIAGRAM 10 324

FUNCTION OF AUTO GREASING SYSTEM 10 325

GREASE REFILL AUTOMATIC STOP SYSTEM 10 326

COMPONENT PARTS OF AUTO GREASING SYSTEM 10 327

SERVICE CENTER 10 331

LAYOUT DRAWING OF SERVICE CENTER 10 331

FUNCTION OF SERVICE CENTER 10 331

00 4 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

UNDERCARRIAGE AND FRAME 10 332

REAR AXLE SUPPORT 10 332

SUSPENSION 10 333

FRONT SUSPENSION 10 334

REAR SUSPENSION 10 335

FRONT SUSPENSION CYLINDER 10 336

REAR SUSPENSION CYLINDER 10 338

WORK EQUIPMENT 10 339

STRUCTURE OF WORK EQUIPMENT 10 339

CAB AND ITS ATTACHMENTS 10 340

ROPS CAB 10 340

CAB MOUNT 10 341

LIFTING SYSTEM 10 342

POWER LADDER SYSTEM 10 342

20 STANDARD VALUE TABLE 20 1

STANDARD VALUE TABLE FOR ENGINE 20 3

STANDARD VALUE TABLE FOR ENGINE: HD1500 8E0 20 3

STANDARD VALUE TABLE FOR MACHINE 20 5

STANDARD VALUE TABLE FOR MACHINE: HD1500 8E0 20 5

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANCE 20 25

30 TEST AND ADJUST 30 1

RELATED INFORMATION TO TEST AND ADJUST 30 6

TOOLS TO TEST AND ADJUST 30 6

ENGINE AND COOLING SYSTEM 30 14

TEST ENGINE SPEED 30 14

TEST EXHAUST GAS COLOR 30 17

TEST BLOWBY PRESSURE 30 20

TEST FUEL PRESSURE 30 22

BLEED AIR FROM FUEL CIRCUIT 30 24

CLEAN AdBlue/DEF TANK 30 25

POWER TRAIN 30 28

TEST POWER TRAIN OIL PRESSURE 30 28

ADJUST TRANSMISSION INPUT SHAFT SPEED SENSOR 30 44

ADJUST TRANSMISSION INTERMEDIATE SHAFT SPEED SENSOR 30 45

ADJUST TRANSMISSION OUTPUT SHAFT SPEED SENSOR 30 46

CHECK AFTER ADJUSTING TRANSMISSION SPEED SENSOR 30 47

FLUSH TORQUE CONVERTER AND TRANSMISSION HYDRAULIC CIRCUIT 30 48

CLEAN FINAL DRIVE CASE MAGNET 30 50

MOVE MACHINE WITH ELECTRICAL SYSTEM PROBLEMS 30 51

STEERING SYSTEM 30 56

TEST STEERING CIRCUIT OIL PRESSURE 30 56

TEST STEERING CYLINDER PRESSURE 30 58

BLEED AIR FROM STEERING CYLINDER CIRCUIT 30 59

BRAKE SYSTEM 30 61

RELEASE PRESSURE IN BRAKE ACCUMULATOR CIRCUIT 30 61

TEST WHEEL BRAKE OIL PRESSURE 30 62

TEST AND ADJUST BRAKE ACCUMULATOR PRESSURE 30 67

TEST AND PRESSURIZE BRAKE ACCUMULATOR WITH NITROGEN GAS 30 70

PROCEDURE TO RELEASE NITROGEN GAS WHEN DISPOSING ACCUMULATOR 30 81

TEST BRAKE PERFORMANCE 30 82

HD1500 8E0 00 5

00 INDEX AND FOREWORD INDEX

BLEED AIR FROM BRAKE CIRCUIT 30 85

TEST PARKING BRAKE OIL PRESSURE 30 89

RELEASE PARKING BRAKE MANUALLY 30 91

TEST THE AMOUNT OF WHEEL BRAKE DISC WEAR 30 93

HYDRAULIC SYSTEM 30 95

TEST HOIST CIRCUIT OIL PRESSURE 30 95

TEST HOIST CYLINDER SUPPLY PRESSURE 30 97

TEST OIL PRESSURE OF HOIST EPC VALVE CIRCUIT 30 98

TEST AND ADJUST FRONT SUSPENSION CYLINDER 30 100

TEST AND ADJUST REAR SUSPENSION CYLINDER 30 106

BLEED AIR FROM HYDRAULIC CIRCUIT 30 112

CALIBRATION OF LADDER POSITION 30 120

WORK EQUIPMENT 30 121

TEST AND ADJUST DUMP BODY POSITIONER SENSOR 30 121

LOWER THE DUMP BODY MANUALLY 30 123

LIFT THE DUMP BODY MANUALLY 30 124

LIFT THE DUMP BODY WITH BUDDY SYSTEM 30 126

CAB AND ITS ATTACHMENTS 30 130

ADJUST STEERING WHEEL TILT LOCK LEVER 30 130

ADJUST RATTLING OPERATOR’S SEAT 30 131

ADJUST CLEARANCE OF ESCAPE DOOR 30 132

LIFTING SYSTEM 30 134

BLEED AIR FROM POWER LADDER CYLINDER 30 134

ELECTRICAL SYSTEM 30 135

SET AND ADJUST EACH EQUIPMENT 30 135

SET AND OPERATE OF MACHINE MONITOR 30 139

START UP KOMTRAX TERMINAL 30 270

STOP USE OF KOMTRAX TERMINAL 30 275

DEFAULT SETTING OF KOMTRAX Plus CONTROLLER 30 277

DEFAULT SETTING OF WIRELESS LAN MODEM 30 280

DOWNLOAD DATA FROM KOMTRAX Plus CONTROLLER 30 282

ADJUST AFTER REPLACEMENT OF KOMTRAX Plus CONTROLLER 30 286

ADJUST AFTER REPLACEMENT OF WIRELESS LAN MODEM 30 289

SET REGION OF Bluetooth® COMPATIBLE RADIO 30 292

VOLTAGE CIRCUIT OF ENGINE CONTROLLER WORK 30 294

BATTERY DISCONNECT SWITCH WORK 30 295

TEST DIODES 30 296

Pm CLINIC 30 297

Pm CLINIC SERVICE 30 297

PERFORM QUICK Pm 30 309

40 TROUBLESHOOTING 40 1

CONTENTS 40 2

RELATED INFORMATION ON TROUBLESHOOTING 40 12

GENERAL TROUBLESHOOTING POINTS 40 12

SEQUENCE OF EVENTS IN TROUBLESHOOTING 40 13

CHECKS BEFORE TROUBLESHOOTING 40 15

INSPECTION PROCEDURE BEFORE TROUBLESHOOTING 40 18

TESTING IN ACCORDANCE WITH TESTING PROCEDURE 40 20

ELECTRICAL SYSTEM TROUBLESHOOTING PREPARATION 40 44

PROCEDURE FOR TESTING AND TROUBLESHOOTING 40 50

00 6 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

SYMPTOM AND TROUBLESHOOTING NUMBERS 40 53

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE 40 56

CONNECTORS LIST AND LAYOUT 40 58

CONNECTOR CONTACT IDENTIFICATION 40 94

T BRANCH BOX AND T BRANCH ADAPTER TABLE 40 136

FUSE LOCATION TABLE 40 142

PREPARATION FOR TROUBLESHOOTING OF MACHINE MONITOR 40 148

PROCEDURES FOR CREATING HARNESS CHECKER ON MACHINE MONITOR LCD UNIT 40 150

FAILURE CODES TABLE 40 156

TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE) 40 194

FAILURE CODE [1500L0] 40 194

FAILURE CODE [15B0NX] 40 195

FAILURE CODE [15F0KM] 40 197

FAILURE CODE [15F0MB] 40 198

FAILURE CODE [15F7KM] 40 199

FAILURE CODE [15G0MW] 40 200

FAILURE CODE [15G7KM] 40 202

FAILURE CODE [15H0MW] 40 203

FAILURE CODE [15J0MW] 40 205

FAILURE CODE [15K0MW] 40 207

FAILURE CODE [15L0MW] 40 209

FAILURE CODE [15M0MW] 40 211

FAILURE CODE [15N0MW] 40 213

FAILURE CODE [15SBL1] 40 215

FAILURE CODE [15SBMA] 40 218

FAILURE CODE [15SCL1] 40 219

FAILURE CODE [15SCMA] 40 222

FAILURE CODE [15SDL1] 40 223

FAILURE CODE [15SDMA] 40 226

FAILURE CODE [15SEL1] 40 227

FAILURE CODE [15SEMA] 40 230

FAILURE CODE [15SFL1] 40 232

FAILURE CODE [15SFMA] 40 235

FAILURE CODE [15SGL1] 40 237

FAILURE CODE [15SGMA] 40 240

FAILURE CODE [15SHL1] 40 242

FAILURE CODE [15SHMA] 40 245

FAILURE CODE [15SJMA] 40 246

FAILURE CODE [2B0QNX] 40 247

FAILURE CODE [2F00KM] 40 248

FAILURE CODE [2G42ZG] 40 250

FAILURE CODE [2G43ZG] 40 251

FAILURE CODE [2G44ZG] 40 252

FAILURE CODE [879AKA] 40 254

FAILURE CODE [879AKB] 40 255

FAILURE CODE [879BKA] 40 256

FAILURE CODE [879BKB] 40 257

FAILURE CODE [879CKA] 40 259

FAILURE CODE [879CKB] 40 260

FAILURE CODE [879EMC] 40 261

HD1500 8E0 00 7

00 INDEX AND FOREWORD INDEX

FAILURE CODE [879FMC] 40 262

FAILURE CODE [879GKX] 40 263

FAILURE CODE [989D00] 40 264

FAILURE CODE [989X00] 40 265

FAILURE CODE [989Y00] 40 266

FAILURE CODE [AA10NX] 40 267

FAILURE CODE [AB00KE] 40 269

FAILURE CODE [AB00KY] 40 271

FAILURE CODE [B@C6NS] 40 272

FAILURE CODE [B@C7NS] 40 273

FAILURE CODE [B@CENS] 40 274

FAILURE CODE [B@JANS] 40 275

FAILURE CODE [D150KB] 40 276

FAILURE CODE [D150KZ] 40 278

FAILURE CODE [D151KB] 40 280

FAILURE CODE [D151KZ] 40 282

FAILURE CODE [D164KY] 40 284

FAILURE CODE [D19HKZ] 40 285

FAILURE CODE [D19JKZ] 40 287

FAILURE CODE [D19QKZ] 40 288

FAILURE CODE [D1EHKA] 40 290

FAILURE CODE [D1EHKB] 40 291

FAILURE CODE [D1EHKY] 40 292

FAILURE CODE [D1ENKZ] 40 293

FAILURE CODE [D1EPKA] 40 295

FAILURE CODE [D1EPKB] 40 297

FAILURE CODE [D1EPKY] 40 299

FAILURE CODE [D1EQKA] 40 300

FAILURE CODE [D1EQKB] 40 302

FAILURE CODE [D1EQKY] 40 304

FAILURE CODE [D1ERKA] 40 306

FAILURE CODE [D1ERKB] 40 308

FAILURE CODE [D1ERKY] 40 310

FAILURE CODE [D1ESKA] 40 312

FAILURE CODE [D1ESKB] 40 314

FAILURE CODE [D1ESKY] 40 316

FAILURE CODE [D1EWKA] 40 318

FAILURE CODE [D1EWKB] 40 320

FAILURE CODE [D1EWKY] 40 322

FAILURE CODE [D1J0KB] 40 324

FAILURE CODE [D5ZHL6] 40 326

FAILURE CODE [D862KA] 40 328

FAILURE CODE [DAF0KT] 40 329

FAILURE CODE [DAF0MB] 40 330

FAILURE CODE [DAF0MC] 40 331

FAILURE CODE [DAF3KK] 40 332

FAILURE CODE [DAF8KB] 40 334

FAILURE CODE [DAFDKB] 40 335

FAILURE CODE [DAFGMC] 40 337

FAILURE CODE [DAFLKA] 40 338

00 8 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

FAILURE CODE [DAFLKB] 40 340

FAILURE CODE [DAFQKR] 40 342

FAILURE CODE [DAQ0KK] 40 343

FAILURE CODE [DAQ0KT] 40 346

FAILURE CODE [DAQ0MC] 40 347

FAILURE CODE [DAQ1KA] 40 348

FAILURE CODE [DAQ2KK] 40 350

FAILURE CODE [DAQ9KQ] 40 352

FAILURE CODE [DAQLKA] 40 353

FAILURE CODE [DAQLKB] 40 355

FAILURE CODE [DAQQKR] 40 357

FAILURE CODE [DAQRKR] 40 358

FAILURE CODE [DAQRMA] 40 359

FAILURE CODE [DAQV00] 40 360

FAILURE CODE [DAQW00] 40 361

FAILURE CODE [DAZ9KQ] 40 362

FAILURE CODE [DAZQKR] 40 363

FAILURE CODE [DB10KT] 40 364

FAILURE CODE [DB10MC] 40 365

FAILURE CODE [DB11KA] 40 366

FAILURE CODE [DB12KK] 40 369

FAILURE CODE [DB13KK] 40 372

FAILURE CODE [DB19KQ] 40 374

FAILURE CODE [DB1LKA] 40 375

FAILURE CODE [DB1LKB] 40 377

FAILURE CODE [DB1QKR] 40 379

FAILURE CODE [DB1QMA] 40 380

FAILURE CODE [DB1RKR] 40 381

FAILURE CODE [DB2QKR] 40 387

FAILURE CODE [DBBUKM] 40 393

FAILURE CODE [DBBUKR] 40 394

FAILURE CODE [DBP0KM] 40 396

FAILURE CODE [DBP0KT] 40 397

FAILURE CODE [DBP0NR] 40 398

FAILURE CODE [DBP5KP] 40 399

FAILURE CODE [DBPLKA] 40 401

FAILURE CODE [DBPLKB] 40 403

FAILURE CODE [DBPQKR] 40 405

FAILURE CODE [DBPRKR] 40 408

FAILURE CODE [DBPRMA] 40 411

FAILURE CODE [DBPUKR] 40 412

FAILURE CODE [DBPVKR] 40 417

FAILURE CODE [DBPWKR] 40 422

FAILURE CODE [DBPXKR] 40 423

FAILURE CODE [DBV0MC] 40 424

FAILURE CODE [DBV1KK] 40 425

FAILURE CODE [DBV6KB] 40 427

FAILURE CODE [DBV7KB] 40 429

FAILURE CODE [DBVLKA] 40 430

FAILURE CODE [DBVLKB] 40 432

HD1500 8E0 00 9

00 INDEX AND FOREWORD INDEX

FAILURE CODE [DBVQKR] 40 434

FAILURE CODE [DBVRKR] 40 435

FAILURE CODE [DBVVKR] 40 436

FAILURE CODE [DBVWKR] 40 437

FAILURE CODE [DDAAL6] 40 438

FAILURE CODE [DDD7KX] 40 440

FAILURE CODE [DDDGL4] 40 442

FAILURE CODE [DDDHL4] 40 444

FAILURE CODE [DDTHKA] 40 446

FAILURE CODE [DDTJKA] 40 448

FAILURE CODE [DDTKKA] 40 450

FAILURE CODE [DDTLKA] 40 452

FAILURE CODE [DDTMKA] 40 454

FAILURE CODE [DDTNKA] 40 456

FAILURE CODE [DDTPKA] 40 458

FAILURE CODE [DDU1KA] 40 460

FAILURE CODE [DF10KA] 40 462

FAILURE CODE [DF10KB] 40 466

FAILURE CODE [DGE5KX] 40 469

FAILURE CODE [DGF1KX] 40 471

FAILURE CODE [DGR2KB] 40 473

FAILURE CODE [DGR2L8] 40 474

FAILURE CODE [DGR4KB] 40 476

FAILURE CODE [DGR4L8] 40 477

FAILURE CODE [DGR6KB] 40 479

FAILURE CODE [DGR6L8] 40 480

FAILURE CODE [DGREKB] 40 482

FAILURE CODE [DGREL8] 40 483

FAILURE CODE [DGT1KX] 40 485

FAILURE CODE [DHP4KY] 40 487

FAILURE CODE [DHP4KZ] 40 489

FAILURE CODE [DHP5KY] 40 491

FAILURE CODE [DHP5KZ] 40 493

FAILURE CODE [DHP6KA] 40 495

FAILURE CODE [DHP6KX] 40 497

FAILURE CODE [DHP6KY] 40 499

FAILURE CODE [DHP6KZ] 40 501

FAILURE CODE [DHP7KA] 40 503

FAILURE CODE [DHP7KX] 40 505

FAILURE CODE [DHP7KY] 40 507

FAILURE CODE [DHP7KZ] 40 509

FAILURE CODE [DHQ2KX] 40 511

FAILURE CODE [DHQ4KX] 40 513

FAILURE CODE [DHQ6KX] 40 515

FAILURE CODE [DHT5KX] 40 517

FAILURE CODE [DHT5L6] 40 519

FAILURE CODE [DHT7KX] 40 520

FAILURE CODE [DHT7L6] 40 522

FAILURE CODE [DHT8KX] 40 523

FAILURE CODE [DHT8ZG] 40 525

00 10 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

FAILURE CODE [DHU2KX] 40 526

FAILURE CODE [DHU3KX] 40 528

FAILURE CODE [DHUBKX] 40 530

FAILURE CODE [DHUCKX] 40 532

FAILURE CODE [DHUDKX] 40 534

FAILURE CODE [DHUEKX] 40 536

FAILURE CODE [DHUHKX] 40 538

FAILURE CODE [DHUJKX] 40 540

FAILURE CODE [DHUKKX] 40 542

FAILURE CODE [DHULKX] 40 544

FAILURE CODE [DHUMKX] 40 546

FAILURE CODE [DHUQKX] 40 548

FAILURE CODE [DHUSKX] 40 550

FAILURE CODE [DJF1KA] 40 552

FAILURE CODE [DK30KX] 40 554

FAILURE CODE [DK51L5] 40 556

FAILURE CODE [DK52KX] 40 559

FAILURE CODE [DK53L8] 40 561

FAILURE CODE [DK54KX] 40 563

FAILURE CODE [DK5VKX] 40 565

FAILURE CODE [DK5VMA] 40 567

FAILURE CODE [DK60KX] 40 568

FAILURE CODE [DKH0KX] 40 570

FAILURE CODE [DKH1KX] 40 572

FAILURE CODE [DLF1KA] 40 574

FAILURE CODE [DLF1LC] 40 575

FAILURE CODE [DLF2KA] 40 577

FAILURE CODE [DLF2LC] 40 578

FAILURE CODE [DLF8LC] 40 580

FAILURE CODE [DLF9LC] 40 582

FAILURE CODE [DLFKLC] 40 584

FAILURE CODE [DLFLLC] 40 586

FAILURE CODE [DLT3KA] 40 588

FAILURE CODE [DLT3LC] 40 589

FAILURE CODE [DPQ1KR] 40 591

FAILURE CODE [DPQ1LD] 40 594

FAILURE CODE [DPQ2KR] 40 597

FAILURE CODE [DPQ3KR] 40 600

FAILURE CODE [DPQ4KB] 40 602

FAILURE CODE [DQ11KM] 40 603

FAILURE CODE [DQ11KT] 40 604

FAILURE CODE [DQ12KM] 40 605

FAILURE CODE [DQ12KT] 40 606

FAILURE CODE [DQ13KM] 40 607

FAILURE CODE [DQ13KT] 40 608

FAILURE CODE [DQ14KM] 40 609

FAILURE CODE [DQ14KT] 40 610

FAILURE CODE [DQ15KM] 40 611

FAILURE CODE [DQ15KT] 40 612

FAILURE CODE [DQ16KM] 40 613

HD1500 8E0 00 11

00 INDEX AND FOREWORD INDEX

FAILURE CODE [DQ16KT] 40 614

FAILURE CODE [DR10KA] 40 615

FAILURE CODE [DR20KA] 40 617

FAILURE CODE [DR30KA] 40 619

FAILURE CODE [DR40KA] 40 621

FAILURE CODE [DR50KA] 40 623

FAILURE CODE [DR60KA] 40 625

FAILURE CODE [DSJ0KR] 40 627

FAILURE CODE [DUMBKB] 40 628

FAILURE CODE [DV00KB] 40 629

FAILURE CODE [DV01KB] 40 631

FAILURE CODE [DW2AKA] 40 633

FAILURE CODE [DW2AKB] 40 634

FAILURE CODE [DW2AKY] 40 636

FAILURE CODE [DW2AL1] 40 637

FAILURE CODE [DW2ALH] 40 638

FAILURE CODE [DW2BKA] 40 639

FAILURE CODE [DW2BKB] 40 640

FAILURE CODE [DW2BKY] 40 641

FAILURE CODE [DW2BL1] 40 642

FAILURE CODE [DW2BLH] 40 643

FAILURE CODE [DW2CKA] 40 644

FAILURE CODE [DW2CKB] 40 645

FAILURE CODE [DW2CKY] 40 647

FAILURE CODE [DW2CL1] 40 648

FAILURE CODE [DW2CLH] 40 649

FAILURE CODE [DW4BK4] 40 650

FAILURE CODE [DW4BMA] 40 653

FAILURE CODE [DW72KZ] 40 656

FAILURE CODE [DW73KA] 40 658

FAILURE CODE [DW73KB] 40 660

FAILURE CODE [DW73KY] 40 662

FAILURE CODE [DW7NKZ] 40 663

FAILURE CODE [DW7SKZ] 40 665

FAILURE CODE [DWNJKZ] 40 667

FAILURE CODE [DWNMKZ] 40 669

FAILURE CODE [DX13KA] 40 671

FAILURE CODE [DX13KB] 40 673

FAILURE CODE [DX13KY] 40 675

FAILURE CODE [DX30K4] 40 676

FAILURE CODE [DX30KA] 40 678

FAILURE CODE [DX30KB] 40 680

FAILURE CODE [DX30KY] 40 682

FAILURE CODE [DX30MA] 40 684

FAILURE CODE [DX33K4] 40 686

FAILURE CODE [DX33KA] 40 688

FAILURE CODE [DX33KB] 40 690

FAILURE CODE [DX33KY] 40 692

FAILURE CODE [DX33MA] 40 694

FAILURE CODE [DX37K4] 40 696

00 12 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

FAILURE CODE [DX37KA] 40 698

FAILURE CODE [DX37KB] 40 700

FAILURE CODE [DX37KY] 40 702

FAILURE CODE [DX37MA] 40 703

FAILURE CODE [DX38K4] 40 705

FAILURE CODE [DX38KA] 40 707

FAILURE CODE [DX38KB] 40 709

FAILURE CODE [DX38KY] 40 711

FAILURE CODE [DX38MA] 40 712

FAILURE CODE [DX42KZ] 40 714

FAILURE CODE [DX43KZ] 40 716

FAILURE CODE [DXH1KA] 40 718

FAILURE CODE [DXH1KB] 40 720

FAILURE CODE [DXH1KY] 40 722

FAILURE CODE [DXH2KA] 40 723

FAILURE CODE [DXH2KB] 40 726

FAILURE CODE [DXH2KY] 40 729

FAILURE CODE [DXH3KA] 40 732

FAILURE CODE [DXH3KB] 40 735

FAILURE CODE [DXH3KY] 40 738

FAILURE CODE [DXH4KA] 40 741

FAILURE CODE [DXH4KB] 40 744

FAILURE CODE [DXH4KY] 40 747

FAILURE CODE [DXH5KA] 40 750

FAILURE CODE [DXH5KB] 40 753

FAILURE CODE [DXH5KY] 40 756

FAILURE CODE [DXH6KA] 40 759

FAILURE CODE [DXH6KB] 40 762

FAILURE CODE [DXH6KY] 40 765

FAILURE CODE [DXH7KA] 40 768

FAILURE CODE [DXH7KB] 40 771

FAILURE CODE [DXH7KY] 40 774

FAILURE CODE [DXHHKA] 40 777

FAILURE CODE [DXHHKB] 40 779

FAILURE CODE [DXHHKY] 40 781

FAILURE CODE [DY30MA] 40 784

FAILURE CODE [DY30MC] 40 787

FAILURE CODE [DY30ME] 40 790

FAILURE CODE [DY32MC] 40 792

FAILURE CODE [F9A0KT] 40 795

FAILURE CODE [F9A0MC] 40 796

FAILURE CODE [F9A1KK] 40 797

FAILURE CODE [F9A2KK] 40 800

FAILURE CODE [F9A9KQ] 40 803

FAILURE CODE [F9ALKA] 40 804

FAILURE CODE [F9ALKB] 40 806

FAILURE CODE [F9AQKR] 40 808

FAILURE CODE [F9AQMA] 40 809

FAILURE CODE [F9ARKR] 40 810

FAILURE CODE [F9AUKA] 40 811

HD1500 8E0 00 13

00 INDEX AND FOREWORD INDEX

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) 40 814

E 1 ENGINE DOES NOT START (ENGINE DOES NOT CRANK) 40 814

E 2 ALL OF LCD UNIT, LED UNIT, AND METER UNIT ON MACHINE MONITOR DISPLAY NOTHING 40 822

E 3 LCD UNIT ON MACHINE MONITOR DISPLAYS NOTHING 40 825

E 4 BACKLIGHT OF LCD UNIT ON MACHINE MONITOR IS ABNORMAL, (BACKLIGHT GOES OUT OR FLICKERS)

