$38

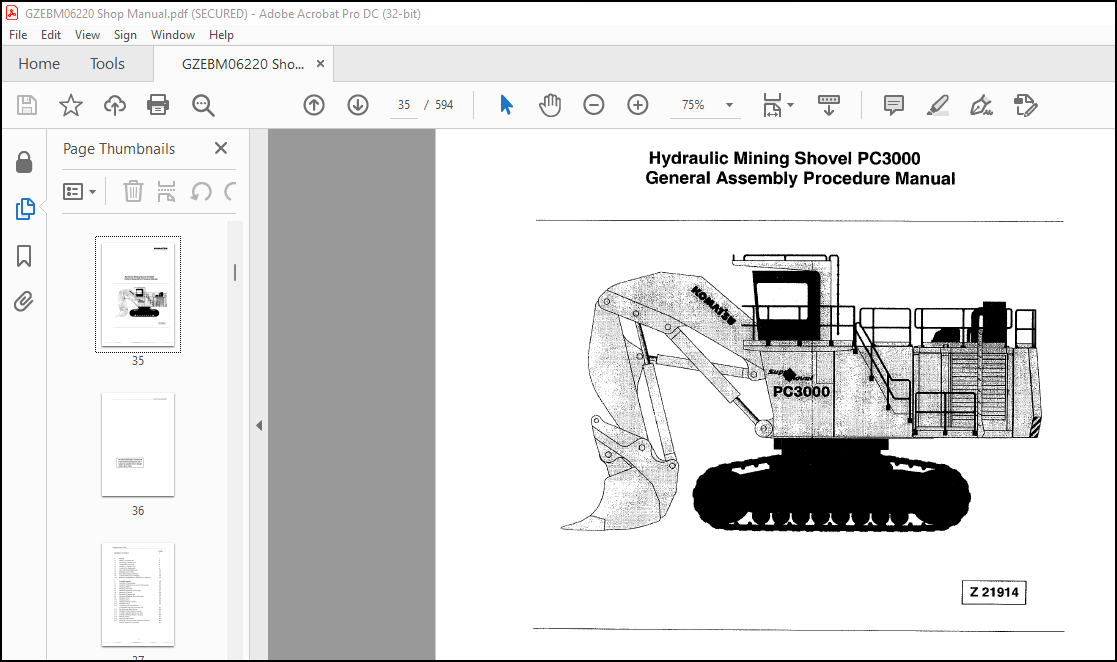

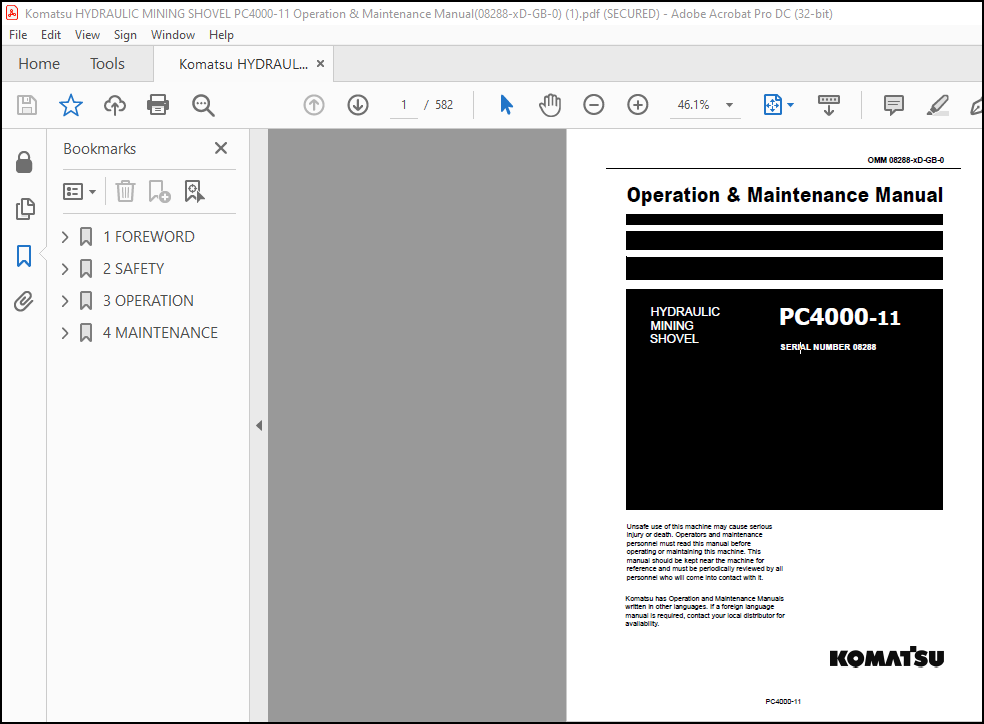

Komatsu HYDRAULIC MINING SHOVEL PC4000-11 Operation & Maintenance Manual(08288-xD-GB-0) – PDF

Komatsu HYDRAULIC MINING SHOVEL PC4000-11 Operation & Maintenance Manual(08288-xD-GB-0) – PDF DOWNLOAD

DESCRIPTION:

SERIAL NUMBER 08288

Komatsu HYDRAULIC MINING SHOVEL PC4000-11 Operation & Maintenance Manual(08288-xD-GB-0) – PDF DOWNLOAD

1.1BEFORE READING THIS MANUAL

This manual gives details of the operation and methods of inspection and maintenance for this machine that must be obeyed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of machines.

Read, understand and follow all precautions and warnings in this manual and on the machine before performing operation and maintenance. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that may involve a potential hazard when the machine is used. Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions. If you carry out any operation, inspection or maintenance under conditions that are not described in this manual, understand that it is your responsibility to take the necessary precautions to ensure safety. In no event should you or others engage in prohibited uses or actions described in this manual. Improper operation and maintenance of the machine can be hazardous and could result in serious injury or death.

If you sell the machine, be sure to give this manual to the new owner together with the machine.

This manual uses the international units (SI) for units of measurement. For reference, units that have been used in the past are given in ( ).

The explanations, values, and illustrations in this manual have been prepared based on the latest information available as of the date of publication. Continuing improvements in the design of this machine may lead to additional changes that are not reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information concerning your machine or with questions regarding information contained in this manual.

The numbers in circles in the illustrations correspond to the numbers in ( ) in the text. (For example:

Komatsu delivers machines that comply with all applicable regulations and standards of the country to which it has been shipped. If the machine has been purchased in another country, it may lack certain safety devices and specifications that are necessary for use in your country. If there is any question about whether your product complies with the applicable standards and regulations of your country, consult Komatsu or your Komatsu distributor before operating the machine.

Always keep the Operation and Maintenance Manual in the storage space provided inside the operator’s cabin (see Fig. 1-1) so that all relevant personnel can read it at any time. If this manual is lost or damaged, contact your distributor immediately to arrange for its replacement.

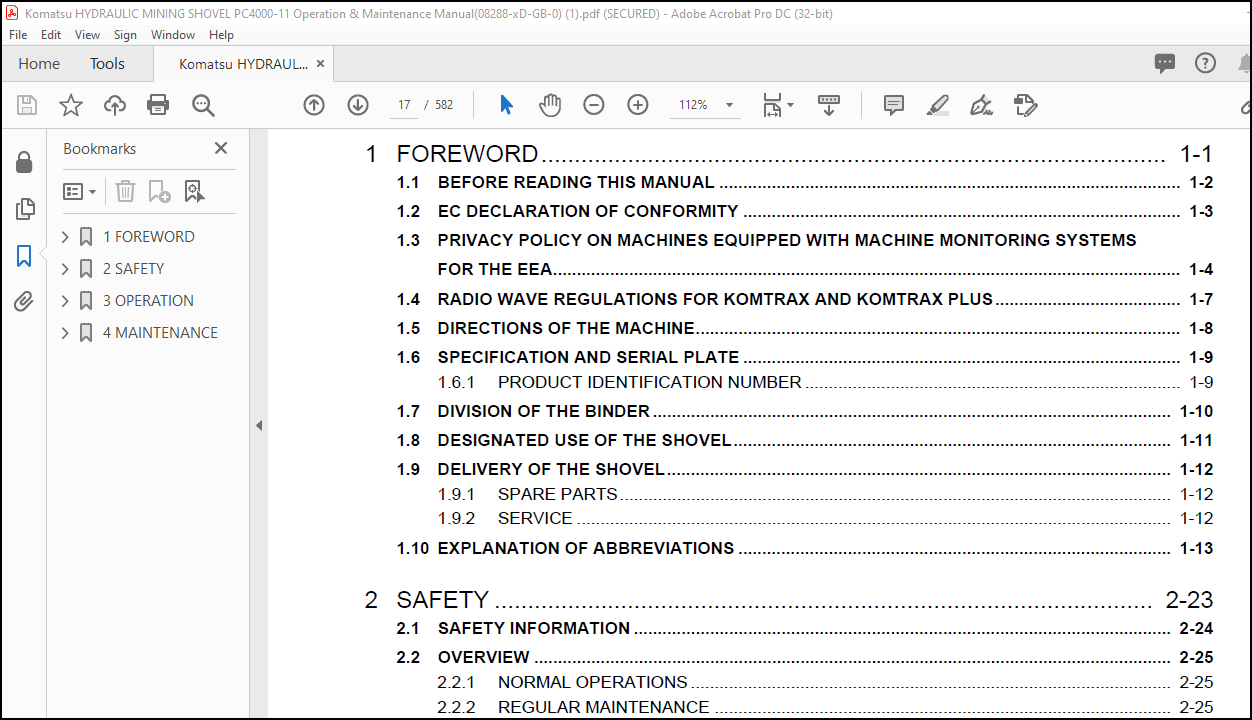

TABLE OF CONTENTS:

Komatsu HYDRAULIC MINING SHOVEL PC4000-11 Operation & Maintenance Manual(08288-xD-GB-0) – PDF DOWNLOAD

1 FOREWORD…………………………………………………………………………………. 1-1

1.1 BEFORE READING THIS MANUAL ……………………………………………………………………………………. 1-2

1.2 EC DECLARATION OF CONFORMITY ……………………………………………………………………………….. 1-3

1.3 PRIVACY POLICY ON MACHINES EQUIPPED WITH MACHINE MONITORING SYSTEMS

FOR THE EEA…………………………………………………………………………………………………………………… 1-4

1.4 RADIO WAVE REGULATIONS FOR KOMTRAX AND KOMTRAX PLUS………………………………… 1-7

1.5 DIRECTIONS OF THE MACHINE………………………………………………………………………………………… 1-8

1.6 SPECIFICATION AND SERIAL PLATE ……………………………………………………………………………….. 1-9

1.6.1 PRODUCT IDENTIFICATION NUMBER ……………………………………………………………………. 1-9

1.7 DIVISION OF THE BINDER ………………………………………………………………………………………………. 1-10

1.8 DESIGNATED USE OF THE SHOVEL……………………………………………………………………………….. 1-11

1.9 DELIVERY OF THE SHOVEL……………………………………………………………………………………………. 1-12

1.9.1 SPARE PARTS…………………………………………………………………………………………………….. 1-12

1.9.2 SERVICE …………………………………………………………………………………………………………….. 1-12

1.10 EXPLANATION OF ABBREVIATIONS ………………………………………………………………………………. 1-13

2 SAFETY ……………………………………………………………………………………… 2-23

2.1 SAFETY INFORMATION ………………………………………………………………………………………………….. 2-24

2.2 OVERVIEW …………………………………………………………………………………………………………………….. 2-25

2.2.1 NORMAL OPERATIONS ……………………………………………………………………………………….. 2-25

2.2.2 REGULAR MAINTENANCE …………………………………………………………………………………… 2-25

2.2.3 TROUBLESHOOTING, ADJUSTMENTS AND REPAIR …………………………………………….. 2-25

2.2.4 ADDITIONAL SAFETY PRECAUTIONS ………………………………………………………………….. 2-25

2.3 SOUND PRESSURE AND VIBRATION LEVELS IN THE OPERATOR’S CAB. ………………………. 2-26

2.3.1 SOUND ……………………………………………………………………………………………………………….. 2-26

2.3.2 VIBRATION………………………………………………………………………………………………………….. 2-26

2.4 GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR……………………. 2-27

2.4.1 UNDERSTANDING THE MACHINE………………………………………………………………………… 2-27

2.4.2 PRECAUTIONS BEFORE STARTING OPERATION ON THE EXCAVATOR ……………….. 2-27

2.4.3 PREPARATIONS FOR SAFE OPERATION……………………………………………………………… 2-27

2.4.4 FIRE PREVENTION ……………………………………………………………………………………………… 2-29

2.4.5 PRECAUTIONS WHEN GETTING ON OR OFF THE MACHINE ………………………………… 2-32

2.4.6 BURN PREVENTION ……………………………………………………………………………………………. 2-33

2.4.7 PRECAUTIONS WHEN CLEANING CAB GLASS …………………………………………………….. 2-34

2.4.8 PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES …………………………………… 2-34

2.4.9 PRECAUTIONS RELATED TO AIRBOURNE AND EJECTED DEBRIS……………………….. 2-35

2.4.10 ELECTROMAGNETIC COMPATIBILITY (EMC) ……………………………………………………….. 2-35

2.4.11 PRECAUTIONS AT JOBSITE ………………………………………………………………………………… 2-36

2.4.12 STARTING MOTOR ……………………………………………………………………………………………… 2-42

2.4.13 OPERATION………………………………………………………………………………………………………… 2-43

2.5 PRECAUTION FOR MAINTENANCE…………………………………………………………………………………. 2-49

2.5.1 GENERAL PRECAUTIONS……………………………………………………………………………………. 2-49

2.5.2 PRECAUTIONS FOR INSPECTION AND MAINTENANCE………………………………………… 2-57

2.5.3 PRECAUTIONS WITH HIGH PRESSURE FLUID……………………………………………………… 2-58

2.6 ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS ……. 2-63

2.6.1 INSPECTION OF THE HYDRAULIC SYSTEM …………………………………………………………. 2-63

2.6.2 TWO WORKERS ONLY WHEN THE MACHINE IS RUNNING DURING

ADJUSTMENTS……………………………………………………………………………………………………. 2-63

2.6.3 AREAS OF POTENTIAL DANGER AROUND THE EXCAVATOR……………………………….. 2-63

2.7 SPECIAL SAFETY EQUIPMENT……………………………………………………………………………………….. 2-64

2.7.1 FRONT GUARD PROTECTIVE STRUCTURE ’FOPS’ FOR OPERATOR’S CAB………….. 2-65

2.7.2 OBJECT HANDLING …………………………………………………………………………………………….. 2-65

2.7.3 LIGHTING ……………………………………………………………………………………………………………. 2-65

2.7.4 WARNING BEACON……………………………………………………………………………………………… 2-65

2.7.5 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD) ……….. 2-65

2.8 SAFETY WARNING SIGNS ………………………………………………………………………………………………. 3-73

2.8.1 LOCATION AND DESCRIPTION OF THE SIGNS …………………………………………………….. 3-74

3 OPERATION …………………………………………………………………………………. 3-1

3.1 FOREWORD……………………………………………………………………………………………………………………… 3-2

3.1.1 CONNECTION OF CUSTOMER ELECTRICAL INSTALLATIONS TO THE

EXCAVATOR …………………………………………………………………………………………………………. 3-2

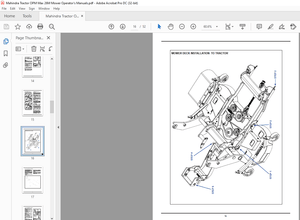

3.2 CONSTRUCTION OF THE SHOVEL ……………………………………………………………………………………. 3-3

3.2.1 OVERALL VIEW …………………………………………………………………………………………………….. 3-3

3.2.2 SUPERSTRUCTURE………………………………………………………………………………………………. 3-4

3.2.3 HYDRAULICALLY OPERATED ACCESS LADDER ………………………………………………….. 3-14

3.2.4 EMERGENCY ESCAPE LADDERS ………………………………………………………………………… 3-20

3.2.5 BOOM ACCESS LADDER AND WALKWAY…………………………………………………………….. 3-28

3.2.6 EMERGENCY ENGINE SHUTDOWN FROM GROUND MAN OR OPERATOR

WARNING SYSTEM ……………………………………………………………………………………………… 3-30

3.2.7 OPERATOR’S CAB WITH INTEGRATED FALLING OBJECT PROTECTIVE

STRUCTURE (FOPS)……………………………………………………………………………………………. 3-32

3.2.8 UNDERCARRIAGE……………………………………………………………………………………………….. 3-42

3.2.9 WORKING ATTACHMENT …………………………………………………………………………………….. 3-43

3.2.10 DIESEL ENGINE TYPE SDA 16V160E-2…………………………………………………………………. 3-45

3.2.11 ENGINE OIL MANAGEMENT SYSTEM …………………………………………………………………… 3-48

3.3 OPERATOR’S CAB – CONTROLS …………………………………………………………………………………….. 3-52

3.3.1 CONTROLS WITH BACKHOE ATTACHMENT…………………………………………………………. 3-52

3.3.2 SAFETY CIRCUIT FOR CONTROLS ………………………………………………………………………. 3-53

3.3.3 CONTROLS WITH BOTTOM DUMP BUCKET ATTACHMENT…………………………………… 3-56

3.3.4 SAFETY CIRCUIT FOR CONTROLS ………………………………………………………………………. 3-57

3.3.5 AUTOMATIC FLOAT POSITION FOR BOOM AND STICK ………………………………………… 3-59

3.3.6 OPERATOR’S CONSOLE ……………………………………………………………………………………… 3-61

3.3.7 INTERFACE PANEL FOR DIAGNOSTICS……………………………………………………………….. 3-67

3.3.8 CONTROL MODULE FOR AUXILIARY CAB HEATER………………………………………………. 3-69

3.4 VEHICLE HEALTH MONITORING SYSTEM KOMTRAX PLUS – HEALTH MONITOR ……………. 3-70

3.4.1 SEQUENCE OF DISPLAYS …………………………………………………………………………………… 3-71

3.4.2 OPENING SCREEN………………………………………………………………………………………………. 3-71

3.4.3 FUNCTION CHECKING SCREEN…………………………………………………………………………… 3-72

3.4.4 MAIN GAUGE SCREENS 1 TO 3……………………………………………………………………………. 3-73

3.4.5 ECO GUIDANCE ………………………………………………………………………………………………….. 3-77

3.4.6 MAINTENANCE ……………………………………………………………………………………………………. 3-81

3.4.7 MONITOR SETTING……………………………………………………………………………………………… 3-81

3.4.8 AUTOMATIC MESSAGES……………………………………………………………………………………… 3-85

3.5 CAMERA SYSTEMS – SPECIAL EQUIPMENT……………………………………………………………………. 3-88

3.5.1 CAMERA SYSTEM – TYPE 1 …………………………………………………………………………………. 3-88

3.5.2 CAMERA SYSTEM – TYPE 2 (KOMVISION) ……………………………………………………………. 3-95

3.6 OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING………………………………. 3-100

3.6.1 DIGITAL DISPLAY………………………………………………………………………………………………. 3-100

3.6.2 AUXILIARY HEATER FOR OPERATOR’S CAB ……………………………………………………… 3-105

3.7 MACHINERY HOUSE …………………………………………………………………………………………………….. 3-106

3.7.1 EMERGENCY ENGINE SHUTDOWN SWITCHES ………………………………………………….. 3-107

3.7.2 MAINTENANCE SAFETY SWITCH AND BATTERY MAIN SWITCHES……………………… 3-109

3.7.3 CENTRAL CONTROL AND FILTER PANEL…………………………………………………………… 3-111

3.8 ELECTRICAL EQUIPMENT IN CAB BASE ………………………………………………………………………. 3-112

3.8.1 STANDARD COMPONENTS IN CAB BASE…………………………………………………………… 3-113

3.8.2 COMPONENTS OF ELECTRICAL PREHEATING SYSTEM IN CAB BASE (WHEN

INSTALLED) ………………………………………………………………………………………………………. 3-117

3.9 CHECKS BEFORE STARTING THE ENGINE …………………………………………………………………… 3-124

3.9.1 OPERATOR’S SEAT ADJUSTMENT …………………………………………………………………….. 3-129

3.10 STARTING THE ENGINE ……………………………………………………………………………………………….. 3-130

3.10.1 STARTING PROCEDURE……………………………………………………………………………………. 3-133

3.10.2 ENGINE WARM-UP…………………………………………………………………………………………….. 3-143

3.10.3 HYDRAULIC OIL WARM-UP………………………………………………………………………………… 3-143

3.11 MOVING THE SHOVEL ………………………………………………………………………………………………….. 3-145

3.11.1 TRAVEL CONTROL WITH FOOT PEDALS ……………………………………………………………. 3-145

3.11.2 TRAVELING INSTRUCTIONS………………………………………………………………………………. 3-147

3.11.3 UNDERCARRIAGE TRACK SLIDERS…………………………………………………………………… 3-150

3.12 SLEWING AND BRAKING THE SUPERSTRUCTURE……………………………………………………….. 3-152

3.12.1 SLEWING THE SUPERSTRUCTURE……………………………………………………………………. 3-152

3.12.2 BRAKING THE SUPERSTRUCTURE ……………………………………………………………………. 3-153

3.12.3 SLEW PARKING BRAKE …………………………………………………………………………………….. 3-153

3.13 WORKING WITH THE ATTACHMENT……………………………………………………………………………… 3-155

3.13.1 COMBINED OPERATION CYCLES ………………………………………………………………………. 3-157

3.14 WORKING INSTRUCTIONS ……………………………………………………………………………………………. 3-159

3.14.1 STABILITY OF THE SHOVEL ………………………………………………………………………………. 3-159

3.14.2 FURTHER OPERATING PRACTICES …………………………………………………………………… 3-161

3.14.3 LOADING TRUCKS ……………………………………………………………………………………………. 3-165

3.15 PARKING THE SHOVEL ………………………………………………………………………………………………… 3-166

3.16 STOPPING THE ENGINE ……………………………………………………………………………………………….. 3-168

3.16.1 RELIEVE PRESSURE IN THE HYDRAULIC SYSTEM…………………………………………….. 3-171

3.17 OPERATION OF THE LUBRICATION SYSTEM………………………………………………………………… 3-172

3.17.1 CENTRAL LUBRICATION SYSTEM ”CLS”…………………………………………………………….. 3-172

3.17.2 SWING CIRCLE PINION LUBRICATION SYSTEM ”SLS” ………………………………………… 3-173

3.18 FIRE DETECTION AND SUPPRESSION SYSTEMS………………………………………………………….. 3-178

3.18.1 DISPLAY MODULE …………………………………………………………………………………………….. 3-183

3.18.2 INTERFACE CONTROL MODULE………………………………………………………………………… 3-185

3.18.3 EXTINGUISHING AGENT TANK ASSEMBLIES AND EXPELLANT GAS

CARTRIDGES ON MACHINERY HOUSE ROOF ……………………………………………………. 3-187

3.19 TRANSFER PUMP FOR HYDRAULIC OIL ……………………………………………………………………….. 3-188

3.19.1 OPERATING THE TRANSFER PUMP…………………………………………………………………… 3-189

3.19.2 FUNCTIONS OF THE TRANSFER PUMP ……………………………………………………………… 3-191

3.20 CENTRAL REFILLING SYSTEM ……………………………………………………………………………………… 3-194

3.20.1 SYSTEMS CONNECTED TO THE REFILLING SYSTEM…………………………………………. 3-195

3.20.2 OPERATING THE HYDRAULIC SERVICE ARM …………………………………………………….. 3-197

3.20.3 RECEIVER PANEL WITH MONITOR BOX …………………………………………………………….. 3-199

3.20.4 REFILLABLE GREASE CONTAINERS OF THE CENTRAL LUBRICATION SYSTEM

AND SWING CIRCLE PINION LUBRICATION SYSTEM………………………………………….. 3-203

3.21 WORK ON THE LOADER ATTACHMENT………………………………………………………………………… 3-206

3.22 TRANSPORTATION AND LIFTING OF THE SHOVEL……………………………………………………….. 3-207

3.22.1 DISASSEMBLING OF THE SHOVEL …………………………………………………………………….. 3-207

3.22.2 TRANSPORTATION AND LIFTING……………………………………………………………………….. 3-207

3.23 RETRIEVAL PROCEDURE……………………………………………………………………………………………… 3-208

3.24 SHOVEL STORAGE ………………………………………………………………………………………………………. 3-209

3.24.1 PREPARING FOR STORAGE………………………………………………………………………………. 3-209

3.24.2 ONE MONTH REPETITIVE SERVICE PERIOD………………………………………………………. 3-209

3.24.3 SIX MONTH REPETITIVE SERVICE PERIOD………………………………………………………… 3-209

3.24.4 PREPARING FOR OPERATION …………………………………………………………………………… 3-210

3.25 TROUBLE SHOOTING …………………………………………………………………………………………………… 3-211

3.25.1 ENGINE …………………………………………………………………………………………………………….. 3-211

3.25.2 HYDRAULIC SYSTEM…………………………………………………………………………………………. 3-212

3.25.3 FINAL DRIVES AND SWING MACHINERY ……………………………………………………………. 3-213

3.25.4 CRAWLER TRACKS……………………………………………………………………………………………. 3-213

4 MAINTENANCE …………………………………………………………………………….. 4-1

4.1 FOREWORD……………………………………………………………………………………………………………………… 4-2

4.1.1 DEFINITIONS ………………………………………………………………………………………………………… 4-2

4.1.2 GENERAL RECOMMENDATIONS……………………………………………………………………………. 4-2

4.2 SAFETY PRECAUTIONS FOR MAINTENANCE …………………………………………………………………… 4-3

4.3 FLUIDS AND LUBRICANTS……………………………………………………………………………………………….. 4-4

4.3.1 FLUIDS AND LUBRICANTS FOR MODERATE AND HOT CLIMATES………………………….. 4-4

4.3.2 LUBRICANTS FOR OPERATION IN COLD AND ARCTIC CLIMATE ……………………………. 4-6

4.4 FILLING CAPACITIES ……………………………………………………………………………………………………… 4-10

4.5 STANDARD TORQUE LIST………………………………………………………………………………………………. 4-11

4.5.1 TORQUE FOR FLANGE JOINTS ……………………………………………………………………………. 4-12

4.5.2 TORQUES FOR SPECIAL COMPONENTS……………………………………………………………… 4-13

4.6 LUBRICATION AND MAINTENANCE SCHEDULE ……………………………………………………………… 4-15

4.6.1 INITIAL SERVICING ……………………………………………………………………………………………… 4-15

4.6.2 SERVICING THE CRITICAL BOLT CONNECTIONS…………………………………………………. 4-16

4.6.3 PERIODIC SERVICING INTERVALS ………………………………………………………………………. 4-16

4.6.4 PERIODIC SERVICING SCHEDULE ………………………………………………………………………. 4-17

4.6.5 MAINTENANCE SCHEDULES OF FILTER ELEMENTS AND OTHER COMPONENTS

OF THE HYDRAULIC SYSTEM ……………………………………………………………………………… 4-23

4.7 SAFETY CRITICAL PARTS………………………………………………………………………………………………. 4-24

4.7.1 REPLACEMENT OF HYDRAULIC HOSE LINES AND FUEL HOSE LINES …………………. 4-24

4.7.2 INSPECTION OF HOSE LINES………………………………………………………………………………. 4-24

4.7.3 PERIODIC REPLACEMENT OF FURTHER SAFETY CRITICAL PARTS …………………….. 4-24

4.7.4 VENTING THE AIR FROM THE FUEL FILTERS ………………………………………………………. 4-27

4.8 INITIAL SERVICING ………………………………………………………………………………………………………… 4-28

4.8.1 INITIAL CHECKS FOR PROPER LUBRICATION……………………………………………………… 4-29

4.8.2 SWING CIRCLE – CHECK GREASE INJECTORS ……………………………………………………. 4-31

4.8.3 SWING CIRCLE TOOTHING LUBRICATION …………………………………………………………… 4-33

4.8.4 CAR BODY AND RACEWAY OF SLEW RING – CHECK GREASE INJECTORS ………….. 4-35

4.8.5 SWING CIRCLE – CHECK TORQUE OF BOLT CONNECTIONS………………………………… 4-37

4.8.6 RETIGHTENING PROCEDURE OF THE CRAWLER CARRIER MOUNTING BOLTS …… 4-39

4.9 EXTENDED SERVICE INTERVALS …………………………………………………………………………………… 4-45

4.9.1 FOR ENGINES EQUIPPED WITH ENGINE OIL MANAGEMENT SYSTEM …………………. 4-45

4.9.2 MAINTENANCE OF THE ENGINE………………………………………………………………………….. 4-49

4.10 ENGINE FUEL FILTER LOCATION …………………………………………………………………………………… 4-50

4.10.1 FUEL LINE CONNECTIONS ON THE ENGINE………………………………………………………… 4-51

4.11 WHEN NECESSARY ……………………………………………………………………………………………………….. 4-52

4.11.1 ENGINE AIR CLEANER SERVICE …………………………………………………………………………. 4-53

4.11.2 AUTOMATIC LUBRICATION SYSTEMS FILL GREASE BARRELS…………………………….. 4-57

4.11.3 TRACK ROLLERS – REPLACE FLOATING SEALS ………………………………………………….. 4-61

4.11.4 GUIDE WHEELS – REPLACE FLOATING SEALS…………………………………………………….. 4-61

4.12 EVERY 10 OPERATING HOURS OR DAILY ………………………………………………………………………. 4-62

4.12.1 WALK-AROUND INSPECTION ………………………………………………………………………………. 4-63

4.12.2 AIR CLEANER – CLEAN PRECLEANER …………………………………………………………………. 4-67

4.12.3 RADIATOR – CHECK COOLANT LEVEL …………………………………………………………………. 4-69

4.12.4 FUEL SYSTEM WATER SEPARATOR – DRAIN WATER…………………………………………… 4-71

4.12.5 BOOM – CHECK LADDER AND WALKWAY…………………………………………………………….. 4-73

4.12.6 ELECTRICAL EQUIPMENT – CHECK VISUALLY …………………………………………………….. 4-73

4.12.7 EMERGENCY ESCAPE ROUTE FROM OPERATOR’S CAB …………………………………….. 4-75

4.13 EVERY 50 OPERATING HOURS OR WEEKLY ………………………………………………………………….. 4-76

4.13.1 SWING GEARS AND MOTOR ADAPTER HOUSINGS – CHECK OIL LEVELS …………….. 4-77

4.13.2 FINAL DRIVE HOUSINGS – CHECK OIL LEVEL………………………………………………………. 4-83

4.13.3 PTO (PUMP DISTRIBUTOR GEAR) AND OIL RESERVOIR – CHECK OIL LEVEL ……….. 4-89

4.13.4 HYDRAULIC ACCESS LADDER – CHECK SAFETY SENSOR …………………………………… 4-91

4.13.5 HYDRAULIC OIL COOLERS – INSPECT AND CLEAN IF NECESSARY ……………………… 4-95

4.14 EVERY 250 OPERATING HOURS OR MONTHLY ………………………………………………………………. 4-96

4.14.1 AIR CONDITIONING …………………………………………………………………………………………….. 4-97

4.14.2 AIR CONDITIONING COMPRESSOR – CHECK DRIVE BELT TENSION…………………….. 4-97

4.14.3 AIR CONDITIONING FOR OPERATOR’S CAB – CHECK REFRIGERANT LEVEL ……… 4-101

4.14.4 UNDERCARRIAGE PIN CONNECTIONS – LUBRICATE………………………………………….. 4-103

4.14.5 SIGNAL HORN COMPRESSOR – LUBRICATE………………………………………………………. 4-103

4.14.6 HYDRAULIC OIL COOLER FAN BEARING HOUSINGS – CHECK FOR LEAKAGE…….. 4-103

4.14.7 RADIATOR FAN BEARING HOUSING – CHECK FOR LEAKAGE …………………………….. 4-103

4.14.8 AUTOMATIC LUBRICATION SYSTEMS – CLEAN BREATHER FILTER ……………………. 4-105

4.14.9 CABIN AIR FILTERS – INSPECT ………………………………………………………………………….. 4-107

4.14.10 WINDSHIELD WASHER SYSTEM – CHECK FLUID LEVEL……………………………………… 4-109

4.14.11 CABIN HEATER FILTER – INSPECT …………………………………………………………………….. 4-111

4.15 EVERY 500 OPERATING HOURS OR MONTHLY …………………………………………………………….. 4-112

4.15.1 BATTERIES – CHECK FLUID LEVEL…………………………………………………………………….. 4-113

4.15.2 PTO (PUMP DISTRIBUTOR GEAR) MAIN PUMP DRIVE SHAFT HOUSINGS

– CHECK OIL LEVEL …………………………………………………………………………………………… 4-115

4.15.3 FUEL TANK – DRAIN CONDENSATION………………………………………………………………… 4-117

4.15.4 CRAWLER TRACK – INSPECTION……………………………………………………………………….. 4-119

4.15.5 GROUND CABLES OF ENGINE, PRELUBRICATION PUMP AND ALTERNATOR

– CHECK FOR CORRECT CONNECTION……………………………………………………………… 4-125

4.15.6 GROUND CABLE OF OPERATOR’S CAB – CHECK FOR CORRECT CONNECTION … 4-127

4.15.7 EMERGENCY OPERATION OF THE HYDRAULIC ACCESS LADDER

– TEST FUNCTIONALITY …………………………………………………………………………………….. 4-131

4.15.8 EMERGENCY ESCAPE LADDERS ………………………………………………………………………. 4-133

4.15.9 CYLINDER ROD PROTECTION (IF EQUIPPED), CHANGE SLIDING BLOCKS…………. 4-135

4.16 EVERY 1000 OPERATING HOURS OR EVERY 6 MONTHS ………………………………………………. 4-136

4.16.1 CRITICAL BOLT CONNECTIONS…………………………………………………………………………. 4-137

4.16.2 HYDRAULIC SYSTEM – FILTER SERVICE ……………………………………………………………. 4-143

4.16.3 PTO (PUMP DISTRIBUTOR GEAR), SWING GEARS AND TRAVEL GEARS

– OIL SAMPLE ANALYSIS ……………………………………………………………………………………. 4-157

4.16.4 SIGNAL HORN COMPRESSOR – CLEAN AND LUBRICATE …………………………………… 4-159

4.16.5 HYDRAULIC TRACK TENSIONING SYSTEM – CHECK ACCUMULATORS ………………. 4-161

4.16.6 HYDRAULIC OIL COOLER – INSPECT AND LUBRICATE DOOR HINGES ……………….. 4-163

4.16.7 MACHINERY HOUSE DOORS – INSPECT AND LUBRICATE DOOR HINGES ………….. 4-165

4.16.8 ALL OTHER HINGES AND AREAS TO LUBRICATE ………………………………………………. 4-167

4.16.9 EMERGENCY ENGINE SHUTDOWN SWITCHES – TEST FUNCTIONALITY …………….. 4-169

4.16.10 ENGINE SHUTDOWN PULL CHAINS – TEST FUNCTIONALITY………………………………. 4-171

4.16.11 ELECTRICAL EQUIPMENT – MAINTENANCE ……………………………………………………….. 4-173

4.16.12 CABIN AIR FILTER – REPLACE PRIMARY FILTER ………………………………………………… 4-175

4.17 EVERY 2000 OPERATING HOURS OR YEARLY ……………………………………………………………… 4-176

4.17.1 HYDRAULIC SYSTEM – CHANGE OIL, REPLACE SUCTION STRAINERS AND

PULSATION DAMPER ………………………………………………………………………………………… 4-177

4.17.2 FILLING THE HYDRAULIC SYSTEM…………………………………………………………………….. 4-187

4.17.3 BLEEDING THE HYDRAULIC SYSTEM ………………………………………………………………… 4-189

4.17.4 GEAR PUMP FOR PTO GEAR LUBRICATION ………………………………………………………. 4-191

4.17.5 EMERGENCY ESCAPE LADDERS – INSPECTION ………………………………………………… 4-193

4.17.6 PREVENTATIVE MAINTENANCE (PM) CLINIC – PERFORM TEST………………………….. 4-195

4.17.7 HYDRAULIC HOSES – CHECK CONDITION………………………………………………………….. 4-197

4.17.8 EMERGENCY ESCAPE ROUTE FROM OPERATOR’S CAB …………………………………… 4-199

4.18 EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR ………………………… 4-200

4.18.1 SWING GEARS AND MOTOR ADAPTER HOUSING – CHANGE OIL ……………………….. 4-201

4.18.2 PTO (PUMP DISTRIBUTOR GEAR) – CHANGE OIL ……………………………………………….. 4-221

4.18.3 CRITICAL BOLT CONNECTIONS – CHECK TORQUE LOAD…………………………………… 4-223

4.18.4 CABIN HEATER FILTER – REPLACE FILTER ELEMENT………………………………………… 4-257

4.18.5 OIL SEPARATOR ELEMENT – REPLACE (IF SO EQUIPPED)…………………………………. 4-259

4.18.6 CHECKING THE STEEL STRUCTURES ……………………………………………………………….. 4-261

4.19 EVERY 6000 OPERATING HOURS OR AT LEAST ONCE A YEAR ……………………………………. 4-262

4.19.1 AUTOMATIC LUBRICATION SYSTEMS – REPLACE GREASE FILTERS………………….. 4-263

4.20 FIRE PREVENTION ……………………………………………………………………………………………………….. 4-264

4.20.1 PRECAUTIONS ………………………………………………………………………………………………….. 4-265

4.21 WELD REPAIRS ……………………………………………………………………………………………………………. 4-266

4.21.1 GENERAL PROTECTIVE MEASURES………………………………………………………………….. 4-267

4.21.2 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE

UNDERCARRIAGE……………………………………………………………………………………………… 4-269

4.21.3 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE

LOADER ATTACHMENT……………………………………………………………………………………… 4-271

4.21.4 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE

SUPERSTRUCTURE ………………………………………………………………………………………….. 4-273

4.21.5 AFTER FINISHING THE WELD REPAIRS ON THE SUPERSTRUCTURE…………………. 4-274

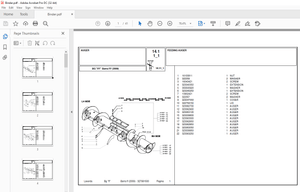

IMAGES PREVIEW OF THE MANUAL: