$34

Komatsu HYDRAULIC MINING SHOVEL PC5500E-6 Assembly and Transport Manual(AM15028E up) – PDF DOWNLOAD

Komatsu HYDRAULIC MINING SHOVEL PC5500E-6 Assembly and Transport Manual(AM15028E up) – PDF DOWNLOAD

DESCRIPTION:

SERIAL NUMBER 15028 and up

Komatsu HYDRAULIC MINING SHOVEL PC5500E-6 Assembly and Transport Manual(AM15028E up) – PDF DOWNLOAD

SAFETY INFORMATION

To enable you to use this machine safely, and to prevent injury to operators, service personnel or bystanders, the

precautions and warnings included in this manual and the safety signs attached to the machine must always be

followed.

The safety information in this manual does not replace any safety rules or laws in your area.

To identify important safety messages in the manual and on the machine labels, the following signal words are

used.

The “Safety Alert Symbol” identifies important safety messages on machines, in manuals, and elsewhere. When

you see this symbol, be alert to the risk of personal injury or death. Follow the instructions in the safety message.

GENERAL

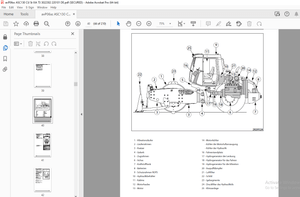

3.1.1 DELIVERY OF THE EXCAVATOR

The excavator is delivered disassembled into its main components. For the correct dimensions and weights, refer

to the packing list of your machine.

To assemble the excavator, follow the instructions in this manual.

TABLE OF CONTENTS:

Komatsu HYDRAULIC MINING SHOVEL PC5500E-6 Assembly and Transport Manual(AM15028E up) – PDF DOWNLOAD

2 SAFETY…………………………………………………………………………………………… 9

2.1 SAFETY INFORMATION…………………………………………………………………………… 10

2.2 OVERVIEW……………………………………………………………………………………. 11

2.2.1 NORMAL OPERATIONS………………………………………………………………………. 11

2.2.2 REGULAR MAINTENANCE…………………………………………………………………….. 11

2.2.3 TROUBLESHOOTING, ADJUSTMENTS AND REPAIR…………………………………………………… 11

2.2.4 ADDITIONAL SAFETY PRECAUTIONS FOR ASSEMBLING, DISASSEMBLING AND TRANSPORTATION OF THE EXCAVATOR…. 11

2.3 SOUND PRESSURE LEVEL IN THE OPERATOR’S CAB……………………………………………………… 12

2.4 GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR…………………………………………. 13

2.4.1 UNDERSTANDING THE MACHINE……………………………………………………………….. 13

2.4.2 PRECAUTIONS BEFORE STARTING OPERATION ON THE EXCAVATOR……………………………………… 13

2.4.3 PREPARATIONS FOR SAFE OPERATION………………………………………………………….. 13

2.4.4 FIRE PREVENTION………………………………………………………………………… 15

2.4.5 PRECAUTIONS WHEN GETTING ON OR OFF THE MACHINE…………………………………………….. 17

2.4.6 BURN PREVENTION………………………………………………………………………… 19

2.4.7 PRECAUTIONS WHEN CLEANING CAB GLASS………………………………………………………. 19

2.4.8 PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES………………………………………………. 20

2.4.9 ELECTROMAGNETIC COMPATIBILITY (EMC)………………………………………………………. 21

2.4.10 PRECAUTIONS AT JOBSITE…………………………………………………………………. 22

2.4.11 STARTING ENGINE……………………………………………………………………….. 27

2.4.12 OPERATION…………………………………………………………………………….. 28

2.5 PRECAUTION FOR MAINTENANCE……………………………………………………………………. 34

2.5.1 GENERAL PRECAUTIONS…………………………………………………………………….. 34

2.5.2 PRECAUTIONS FOR INSPECTION AND MAINTENANCE………………………………………………… 42

2.5.3 PRECAUTIONS WITH HIGH PRESSURE FLUID……………………………………………………… 43

2.6 ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS…………………………………. 47

2.6.1 INSPECTION OF THE HYDRAULIC SYSTEM……………………………………………………….. 47

2.6.2 TWO WORKERS ONLY WHEN THE MACHINE IS RUNNING DURING ADJUSTMENTS……………………………… 47

2.6.3 AREAS OF POTENTIAL DANGER AROUND THE EXCAVATOR…………………………………………….. 47

2.7 SPECIAL SAFETY EQUIPMENT……………………………………………………………………… 48

2.7.1 FRONT GUARD PROTECTIVE STRUCTUR ’FOPS’ FOR OPERATOR’S CAB…………………………………… 49

2.7.2 OBJECT HANDLING………………………………………………………………………… 49

2.7.3 LIGHTING………………………………………………………………………………. 49

2.7.4 WARNING BEACON…………………………………………………………………………. 49

2.7.5 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD)………………………………… 49

2.8 ADDITIONAL SAFETY PRECAUTIONS…………………………………………………………………. 57

2.8.1 WHEN ASSEMBLING THE EXCAVATOR……………………………………………………………. 57

2.8.2 WHEN DISASSEMBLING THE EXCAVATOR…………………………………………………………. 57

2.8.3 WHEN TRANSPORTING THE DISASSEMBLED EXCAVATOR………………………………………………. 58

3 GENERAL………………………………………………………………………………………….. 59

3.1 GENERAL…………………………………………………………………………………….. 60

3.1.1 DELIVERY OF THE EXCAVATOR……………………………………………………………….. 60

3.1.2 ASSEMBLING THE EXCAVATOR………………………………………………………………… 60

3.1.3 LIFTING AND TRANSPORTATION………………………………………………………………. 60

3.1.4 ELECTRICAL ENERGY………………………………………………………………………. 61

3.1.5 ELECTROMAGNETIC COMPATIBILITY (EMC)………………………………………………………. 61

3.1.6 MONITORING SYSTEMS OF THE MACHINE………………………………………………………… 61

3.2 ASSEMBLY SITE REQUIREMENTS……………………………………………………………………. 62

3.2.1 CONFIGURATION OF COMPONENTS ON ERECTION SITE (EXAMPLE)……………………………………… 62

3.2.2 REQUIRED CRANES………………………………………………………………………… 63

3.2.3 MANPOWER / ASSEMBLY TIME………………………………………………………………… 63

3.2.4 TOOLS AND EQUIPMENT FOR ASSEMBLY…………………………………………………………. 64

3.2.5 STANDARD APPLICATION TORQUE CHART………………………………………………………… 67

3.2.6 PREPARATIONS FOR ASSEMBLY……………………………………………………………….. 70

3.3 LIFTING OF THE MAIN COMPONENTS………………………………………………………………… 72

3.3.1 SAFETY PRECAUTIONS FOR LIFTING OF COMPONENTS………………………………………………. 73

3.3.2 LIFTING ATTACHMENT POINTS AND WEIGHTS…………………………………………………….. 73

3.3.3 CRAWLER SIDE FRAME WITHOUT TRACKS………………………………………………………… 73

3.3.4 CARBODY……………………………………………………………………………….. 75

3.3.5 SUPERSTRUCTURE PLATFORM…………………………………………………………………. 77

3.3.6 MACHINERY HOUSE………………………………………………………………………… 79

3.3.7 FACE SHOVEL BOOM……………………………………………………………………….. 81

3.3.8 BACKHOE BOOM…………………………………………………………………………… 83

3.3.9 COUNTERWEIGHT LIFTING FOR HORIZONTAL TRANSPORT…………………………………………….. 85

3.3.10 COUNTERWEIGHT ERECTING FOR VERTICAL TRANSPORT…………………………………………….. 87

3.3.11 COUNTERWEIGHT LIFTING FOR VERTICAL TRANSPORT……………………………………………… 89

3.3.12 HIGH VOLTAGE SWITCH CABINET…………………………………………………………….. 91

3.3.13 CAB BASE……………………………………………………………………………… 93

3.3.14 FACE SHOVEL STICK……………………………………………………………………… 95

3.3.15 BACKHOE STICK…………………………………………………………………………. 97

3.3.16 FACE SHOVEL BACK WALL………………………………………………………………….. 99

3.3.17 FACE SHOVEL CLAM SHELL………………………………………………………………….101

3.3.18 BACKHOE BUCKET…………………………………………………………………………103

3.3.19 BASIC MEASUREMENTS……………………………………………………………………..104

3.4 GENERAL INSTALLATION PROCEDURES FOR HYDRAULIC HOSE LINES………………………………………….105

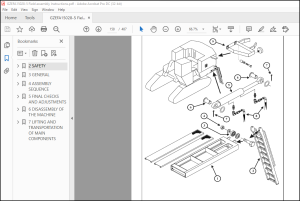

4 ASSEMBLY SEQUENCE………………………………………………………………………………….107

4.1 ASSEMBLY SEQUENCE OF FACE SHOVEL MACHINES……………………………………………………….108

4.1.1 ASSEMBLY SEQUENCE UNDER CONSIDERATION OF THE MACHINE’S STABILITY……………………………..109

4.1.2 STABILITY IN RELATION TO ASSEMBLY STAGE……………………………………………………110

4.2 ASSEMBLY SEQUENCE OF BACKHOE MACHINES…………………………………………………………..114

4.2.1 ASSEMBLY SEQUENCE UNDER CONSIDERATION OF THE MACHINE’S STABILITY……………………………..115

4.3 ASSEMBLY OF UNDERCARRIAGE……………………………………………………………………..116

4.3.1 ASSEMBLY OF TRACKS………………………………………………………………………117

4.3.2 ATTACH CARBODY TO SIDE FRAME……………………………………………………………..118

4.3.3 DETERMINING THE TIGHTENING TORQUE…………………………………………………………125

4.3.4 SPECIAL HYDRAULIC TORQUE WRENCH…………………………………………………………..129

4.3.5 ATTACHING THE FINAL DRIVES……………………………………………………………….130

4.3.6 MOUNTING OF TRAVEL GEARS WITH PROTECTION KIT……………………………………………….134

4.3.7 CLOSING THE TRACKS………………………………………………………………………136

4.3.8 CONNECT HYDRAULIC LINES TO THE TRAVEL MOTORS……………………………………………….137

4.3.9 HYDRAULIC TRACK TENSIONING SYSTEM…………………………………………………………142

4.3.10 MOUNTING OF THE CABLE DRUM………………………………………………………………145

4.4 MOUNTING SUPERSTRUCTURE PLATFORM ONTO UNDERCARRIAGE………………………………………………146

4.4.1 INSTALLATION OF SLEW ANGLE WARNING SYSTEM………………………………………………….152

4.5 MOUNTING MACHINERY HOUSE ONTO THE SUPERSTRUCTURE PLATFORM…………………………………………156

4.6 MOUNTING OF HYDRAULIC ACCESS LADDER…………………………………………………………….158

4.6.1 CONNECTING THE EMERGENCY ACTUATION CHAINS………………………………………………….160

4.7 PRE-ASSEMBLY OF FACE SHOVEL BOOM……………………………………………………………….162

4.7.1 GENERAL INSTALLATION INSTRUCTIONS FOR ATTACHMENT PINS……………………………………….164

4.7.2 ATTACH BOOM CYLINDERS AND STICK CYLINDERS TO THE BOOM……………………………………….166

4.7.3 ATTACH BOOM TO SUPERSTRUCTRE A-FRAME………………………………………………………170

4.7.4 CLAMP RAILS FOR HYDRAULIC HOSE LINES FROM SUPERSTRUCTURE TO BOOM……………………………..173

4.8 PRE-ASSEMBLY OF BACKHOE BOOM…………………………………………………………………..174

4.8.1 ATTACH BOOM CYLINDERS AND STICK CYLINDERS TO THE BOOM……………………………………….176

4.8.2 ATTACH BOOM TO SUPERSTRUCTRE A-FRAME………………………………………………………180

4.9 MOUNTING OF COUNTERWEIGHT……………………………………………………………………..182

4.10 ATTACHING THE HIGH VOLTAGE SWITCH CABINET………………………………………………………184

4.10.1 MECHANICAL INSTALLATION…………………………………………………………………185

4.10.2 ESTABLISHING OF HIGH VOLTAGE CABLE CONNECTIONS…………………………………………….187

4.11 ATTACHING THE CAB BASE……………………………………………………………………….190

4.11.1 MECHANICAL INSTALLATION…………………………………………………………………191

4.11.2 MAKING ELECTRICAL CABLE CONNECTIONS………………………………………………………193

4.11.3 CONNECT THE FIRE SUPPRESSION SYSTEM PIPING BETWEEN HIGH VOLTAGE CABINET AND CAB BASE…………..195

4.11.4 CABLE CONNECTOR PLATE ON CAB BASE ROOF FOR MACHINES WITH VHMS ONLY…………………………..197

4.12 ATTACHING THE CAB WITH SUPPORT FRAME TO THE CAB BASE…………………………………………….198

4.12.1 CABLE CONNECTIONS CAB TO CAB BASE FOR ECS MACHINES ONLY…………………………………….200

4.13 CONNECTING HIGH PRESSURE HOSES FROM MAIN PUMPS TO CHECK VALVES……………………………………202

4.14 ATTACHING INTERMEDIATE PIPE TO THE SUCTION OIL RESERVOIR…………………………………………204

4.15 ATTACHING THE HYDRAULIC OIL RESERVOIR………………………………………………………….206

4.16 ATTACHING THE HYDRAULIC OIL COOLER…………………………………………………………….208

4.16.1 CONNECTING THE HYDRAULIC HOSE LINES OF RETURN OIL CIRCUIT…………………………………..210

4.16.2 CONNECTING THE HOSE LINES OF GEAR OIL COOLING CIRCUITS……………………………………..212

4.16.3 CONNECTING THE HOSE LINES OF THE COOLER FAN MOTORS…………………………………………215

4.16.4 CONNECTING THE BACK PRESSURE HOSES OF SWING MOTORS…………………………………………216

4.16.5 CONNECTING THE HOSE LINES OF THE TRANSFER PUMP…………………………………………….218

4.17 CONNECTING HYDRAULIC LINES TO THE ROTARY JOINT………………………………………………….220

4.17.1 CONNECTING THE LEAKAGE OIL LINE, RETURN OIL LINE AND CONTROL OIL LINE TO THE ROTARY JOINT………222

4.18 ATTACHING THE HANDRAILS, CATWALKS AND STEPS…………………………………………………….224

4.19 ATTACHING THE CENTRAL LUBRICATION UNIT…………………………………………………………226

4.19.1 CONNECTING THE HYDRAULIC LINES AND GREASE LINES……………………………………………228

4.19.2 CONNECTING GREASE LINES OF THE SWING CIRCLE PINION LUBRICATION SYSTEM………………………..232

4.19.3 CONNECTING GREASE LINES OF THE CENTRAL LUBRICATION SYSTEM…………………………………..234

4.20 CENTRAL REFILLING SYSTEM……………………………………………………………………..236

4.20.1 CONNECTING THE REFILLING LINES…………………………………………………………..237

4.21 ATTACHING THE SERVICE CRANE (IF SO EQUIPPED)……………………………………………………238

4.22 PRE-CHECKS PRIOR TO INITIAL START UP…………………………………………………………..240

4.23 HIGH VOLTAGE INTERLOCK SYSTEM…………………………………………………………………242

4.23.1 APPLYING HIGH VOLTAGE CURRENT TO THE MACHINE………………………………………………243

4.24 CHECKING DIRECTION OF MOTOR ROTATION…………………………………………………………..246

4.25 CHECK AND ADJUST ALIGNMENT OF MAIN MOTORS………………………………………………………248

4.25.1 ALIGNMENT TOLERANCES……………………………………………………………………255

4.25.2 SHIM SETS……………………………………………………………………………..255

4.25.3 RECOMMENDED TOOLS FOR MOTOR ALIGNMENT…………………………………………………….257

4.26 FILLING AND BLEEDING THE HYDRAULIC SYSTEM………………………………………………………258

4.26.1 FILLING THE HYDRAULIC SYSTEM…………………………………………………………….259

4.26.2 BLEEDING THE HYDRAULIC SYSTEM……………………………………………………………260

4.27 BLEEDING GEAR PUMPS FOR PTO GEAR LUBRICATION……………………………………………………264

4.28 ASSEMBLY FACE SHOVEL ATTACHMENT……………………………………………………………….266

4.28.1 ATTACHING THE BUCKET CYLINDERS TO THE BOOM………………………………………………..267

4.28.2 ATTACHING THE STICK TO THE BOOM………………………………………………………….269

4.28.3 CONNECTING HOSE LINES FROM DISTRIBUTOR MANIFOLD TO BOOM…………………………………….270

4.28.4 CONNECTING HOSE LINES FROM BOOM TO BOOM CYLINDERS………………………………………….270

4.28.5 CONNECTING HOSE LINES FROM BOOM TO STICK CYLINDERS…………………………………………273

4.28.6 CONNECTING HOSE LINES FROM STICK TO BUCKET CYLINDERS……………………………………….275

4.28.7 CONNECTING STICK CYLINDERS TO THE STICK…………………………………………………..276

4.29 BLEEDING HYDRAULIC CIRCUITS…………………………………………………………………..278

4.29.1 BLEEDING THE SWING PARKING BRAKE CIRCUIT………………………………………………….279

4.29.2 BLEEDING THE TRAVEL PARKING BRAKE CIRCUIT…………………………………………………279

4.29.3 BLEEDING THE HYDRAULIC TRACK TENSIONING CIRCUIT……………………………………………281

4.29.4 BLEEDING HYDRAULIC CIRCUIT OF ACCESS LADDER……………………………………………….282

4.29.5 BLEEDING HYDRAULIC CIRCUIT OF ATTACHMENT CYLINDERS…………………………………………282

4.29.6 BLEEDING HYDRAULIC CIRCUIT OF SWING MOTORS………………………………………………..283

4.30 ATTACHING FACE SHOVEL TO THE STICK…………………………………………………………….284

4.30.1 ATTACHING BUCKET BACK WALL TO THE STICK…………………………………………………..285

4.30.2 CONNECTING HOSE LINES FROM STICK TO BUCKET CLAM CYLINDERS…………………………………..287

4.30.3 ATTACHING THE CLAM SHELL TO BUCKET BACK WALL………………………………………………289

4.30.4 CONNECTING GREASE LINES OF THE FACE SHOVEL ATTACHMENT………………………………………291

4.30.5 CONNECTING GREASE LINES ON THE BUCKET…………………………………………………….293

4.30.6 BLEEDING HYDRAULIC CIRCUIT OF BUCKET CLAM CYLINDERS………………………………………..293

4.31 ASSEMBLY BACKHOE ATTACHMENT…………………………………………………………………..294

4.31.1 CONNECTING HOSE LINES FROM DISTRIBUTOR MANIFOLD TO BOOM…………………………………….295

4.31.2 CONNECTING HOSE LINES FROM BOOM TO BOOM CYLINDERS………………………………………….296

4.31.3 CONNECTING HOSE LINES FROM BOOM TO STICK CYLINDERS…………………………………………297

4.31.4 ATTACHING THE STICK TO THE BOOM………………………………………………………….299

4.31.5 CONNECTING HOSE LINES FROM BOOM TO BUCKET CYLINDERS………………………………………..301

4.32 BLEEDING HYDRAULIC CIRCUITS…………………………………………………………………..302

4.32.1 BLEEDING THE SWING PARKING BRAKE CIRCUIT………………………………………………….303

4.32.2 BLEEDING THE TRAVEL PARKING BRAKE CIRCUIT…………………………………………………303

4.32.3 BLEEDING THE HYDRAULIC TRACK TENSIONING CIRCUIT……………………………………………305

4.32.4 BLEEDING HYDRAULIC CIRCUIT OF ACCESS LADDER……………………………………………….306

4.32.5 BLEEDING HYDRAULIC CIRCUIT OF ATTACHMENT CYLINDERS…………………………………………306

4.32.6 BLEEDING HYDRAULIC CIRCUIT OF SWING MOTORS………………………………………………..307

4.33 ATTACHING BACKHOE BUCKET TO THE STICK………………………………………………………….308

4.33.1 CONNECTING GREASE LINES OF THE BACKHOE ATTACHMENT………………………………………….313

4.34 BLEEDING HYDRAULIC CIRCUITS OF THE TRAVEL MOTORS………………………………………………..314

5 FINAL CHECKS AND ADJUSTMENTS………………………………………………………………………..315

5.0.1 COMMISSIONING CHECK LIST…………………………………………………………………….317

5.0.2 ADJUSTMENT OF AUTOMATIC LUBRICATION SYSTEMS……………………………………………………317

5.0.3 MAIN PUMP ADJUSTMENT IN RELATION TO ALTITUDE AT THE MINE SITE……………………………………319

5.0.4 PRESSURE COMPENSATION OF SEALED COMPONENTS…………………………………………………….319

5.0.5 FINAL ADJUSTMENT OF SLEW ANGLE WARNING SYSTEM………………………………………………….320

5.0.6 PLACING THE FIRE DETECTION AND SUPPRESSION SYSTEM IN SERVICE…………………………………….322

5.1 COMMISSIONING OF THE AIR CONDITIONING…………………………………………………………..344

5.1.1 AIR CONDITIONING FOR OPERATOR’S CAB……………………………………………………….347

5.1.2 AIR CONDITIONING FOR MEDIUM AND HIGH VOLTAGE SWITCH CABINETS…………………………………349

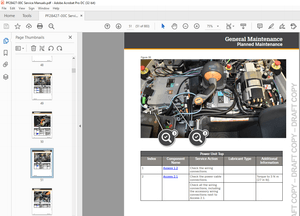

5.2 PERFORM THE PM-CLINIC PROCEDURE ACCORDING TO THE PM-CLINIC PROCEDURE MANUAL…………………………355

5.2.1 VISUAL INSPECTION……………………………………………………………………….356

5.2.2 TRAVELLING INSTRUCTIONS………………………………………………………………….356

5.3 HANDLING OF DOCUMENTATION AFTER ASSEMBLY AND COMMISSIONING………………………………………..357

6 DISASSEMBLY OF THE MACHINE………………………………………………………………………….359

6.0.1 SAFETY PRECAUTIONS FOR DISASSEMBLING THE MACHINE……………………………………………….361

6.0.2 GROUNDING PROCEDURE OF THE HIGH VOLTAGE SYSTEM…………………………………………………361

6.0.3 DISASSEMBLY SEQUENCE OF FACE SHOVEL MACHINES…………………………………………………..368

6.0.4 DISASSEMBLY SEQUENCE OF BACKHOE MACHINES………………………………………………………370

6.0.5 DISPOSAL OF WASTE MATERIAL…………………………………………………………………..372

6.0.6 LIFTING AND TRANSPORTATION OF MAIN COMPONENTS………………………………………………….372

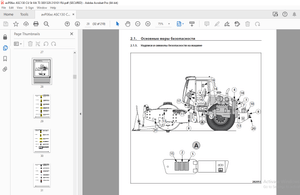

7 LIFTING AND TRANSPORTATION OF MAIN COMPONENTS…………………………………………………………373

7.1 LIFTING OF THE MAIN COMPONENTS…………………………………………………………………374

7.1.1 SAFETY PRECAUTIONS FOR LIFTING OF COMPONENTS……………………………………………….375

7.1.2 LIFTING ATTACHMENT POINTS AND WEIGHTS……………………………………………………..375

7.1.3 CRAWLER SIDE FRAME WITHOUT TRACKS…………………………………………………………375

7.1.4 CARBODY [DIESEL DRIVE]…………………………………………………………………..377

7.1.5 CARBODY [ELECTRIC DRIVE]…………………………………………………………………379

7.1.6 SUPERSTRUCTURE PLATFORM………………………………………………………………….381

7.1.7 MACHINERY HOUSE [DIESEL DRIVE]……………………………………………………………383

7.1.8 MACHINERY HOUSE [ELECTRIC DRIVE]………………………………………………………….385

7.1.9 FACE SHOVEL BOOM………………………………………………………………………..387

7.1.10 BACKHOE BOOM…………………………………………………………………………..389

7.1.11 COUNTERWEIGHT LIFTING FOR HORIZONTAL TRANSPORT [DIESEL DRIVE]……………………………….391

7.1.12 COUNTERWEIGHT ERECTING FOR VERTICAL TRANSPORT [DIESEL DRIVE]………………………………..393

7.1.13 COUNTERWEIGHT LIFTING FOR VERTICAL TRANSPORT [DIESEL DRIVE]…………………………………395

7.1.14 COUNTERWEIGHT LIFTING FOR HORIZONTAL TRANSPORT [ELECTRIC DRIVE]……………………………..397

7.1.15 COUNTERWEIGHT ERECTING FOR VERTICAL TRANSPORT [ELECTRIC DRIVE]………………………………399

7.1.16 COUNTERWEIGHT LIFTING FOR VERTICAL TRANSPORT [ELECTRIC DRIVE]……………………………….401

7.1.17 FUEL TANK [DIESEL DRIVE]………………………………………………………………..403

7.1.18 HIGH VOLTAGE SWITCH CABINET [ELECTRIC DRIVE]………………………………………………405

7.1.19 CAB BASE………………………………………………………………………………407

7.1.20 FACE SHOVEL STICK………………………………………………………………………409

7.1.21 BACKHOE STICK………………………………………………………………………….411

7.1.22 FACE SHOVEL BACK WALL…………………………………………………………………..413

7.1.23 FACE SHOVEL CLAM SHELL………………………………………………………………….415

7.1.24 BACKHOE BUCKET…………………………………………………………………………417

7.2 TRANSPORTATION OF THE MAIN COMPONENTS…………………………………………………………..418

7.2.1 SAFETY PRECAUTIONS FOR TRANSPORTATION OF THE MAIN COMPONENTS…………………………………418

7.2.2 TIE-DOWN OF UNPACKED EXCAVATOR TRANSPORT UNITS……………………………………………..418

7.2.3 CRAWLER TRACKS [1800 mm]…………………………………………………………………423

7.2.4 CRAWLER TRACKS [1350 mm]…………………………………………………………………425

7.2.5 CRAWLER SIDE FRAME WITHOUT TRACKS…………………………………………………………427

7.2.6 CARBODY [DIESEL DRIVE]…………………………………………………………………..429

7.2.7 CARBODY [ELECTRIC DRIVE]…………………………………………………………………431

7.2.8 SUPERSTRUCTURE PLATFORM………………………………………………………………….433

7.2.9 MACHINERY HOUSE [DIESEL DRIVE]……………………………………………………………439

7.2.10 MACHINERY HOUSE [ELECTRIC DRIVE]…………………………………………………………441

7.2.11 FACE SHOVEL BOOM……………………………………………………………………….443

7.2.12 BACKHOE BOOM…………………………………………………………………………..445

7.2.13 COUNTERWEIGHT [DIESEL DRIVE]…………………………………………………………….447

7.2.14 COUNTERWEIGHT [ELECTRIC DRIVE]…………………………………………………………..449

7.2.15 FUEL TANK [DIESEL DRIVE]………………………………………………………………..451

7.2.16 HIGH VOLTAGE SWITCH CABINET [ELECTRIC DRIVE]………………………………………………455

7.2.17 CAB BASE………………………………………………………………………………457

7.2.18 FACE SHOVEL STICK………………………………………………………………………459

7.2.19 BACKHOE STICK………………………………………………………………………….461

7.2.20 FACE SHOVEL BACK WALL…………………………………………………………………..463

7.2.21 FACE SHOVEL CLAM SHELL………………………………………………………………….465

7.2.22 BACKHOE BUCKET…………………………………………………………………………467

7.2.23 COMPONENTS DELIVERED IN TRANSPORT BOXES…………………………………………………..467

IMAGES PREVIEW OF THE MANUAL: