$36

Komatsu HYDRAULIC MINING SHOVEL PC8000E-6 Shop Manual(SMPC8000E-6) – PDF DOWNLOAD

Komatsu HYDRAULIC MINING SHOVEL PC8000E-6 Shop Manual(SMPC8000E-6) – PDF DOWNLOAD

DESCRIPTION:

SERIAL NUMBERS 12089 – 12093

Komatsu HYDRAULIC MINING SHOVEL PC8000E-6 Shop Manual(SMPC8000E-6) – PDF DOWNLOAD

1.1 CONTENTS OF THE BINDER

Assembled in this file are the Service Manual with explanation and adjustment of the major components and circuits

for your KOMATSU Hydraulic Mining Shovel PC8000-6 Diesel with X2 controller and the enhanced VHMS

system.

1.2 FOREWORD

Observe the instructions in these manuals for:

– your Personal SAFETY

– Operating SAFETY, and

– READY and EFFICIENT PERFORMANCE of your KOMATSU Hydraulic Mining Shovel.

With this SERVICE MANUAL KOMATSU provides you with the description of the construction and the function of

the major systems of the Hydraulic Excavator PC8000-6D.

We describe for you all functions and how to carry out the inspections and adjustments.

How do you find “your” desired information?

In the TABLE OF CONTENT all the functions and components are shown in their sequence of the description.

NOTE! Periodic preventive inspections and maintenance are the surest means of keeping the machine in

proper working order. Prompt detection and correction of minor irregularities, and immediate replacement

of worn out or broken parts will prevent failures and avoid expenses.

Replace damaged graphics and symbols at the machine.

Observe safety precautions to prevent injury and damage.

If after reading this SERVICE MANUAL you can give us suggestions and comments for improvements – please do

not hesitate to contact us.

TABLE OF CONTENTS:

Komatsu HYDRAULIC MINING SHOVEL PC8000E-6 Shop Manual(SMPC8000E-6) – PDF DOWNLOAD