40 827

E 5 LCD ON MACHINE MONITOR DOES NOT DISPLAY PROPERLY 40 829

E 6 METER UNIT DISPLAY ON MACHINE MONITOR IS ABNORMAL 40 831

E 7 NIGHT LIGHTING LAMP OF METER UNIT ON MACHINE MONITOR IS ABNORMAL 40 834

E 8 LED UNIT LAMP ON MACHINE MONITOR IS ABNORMAL 40 837

E 9 NIGHT LIGHTING LAMP OF SWITCH PANEL ON MACHINE MONITOR IS ABNORMAL OR SWITCH DOES

NOT OPERATE PROPERLY 40 839

E 10 2 SWITCHES OPERATION OF SWITCH PANEL ON MACHINE MONITOR DOES NOT FUNCTION 40 841

E 11 SWITCH PANEL BUZZER OF MACHINE MONITOR IS ABNORMAL 40 843

E 12 SOME ITEMS OF GAUGES AND CAUTION LAMPS ON MACHINE MONITOR ARE NOT DISPLAYED

PROPERLY 40 845

E 13 REARVIEW MONITOR DOES NOT LIGHT UP OR BACKLIGHT FLICKERS 40 846

E 14 REARVIEW MONITOR IMAGES ARE NOT DISPLAYED CLEARLY 40 848

E 15 REARVIEW MONITOR BRIGHTNESS CANNOT BE ADJUSTED 40 851

E 16 NIGHT LIGHTING LAMP OF REARVIEW MONITOR IS ABNORMAL 40 854

E 17 REARVIEW MONITOR IS NOT DISPLAYED IN CONJUNCTION WITH REVERSE WHEN THE CONSTANT

DISPLAY SETTING IS DISABLED 40 856

E 18 REARVIEW MONITOR REFERENCE LINE IS NOT DISPLAYED WHEN THE REFERENCE LINE DISPLAY

SETTING IS ENABLED 40 859

E 19 FUEL LEVEL GAUGE DOES NOT INDICATE CORRECT LEVEL 40 861

E 20 SEAT BELT CAUTION LAMP INDICATION IS ABNORMAL 40 863

E 21 MACHINE MONITOR CANNOT BE OPERATED WHEN STARTING SWITCH IS IN OFF POSITION 40 865

E 22 ALARM BUZZER DOES NOT SOUND 40 866

E 23 ALARM BUZZER DOES NOT STOP SOUNDING 40 868

E 24 AISS FUNCTION DOES NOT OPERATE PROPERLY 40 870

E 25 HOIST LEVER DOES NOT OPERATE PROPERLY 40 872

E 26 TURN SIGNAL LAMP AND WINKER LAMP (HAZARD LAMP) DO NOT OPERATE PROPERLY 40 874

E 27 NONE OF HEADLAMP, CLEARANCE LAMP, AND TAIL LAMP LIGHTS 40 878

E 28 SMALL LAMP (CLEARANCE LAMP) DOES NOT LIGHT UP 40 881

E 29 TAIL LAMP DOES NOT LIGHT UP 40 884

E 30 HEADLAMP (LOW BEAM) DOES NOT LIGHT UP 40 887

E 31 HEADLAMP (HIGH BEAM) DOES NOT LIGHT UP 40 890

E 32 NEITHER (LOW BEAM) NOR (HIGH BEAM) HEADLAMPS LIGHTS UP 40 893

E 33 HIGH BEAMS DO NOT LIGHT UP WHILE PASSING SWITCH IS OPERATED 40 895

E 34 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY 40 897

E 35 DATA DOWNLOADING BY USING WIRELESS LAN CAN NOT BE PERFORMED 40 899

E 36 KomVision MONITOR DOES NOT LIGHT UP OR BACKLIGHT FLICKERS 40 900

E 37 KomVision MONITOR IMAGES ARE NOT DISPLAYED CLEARLY 40 903

E 38 KomVision MONITOR BRIGHTNESS CANNOT BE ADJUSTED 40 908

E 39 NIGHT LIGHTING LAMP OF KomVision MONITOR IS ABNORMAL 40 911

E 40 PART OF THE CAMERA IMAGE IS NOT DISPLAYED ON THE KomVision MONITOR 40 914

E 41 IMAGE ON KomVision MONITOR IS NOT DISPLAYED PROPERLY AFTER CALIBRATION 40 916

E 42 EXTERNAL POWER SUPPLY ENGINE OIL PAN HEATER DOES NOT OPERATE 40 917

E 43 EXTERNAL POWER SUPPLY BRAKE TANK HEATER DOES NOT OPERATE 40 919

E 44 EXTERNAL POWER SUPPLY TRANSMISSION OIL PAN HEATER DOES NOT OPERATE 40 921

00 14 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

E 45 EXTERNAL POWER SUPPLY HYDRAULIC TANK HEATER DOES NOT OPERATE 40 923

E 46 BUZZER DOES NOT SOUND WHEN POWER LADDER IS OPERATED 40 925

E 47 POWER LADDER PUMP DOES NOT OPERATE 40 927

TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE) 40 929

INFORMATION MENTIONED IN TROUBLESHOOTING TABLE (H MODE) 40 929

FAILURE MODE AND CAUSE TABLE 40 930

H 1 MACHINE DOES NOT START 40 943

H 2 MACHINE DOES NOT TRAVEL SMOOTHLY (MACHINE HUNTS) 40 946

H 3 LOCKUP IS NOT RELEASED 40 947

H 4 ABNORMALLY STRONG SHOCKS RESULT FROM STARTING OF MACHINE AND GEAR SHIFTING 40 948

H 5 GEAR IS NOT UPSHIFTED 40 950

H 6 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING IN LOCKUP DRIVE MODE AT ALL GEAR

SPEEDS 40 953

H 7 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING IN TORQUE CONVERTER DRIVE MODE

40 954

H 8 MACHINE LACKS TRAVEL SPEED OR POWER WHEN TRAVELING AT PARTICULAR GEAR SPEED 40 955

H 9 LARGE TIME LAG IS OBSERVED WHEN MACHINE STARTS AND GEAR IS SHIFTED 40 957

H 10 OIL TEMPERATURE OF TORQUE CONVERTER IS HIGH 40 960

H 11 OIL PRESSURE OF TORQUE CONVERTER IS LOW 40 961

H 12 STEERING WHEEL IS HEAVY TO OPERATE 40 962

H 13 STEERING WHEEL CANNOT BE OPERATED 40 963

H 14 STEERING WHEEL WAGGLES 40 964

H 15 FRONT BRAKE DOES NOT APPLY SUFFICIENTLY 40 965

H 16 REAR BRAKE DOES NOT APPLY SUFFICIENTLY 40 967

H 17 DUMP BODY RISING SPEED IS LOW 40 969

H 18 HYDRAULIC DRIFT OF DUMP BODY IS LARGE 40 971

H 19 DUMP BODY DOES NOT MOVE 40 972

H 20 FAN SPEED IS UNUSUAL (EXCESSIVELY HIGH OR LOW, OR FAN STOPS) 40 974

H 21 UNUSUAL NOISE IS HEARD FROM AROUND FAN 40 975

H 22 POWER LADDER DOES NOT MOVE OR ITS SPEED IS LOW 40 976

50 DISASSEMBLY AND ASSEMBLY 50 1

ABBREVIATIONS 50 7

DISASSEMBLE AND ASSEMBLE RELATED INFORMATION 50 12

HOW TO READ THIS MANUAL 50 12

COATING MATERIALS LIST 50 14

SPECIAL TOOL LIST 50 17

DIAGRAMS OF SPECIAL TOOLS 50 39

ENGINE AND COOLING SYSTEM 50 48

REMOVE AND INSTALL RADIATOR ASSEMBLY 50 48

REMOVE AND INSTALL OIL COOLER ASSEMBLY 50 116

REMOVE AND INSTALL ENGINE ASSEMBLY 50 147

REMOVE AND INSTALL DAMPER ASSEMBLY 50 225

DISASSEMBLE AND ASSEMBLE OF DAMPER ASSEMBLY 50 229

DISASSEMBLE AND ASSEMBLE OF RADIATOR ASSEMBLY 50 236

REMOVE AND INSTALL AdBlue/DEF TANK ASSEMBLY 50 248

REMOVE AND INSTALL AdBlue/DEF TANK SENSOR FLANGE ASSEMBLY 50 280

REMOVE AND INSTALL AdBlue/DEF TANK SENSOR 50 301

REMOVE AND INSTALL AdBlue/DEF TANK STRAINER 50 305

REMOVE AND INSTALL SCR ASSEMBLY 50 307

REMOVE AND INSTALL AdBlue/DEF INJECTOR 50 337

HD1500 8E0 00 15

00 INDEX AND FOREWORD INDEX

REMOVE AND INSTALL AdBlue/DEF PUMP 50 338

REMOVE AND INSTALL AdBlue/DEF HOSE 50 347

POWER TRAIN 50 377

REMOVE AND INSTALL FRONT DRIVE SHAFT 50 377

REMOVE AND INSTALL REAR DRIVE SHAFT ASSEMBLY 50 386

REMOVE AND INSTALL TORQUE CONVERTER AND TRANSMISSION ASSEMBLY 50 392

DISCONNECT AND CONNECT TORQUE CONVERTER AND TRANSMISSION ASSEMBLY 50 428

DISASSEMBLE AND ASSEMBLE OF TORQUE CONVERTER AND PTO ASSEMBLY 50 453

DISASSEMBLE AND ASSEMBLE OF TRANSMISSION ASSEMBLY 50 490

REMOVE AND INSTALL DIFFERENCIAL ASSEMBLY 50 551

DISASSEMBLE AND ASSEMBLE OF DIFFERENTIAL ASSEMBLY 50 557

REMOVE AND INSTALL FINAL DRIVE CARRIER ASSEMBLY 50 586

DISASSEMBLE AND ASSEMBLE OF FINAL DRIVE CARRIER ASSEMBLY 50 591

BRAKE SYSTEM 50 605

REMOVE AND INSTALL FRONT WHEEL HUB AND BRAKE ASSEMBLY 50 605

DISASSEMBLE AND ASSEMBLE OF FRONT WHEEL HUB AND BRAKE ASSEMBLY 50 620

REMOVE AND INSTALL FINAL DRIVE AND REAR BRAKE ASSEMBLY 50 643

DISASSEMBLE AND ASSEMBLE OF FINAL DRIVE AND REAR BRAKE ASSEMBLY 50 645

STEERING SYSTEM 50 681

REMOVE AND INSTALL STEERING VALVE ASSEMBLY 50 681

REMOVE AND INSTALL O RING OF STEERING VALVE ASSEMBLY 50 687

REMOVE AND INSTALL STEERING CYLINDER ASSEMBLY 50 693

DISASSEMBLE AND ASSEMBLE OF STEERING CYLINDER ASSEMBLY 50 707

UNDERCARRIAGE AND FRAME 50 712

REMOVE AND INSTALL FRONT WHEEL ASSEMBLY 50 712

REMOVE AND INSTALL REAR WHEEL ASSEMBLY 50 719

REMOVE AND INSTALL FRONT SUSPENSION CYLINDER ASSEMBLY 50 724

DISASSEMBLE AND ASSEMBLE OF FRONT SUSPENSION CYLINDER ASSEMBLY (CYLINDER WITH BUFFER

RING) 50 738

REMOVE AND INSTALL KING PIN 50 742

REMOVE AND INSTALL REAR SUSPENSION CYLINDER ASSEMBLY 50 745

DISASSEMBLE AND ASSEMBLE OF REAR SUSPENSION CYLINDER ASSEMBLY (CYLINDER WITH BUFFER

RING) 50 751

HYDRAULIC SYSTEM 50 756

REMOVE AND INSTALL FLOW AMPLIFIER VALVE ASSEMBLY 50 756

REMOVE AND INSTALL O RING of FLOW AMPLIFIER VALVE ASSEMBLY 50 771

REMOVE AND INSTALL HOIST VALVE ASSEMBLY 50 777

REMOVE AND INSTALL HOIST CYLINDER HEAD ASSEMBLY 50 792

DISASSEMBLE AND ASSEMBLE OF HOIST CYLINDER ASSEMBLY 50 795

WORK EQUIPMENT 50 807

REMOVE AND INSTALL DUMP BODY ASSEMBLY 50 807

CAB AND ITS ATTACHMENTS 50 817

REMOVE AND INSTALL OPERATOR CAB ASSEMBLY 50 817

REMOVE AND INSTALL OPERATOR CAB GLASS 50 887

REMOVE AND INSTALL AIR CONDITIONER UNIT ASSEMBLY 50 900

REMOVE AND INSTALL OPERATOR’S SEAT ASSEMBLY 50 920

REMOVE AND INSTALL SEAT BELT 50 925

ELECTRICAL SYSTEM 50 927

REMOVE AND INSTALL RETARDER AND HOIST CONTROLLER ASSEMBLY 50 927

REMOVE AND INSTALL TRANSMISSION CONTROLLER ASSEMBLY 50 929

00 16 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

REMOVE AND INSTALL MONITOR CONTROLLER ASSEMBLY 50 931

REMOVE AND INSTALL MACHINE MONITOR ASSEMBLY 50 933

REMOVE AND INSTALL KOMTRAX PLUS CONTROLLER ASSEMBLY 50 938

REMOVE AND INSTALL KOMTRAX TERMINAL ASSEMBLY 50 940

REMOVE AND INSTALL REARVIEW CAMERA 50 942

REMOVE AND INSTALL KomVision CAMERA 50 943

REMOVE AND INSTALL KomVision RADAR 50 956

REMOVE AND INSTALL KomVision CONTROLLER ASSEMBLY 50 967

REMOVE AND INSTALL WIRELESS LAN UNIT ASSEMBLY 50 969

60 MAINTENANCE STANDARD 60 1

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD 60 4

ENGINE AND COOLING SYSTEM 60 6

MAINTENANCE STANDARD OF ENGINE MOUNT 60 6

MAINTENANCE STANDARD OF DAMPER 60 7

MAINTENANCE STANDARD OF FRONT BRAKE COOLING REMOTE MOTOR 60 9

MAINTENANCE STANDARD OF REAR BRAKE COOLING REMOTE MOTOR 60 11

POWER TRAIN 60 13

MAINTENANCE STANDARD OF DRIVE SHAFT 60 13

MAINTENANCE STANDARD OF TORQUE CONVERTER AND TRANSMISSION MOUNT 60 15

MAINTENANCE STANDARD OF TORQUE CONVERTER AND PTO 60 16

MAINTENANCE STANDARD OF TORQUE CONVERTER VALVE 60 20

MAINTENANCE STANDARD OF TORQUE CONVERTER REGULATOR VALVE 60 22

MAINTENANCE STANDARD OF TRANSMISSION 60 23

MAINTENANCE STANDARD OF TRANSMISSION CONTROL VALVE 60 29

MAINTENANCE STANDARD OF FORWARD AND REVERSE CLUTCH ECMV AND GEAR SPEED CLUTCH ECMV

60 30

MAINTENANCE STANDARD OF LOCKUP CLUTCH ECMV 60 31

MAINTENANCE STANDARD OF TRANSMISSION LUBRICATION SELECTOR VALVE 60 32

MAINTENANCE STANDARD OF FRONT AXLE 60 33

MAINTENANCE STANDARD OF REAR AXLE 60 34

MAINTENANCE STANDARD OF DIFFERENTIAL 60 35

MAINTENANCE STANDARD OF FINAL DRIVE 60 36

STEERING SYSTEM 60 37

MAINTENANCE STANDARD OF STEERING COLUMN 60 37

MAINTENANCE STANDARD OF STEERING CONTROL LINKAGE 60 38

MAINTENANCE STANDARD OF STEERING CYLINDER 60 41

BRAKE SYSTEM 60 42

MAINTENANCE STANDARD OF FRONT SLACK ADJUSTER 60 42

MAINTENANCE STANDARD OF REAR SLACK ADJUSTER 60 43

MAINTENANCE STANDARD OF FRONT BRAKE AND PARKING BRAKE 60 44

MAINTENANCE STANDARD OF REAR BRAKE AND PARKING BRAKE 60 45

UNDERCARRIAGE AND FRAME 60 46

MAINTENANCE STANDARD OF FRONT SUSPENSION CYLINDER 60 46

MAINTENANCE STANDARD OF REAR SUSPENSION CYLINDER 60 48

MAINTENANCE STANDARD OF REAR AXLE SUPPORT 60 49

HYDRAULIC SYSTEM 60 50

MAINTENANCE STANDARD OF STEERING PUMP 60 50

MAINTENANCE STANDARD OF DRIVE PUMP OF HOIST AND FRONT BRAKE COOLING REMOTE MOTOR

60 54

MAINTENANCE STANDARD OF DRIVE PUMP OF REAR BRAKE COOLING REMOTE MOTOR 60 56

HD1500 8E0 00 17

00 INDEX AND FOREWORD INDEX

MAINTENANCE STANDARD OF SERVO VALVE OF DRIVE PUMP OF REAR BRAKE COOLING REMOTE MOTOR

60 58

MAINTENANCE STANDARD OF BRAKE CHARGE PUMP 60 59

MAINTENANCE STANDARD OF FRONT BRAKE COOLING AND POWER TRAIN TRIPLEX PUMP 60 61

MAINTENANCE STANDARD OF FRONT BRAKE COOLING REMOTE PUMP 60 63

MAINTENANCE STANDARD OF REAR BRAKE COOLING REMOTE AND AXLE OIL CIRCULATION 4 SPOOL

PUMP 60 65

WORK EQUIPMENT 60 67

MAINTENANCE STANDARD OF HOIST CYLINDER 60 67

CAB AND ITS ATTACHMENTS 60 68

MAINTENANCE STANDARD OF CAB MOUNT 60 68

80 THE OTHER INFORMATION 80 1

AIR CONDITIONER SYSTEM 80 4

PRECAUTIONS FOR REFRIGERANT 80 4

AIR CONDITIONER COMPONENT 80 5

SPECIFICATIONS OF AIR CONDITIONER 80 7

CONFIGURATION AND FUNCTION OF REFRIGERATION CYCLE 80 8

OUTLINE OF REFRIGERATION CYCLE 80 9

COMPONENT PARTS OF AIR CONDITIONER SYSTEM 80 11

COMPONENT PARTS OF AIR CONDITIONER UNIT 80 14

AIR CONDITIONER CONTROLLER 80 18

COMPRESSOR 80 19

CONDENSER 80 20

SENSORS FOR AIR CONDITIONER SYSTEM 80 21

EXPLANATION OF PROCEDURE FOR TESTING AND TROUBLESHOOTING OF AIR CONDITIONER 80 22

CIRCUIT DIAGRAM AND ARRANGEMENT OF CONNECTOR PINS FOR AIR CONDITIONER 80 24

AIR CONDITIONER SYSTEM DIAGRAM 80 26

INSTALLATION LOCATIONS OF AIR CONDITIONER PARTS AND ARRANGEMENT OF CONNECTORS 80 29

TESTING AIR LEAKAGE (DUCT) 80 32

TESTING AIR CONDITIONER USING SELF DIAGNOSIS FUNCTION 80 35

HOW TO OPEN THE ELECTRICAL SYSTEM ABNORMALITY RECORD SCREEN IN SERVICE MODE OF THE

MACHINE MONITOR 80 36

TEST VENT (MODE) CHANGEOVER 80 38

TESTING FRESH/RECIRC AIR CHANGEOVER 80 39

TEST (TRIPLE) PRESSURE SWITCH FOR REFRIGERANT 80 40

TEST RELAYS 80 42

AIR CONDITIONER TROUBLESHOOTING CHART 1 80 43

AIR CONDITIONER TROUBLESHOOTING CHART 2 80 44

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE 80 47

TROUBLESHOOTING USING GAUGE PRESSURE 80 66

CONNECTION OF SERVICE TOOL 80 68

PRECAUTIONS FOR DISCONNECTING AND CONNECTING HOSES AND TUBES IN AIR CONDITIONER PIPINGS

80 69

HANDLE COMPRESSOR OIL 80 71

METHOD FOR REPLACING DESICCANT 80 73

KomVision SYSTEM 80 75

STRUCTURE AND OPERATION OF KomVision SYSTEM 80 75

TESTING AND ADJUSTING KomVision SYSTEM 80 93

CAMERA CALIBRATION 80 116

TROUBLESHOOTING OF KomVision SYSTEM 80 157

00 18 HD1500 8E0

INDEX 00 INDEX AND FOREWORD

90 CIRCUIT DIAGRAMS 90 1

HOW TO READ ELECTRICAL WIRE CODE 90 3

HYDRAULIC CIRCUIT DIAGRAM 90 7

SYMBOLS USED IN HYDRAULIC CIRCUIT DIAGRAM 90 7

HYDRAULIC CIRCUIT DIAGRAM OF STEERING, HOIST 90 11

POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM 90 13

HYDRAULIC CIRCUIT DIAGRAM OF BRAKE SYSTEM 90 15

HYDRAULIC CIRCUIT DIAGRAM FOR POWER LADDER 90 17

HYDRAULIC CIRCUIT DIAGRAM OF MACHINE LOCKOUT SYSTEM 90 19

HYDRAULIC CIRCUIT DIAGRAM OF STEERING, HOIST (REVERSE 1ST + RIGHT TURN + BRAKE OPERATION)

90 21

HYDRAULIC CIRCUIT DIAGRAM OF POWER TRAIN (AT REVERSE 1ST + RIGHT TURN + BRAKE OPERATION)

90 23

HYDRAULIC CIRCUIT DIAGRAM OF BRAKE (REVERSE 1ST + RIGHT TURN + BRAKE OPERATION) 90 25

HYDRAULIC CIRCUIT DIAGRAM OF STEERING, HOIST (HOIST RAISE, FORWARD 2ND) 90 27

HYDRAULIC CIRCUIT DIAGRAM OF POWER TRAIN (AT HOIST RAISE + FORWARD 2ND OPERATION) 90 29

HYDRAULIC CIRCUIT DIAGRAM OF BRAKE (RETARDER BRAKE OPERATION) 90 31

ELECTRICAL CIRCUIT DIAGRAM 90 33

SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90 33

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (1/10) 90 37

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (2/10) 90 39

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (3/10) 90 41

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (4/10) 90 43

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (5/10) 90 45

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (6/10) 90 47

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (7/10) 90 49

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (8/10) 90 51

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (9/10) 90 53

INSIDE CAB ELECTRICAL CIRCUIT DIAGRAM (10/10) 90 55

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (1/11) 90 57

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (2/11) 90 59

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (3/11) 90 61

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (4/11) 90 63

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (5/11) 90 65

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (6/11) 90 67

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (7/11) 90 69

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (8/11) 90 71

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (9/11) 90 73

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (10/11) 90 75

ELECTRICAL CIRCUIT DIAGRAM OF MACHINE (11/11) 90 77

INDEX 1

DESCRIPTION:

Komatsu HD1500-8E0 Dump Truck Shop Manual SEN06836-05 – PDF DOWNLOAD

SERIAL NUMBERS 85001 and up

FOREWORD, SAFETY, BASIC INFORMATION

HOW TO READ THE SHOP MANUAL

• Some of the attachments and options described in this shop manual may not be available in some areas. If

they are required, consult your Komatsu distributor.

• The materials and specifications are subject to change without notice.

• Shop Manuals are available for “machine part” and “engine part”. For the engine unit, see the shop manual

for the machine which has the same engine model.

• Actual machine may differ from the images which are contained in this manual. A typical model is shown in

the illustrations of this shop manual.

Composition of the shop manual

This shop manual contains technical information necessary to perform services in workshops. It is divided into

the following chapters for the ease of use.

00 INDEX AND FOREWORD

This section describes the index, foreword, safety, and basic information.

01 SPECIFICATIONS

This section describes the specifications of the machine.

10 STRUCTURE AND FUNCTION

This section describes the structure and operation of each component with respect to each system. “STRUCTURE

AND FUNCTION” is helpful in not only understanding the structure of each component but performing

troubleshooting.

20 STANDARD VALUE TABLE

This section describes the standard values for new machine and failure criteria for testing and adjusting, and

troubleshooting. Use the standard values table to check the standard values for testing and adjusting, and judge

troubles in troubleshooting.

30 TESTING AND ADJUSTING

This section describes the measuring tools and measuring methods for testing and adjusting as well as the adjusting

method of each part. The standard values and repair limit for TESTING AND ADJUSTING are described

in “STANDARD VALUE TABLE”.

40 TROUBLESHOOTING

This section describes troubleshooting of failure part and its remedy method on the occurrence of the failure.

Descriptions of troubleshooting are sorted by failure mode.

50 DISASSEMBLY AND ASSEMBLY

This section describes the special tools, work procedures, and safety precautions necessary for removal, installation,

disassembly, and assembly of the components and parts. In addition, tightening torques, quantity, and

weight of the coating materials, lubricants, and coolant necessary to these works are shown.

60 MAINTENANCE STANDARD

This section describes the maintenance standard value of each component. The maintenance standard shows

the criteria and remedies for disassembly and assembly.

80 THE OTHER INFORMATION

This section describes the structure and function, testing and adjusting, and troubleshooting for all of the other

components or equipment which cannot be separately classified in the appendix.

90 Circuit diagrams

This section describes hydraulic circuit diagrams and electrical circuit diagrams.

IMAGES PREVIEW OF THE MANUAL: