$35

Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual EEAM022200 – PDF DOWNLOAD

Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual EEAM022200 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual EEAM022200 – PDF DOWNLOAD

Language : English

Pages : 386

Downloadable : Yes

File Type : PDF

Size: 16.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual EEAM022200 – PDF DOWNLOAD

- The Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual (EEAM022200) is a comprehensive resource for anyone who operates or maintains the Komatsu PC1800-6 hydraulic excavator. This manual provides important information on how to safely and effectively operate and maintain the excavator to ensure that it performs at its best and has a long, reliable service life.

- The manual includes detailed information on the various systems and components of the Komatsu PC1800-6 hydraulic excavator, including the hydraulic, electrical, and mechanical systems. This information is critical for understanding how the excavator functions and how to perform routine maintenance and repairs. The manual also provides step-by-step instructions for performing regular maintenance procedures, such as checking and replacing fluids, filters, and other components.

- The Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual also includes important safety information, including guidelines for safe operation and guidelines for working around the excavator. This information is crucial for ensuring that the excavator is operated safely and that workers are protected from potential hazards.

- In addition to providing important information on the operation and maintenance of the Komatsu PC1800-6 hydraulic excavator, the manual also includes detailed information on troubleshooting common problems that may arise with the excavator. This information can be invaluable for diagnosing and resolving issues quickly and efficiently, helping to minimize downtime and keep the excavator working.

- Overall, the Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual is an essential resource for anyone who operates or maintains the Komatsu PC1800-6 hydraulic excavator. Whether you are an experienced operator or just starting out, this manual provides a wealth of information that can help you get the most out of your excavator and keep it in top working condition.

TABLE OF CONTENTS:

Komatsu PC1800-6 Hydraulic Excavator Operation & Maintenance Manual EEAM022200 – PDF DOWNLOAD

FOREWORD……………………………………………………………………………….. 3

FOREWORD……………………………………………………………………………. 4

SAFETY INFORMATION…………………………………………………………………… 5

INTRODUCTION………………………………………………………………………… 7

DIRECTIONS OF MACHINE…………………………………………………………….. 7

PRODUCT INFORMATION………………………………………………………………….. 8

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION………………………………………… 8

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION…………………………………………. 8

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION………………………………….. 9

SERVICE METER LOCATION……………………………………………………………. 9

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR…………………………………………. 10

CONTENTS……………………………………………………………………………. 11

SAFETY…………………………………………………………………………………. 15

SAFETY INFORMATION…………………………………………………………………… 16

POSITION FOR ATTACHING SAFETY LABELS…………………………………………………… 18

POSITION FOR ATTACHING SAFETY LABELS……………………………………………….. 19

SAFETY LABELS……………………………………………………………………. 20

SAFETY INFORMATION…………………………………………………………………… 25

SAFETY RULES…………………………………………………………………….. 25

IF ABNORMALITIES ARE FOUND………………………………………………………… 25

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS………………………………………….. 25

FIRE EXTINGUISHER AND FIRST AID KIT………………………………………………… 25

SAFETY EQUIPMENT…………………………………………………………………. 26

KEEP MACHINE CLEAN……………………………………………………………….. 26

KEEP OPERATOR’S COMPARTMENT CLEAN………………………………………………….. 26

LEAVING OPERATOR’S SEAT WITH LOCK………………………………………………….. 26

HANDRAILS AND STEPS………………………………………………………………. 27

MOUNTING AND DISMOUNTING………………………………………………………….. 28

NO PERSONS ON ATTACHMENTS…………………………………………………………. 28

BURN PREVENTION………………………………………………………………….. 28

FIRE PREVENTION AND EXPLOSION PREVENTION……………………………………………. 29

ACTION IF FIRE OCCURS…………………………………………………………….. 30

WINDSHIELD WASHER FLUID…………………………………………………………… 30

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION………………………. 30

ATTACHMENT INSTALLATION…………………………………………………………… 30

ATTACHMENT COMBINATIONS…………………………………………………………… 31

CAB WIDOW GLASSES………………………………………………………………… 31

UNAUTHORIZED MODIFICATIONS………………………………………………………… 31

SAFETY AT JOBSITE………………………………………………………………… 31

WORKING ON LOOSE GROUND…………………………………………………………… 32

DISTANCE TO HIGH VOLTAGE CABLES……………………………………………………. 32

ENSURE GOOD VISIBILITY……………………………………………………………. 32

VENTILATION FOR ENCLOSED AREA……………………………………………………… 33

SIGNALMAN’S SIGNAL AND SIGNS………………………………………………………. 33

EMERGENCY EXIT FROM OPERATOR’S CAB…………………………………………………. 33

ASBESTOS DUST HAZARD PREVENTION……………………………………………………. 33

SAFETY MACHINE OPERATION……………………………………………………………… 34

STARTING ENGINE………………………………………………………………….. 34

CHECKS BEFORE STARTING ENGINE………………………………………………….. 34

SAFETY RULES FOR STARTING ENGINE……………………………………………….. 35

STARTING ENGINE IN COLD WEATHER………………………………………………… 35

OPERATION……………………………………………………………………….. 36

CHECKS AFTER STARTING ENGINE…………………………………………………… 36

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS…………………………………….. 36

SAFETY RULES FOR TRAVELING…………………………………………………….. 37

TRAVELING ON SLOPES…………………………………………………………… 38

OPERATIONS ON SLOPES………………………………………………………….. 39

PROHIBITED OPERATIONS…………………………………………………………. 39

OPERATIONS ON SNOW……………………………………………………………. 41

PARKING MACHINE………………………………………………………………. 41

TRANSPORTATION…………………………………………………………………… 42

SHIPPING THE MACHINE………………………………………………………….. 42

BATTERY…………………………………………………………………………. 43

BATTERY HAZARD PREVENTION……………………………………………………… 43

STARTING ENGINE WITH BOOSTER CABLES…………………………………………….. 44

TOWING………………………………………………………………………….. 45

SAFETY RULES FOR TOWING……………………………………………………….. 45

LIFTING OBJECTS WITH BUCKET……………………………………………………….. 46

SAFETY RULES FOR LIFTING OBJECTS……………………………………………….. 46

SAFETY MAINTENANCE INFORMATION………………………………………………………… 47

WARNING TAG……………………………………………………………………… 47

KEEP WORK PLACE CLEAN AND TIDY…………………………………………………….. 47

APPOINT LEADER WHEN WORKING WITH OTHERS…………………………………………….. 47

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE…………………………………………. 48

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…………………………………… 49

PROPER TOOLS…………………………………………………………………….. 49

ACCUMULATOR……………………………………………………………………… 50

PERSONNEL……………………………………………………………………….. 50

ATTACHMENTS……………………………………………………………………… 50

WORK UNDER THE MACHINE……………………………………………………………. 50

NOISE…………………………………………………………………………… 51

WHEN USING HAMMER………………………………………………………………… 51

WELDING WORKS……………………………………………………………………. 51

REMOVING BATTERY TERMINALS………………………………………………………… 51

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…………………… 52

DO NOT DISASSEMBLE RECOIL SPRINGS………………………………………………….. 52

SAFETY RULES FOR HIGH-PRESSURE OIL…………………………………………………. 52

PRECAUTION FOR HIGH FUEL PRESSURE………………………………………………….. 53

SAFETY HANDLING HIGH-PRESSURE HOSES………………………………………………… 53

PRECAUTION FOR HIGH VOLTAGE……………………………………………………….. 53

WASTE MATERIALS………………………………………………………………….. 53

AIR CONDITIONER MAINTENANCE……………………………………………………….. 54

COMPRESSED AIR…………………………………………………………………… 54

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS……………………………………….. 54

OPERATION………………………………………………………………………………. 55

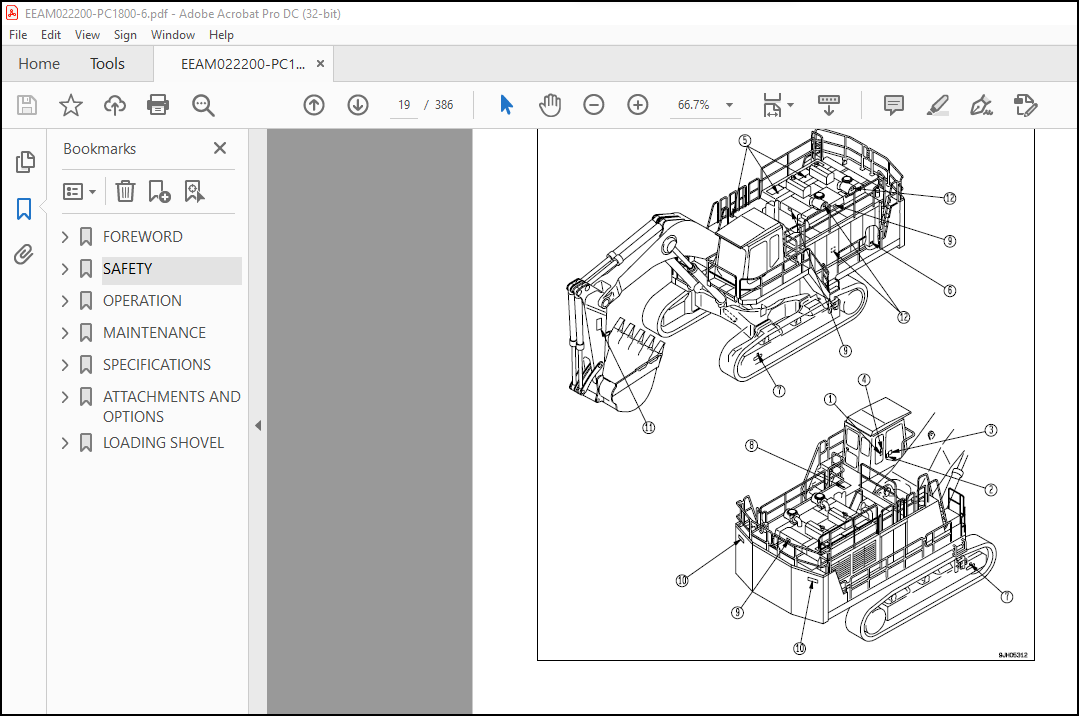

GENERAL VIEW………………………………………………………………………… 56

GENERAL VIEW OF MACHINE…………………………………………………………… 56

GENERAL VIEW OF CONTROLS AND GAUGES………………………………………………… 57

EXPLANATION OF COMPONENTS…………………………………………………………….. 59

MACHINE MONITOR………………………………………………………………….. 59

BASIC CHECK ITEMS…………………………………………………………….. 61

CAUTION ITEMS………………………………………………………………… 63

EMERGENCY STOP ITEMS………………………………………………………….. 65

METER DISPLAY PORTION…………………………………………………………. 67

PILOT DISPLAY………………………………………………………………… 67

GAUGES AND METER……………………………………………………………… 68

MONITOR SWITCHES……………………………………………………………… 71

CGC MONITOR……………………………………………………………………… 73

CGC MONITOR………………………………………………………………….. 73

CHANGES OF SCREEN AND CONTENT OF DISPLAY ON CGC MONITOR…………………………… 74

EXPLANATION OF SCREENS………………………………………………………… 76

SWITCHES…………………………………………………………………………111

STARTER SELECTOR SWITCH………………………………………………………..112

STARTING SWITCH……………………………………………………………….112

PREHEATING SWITCH……………………………………………………………..112

FUEL CONTROL DIAL (FRONT ENGINE)………………………………………………..113

FUEL CONTROL DIAL (REAR ENGINE)…………………………………………………113

CIGARETTE LIGHTER……………………………………………………………..113

LAMP SWITCH…………………………………………………………………..113

STEP LIGHT SWITCH……………………………………………………………..114

SWING LOCK SWITCH……………………………………………………………..114

ROOM LAMP SWITCH………………………………………………………………115

MACHINE PUSH-UP SWITCH…………………………………………………………115

FOG LAMP SWITCH……………………………………………………………….115

BOOM SHOCKLESS CONTROL SWITCH…………………………………………………..116

ROTATING LAMP SWITCH…………………………………………………………..116

ALARM BUZZER STOP SWITCH……………………………………………………….116

WINDSHIELD WIPER SWITCH………………………………………………………..117

GREASING SWITCH……………………………………………………………….117

HORN SWITCH…………………………………………………………………..117

TRUCK COUNTER SWITCH…………………………………………………………..118

ROOM LAMP SWITCH………………………………………………………………119

ROOM LAMP SWITCH………………………………………………………………120

ROOM LAMP SWITCH………………………………………………………………120

PUMP DRIVE EMERGENCY SWITCH…………………………………………………….120

SWING HOLDING BRAKE REPLEASE SWITCH……………………………………………..121

SPARE SOCKET………………………………………………………………….121

ENGINE EMERGENCY STOP SWITCH……………………………………………………121

LAMP…………………………………………………………………………….122

ENGINE EMERGENCY STOP LAMP……………………………………………………..123

AUTO GREASING CAUTION LAMP……………………………………………………..124

LADDER WARNING LAMP……………………………………………………………124

TRUCK COUNTER LAMP…………………………………………………………….125

CONTROL LEVERS, PEDALS…………………………………………………………….126

SAFETY LOCK LEVER……………………………………………………………..127

TRAVEL LEVERS…………………………………………………………………128

WORK EQUIPMENT CONTROL LEVER……………………………………………………129

DOOR LOCK………………………………………………………………………..130

POCKET…………………………………………………………………………..130

EMERGENCY ESCAPE HAMMER……………………………………………………………130

EMERGENCY ESCAPE LADDER……………………………………………………………131

FIRE EXTINGUISHER…………………………………………………………………131

CAP, COVER WITH LOCK………………………………………………………………132

METHOD OF OPENING AND CLOSING CAP WITH LOCK………………………………………132

METHOD OF OPENING AND CLOSING COVER WITH LOCK…………………………………….132

ASHTRAY………………………………………………………………………….132

HANDLING AIR CONDITIONER…………………………………………………………..133

GENERAL LOCATIONS OF CONTROL PANEL………………………………………………133

USE AIR CONDITIONER WITH CARE…………………………………………………..140

CAR RADIO………………………………………………………………………..141

EXPLANATION OF COMPONENTS………………………………………………………141

CONTROLS OF RADIO……………………………………………………………..144

AUXILIARY ELECTRIC POWER……………………………………………………….146

FUSE…………………………………………………………………………….146

CIRCUIT BREAKER…………………………………………………………………..147

CIRCUIT BREAKER (20A)………………………………………………………….147

CIRCUIT-BREAKER (40A)………………………………………………………….147

FUSE, CIRCUIT BREAKER CAPACITY AND NAME OF CIRCUIT………………………………..148

FUSE…………………………………………………………………………149

CONTROLLER (COMPUTER)……………………………………………………………..150

TOOLBOX………………………………………………………………………….151

HANDLING GREASE PUMP AND GREASE GUN…………………………………………………151

HANDLING ACCUMULATOR………………………………………………………………155

METHOD OF RELEASING PRESSURE IN CONTROL CIRCUIT ON MACHINE EQUIPPED WITH ACCUMULATOR….155

ORBCOMM CONTROLLER………………………………………………………………..156

MACHINE OPERATIONS AND CONTROLS………………………………………………………..157

BEFORE STARTING ENGINE…………………………………………………………….157

WALK-AROUND CHECKS…………………………………………………………….157

CHECKS BEFORE STARTING…………………………………………………………158

ADJUST BEFORE OPERATION………………………………………………………..170

SEAT BELT…………………………………………………………………….173

OPERATIONS BEFORE STARTING ENGINE……………………………………………….175

STARTING ENGINE…………………………………………………………………..178

NORMAL STARTING……………………………………………………………….178

STARTING ENGINE IN COLD WEATHER…………………………………………………180

AFTER STARTING ENGINE……………………………………………………………..183

BREAKING-IN THE NEW MACHINE…………………………………………………….183

WARMING-UP OPERATION…………………………………………………………..184

IN COLD AREAS…………………………………………………………………….187

STOPPING THE ENGINE……………………………………………………………….190

NORMAL STOPPING……………………………………………………………….190

STOPPING IN EMERGENCIES………………………………………………………..190

CHECK AFTER SHUT OFF ENGINE………………………………………………………..193

MACHINE OPERATION…………………………………………………………………194

PREPARATIONS FOR MOVING THE MACHINE OFF………………………………………….194

MOVING MACHINE FORWARD…………………………………………………………195

MOVING MACHINE BACKWARD………………………………………………………..196

STOPPING MACHINE………………………………………………………………197

STEERING THE MACHINE………………………………………………………………198

STEERING……………………………………………………………………..198

SWINGING…………………………………………………………………………200

WORK EQUIPMENT CONTROLS AND OPERATIONS………………………………………………201

HANDLING WORKING MODE……………………………………………………………..202

WORKING MODE………………………………………………………………….202

PROHIBITED OPERATIONS……………………………………………………………..203

OPERATIONS USING SWING FORCE……………………………………………………203

OPERATIONS USING TRAVEL FORCE…………………………………………………..203

OPERATIONS USING HYDRAULIC CYLINDER STROKE ENDS…………………………………..203

OPERATIONS USING BUCKET DROPPING FORCE…………………………………………..204

OPERATIONS USING MACHINE DROPPING FORCE………………………………………….204

DIGGING HARD ROCKY GROUND………………………………………………………204

GENERAL OPERATION INFORMATION………………………………………………………205

TRAVELING…………………………………………………………………….205

PERMISSIBLE WATER DEPTH………………………………………………………..205

TRAVELING ON SLOPES……………………………………………………………….206

TRAVELING DOWNHILL…………………………………………………………….207

ENGINE STOPPED ON SLOPE………………………………………………………..207

PRECAUTIONS ON SLOPES………………………………………………………….207

ESCAPE FROM MUD…………………………………………………………………..208

STUCK ONE SIDE OF TRACK………………………………………………………..208

STUCK BOTH SIDES OF TRACKS……………………………………………………..208

RECOMMENDED APPLICATIONS…………………………………………………………..209

BACKHOE WORK………………………………………………………………….209

LOADING WORK………………………………………………………………….209

REPLACEMENT AND INVERSION OF BUCKET…………………………………………………210

REPLACEMENT…………………………………………………………………..210

PARKING MACHINE…………………………………………………………………..212

CHECK AFTER FINISHING WORK…………………………………………………………213

LOCKING………………………………………………………………………….214

TRANSPORTATION……………………………………………………………………….215

PRECAUTIONS FOR TRANSPORTATION……………………………………………………..215

REMOVAL AND INSTALLATION OF MIRRORS……………………………………………..215

LIFTING MACHINE…………………………………………………………………..216

PARTS FOR TRANSPORT……………………………………………………………….216

COLD WEATHER OPERATION………………………………………………………………..217

COLD WEATHER OPERATION INFORMATION………………………………………………….217

FUEL AND LUBRICANTS……………………………………………………………217

COOLING SYSTEM COOLANT…………………………………………………………217

BATTERY………………………………………………………………………218

AFTER DAILY WORK COMPLETION………………………………………………………..219

AFTER COLD WEATHER SEASON………………………………………………………….219