1 INTRODUCTION……………………………………………………………………………. 1-1

1.1 CONTENTS OF THE BINDER…………………………………………………………………………………………….. 1-2

1.2 FOREWORD …………………………………………………………………………………………………………………….. 1-2

1.3 RECOMMENDATIONS FOR ENVIRONMENTALLY FRIENDLY OPERATION

AND MAINTENANCE OF HYDRAULIC MINING SHOVELS…………………………………………………… 1-4

1.4 EXPLANATION OF ABBREVIATIONS ………………………………………………………………………………… 1-5

1.5 DIAGRAMS AND ILLUSTRATIONS IN THIS MANUAL …………………………………………………………. 1-6

2 SAFETY ……………………………………………………………………………………….. 2-1

2.1 SAFETY INFORMATION ……………………………………………………………………………………………………. 2-2

2.2 OVERVIEW ………………………………………………………………………………………………………………………. 2-3

2.2.1 NORMAL OPERATIONS…………………………………………………………………………………………. 2-3

2.2.2 REGULAR MAINTENANCE …………………………………………………………………………………….. 2-3

2.2.3 TROUBLESHOOTING, ADJUSTMENTS AND REPAIR ………………………………………………. 2-3

2.2.4 ADDITIONAL SAFETY PRECAUTIONS FOR ASSEMBLING, DISASSEMBLING

AND TRANSPORTATION OF THE EXCAVATOR………………………………………………………. 2-3

2.3 SOUND PRESSURE LEVEL IN THE OPERATOR’S CAB. …………………………………………………….. 2-4

2.4 GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR……………………… 2-5

2.4.1 UNDERSTANDING THE MACHINE………………………………………………………………………….. 2-5

2.4.2 PRECAUTIONS BEFORE STARTING OPERATION ON THE EXCAVATOR …………………. 2-5

2.4.2.1 ENSURING SAFE OPERATION…………………………………………………………………. 2-5

2.4.3 PREPARATIONS FOR SAFE OPERATION……………………………………………………………….. 2-5

2.4.3.1 PRECAUTIONS REGARDING SAFETY RELATED EQUIPMENT ………………….. 2-5

2.4.3.2 INSPECTING THE MACHINE ……………………………………………………………………. 2-5

2.4.3.3 WEAR WELL FITTING CLOTHES AND PROTECTIVE EQUIPMENT……………… 2-6

2.4.3.4 KEEP MACHINE CLEAN…………………………………………………………………………… 2-6

2.4.3.5 PRECAUTIONS INSIDE OPERATOR’S COMPARTMENT…………………………….. 2-6

2.4.3.6 PROVIDE FIRE EXTINGUISHER AND FIRST AID KIT …………………………………. 2-7

2.4.3.7 IF A PROBLEM IS FOUND………………………………………………………………………… 2-7

2.4.4 FIRE PREVENTION ……………………………………………………………………………………………….. 2-7

2.4.4.1 PRECAUTIONS TO PREVENT FIRE ………………………………………………………….. 2-7

2.4.4.2 ACTION IF FIRE OCCURS………………………………………………………………………… 2-8

2.4.4.3 EMERGENCY EXIT FROM OPERATOR’S CAB…………………………………………… 2-9

2.4.5 PRECAUTIONS WHEN GETTING ON OR OFF THE MACHINE ………………………………….. 2-9

2.4.5.1 USE HANDRAILS AND STEPS WHEN GETTING ON OR OFF THE MACHINE . 2-9

2.4.5.2 NO JUMPING ON OR OFF THE MACHINE…………………………………………………. 2-9

2.4.5.3 NO PEOPLE ON THE ATTACHMENT ………………………………………………………… 2-9

2.4.5.4 WORKING IN HIGH PLACES…………………………………………………………………….. 2-9

2.4.5.5 LEAVING OPERATOR’S SEAT WITH LOCK……………………………………………… 2-10

2.4.5.6 LEAVING THE MACHINE………………………………………………………………………… 2-10

2.4.6 BURN PREVENTION ……………………………………………………………………………………………. 2-11

2.4.6.1 HOT COOLANT ……………………………………………………………………………………… 2-11

2.4.6.2 HOT OIL ……………………………………………………………………………………………….. 2-11

2.4.7 PRECAUTIONS WHEN CLEANING CAB GLASS …………………………………………………….. 2-11

2.4.8 PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…………………………………… 2-12

2.4.8.1 UNAUTHORIZED MODIFICATION …………………………………………………………… 2-12

2.4.8.2 PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…………………. 2-12

2.4.9 PRECAUTIONS AT JOBSITE…………………………………………………………………………………. 2-13

2.4.9.1 VISIBILITY FROM OPERATOR’S SEAT ……………………………………………………. 2-14

2.4.9.2 CAMERA SYSTEM WITH MONITORS………………………………………………………. 2-14

2.4.9.3 ENSURE GOOD VISIBILITY…………………………………………………………………….. 2-14

2.4.9.4 CHECKING SIGNS AND SIGNALMAN’S SIGNALS…………………………………….. 2-14

2.4.9.5 INVESTIGATE AND CONFIRM JOBSITE CONDITIONS……………………………… 2-15

2.4.9.6 DO NOT GO CLOSE TO HIGH VOLTAGE CABLES …………………………………… 2-15

2.4.9.7 WORKING ON LOOSE GROUND…………………………………………………………….. 2-16

2.4.9.8 GAS, DUST, STEAM AND SMOKE…………………………………………………………… 2-16

2.4.9.9 VENTILATION OF ENCLOSED AREAS…………………………………………………….. 2-17

2.4.10 STARTING ENGINE ……………………………………………………………………………………………… 2-18

2.4.10.1 WARNING TAG………………………………………………………………………………………. 2-18

2.4.10.2 CHECKS BEFORE STARTING ENGINE……………………………………………………. 2-18

2.4.10.3 PRECAUTION WHEN STARTING ENGINE……………………………………………….. 2-18

2.4.10.4 PRECAUTION IN COLD AREAS………………………………………………………………. 2-19

2.4.11 OPERATION………………………………………………………………………………………………………… 2-19

2.4.11.1 CHECKS BEFORE OPERATION ……………………………………………………………… 2-19

2.4.11.2 PRECAUTIONS WHEN TRAVELLING IN FORWARD OR REVERSE …………… 2-20

2.4.11.3 PRECAUTIONS WHEN TRAVELLING ………………………………………………………. 2-21

2.4.11.4 TRAVELLING ON SLOPES ……………………………………………………………………… 2-22

2.4.11.5 OPERATIONS ON SLOPES…………………………………………………………………….. 2-23

2.4.11.6 PROHIBITED OPERATIONS……………………………………………………………………. 2-23

2.4.11.7 TRAVELLING ON FROZEN OR SNOW COVERED SURFACES………………….. 2-24

2.4.11.8 PARKING THE MACHINE ……………………………………………………………………….. 2-24

2.4.11.9 TRANSPORTATION ……………………………………………………………………………….. 2-24

2.5 PRECAUTION FOR MAINTENANCE…………………………………………………………………………………. 2-25

2.5.1 GENERAL PRECAUTIONS……………………………………………………………………………………. 2-25

2.5.1.1 SELECTION AND QUALIFICATION OF PERSONNEL –

BASIC RESPONSIBILITIES……………………………………………………………………… 2-26

2.5.1.2 STOP ENGINE FOR MAINTENANCE……………………………………………………….. 2-27

2.5.1.3 WARNING TAG………………………………………………………………………………………. 2-28

2.5.1.4 KEEP WORKPLACE CLEAN AND TIDY……………………………………………………. 2-29

2.5.1.5 APPOINT LEADER WHEN WORKING WITH OTHERS ………………………………. 2-29

2.5.1.6 TWO WORKERS FOR MAINTENANCE WHEN THE MACHINE IS RUNNING.. 2-30

2.5.1.7 INSTALLING, REMOVING OR STORING ATTACHMENTS…………………………. 2-30

2.5.1.8 PRECAUTIONS WHEN WORKING UNDER THE MACHINE OR EQUIPMENT 2-31

2.5.1.9 NOISE …………………………………………………………………………………………………… 2-31

2.5.1.10 WHEN USING A HAMMER………………………………………………………………………. 2-31

2.5.1.11 PROPER TOOLS……………………………………………………………………………………. 2-32

2.5.1.12 ACCUMULATOR…………………………………………………………………………………….. 2-32

2.5.1.13 PERSONNEL …………………………………………………………………………………………. 2-32

2.5.2 PRECAUTIONS FOR INSPECTION AND MAINTENANCE………………………………………… 2-33

2.5.2.1 PRECAUTION WHEN WELDING……………………………………………………………… 2-33

2.5.2.2 BATTERY HANDLING …………………………………………………………………………….. 2-33

2.5.3 PRECAUTIONS WITH HIGH PRESSURE FLUID……………………………………………………… 2-34

2.5.3.1 PRECAUTIONS WITH HIGH FUEL PRESSURE ………………………………………… 2-34

2.5.3.2 HANDLING HIGH PRESSURES HOSES OR PIPES …………………………………… 2-35

2.5.3.3 REPLACEMENT OF HOSE LINES……………………………………………………………. 2-35

2.5.3.4 INSPECTION OF HOSE LINES………………………………………………………………… 2-35

2.5.3.5 PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS……………………….. 2-36

2.5.3.6 PRECAUTIONS FOR HIGH VOLTAGE……………………………………………………… 2-36

2.5.3.7 AIR CONDITIONING MAINTENANCE ………………………………………………………. 2-36

2.5.3.8 COMPRESSED AIR………………………………………………………………………………… 2-37

2.5.3.9 WASTE MATERIALS………………………………………………………………………………. 2-37

2.6 ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS……. 2-38

2.6.1 INSPECTION OF THE HYDRAULIC SYSTEM …………………………………………………………. 2-38

2.6.2 TWO WORKERS ONLY WHEN THE MACHINE IS RUNNING DURING ADJUSTMENTS 2-38

2.6.3 AREAS OF POTENTIAL DANGER AROUND THE EXCAVATOR……………………………….. 2-38

2.7 SPECIAL SAFETY EQUIPMENT……………………………………………………………………………………….. 2-40

2.7.1 FRONT GUARD PROTECTIVE STRUCTUR ’FOPS’ FOR OPERATOR’S CAB ……………. 2-41

2.7.2 OBJECT HANDLING …………………………………………………………………………………………….. 2-41

2.7.3 LIGHTING ……………………………………………………………………………………………………………. 2-41

2.7.4 WARNING BEACON …………………………………………………………………………………………….. 2-41

2.7.5 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD) ……….. 2-41

2.7.5.1 SAFETY HARNESS IN CONFORMITY WITH EN 361

(EUROPEAN STANDARD)………………………………………………………………………. 2-41

2.7.5.2 INSTRUCTIONS FOR USE ……………………………………………………………………… 2-43

2.7.5.3 PRIOR TO USING THE HARNESS (1), THE WEARER SHALL ……………………. 2-45

2.7.5.4 RECOMMENDATIONS FOR USE OF THE HOLDING HOOKS

AND HOLD-BACK HOOKS OF THE SAFETY HARNESS (1),………………………. 2-45

2.7.5.5 INSTRUCTIONS FOR USE ……………………………………………………………………… 2-47

3 SPECIFICATIONS …………………………………………………………………………. 3-1

3.1 LIFTING GEARS……………………………………………………………………………………………………………….. 3-2

3.2 SAFETY HINTS FOR SLING ACCESSORY …………………………………………………………………………. 3-4

3.3 STANDARD TIGHTENING TORQUE CHART ………………………………………………………………………. 3-5

3.4 CONVERSION TABLE……………………………………………………………………………………………………….. 3-6

3.5 BLIND PLUGS ………………………………………………………………………………………………………………… 3-12

3.6 CLASSIFICATION OF THREADS TO THE NOMINAL WIDTH ……………………………………………… 3-14

3.7 PLUGS AND FITTINGS ACCORDING TO ISO 8434-1 / DIN 2353 ………………………………………… 3-15

4 MAIN ASSEMBLY GROUPS …………………………………………………………… 4-1

4.1 GENERAL LAYOUT ………………………………………………………………………………………………………….. 4-2

4.2 SUPERSTRUCTURE …………………………………………………………………………………………………………. 4-4

4.3 MACHINE HOUSE …………………………………………………………………………………………………………….. 4-8

4.4 HYDRAULIC OIL TANK……………………………………………………………………………………………………. 4-10

4.5 HYDRAULIC OIL COOLER ………………………………………………………………………………………………. 4-12

4.6 HIGH VOLTAGE SWITCH CABINET …………………………………………………………………………………. 4-14

4.7 CAB SUPPORT……………………………………………………………………………………………………………….. 4-20

4.7.1 X2 – LOW VOLTAGE SWITCH BOARD (LOCATION 12) …………………………………………… 4-21

4.7.2 EXTRA LOW VOLTAGE SWITCH BOARD (LOCATION 11) ………………………………………. 4-23

4.8 SLIP RING UNIT ……………………………………………………………………………………………………………… 4-24

4.9 OPERATOR’S CAB …………………………………………………………………………………………………………. 4-28

4.10 CONTROL BLOCKS………………………………………………………………………………………………………… 4-30

4.11 SWING MACHINERY……………………………………………………………………………………………………….. 4-32

4.11.1 SWING MACHINERY L&S …………………………………………………………………………………….. 4-32

4.11.2 SWING MACHINERY SIEBENHAAR ………………………………………………………………………. 4-34

4.12 UNDERCARRIAGE………………………………………………………………………………………………………….. 4-36

4.13 ATTACHMENTS………………………………………………………………………………………………………………. 4-38

4.13.1 FRONT SHOVEL ATTACHMENT (FSA) ………………………………………………………………….. 4-38

4.13.2 BACKHOE ATTACHMENT (BHA) …………………………………………………………………………… 4-40

5 DRIVE ………………………………………………………………………………………….. 5-1

5.1 ELECTRIC DRIVE – SAFETY AND OPERATION INSTRUCTION DOCUMENTS………………………. 5-2

5.2 PRIME DRIVE ASSEMBLY…………………………………………………………………………………………………. 5-4

5.3 ELECTRIC MOTORS …………………………………………………………………………………………………………. 5-6

5.3.1 LOCATION OF ATTACHING PARTS………………………………………………………………………… 5-6

5.3.1.1 MOTOR TYPE PLATE ………………………………………………………………………………. 5-7

5.3.1.2 TYPE PLATE FOR THE MOTOR BEARINGS………………………………………………. 5-8

5.3.2 MOTOR BEARINGS & GREASE EQUIPMENT ………………………………………………………… 5-10

5.3.3 MONITORING OF THE MOTOR BEARING TEMPERATURE…………………………………….. 5-12

5.3.4 MONITORING OF THE MOTOR WINDING TEMPERATURE…………………………………….. 5-13

5.3.5 JUNCTION BOX FOR THE MOTOR MONITORING DEVICE …………………………………….. 5-14

5.3.6 CHECKING OF THE BEARING CONDITION……………………………………………………………. 5-15

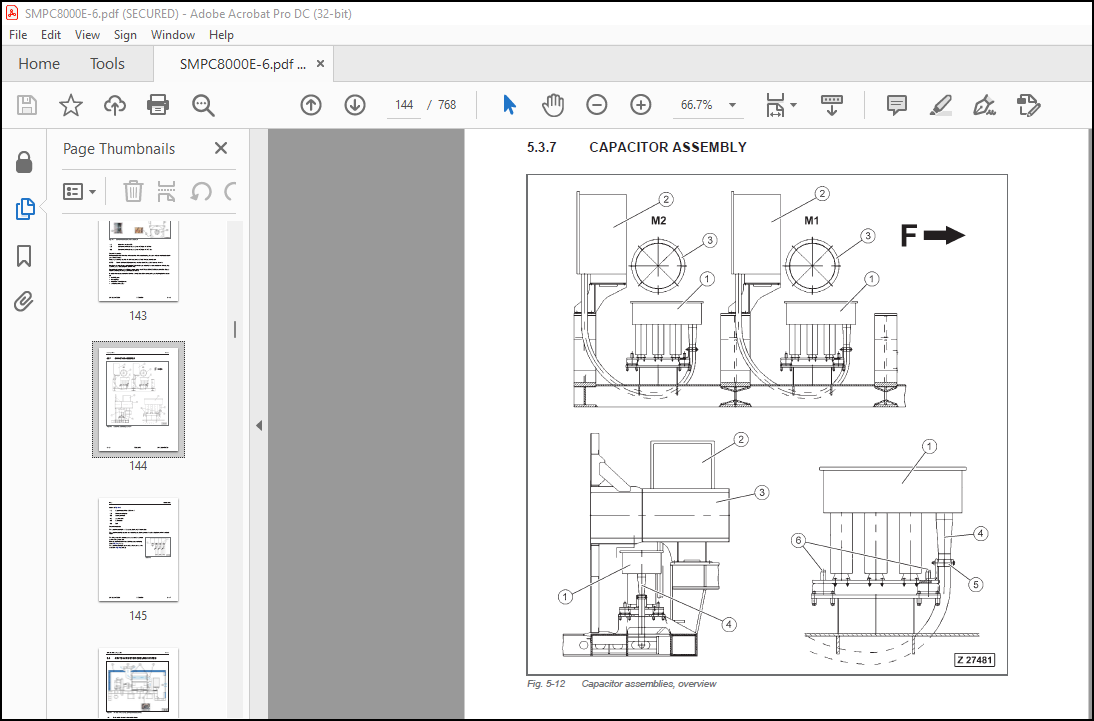

5.3.7 CAPACITOR ASSEMBLY………………………………………………………………………………………. 5-16

5.4 AIR-TO-AIR MOTOR COOLING SYSTEM ………………………………………………………………………….. 5-18

5.5 INITIAL START-UP PROCEDURE …………………………………………………………………………………….. 5-19

5.5.1 MAIN SUPPLY CABLE ………………………………………………………………………………………….. 5-20

5.5.2 MACHINE CONFIGURATION (VIA CODESYS)………………………………………………………… 5-21

5.5.3 MOTOR PROTECTION RELAY (SPAM 150 C) ………………………………………………………… 5-26

5.5.4 MOTOR ALIGNMENT……………………………………………………………………………………………. 5-28

5.5.5 MOTOR ROTATION DIRECTION …………………………………………………………………………… 5-30

5.5.6 STARTING & RE-STARTING THE ELECTRIC MOTORS ………………………………………….. 5-30

5.5.7 SUPERVISION DURING THE FIRST MOTOR RUNNING PERIOD…………………………….. 5-31

5.6 FLEXIBLE COUPLING……………………………………………………………………………………………………… 5-32

5.6.1 COUPLING INSPECTION ……………………………………………………………………………………… 5-33

5.6.2 COUPLING REPLACEMENT …………………………………………………………………………………. 5-34

5.7 PUMP DISTRIBUTOR GEARBOX (PTO)……………………………………………………………………………. 5-36

5.7.1 PUMP DRIVE SHAFT HOUSING / SPLINE LUBRICATION ……………………………………….. 5-38

5.7.2 PTO LUBRICATION AND COOLING ………………………………………………………………………. 5-40

5.7.2.1 CHECKS AND ADJUSTMENTS ……………………………………………………………….. 5-42

5.7.3 HYDRAULIC PUMPS – LOCATION, DRIVE SPEED AND FLOW RATES……………………. 5-44

6 HYDRAULIC OIL TANK ………………………………………………………………….. 6-1

6.1 GENERAL LAYOUT…………………………………………………………………………………………………………… 6-2

6.2 LOCATION OF THE ELECTRIC EQUIPMENT………………………………………………………………………. 6-4

6.3 SUCTION OIL TANK WITH STRAINERS……………………………………………………………………………… 6-6

6.4 RETURN OIL COLLECTOR PIPE WITH STRAINER……………………………………………………………… 6-8

6.5 BACK PRESSURE VALVE……………………………………………………………………………………………….. 6-10

6.6 TRANSFER PUMP…………………………………………………………………………………………………………… 6-12

6.7 RETURN AND LEAK OIL FILTER……………………………………………………………………………………… 6-14

6.8 BREATHER FILTER ………………………………………………………………………………………………………… 6-16

7 HYDRAULIC OIL COOLING……………………………………………………………. 7-1

7.1 OVERALL VIEW OF THE HYDRAULIC OIL COOLING …………………………………………………………. 7-2

7.2 FUNCTION OF THE HYDRAULIC OIL COOLING CIRCUIT …………………………………………………… 7-4

7.2.1 STANDARD HYDRAULIC OIL COOLING CIRCUIT ……………………………………………………. 7-4

7.2.2 ADDITIONAL OIL COOLING CIRCUIT ……………………………………………………………………… 7-6

7.3 ADJUSTMENT OF THE BACK PRESSURE VALVE……………………………………………………………… 7-8

7.4 FAN DRIVE – STANDARD OIL COOLER……………………………………………………………………………. 7-10

7.4.1 TWO STAGE COOLER FAN DRIVE RPM CONTROL ………………………………………………. 7-10

7.4.2 FIXED DISPLACEMENT PUMP WITH VARIABLE SETTING……………………………………… 7-12

7.4.3 PRESSURE RELIEF VALVES………………………………………………………………………………… 7-14

7.4.4 SOLENOID VALVES …………………………………………………………………………………………….. 7-16

7.5 ADJUSTMENT OF THE COOLER FAN DRIVE SPEED ……………………………………………………….. 7-18

7.5.1 MAXIMUM SPEED ……………………………………………………………………………………………….. 7-18

7.5.2 MEDIUM SPEED ………………………………………………………………………………………………….. 7-20

7.6 FAN DRIVE – ADDITIONAL OIL COOLER………………………………………………………………………….. 7-22

7.6.1 FUNCTION OF THE ADDITIONAL COOLER FAN RPM CONTROL……………………………. 7-23

7.6.2 ADJUSTMENT OF THE ADDITIONAL COOLER FAN DRIVE SPEED…………………………. 7-23

8 CONTROLLING …………………………………………………………………………….. 8-1

8.1 GENERAL LAYOUT ………………………………………………………………………………………………………….. 8-2

8.2 CONTROL AND FILTER PANELS – LOCATION OF COMPONENTS …………………………………….. 8-4

8.2.1 MAIN VALVE CARTRIDGE BLOCK ………………………………………………………………………….. 8-4

8.2.2 CONTROL AND FILTER PANELS MOUNTED ON THE PTOS…………………………………… 8-10

8.3 PILOT PRESSURE SUPPLY AND ADJUSTMENTS ……………………………………………………………. 8-12

8.3.1 PILOT PRESSURE CIRCUIT …………………………………………………………………………………. 8-13

8.3.2 CHECKS AND ADJUSTMENTS OF PILOT PRESSURE……………………………………………. 8-16

8.3.3 REMOTE CONTROL VALVES ARRANGEMENT……………………………………………………… 8-20

8.4 FUNCTION OF THE ELECTRO-HYDRAULIC CONTROL SYSTEM………………………………………. 8-22

8.5 HAND LEVER (JOYSTICK) CONTROL ……………………………………………………………………………… 8-26

8.6 FOOT PEDAL CONTROL…………………………………………………………………………………………………. 8-28

8.7 PROPORTIONAL AMPLIFIER MODULE, TYPE A………………………………………………………………. 8-30

8.8 PROPORTIONAL AMPLIFIER MODULE, TYPE B………………………………………………………………. 8-32

8.9 RAMP TIME MODULE……………………………………………………………………………………………………… 8-34

8.10 ADJUSTMENT OF AMPLIFIER MODULES………………………………………………………………………… 8-36

8.10.1 GENERAL……………………………………………………………………………………………………………. 8-37

8.10.2 ADJUSTING THE AMPLIFIER MODULE, TYPE A ……………………………………………………. 8-38

8.10.3 ADJUSTING THE AMPLIFIER MODULE, TYPE B ……………………………………………………. 8-40

8.11 ADJUSTING THE RAMP TIME MODULE…………………………………………………………………………… 8-42

9 COMPONENTS …………………………………………………………………………….. 9-1

9.1 MAIN CONTROL BLOCKS AND HIGH PRESSURE FILTERS (FSA) ……………………………………… 9-2

9.2 DISTRIBUTOR MANIFOLD – LOCATION OF RESTRICTOR BLOCKS

AND ANTI-CAVITATION VALVES………………………………………………………………………………………. 9-6

9.3 RESTRICTOR BLOCK WITH SECONDARY RELIEF VALVE…………………………………………………. 9-8

9.4 ANTI-CAVITATION VALVE (ACV) BLOCK ………………………………………………………………………… 9-10

9.4.1 ACV BLOCK ON CONTROL BLOCKS…………………………………………………………………….. 9-10

9.4.2 ACV BLOCK ON TOP OF THE MANIFOLD……………………………………………………………… 9-12

9.5 REMOTE CONTROL VALVES ………………………………………………………………………………………….. 9-14

9.6 4/3 DIRECTIONAL SOLENOID VALVES ……………………………………………………………………………. 9-16

9.7 PROPORTIONAL SOLENOID VALVES……………………………………………………………………………… 9-18

9.8 HIGH-PRESSURE FILTER (SCREEN)……………………………………………………………………………….. 9-20

9.9 CONTROL BLOCKS AND VALVES…………………………………………………………………………………… 9-22

9.10 TRAVEL BRAKE VALVE………………………………………………………………………………………………….. 9-34

9.11 PRESSURE REDUCING VALVE……………………………………………………………………………………….. 9-36

9.12 4/2 DIRECTIONAL VALVES……………………………………………………………………………………………… 9-38

9.13 PRESSURE DOUBLE STAGE VALVE……………………………………………………………………………….. 9-40

9.14 HYDRAULIC CYLINDER ………………………………………………………………………………………………….. 9-42

10 MAIN HYDRAULIC PUMPS AND PUMP REGULATION …………………… 10-1

10.1 GENERAL ………………………………………………………………………………………………………………………. 10-2

10.1.1 LAYOUT………………………………………………………………………………………………………………. 10-2

10.1.2 PUMP REGULATION SYSTEM (“OPEN SENSING SYSTEM”) ………………………………….. 10-5

10.1.3 PUMP REGULATION SYSTEM — VALVE FUNCTION……………………………………………… 10-6

10.2 MAIN PUMPS………………………………………………………………………………………………………………….. 10-8

10.2.1 PUMP BEARING FLUSHING / LUBRICATION ……………………………………………………….. 10-10

10.2.2 OPERATING PRINCIPLE…………………………………………………………………………………….. 10-12

10.2.3 CHECKS / ADJUSTMENTS………………………………………………………………………………….. 10-28

10.2.3.1 QMAX AND QMIN ADJUSTMENT BOLTS……………………………………………….. 10-30

10.3 ELECTRONIC PUMP REGULATION SYSTEM………………………………………………………………….. 10-32

10.3.1 ELECTRONIC LOAD LIMITING CONTROL – GENERAL…………………………………………. 10-33

10.3.2 MICROCONTROLLER RC4-4 ………………………………………………………………………………. 10-34

10.3.3 SIGNAL RECTIFIER MODULE……………………………………………………………………………… 10-36

10.3.3.1 CHECKS AND ADJUSTMENTS ……………………………………………………………… 10-38

10.4 HYDRAULIC CONSTANT REGULATION SYSTEM (EMERGENCY MODE)…………………………. 10-40

10.4.1 GENERAL………………………………………………………………………………………………………….. 10-41

10.5 PUMP REGULATION SYSTEM, CHECKS AND ADJUSTMENTS……………………………………….. 10-43

10.5.1 POWER CHECK…………………………………………………………………………………………………. 10-43

10.5.2 ELECTRONIC LOAD LIMIT REGULATION, XLR BASIC ADJUSTMENT……………………. 10-46

10.5.2.1 METHOD “A” WITH 24 V SUPPLY………………………………………………………….. 10-48

10.5.2.2 METHOD “B” WITH BODAS SOFTWARE………………………………………………… 10-50

10.5.3 ELECTRONIC LOAD LIMIT REGULATION, RC4 FUNCTION CHECK ………………………. 10-54

10.5.4 HYDRAULIC CONTROL (EMERGENCY MODE) ……………………………………………………. 10-56

10.5.5 PRESSURE CUT-OFF VALVE……………………………………………………………………………… 10-58

10.6 ENERGY EFFICIENCY …………………………………………………………………………………………………… 10-60

10.6.1 GENERAL………………………………………………………………………………………………………….. 10-61

10.6.2 CHECKS AND ADJUSTMENTS……………………………………………………………………………. 10-62

11 OPERATING HYDRAULICS………………………………………………………….. 11-1

11.1 GENERAL ………………………………………………………………………………………………………………………. 11-2

11.1.1 FLOATING FUNCTION FOR BOOM AND STICK CYLINDER (FSA) …………………………… 11-4

11.2 HYDRAULICS FOR THE ATTACHMENT CYLINDERS FSA…………………………………………………. 11-6

11.2.1 ELECTRIC / HYDRAULIC FLOWCHART “BOOM UP” (FSA)……………………………………… 11-6

11.2.2 ELECTRIC / HYDRAULIC FLOWCHART “BOOM DOWN” (FSA), AUTO-FLOAT ON ……. 11-8

11.2.3 ELECTRIC / HYDRAULIC FLOWCHART “BOOM DOWN” (FSA), AUTO-FLOAT OFF … 11-10

11.2.4 ELECTRIC / HYDRAULIC FLOWCHART “STICK OUT” (FSA)………………………………….. 11-12

11.2.5 ELECTRIC / HYDRAULIC FLOWCHART “STICK IN” (FSA), AUTO-FLOAT ON …………. 11-14

11.2.6 ELECTRIC / HYDRAULIC FLOWCHART “STICK IN” (FSA), AUTO-FLOAT OFF………… 11-16

11.2.7 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET FILL” (FSA) ………………………………. 11-18

11.2.8 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET DUMP” (FSA)……………………………. 11-20

11.2.9 ELECTRIC / HYDRAULIC FLOWCHART “CLAM OPEN” (FSA)………………………………… 11-22

11.2.10 ELECTRIC / HYDRAULIC FLOWCHART “CLAM CLOSE” (FSA)………………………………. 11-24

11.2.11 CHECKS AND ADJUSTMENTS OF THE MAIN RELIEF VALVES (MRV), FSA…………… 11-26

11.2.12 CHECKS AND ADJUSTMENTS OF THE SECONDARY RELIEF VALVES (SRV), FSA.. 11-28

11.2.12.1 BOOM CYLINDER, PISTON SIDE (FSA)…………………………………………………. 11-28

11.2.12.2 BOOM CYLINDER, PISTON ROD SIDE (FSA)…………………………………………. 11-32

11.2.12.3 STICK CYLINDER, PISTON SIDE (FSA) …………………………………………………. 11-36

11.2.12.4 STICK CYLINDER, PISTON ROD SIDE (FSA) …………………………………………. 11-40

11.2.12.5 BUCKET CYLINDER, PISTON SIDE (FSA) ……………………………………………… 11-44

11.2.12.6 BUCKET CYLINDER, PISTON SIDE (FSA) ……………………………………………… 11-48

11.2.12.7 CLAM CYLINDER, PISTON ROD SIDE (FSA), CLAM OPEN……………………… 11-52

11.2.12.8 CLAM CYLINDER, PISTON SIDE (FSA), CLAM CLOSE……………………………. 11-56

11.2.13 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED – BOOM……………………. 11-60

11.2.14 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED – STICK ……………………. 11-64

11.2.15 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED – BUCKET ………………… 11-68

11.2.16 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED – CLAM…………………….. 11-72

11.3 HYDRAULICS FOR THE SWING CIRCUIT……………………………………………………………………….. 11-74

11.3.1 SWING CIRCUIT ………………………………………………………………………………………………… 11-74

11.3.2 SWING MOTOR …………………………………………………………………………………………………. 11-78

11.3.3 SWING GEARBOX (L&S)…………………………………………………………………………………….. 11-82

11.3.4 SWING GEARBOX (SIEBENHAAR) ……………………………………………………………………… 11-84

11.3.5 SWING PARKING BRAKE (L&S) ………………………………………………………………………….. 11-86

11.3.6 SWING PARKING BRAKE (SIEBENHAAR)……………………………………………………………. 11-88

11.3.7 SWING BRAKE VALVE……………………………………………………………………………………….. 11-90

11.3.8 ELECTRIC / HYDRAULIC FLOWCHART “SWING LEFT” ………………………………………… 11-94

11.3.9 ELECTRIC / HYDRAULIC FLOWCHART “SWING RIGHT”………………………………………. 11-96

11.3.10 CHECKS AND ADJUSTMENTS FOR THE SWING CIRCUIT …………………………………… 11-98

11.3.11 FUNCTION CHECK FOR HYDRAULIC SWING BRAKE ………………………………………… 11-102

11.3.12 FUNCTION CHECK FOR THE SWING PARKING BRAKE……………………………………… 11-104

11.4 HYDRAULICS FOR THE TRAVEL CIRCUIT …………………………………………………………………… 11-108

11.4.1 TRAVEL CIRCUIT …………………………………………………………………………………………….. 11-109

11.4.2 TRAVEL MOTOR………………………………………………………………………………………………. 11-112

11.4.3 ROTARY JOINT………………………………………………………………………………………………… 11-114

11.4.4 TRAVEL GEARBOX ………………………………………………………………………………………….. 11-116

11.4.5 TRAVEL PARKING BRAKE (L&S) ………………………………………………………………………. 11-118

11.4.6 TRAVEL PARKING BRAKE (ZOLLERN)………………………………………………………………. 11-120

11.4.7 TRAVEL BRAKE VALVE ……………………………………………………………………………………. 11-122

11.4.8 ELECTRIC / HYDRAULIC FLOWCHART “TRAVEL FORWARD”…………………………….. 11-124

11.4.9 ELECTRIC / HYDRAULIC FLOWCHART “TRAVEL BACKWARDS” ………………………… 11-126

11.4.10 CHECKS AND ADJUSTMENTS FOR THE TRAVEL CIRCUIT………………………………… 11-128

11.4.11 FUNCTION CHECK FOR THE TRAVEL PARKING BRAKE……………………………………. 11-130

12 HYDRAULIC TRACK TENSIONING SYSTEM …………………………………. 12-1

12.1 GENERAL ………………………………………………………………………………………………………………………. 12-2

12.2 FUNCTIONAL DESCRIPTION…………………………………………………………………………………………… 12-4

12.3 DOUBLE-STAGE VALVE …………………………………………………………………………………………………. 12-8

12.4 TENSIONING CYLINDER ……………………………………………………………………………………………….. 12-10

12.5 ADJUSTMENTS / CHECKS…………………………………………………………………………………………….. 12-12

13 ACCESS LADDER, HYDRAULICALLY OPERATED…………………………. 13-1

13.1 GENERAL ………………………………………………………………………………………………………………………. 13-2

13.2 FUNCTION OF THE HYDRAULICALLY OPERATED ACCESS LADDER………………………………. 13-4

13.3 ADJUSTMENTS / CHECKS………………………………………………………………………………………………. 13-8

14 CENTRAL REFILLING SYSTEM (SERVICE ARM)…………………………… 14-1

14.1 SERVICE ARM………………………………………………………………………………………………………………… 14-2

14.2 MONITORING AND CONTROL BOX …………………………………………………………………………………. 14-4

14.3 FUNCTION ……………………………………………………………………………………………………………………… 14-6

14.4 CHECKS AND ADJUSTMENTS………………………………………………………………………………………… 14-8

15 HINTS FOR READING THE HYDRAULIC DIAGRAM……………………….. 15-1

15.1 GENERAL ………………………………………………………………………………………………………………………. 15-2

15.2 HYDRAULIC SYMBOLS…………………………………………………………………………………………………… 15-4

15.2.1 LINES, UNIONS……………………………………………………………………………………………………. 15-5

15.2.2 COMPONENTS, VALVES ……………………………………………………………………………………… 15-7

15.2.3 SENSORS……………………………………………………………………………………………………………. 15-7

15.2.4 VALVES, VALVE COMPONENTS…………………………………………………………………………… 15-8

15.2.5 PUMP, MOTOR, CYLINDER ………………………………………………………………………………… 15-12

16 HINTS FOR READING THE ELECTRIC WIRING DIAGRAM …………….. 16-1

16.1 GENERAL ………………………………………………………………………………………………………………………. 16-2

16.2 REFERENCE CODE OF THE ELECTRICAL COMPONENTS……………………………………………….. 16-3

16.2.1 AREA CODE………………………………………………………………………………………………………… 16-3

16.2.2 COMPONENT IDENTIFYING LETTER ……………………………………………………………………. 16-5

16.3 GRAPHICAL SYMBOLS…………………………………………………………………………………………………… 16-6

16.4 DRAWING CONCEPT…………………………………………………………………………………………………….. 16-10

16.5 CABLE MARKING …………………………………………………………………………………………………………. 16-20

17 KOMTRAX PLUS & MTC CONTROL SYSTEM………………………………… 17-1

17.1 GENERAL ………………………………………………………………………………………………………………………. 17-2

17.2 SPECIFICATIONS FOR OPERATORS ………………………………………………………………………………. 17-5

17.2.1 SEQUENCE OF DISPLAYS …………………………………………………………………………………… 17-6

17.2.2 OPENING SCREEN………………………………………………………………………………………………. 17-6

17.2.3 MAIN GAUGE SCREENS 1 TO 3……………………………………………………………………………. 17-7

17.2.4 ENERGY CONSUMPTION SCREEN…………………………………………………………………….. 17-10

17.2.5 FAILURE MESSAGE HISTORY FOR THE OPERATOR ………………………………………….. 17-12

17.2.6 MAIN GAUGE SCREENS – CHANGING OF TIME / SMR / DATE ……………………………… 17-14

17.2.7 MAINTENANCE MONITOR………………………………………………………………………………….. 17-15

17.2.8 SETTINGS FOR OPERATOR ………………………………………………………………………………. 17-17

17.2.9 AUTOMATIC MESSAGES……………………………………………………………………………………. 17-24

17.3 TABLES OF ALL PROVIDED MESSAGES ………………………………………………………………………. 17-27

17.3.1 TABLE OF G-CODES…………………………………………………………………………………………. 17-28

17.3.2 TABLE OF AVAILABLE INSTRUCTION MESSAGES ……………………………………………… 17-36

17.4 FLOW CHARTS (1-4) OF KOMTRAX PLUS MAIN SCREENS ……………………………………………. 17-39

17.5 KOMTRAX PLUS SERVICE LEVEL…………………………………………………………………………………. 17-44

17.5.1 EXPLANATION OF THE BUTTON SYMBOLS (SERVICE LEVEL) ……………………………. 17-46

17.5.2 SERVICE MENU SELECT SCREEN……………………………………………………………………… 17-47

17.5.3 REAL TIME MENU SELECT SCREEN ………………………………………………………………….. 17-48

17.5.3.1 REAL TIME MENU, OPTION: 01 MOTOR 1 …………………………………………….. 17-49

17.5.3.2 REAL TIME MENU, OPTION: 02 MOTOR 2 …………………………………………….. 17-49

17.5.3.3 REAL TIME MENU, OPTION: 03 PTO 1 ………………………………………………….. 17-50

17.5.3.4 REAL TIME MENU, OPTION: 04 PTO 2 ………………………………………………….. 17-50

17.5.3.5 REAL TIME MENU, OPTION: 05 HYDRAULIC …………………………………………. 17-51

17.5.3.6 REAL TIME MENU, OPTION: 06 SLEW…………………………………………………… 17-52

17.5.3.7 REAL TIME MENU, OPTION: 07 ELECTRICAL EQUIPMENT ……………………. 17-53

17.5.3.8 REAL TIME MENU, OPTION: 08 EMERGENCY STOP……………………………… 17-54

17.5.3.9 REAL TIME MENU, OPTION: 09 HEATER ………………………………………………. 17-55

17.5.3.10 REAL TIME MENU, OPTION: 10 MANUAL SWITCH…………………………………. 17-56

17.5.3.11 REAL TIME MENU, OPTION: 11 CENTRAL LUBE SYSTEM 1…………………… 17-57

17.5.3.12 REAL TIME MENU, OPTION: 12 SLEW RING GEAR LUBE SYSTEM ………… 17-58

17.5.3.13 REAL TIME MENU, OPTION: 13 CENTRAL LUBE SYSTEM 2…………………… 17-59

17.5.3.14 REAL TIME MENU, OPTION: 14 CABLE DRUM ………………………………………. 17-60

17.5.3.15 REAL TIME MENU, OPTION: 15 WINDSCREEN WIPER ………………………….. 17-61

17.5.3.16 REAL TIME MENU, OPTION: 16 LADDER ………………………………………………. 17-62

17.5.3.17 REAL TIME MENU, OPTION: 17 SERVICE ARM……………………………………… 17-63

17.5.3.18 REAL TIME MENU, OPTION: 18 PILOT CONTROL………………………………….. 17-64

17.5.3.19 REAL TIME MENU, OPTION: 19 OTHER ITEMS ……………………………………… 17-65

17.5.3.20 REAL TIME MENU, OPTION: 20 OUTPUT SIGNALS ……………………………….. 17-66

17.5.3.21 OUTPUT SIGNALS WITH DEACTIVATED MTC EVALUATION………………….. 17-69

17.5.4 PM-CLINIC…………………………………………………………………………………………………………. 17-71

17.5.4.1 GENERAL……………………………………………………………………………………………. 17-71

17.5.4.2 POWER CHECK…………………………………………………………………………………… 17-72

17.5.5 SERIAL/GCC NO. SETTING ………………………………………………………………………………… 17-73

17.5.6 MEMORY CLEAR……………………………………………………………………………………………….. 17-74

17.5.6.1 INPUT MEMORY CLEAR ID…………………………………………………………………… 17-74

17.5.6.2 MEMORY CLEAR SCREEN…………………………………………………………………… 17-75

17.5.7 FAILURE HISTORY…………………………………………………………………………………………….. 17-76

17.5.8 MAINTENANCE MONITOR………………………………………………………………………………….. 17-77

17.5.9 SNAPSHOT ……………………………………………………………………………………………………….. 17-78

17.5.10 SETTINGS…………………………………………………………………………………………………………. 17-79

17.5.10.1 CENTRAL LUBRICATION SYSTEM (CLS 1), SCREEN 1/12 ……………………… 17-79

17.5.10.2 SWING LUBRICATION SYSTEM (SLS), SCREEN 2/12…………………………….. 17-80

17.5.10.3 CENTRAL LUBRICATION SYSTEM (CLS 2), SCREEN 3/12 ……………………… 17-81

17.5.10.4 QMIN – QMAX SETTING, SCREEN 4/12 …………………………………………………. 17-82

17.5.10.5 OTHER SETTINGS 1/2, SCREEN 5/12……………………………………………………. 17-82

17.5.10.6 OTHER SETTINGS 2/2, SCREEN 6/12……………………………………………………. 17-84

17.5.10.7 SHUTDOWN BYPASS ON/OFF……………………………………………………………… 17-87

17.6 INTERFACE-CONNECTION KOMTRAX PLUS CONTROLLER ………………………………………….. 17-90

17.6.1 KOMTRAX PLUS CONTROLLER …………………………………………………………………………. 17-91

17.7 WIRING OF THE KOMTRAX PLUS CONTROLLER…………………………………………………………… 17-92

17.8 MTC CONTROL SYSTEM GLOBAL LAYOUT…………………………………………………………………… 17-96

17.8.1 MTC (MASTER TURBO CONTROLLER)……………………………………………………………….. 17-98

17.8.1.1 MTC FLOWCHART……………………………………………………………………………….. 17-98

17.8.1.2 MTC FEATURES ………………………………………………………………………………….. 17-98

17.8.1.3 MTC FIRMWARE AND SOFTWARE……………………………………………………….. 17-99

17.8.1.4 VIEW ONTO THE MTC UNIT AND ITS CONNECTORS…………………………… 17-100

17.9 GLOBAL LAYOUT OF THE INTERNAL CAN BUS ………………………………………………………….. 17-102

17.9.1 GENERAL INFORMATION ON A CAN BUS SYSTEM…………………………………………… 17-102

17.9.1.1 GENERAL CAN BUS DESCRIPTION…………………………………………………….. 17-103

17.9.1.2 CAN BUS TROUBLESHOOTING ………………………………………………………….. 17-103

17.9.1.3 CAN BUS WIRING………………………………………………………………………………. 17-104

17.9.1.4 CAN BUS END RESISTOR ………………………………………………………………….. 17-106

17.10THE NODES IN THE CAN BUS SYSTEM……………………………………………………………………….. 17-108

17.10.1 GLOBAL LAYOUT …………………………………………………………………………………………….. 17-108

17.10.2 INTRODUCTION……………………………………………………………………………………………….. 17-110

17.10.2.1 ICN-V FEATURES ………………………………………………………………………………. 17-110

17.10.2.2 ICN-D FEATURES ………………………………………………………………………………. 17-112

17.10.3 NODE DIP-SWITCHES………………………………………………………………………………………. 17-113

17.10.4 NODE BOX ………………………………………………………………………………………………………. 17-114

17.10.5 NODE LOCATIONS ON THE MACHINE………………………………………………………………. 17-116

17.10.5.1 NODE & LOCATION CHART………………………………………………………………… 17-117

17.10.5.2 EXEMPLARY VIEW ONTO THE CAN BUS CONTROL COMPONENTS

IN A CAB BASE ………………………………………………………………………………….. 17-118

18 LUBRICATION SYSTEM ………………………………………………………………. 18-1

18.1 GENERAL OVERVIEW (SLS & CLS1/2)……………………………………………………………………………. 18-2

18.1.1 GENERAL DESCRIPTION …………………………………………………………………………………….. 18-3

18.2 BASIC FUNCTION OF THE LUBRICATION SYSTEMS……………………………………………………….. 18-4

18.3 CENTRAL LUBRICATION SYSTEM (CLS 1&2) …………………………………………………………………. 18-6

18.3.1 GENERAL INFORMATION ON THE CLS (CLS1/2) ………………………………………………….. 18-8

18.3.1.1 MANUAL LUBE ACTIVATION ………………………………………………………………….. 18-8

18.4 SWING CIRCLE LUBRICATION SYSTEM (SLS) ………………………………………………………………. 18-10

18.4.1 GENERAL INFORMATION ON THE SLS ………………………………………………………………. 18-12

18.4.1.1 MANUAL LUBE ACTIVATION ………………………………………………………………… 18-12

18.5 LUBRICATION CYCLE…………………………………………………………………………………………………… 18-13

18.5.1 OPERATION AND CONTROL………………………………………………………………………………. 18-13

18.5.2 LUBRICATION CYCLE – COMPONENTS ……………………………………………………………… 18-14

18.5.3 LUBRICATION CYCLE – PROCESSING……………………………………………………………….. 18-16

18.5.4 TIME SEGMENTS & SWITCH POINTS OF A LUBRICATION CYCLE……………………….. 18-17

18.5.5 LUBRICATION MODES……………………………………………………………………………………….. 18-18

18.5.5.1 AUTOMATIC LUBRICATION MODE ……………………………………………………….. 18-18

18.5.5.2 MANUAL LUBRICATION MODE …………………………………………………………….. 18-18

18.5.5.3 VHMS SERVICE MODE ………………………………………………………………………… 18-18

18.6 HYDRAULICALLY DRIVEN LUBE PUMP…………………………………………………………………………. 18-20

18.6.1 ADJUSTMENT OF LUBE PUMP SPEED & WORKING PRESSURE …………………………. 18-22

18.6.1.1 STROKE SPEED ADJUSTMENT ……………………………………………………………. 18-23

18.6.1.2 WORKING PRESSURE ADJUSTMENT…………………………………………………… 18-24

18.7 LUBRICANT INJECTORS ………………………………………………………………………………………………. 18-26

18.7.1 TIGHTENING TORQUES FOR FITTINGS AT GREASE INJECTORS……………………….. 18-27

18.7.2 INJECTOR TYPE DESCRIPTION …………………………………………………………………………. 18-28

18.7.3 ADJUSTMENT OF THE LUBRICANT OUTPUT ……………………………………………………… 18-28

18.7.4 OPERATION PRINCIPLE OF LUBRICANT INJECTORS…………………………………………. 18-30

18.7.4.1 FUNCTION DESCRIPTION……………………………………………………………………. 18-31

18.7.5 CONNECTION OF ONE OR MORE INJECTORS …………………………………………………… 18-32

18.8 VENT VALVE ………………………………………………………………………………………………………………… 18-34

18.8.1 DESCRIPTION …………………………………………………………………………………………………… 18-35

18.9 END-LINE SWITCH………………………………………………………………………………………………………… 18-36

18.9.1 DESCRIPTION …………………………………………………………………………………………………… 18-37

18.9.2 CLS END-LINE SWITCH ADJUSTMENT……………………………………………………………….. 18-38

18.9.3 SLS END-LINE SWITCH ADJUSTMENT……………………………………………………………….. 18-40

18.10IN-LINE FILTER…………………………………………………………………………………………………………….. 18-42

18.10.1 DESCRIPTION …………………………………………………………………………………………………… 18-43

18.10.2 MAINTENANCE PROCEDURE…………………………………………………………………………….. 18-43

18.11LUBRICANT LEVEL SENSOR………………………………………………………………………………………… 18-44

18.11.1 DESCRIPTION …………………………………………………………………………………………………… 18-45

18.11.1.1 LEDS AT THE SONAR SENSOR……………………………………………………………. 18-46

18.12COMMISSIONING …………………………………………………………………………………………………………. 18-48

18.12.1 COMMISSIONING OF THE CLS1 & CLS2 LUBRICATION SYSTEMS………………………. 18-48

18.12.2 FINE ADJUSTMENT……………………………………………………………………………………………. 18-49

18.12.3 COMMISSIONING OF THE SLS LUBRICATION SYSTEM ………………………………………. 18-50

19 DEEP TEMPERATURE EQUIPMENT (OPTION)……………………………… 19-1

19.1 GENERAL INFORMATION……………………………………………………………………………………………….. 19-2

19.1.1 INTRODUCTION ………………………………………………………………………………………………….. 19-2

19.1.2 DEEP TEMPERATURE COMPONENTS OVERVIEW……………………………………………….. 19-2

19.1.3 POWER SUPPLY PRECONDITIONS FOR PREHEATING ………………………………………… 19-3

19.1.4 POWER REQUIREMENTS FOR PREHEATING SYSTEMS ………………………………………. 19-4

19.2 PREHEATING PROCEDURE ……………………………………………………………………………………………. 19-5

19.2.1 GLOBAL FLOW CHART OF THE PREHEATING PROCEDURE ………………………………… 19-5

19.2.2 STARTING THE PREHEATING PROCEDURE ………………………………………………………… 19-6

19.2.3 PREHEATING OF OPERATOR’S CAB AND DIESEL ENGINE

[COOLANT SYSTEM] 19-7

19.2.4 PREHEATING OF LUBRICANTS AND SUPERSTRUCTURE (DIESEL)

[ELECTRIC SYSTEM] …………………………………………………………………………………………… 19-8

19.3 CONSTANT HEATING OF TRAVEL MOTORS (TTT EQUIPMENT BELOW-40°C ONLY) ……….. 19-9

19.4 COMPONENT LOCATION………………………………………………………………………………………………. 19-10

19.4.1 ELECTRIC HEATING ELEMENTS FOR HYDRAULIC & BATTERIES

[ELECTRIC MACHINE]………………………………………………………………………………………… 19-10

19.4.2 ELECTRIC HEATING ELEMENTS FOR HYDRAULICS

[DIESEL MACHINE]…………………………………………………………………………………………….. 19-12

19.4.3 ELECTRIC HEATING ELEMENTS FOR ENGINES & BATTERIES

[DIESEL MACHINE]…………………………………………………………………………………………….. 19-14

19.5 COMPONENTS OF TT EQUIPMENT ……………………………………………………………………………….. 19-16

19.5.1 PREHEATING COMPONENTS ON A DIESEL MACHINE………………………………………… 19-16

19.5.2 PREHEATING COMPONENTS ON AN ELECTRIC MACHINE …………………………………. 19-17

19.5.3 EXEMPLARY WIRING DIAGRAMS FOR PREHEATING SYSTEMS …………………………. 19-18

19.5.3.1 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 1 OF 3 … 19-18

19.5.3.2 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 2 OF 3 … 19-19

19.5.3.3 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 3 OF 3 … 19-20

19.5.3.4 WIRING DIAGRAM “SUCTION OIL MANIFOLD PREHEATING”…………………. 19-21

19.5.3.5 WIRING DIAGRAM “PTO PREHEATING”………………………………………………… 19-22

19.5.3.6 WIRING DIAGRAM “BATTERY HEATER PADS”………………………………………. 19-23

IMAGES PREVIEW OF THE MANUAL: