$24

Komatsu Hydraulic Mining Shovel PC4000 Field Assembly Instruction Manual – PDF DOWNLOAD

Komatsu Hydraulic Mining Shovel PC4000 Field Assembly Instruction Manual – PDF DOWNLOAD

FILE DETAILS:

Komatsu Hydraulic Mining Shovel PC4000 Field Assembly Instruction Manual – PDF DOWNLOAD

Language : English

Pages : 94

Downloadable : Yes

File Type : PDF

Size: 2.68 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu Hydraulic Mining Shovel PC4000 Field Assembly Instruction Manual – PDF DOWNLOAD

- The Komatsu PC4000 hydraulic mining shovel is a large and powerful machine designed for use in heavy mining operations. The Field Assembly Instruction Manual provides detailed instructions for the assembly of this mining shovel. The manual is intended to be used by experienced technicians and mechanics who have the necessary knowledge and skills to perform the procedures described in the manual.

- The manual covers various topics such as safety information, assembly procedures, and adjustments that need to be made during the assembly process. It provides step-by-step instructions for each procedure, along with diagrams and illustrations to help technicians understand the procedures. The manual also includes a list of recommended tools and spare parts that are needed for the assembly process.

- It is important to follow the instructions and procedures outlined in the manual to ensure the safe and proper assembly of the mining shovel. The manual provides information on how to properly install and adjust the various systems and components of the machine, such as the engine, hydraulic system, electrical system, and undercarriage components. By following the procedures in the manual, technicians can ensure that the machine is assembled correctly and will operate safely and efficiently once it is in use.

- In summary, the Komatsu PC4000 Field Assembly Instruction Manual provides valuable information for the assembly of this hydraulic mining shovel. The manual is essential for experienced technicians who are responsible for assembling the machine. By following the procedures in the manual, technicians can ensure that the mining shovel is assembled correctly and will operate safely and efficiently once it is in use.

TABLE OF CONTENTS:

Komatsu Hydraulic Mining Shovel PC4000 Field Assembly Instruction Manual – PDF DOWNLOAD

MAIN MENU……………………………………………………………………………………………….. 0

COVER…………………………………………………………………………………………………… 1

GENERAL CONTENT………………………………………………………………………………………….. 3

1. Overviews…………………………………………………………………………………………….. 5

1.1 Overview Superstructure (Z22586)……………………………………………………………………. 5

1.2 Overview Engine House (Z21446)……………………………………………………………………… 7

2. General………………………………………………………………………………………………. 9

2.1 Delivery of the Excavator………………………………………………………………………….. 9

2.2 Assembling of the Excavator………………………………………………………………………… 9

2.3 Transportation and Lifting………………………………………………………………………….11

2.4 Manpower / Assembly Time……………………………………………………………………………13

2.5 Assembly Site Requirements………………………………………………………………………….15

2.6 Space and Placing Requirements………………………………………………………………………19

2.7 Preparation for Assembly……………………………………………………………………………19

2.8 Basic Measurements (Z23038)…………………………………………………………………………21

2.9 Transport Dimensions and Weights (as example)…………………………………………………………21

3. Assembly Sequence………………………………………………………………………………………23

3.1. Assembly of Undercarriage (Z21859)………………………………………………………………….23

3.1.1. Mounting of travel gear breather filters (Z21860)……………………………………………….25

3.1.2 Track tensioning system (Z23037)……………………………………………………………….27

3.2. Assembly of Superstructure onto the Undercarriage (Z23863)…………………………………………….29

3.3 Assembly of engine house (Z21863)……………………………………………………………………31

3.4 Mounting of Boom (Z21864)…………………………………………………………………………..33

3.5. Mounting of Hydraulic Oil Tank (Z23039)……………………………………………………………..35

3.6. Mounting of Hydraulic Oil Cooler (Z21866)……………………………………………………………37

3.7. Mounting of Fuel Tank (Z21867)……………………………………………………………………..39

3.8 Mounting of hydraulic access ladder (Z21871)………………………………………………………….41

3.9. Mounting of Cab Base (Z21868)………………………………………………………………………43

3.10 Mounting of Counterweight (Z21869)………………………………………………………………….45

3.11 Mounting of Handrails, Steps and Gratings (Z23033)……………………………………………………47

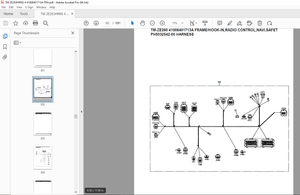

3.12 Mounting of Cable transfer to the Operators Cab (Z22937)………………………………………………49

3.13 Mounting of Cab with Support Frame (Z22938; Z22939)…………………………………………………..53

3.13.1 Mounting of the Cab air cleaner (Cab support to Cab) (Z22940)…………………………………….55

3.14 Mounting of Bucket Cylinders (Z21873)……………………………………………………………….57

3.15 Mounting of Stick (Bullclam bucket) (Z21874)…………………………………………………………59

3.15.1 Mounting of Stick (Backhoe attachment) (Z23034)…………………………………………………61

3.16 Filling up hydraulic oil tank (Z21585)………………………………………………………………63

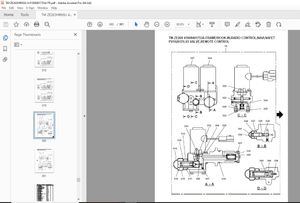

3.17 Bleed air from all hydraulic pumps and check the Oil Level in all four Main Pump Housings (Z21693; Z22513)….65

3.18 Filling up fuel tank………………………………………………………………………………67

3.19 Pre-checks for initial Start-up…………………………………………………………………….69

3.20 Mounting of stick cylinders to the stick (Z21875)…………………………………………………….73

3.21 Assembly of Bullclam Bucket to the Stick (Z21876)…………………………………………………….75

3.22 Mounting of the Pin Seals (Z22042)………………………………………………………………….79

3.22.1 Mounting of the Pin Seals (Backhoe) (Z23035)……………………………………………………81

3.23 Connection of the cable harnesses to the terminal rails in the switch box “X2” (Z21879)…………………..83

3.24 Putting the Central Lubrication System into operation (Z21880)…………………………………………87

3.25 Metric standard thread…………………………………………………………………………….89