LONG TERM STORAGE…………………………………………………………………….220

BEFORE STORAGE……………………………………………………………………220

DURING STORAGE……………………………………………………………………220

AFTER STORAGE…………………………………………………………………….221

STARTING MACHINE AFTER LONG-TERM STORAGE…………………………………………221

TROUBLESHOOTING………………………………………………………………………222

AFTER RUNNING OUT OF FUEL………………………………………………………….222

PHENOMENA THAT ARE NOT FAILURES…………………………………………………….223

TOWING THE MACHINE………………………………………………………………..224

PRECAUTIONS ON PARTICULAR JOBSITES………………………………………………….224

DISCHARGED BATTERY………………………………………………………………..225

REMOVAL AND INSTALLATION OF BATTERY……………………………………………..226

BATTERY CHARGES……………………………………………………………….226

STARTING ENGINE WITH BOOSTER CABLES……………………………………………..227

OTHER TROUBLE…………………………………………………………………….229

ELECTRICAL SYSTEM……………………………………………………………..229

CHASSIS………………………………………………………………………230

ENGINE……………………………………………………………………….231

ELECTRONIC CONTROL SYSTEM………………………………………………………233

MAINTENANCE……………………………………………………………………………..235

MAINTENANCE INFORMATION……………………………………………………………….236

SERVICE METER READING……………………………………………………………..236

KOMATSU GENUINE REPLACEMENT PARTS…………………………………………………..236

KOMATSU GENUINE LUBRICANTS…………………………………………………………236

WINDSHIELD WASHER FLUID……………………………………………………………236

FRESH AND CLEAN LUBRICANTS…………………………………………………………236

CHECK DRAINED OIL AND USED FILTER…………………………………………………..236

FUEL STRAINER…………………………………………………………………….236

WELDING INSTRUCTIONS………………………………………………………………236

DO NOT DROP THINGS INSIDE MACHINE…………………………………………………..237

DUSTY JOBSITE…………………………………………………………………….237

AVOID MIXING LUBRICANTS……………………………………………………………237

LOCKING THE INSPECTION COVERS………………………………………………………237

HYDRAULIC SYSTEM – AIR BLEEDING…………………………………………………….237

HYDRAULIC HOSE INSTALLATION………………………………………………………..237

CHECKS AFTER INSPECTION AND MAINTENANCE WORKS………………………………………..238

LUBRICANTS, COOLANT AND FILTERS………………………………………………………..239

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC………………………………..239

OIL………………………………………………………………………….239

FUEL…………………………………………………………………………239

COOLING SYSTEM COOLANT…………………………………………………………240

GREASE……………………………………………………………………….240

CARRYING OUT KOWA (Komatsu Oil Wear Analysis)…………………………………….240

OIL AND FUEL STORAGE…………………………………………………………..241

FILTERS………………………………………………………………………242

ELECTRIC SYSTEM MAINTENANCE………………………………………………………..242

WEAR PARTS LIST………………………………………………………………………243

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE……………………….244

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS……………………………………..244

TIGHTENING TORQUE SPECIFICATIONS……………………………………………………….248

TIGHTENING TORQUE LIST…………………………………………………………….248

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS……………………………………………249

SAFETY CRITICAL PARTS……………………………………………………………..250

MAINTENANCE SCHEDULE………………………………………………………………….252

MAINTENANCE SCHEDULE CHART…………………………………………………………252

Initial 100 Hours Maintenance (Only after the first 250 hours)……………………..252

Initial 250 Hours Maintenance (Only after the first 250 hours)……………………..252

When Required…………………………………………………………………252

Checks Before Starting…………………………………………………………252

Every 10 Hours Maintenance……………………………………………………..252

Every 100 Hours Maintenance…………………………………………………….253

Every 250 Hours Maintenance…………………………………………………….253

Every 500 Hours Maintenance…………………………………………………….253

Every 1000 Hours Maintenance……………………………………………………253

Every 2000 Hours Maintenance……………………………………………………254

Every 4000 Hours Maintenance……………………………………………………254

Every 5000 Hours Maintenance……………………………………………………254

Every 8000 Hours Maintenance……………………………………………………254

MAINTENANCE PROCEDURE…………………………………………………………………255

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)…………………………255

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)…………………………255

WHEN REQUIRED…………………………………………………………………….256

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT……………………………………..256

CLEAN INSIDE OF COOLING SYSTEM………………………………………………….259

CHECK AND TIGHTEN TRACK SHOE BOLTS………………………………………………263

CHECK AND ADJUST TRACK TENSION………………………………………………….264

CHECK ELECTRICAL INTAKE AIR HEATER………………………………………………267

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)…………………………………………268

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)……………………………………….271

ADJUST BUCKET CLEARANCE………………………………………………………..272

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID……………………………………….273

CHECK AND ADJUST AIR CONDITIONER………………………………………………..274

CLEANING, REMOVING DIRT FROM LINE FILTER…………………………………………275

REPLACEMENT OF FAN BELT AND ADJUSTMENT OF AUTO TENSIONER…………………………..276

GREASE LADDER…………………………………………………………………277

INSPECT SEALANT AROUND ENGINE COOLING SYSTEM……………………………………..278

CHECK FOR LOOSE AFTERCOOLER HOSE CLAMPS………………………………………….279

PROCEDURE FOR BLEEDING AIR FROM HYDRAULIC CIRCUIT…………………………………279

METHOD FOR RELEASING INTERNAL PRESSURE IN HYDRAULIC CIRCUIT………………………..287

CHECK BEFORE STARTING……………………………………………………………..289

EVERY 10 HOURS MAINTENANCE…………………………………………………………290

LUBRICATING…………………………………………………………………..290

EVERY 100 HOURS MAINTENANCE………………………………………………………..294

CHECK OIL LEVEL IN SWING MACHINERY CASE………………………………………….294

EVERY 250 HOURS MAINTENANCE………………………………………………………..295

GREASING FAN PULLEY ASSEMBLY, TENSION PULLEY ASSEMBLY……………………………..295

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL……………………………………..295

CHECK LEVEL OF BATTERY ELECTROLYTE………………………………………………296

REPLACE FILTER ELEMENT OF HYDRAULIC TANK BREATHER…………………………………298

CHECK, WASH FUEL STRAINER………………………………………………………299

CHECK AND TIGHTEN TRACK FRAME AND AXLE CONNECTING BOLTS……………………………300

CHECK ALTERNATOR DRIVE BELT TENSION, ADJUST………………………………………301

CHECK ADJUST TENSION OF AIR CONDITIONER COMPRESSOR BELT……………………………303

EVERY 500 HOURS MAINTENANCE………………………………………………………..305

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…………………..305

REPLACE FUEL FILTER CARTRIDGE…………………………………………………..308

CLEAN PILOT FILTER STRAINER…………………………………………………….310

CLEAN HYDRAULIC FILTER STRAINER FOR AUTO GREASING DRIVE……………………………310

CHANGE HYDRAULIC FILTER ELEMENT…………………………………………………311

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS, FUEL COOLER AND AFTER COOLER FINS…..312

CLEAN INTERNAL AND EXTERNAL AIR FILTERS OF AIR CONDITIONER SYSTEM…………………..314

CLEAN STRAINER OF PTO LUBRICATING OIL FILTER……………………………………..316

CHECK, REPLACE, ADJUST FAN BELT…………………………………………………317

CHECK, REPLACE HYDRAULIC PUMP DRAIN FILTER CARTRIDGE………………………………318

REPLACING SWING MOTOR DRAIN FILTER CARTRIDGE……………………………………..319

REPLACING TRAVEL MOTOR DRAIN FILTER CARTRIDGE…………………………………….320

EVERY 1000 HOURS MAINTENANCE……………………………………………………….321

CHANGE OIL IN SWING MACHINERY CASE………………………………………………321

CHANGE OIL IN PTO CASE…………………………………………………………323

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER……………………………………….323

REPLACE CORROSION RESISTOR CARTRIDGE…………………………………………….324

INSPECTION OF WELDED STRUCTURE AFTER INITIAL 4000 HOURS SERVICE…………………….324

EVERY 2000 HOURS MAINTENANCE……………………………………………………….325

CHANGE OIL IN FINAL DRIVE CASE………………………………………………….325

CHANGE OIL IN HYDRAULIC TANK, WASH STRAINER………………………………………326

CHECK SWING PINION GREASE LEVEL, ADD GREASE………………………………………329

CLEAN ENGINE BREATHER………………………………………………………….329

CLEAN, CHECK TURBOCHARGER………………………………………………………329

CHECK ALTERNATOR AND STARTING MOTOR……………………………………………..329

CHECK ENGINE VALVE CLEARANCES, ADJUST……………………………………………330

CHECK INJECTOR………………………………………………………………..330

EVERY 4000 HOURS MAINTENENCE……………………………………………………….331

CHECK WATER PUMP………………………………………………………………331

CHECK VIBRATION DAMPER…………………………………………………………331

CHECK FAN PULLEY AND TENSION PULLEY……………………………………………..331

REPLACE INJECTOR NOZZLE ASSEMBLY………………………………………………..331

CHECK FOR LOOSENESS OF HIGH-PRESSURE CLAMP, HARDENING OF RUBBER…………………….332

CHECK FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER……………………333

CHECK, ADJUST AIR COMPRESSOR……………………………………………………333

CHECK WELDED STRUCTURE…………………………………………………………334

EVERY 5000 HOURS MAINTENANCE……………………………………………………….337

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER……………………………………..337

EVERY 8000 HOURS MAINTENANCE……………………………………………………….340

REPLACE HIGH-PRESSURE PIPING CLAMP………………………………………………340

REPLACE FUEL SPRAY PREVENTION CAP……………………………………………….340

SPECIFICATIONS…………………………………………………………………………..341

SPECIFICATIONS……………………………………………………………………….342

ATTACHMENTS AND OPTIONS…………………………………………………………………..345

GENERAL PRECAUTIONS…………………………………………………………………..346

PRECAUTIONS RELATED TO SAFETY………………………………………………………346

PRECAUTIONS WHEN INSTALLING ATTACHMENTS……………………………………………..348

ATTACHMENT GUIDE……………………………………………………………………..349

COMBINATIONS OF WORK EQUIPMENT……………………………………………………..349

PROTECTIVE GUARD………………………………………………………………….350

AUTO GREASING SYSTEM………………………………………………………………351

CONTROL DEVICES……………………………………………………………….352

LOADING SHOVEL…………………………………………………………………………..355

GENERAL VIEW…………………………………………………………………………356

GENERAL VIEW OF MACHINE……………………………………………………………356

GENERAL VIEW OF CONTROLS AND GAUGES…………………………………………………357

EXPLANATION OF COMPONENTS……………………………………………………………..358

SWITCHES…………………………………………………………………………358

AUTOMATIC LEVEL CROWDING/BUCKET ANGLE COMPENSATION SWITCH………………………….358

AUTOMATIC LEVEL CROWDING SWITCH…………………………………………………358

BUCKET ANGLE COMPENSATION SWITCH………………………………………………..358

BOTTOM DUMP SWITCH…………………………………………………………….359

HORN SWITCH…………………………………………………………………..359

CONTROL BOX………………………………………………………………………359

OPERATIONS…………………………………………………………………………..360

OPERATION OF WORK EQUIPMENT………………………………………………………..360

PRECAUTIONS DURING OPERATION……………………………………………………….362

EXCAVATOR WORK……………………………………………………………………366

PRECAUTIONS WHEN DISASSEMBLING MACHINE………………………………………………….367

RELEASING PRESSURE………………………………………………………………..367

RELEASING PRESSURE FROM WORK EQUIPMENT CIRCUIT, SWING CIRCUIT, TRAVEL CIRCUIT………..367

RELEASING PRESSURE IN ACCUMULATOR CIRCUIT………………………………………..367

TROUBLESHOOTING………………………………………………………………………368

WORK EQUIPMENT AUTOMATIC CONTROL CONTROLLER………………………………………….368

TRANSPORTATION……………………………………………………………………….369

MACHINE CONFIGURATION FOR TRANSPORT…………………………………………………369

MAINTENANCE SCHEDULE………………………………………………………………….370

EVERY 10 HOURS MAINTENANCE…………………………………………………………370

PREPARATIONS BEFORE LUBRICATION…………………………………………………370

LUBRICATION…………………………………………………………………..373

SPECIFICATION………………………………………………………………………..379

COMBINATION OF WORK EQUIPMENT………………………………………………………….381

COMBINATION OF WORK EQUIPMENT………………………………………………………381

INDEX……………………………………………………………………………….383