$37

Komatsu PC2000-11R Hydraulic Excavator Operation & Maintenance Manual PEN01462-03 – PDF DOWNLOAD

Komatsu PC2000-11R Hydraulic Excavator Operation & Maintenance Manual PEN01462-03 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC2000-11R Hydraulic Excavator Operation & Maintenance Manual PEN01462-03 – PDF DOWNLOAD

Language : English

Pages : 599

Downloadable : Yes

File Type : PDF

Size: 38 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC2000-11R Hydraulic Excavator Operation & Maintenance Manual PEN01462-03 – PDF DOWNLOAD

READ THIS MANUAL:

- This manual gives details of the operation and methods of inspection and maintenance for this machine that

must be observed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental

safety rules for the operation and maintenance of machines. - Read, understand and follow all precautions and warnings in this manual and on the machine before performing

operation and maintenance. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that might involve a potential hazard when the machine is used. - Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions.

If you perform any operation, inspection, or maintenance under conditions that are not described in this manual,

understand that it is your responsibility to take the necessary precautions to ensure safety. In no event should

you or others engage in the prohibited uses or actions described in this manual. It is dangerous to perform improper

operation and maintenance of the machine. It may cause serious injury or death.

If you sell the machine, be sure to give this manual to the new owner together with the machine. - Always keep this Operation and Maintenance Manual in the indicated location so that all relevant personnel can

read it at any time.

Keep it in the magazine box on the left side of the operator’s

seat. - If this manual is lost, damaged, or unreadable, contact Komatsu or your Komatsu distributor and tell them about

the machine model name and the serial No. immediately to arrange for its replacement.

For the machine model name and the serial No., see the machine serial No. plate. In order to arrange the proper

Operation and Maintenance Manual, you will need to provide the machine model name and the serial No. - This manual uses the International System of Units (SI) for units of measurement. For reference, units that have

been used in the past are given in { }. - The explanations, values, and illustrations in this manual have been prepared based on the latest information

available as of the date of its publication. Continuing improvements in the design of this machine may lead to

additional changes that are not reflected in this manual. If there is any question or suggestion, consult your Komatsu

distributor. - The numbers in the illustrations correspond to the numbers in ( ) in the text. (Example: 1 → (1))

Komatsu delivers machines that comply with all applicable regulations and standards of the country to which it

has been shipped. If this machine has been purchased in another country, it may lack certain safety devices and

specifications that are necessary for use in your country. If there is any question about whether your product

complies with the applicable standards and regulations of your country, consult your Komatsu distributor before

operating the machine.

TABLE OF CONTENTS:

Komatsu PC2000-11R Hydraulic Excavator Operation & Maintenance Manual PEN01462-03 – PDF DOWNLOAD

COVER………………………………………………………………………………………………………………………………… 1

FOREWORD…………………………………………………………………………………………………………………………….. 2

CONTENTS…………………………………………………………………………………………………………………………. 3

READ THIS MANUAL………………………………………………………………………………………………………………….. 7

SAFETY INFORMATION………………………………………………………………………………………………………………… 8

INTRODUCTION……………………………………………………………………………………………………………………… 9

MAIN USE OF MACHINE……………………………………………………………………………………………………………. 9

DIRECTIONS OF MACHINE………………………………………………………………………………………………………….. 9

VISIBILITY FROM OPERATOR’S SEAT…………………………………………………………………………………………………. 10

PRODUCT INFORMATION……………………………………………………………………………………………………………….. 11

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…………………………………………………………….. 11

LOCATION OF ENGINE NUMBER PLATE…………………………………………………………………………………………………. 11

SERVICE METER LOCATION…………………………………………………………………………………………………………. 12

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR………………………………………………………………………………………. 12

ABBREVIATION LIST…………………………………………………………………………………………………………………. 13

SAFETY………………………………………………………………………………………………………………………………. 14

SAFETY LABELS…………………………………………………………………………………………………………………….. 15

LOCATION OF SAFETY LABELS………………………………………………………………………………………………………. 16

CONTENTS OF SAFETY LABELS………………………………………………………………………………………………………. 19

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE……………………………………………………………………………….. 26

PRECAUTIONS BEFORE STARTING OPERATION……………………………………………………………………………………………. 26

ENSURE SAFE OPERATION………………………………………………………………………………………………………. 26

UNDERSTAND THE MACHINE……………………………………………………………………………………………………… 26

PREPARATIONS FOR SAFE OPERATION…………………………………………………………………………………………………. 26

PRECAUTIONS FOR SAFETY-RELATED EQUIPMENT……………………………………………………………………………………… 26

INSPECT MACHINE……………………………………………………………………………………………………………. 26

WEAR WELL-FITTING CLOTHES AND PROTECTIVE EQUIPMENT…………………………………………………………………………….. 26

KEEP MACHINE CLEAN…………………………………………………………………………………………………………. 27

PRECAUTIONS FOR INSIDE OPERATOR’S COMPARTMENT…………………………………………………………………………………. 27

PROVIDE FIRE EXTINGUISHER AND FIRST AID KIT…………………………………………………………………………………… 27

IF ANY PROBLEM IS FOUND…………………………………………………………………………………………………….. 27

PRECAUTIONS TO PREVENT FIRE…………………………………………………………………………………………………….. 28

ACTIONS IF FIRE OCCURS……………………………………………………………………………………………………… 28

PREVENT FIRE………………………………………………………………………………………………………………. 28

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE……………………………………………………………………………………….. 30

USE HANDRAILS AND STEPS WHEN GETTING ON OR OFF MACHINE…………………………………………………………………………. 30

NO JUMPING ON OR OFF MACHINE………………………………………………………………………………………………… 30

NO PEOPLE ON ATTACHMENTS……………………………………………………………………………………………………. 30

PRECAUTIONS WHEN STANDING UP FROM OPERATOR’S SEAT……………………………………………………………………………… 31

PRECAUTIONS WHEN LEAVING MACHINE…………………………………………………………………………………………….. 31

EMERGENCY EXIT FROM OPERATOR’S CAB…………………………………………………………………………………………… 31

DO NOT GET CAUGHT IN WORK EQUIPMENT……………………………………………………………………………………………… 31

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES……………………………………………………………………………………… 32

PROTECTION AGAINST FALLING, FLYING OR INTRUDING OBJECTS……………………………………………………………………………. 32

UNAUTHORIZED MODIFICATION………………………………………………………………………………………………………. 32

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS……………………………………………………………………………………. 33

PRECAUTIONS RELATED TO CAB GLASS………………………………………………………………………………………………… 33

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING…………………………………………………………………………………… 33

PRECAUTIONS FOR OPERATION………………………………………………………………………………………………………….. 34

PRECAUTIONS FOR JOBSITE………………………………………………………………………………………………………… 34

INVESTIGATE AND CONFIRM JOBSITE CONDITIONS……………………………………………………………………………………. 34

PRECAUTIONS WHEN WORKING ON LOOSE GROUND……………………………………………………………………………………… 34

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES……………………………………………………………………………………….. 34

ENSURE GOOD VISIBILITY……………………………………………………………………………………………………… 35

CHECK SIGNS AND SIGNALMAN’S SIGNALS………………………………………………………………………………………….. 35

BEWARE OF ASBESTOS DUST…………………………………………………………………………………………………….. 36

START ENGINE………………………………………………………………………………………………………………….. 36

USE WARNING TAGS…………………………………………………………………………………………………………… 36

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE………………………………………………………………………………….. 37

PRECAUTIONS WHEN STARTING ENGINE…………………………………………………………………………………………….. 38

IN COLD WEATHER……………………………………………………………………………………………………………. 38

START ENGINE WITH JUMPER CABLES……………………………………………………………………………………………… 38

START WITH JUMP START RECEPTACLE…………………………………………………………………………………………….. 38

PRECAUTIONS FOR OPERATION………………………………………………………………………………………………………. 39

CHECKS BEFORE OPERATION…………………………………………………………………………………………………….. 39

PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE AND SWINGING…………………………………………………………………… 40

PRECAUTIONS WHEN TRAVELING………………………………………………………………………………………………….. 41

PRECAUTIONS WHEN TRAVELING ON SLOPES…………………………………………………………………………………………. 42

PRECAUTIONS WHEN OPERATING ON SLOPES…………………………………………………………………………………………. 43

PROHIBITED OPERATIONS………………………………………………………………………………………………………. 43

PRECAUTIONS WHEN OPERATING ON SNOW OR FROZEN SURFACES………………………………………………………………………….. 45

PRECAUTIONS WHEN PARKING MACHINE…………………………………………………………………………………………….. 45

PRECAUTIONS FOR TRANSPORTATION………………………………………………………………………………………………….. 46

PRECAUTIONS WHEN LOADING AND UNLOADING……………………………………………………………………………………….. 46

TOWING AND BEING TOWED…………………………………………………………………………………………………………. 47

PRECAUTIONS FOR TOWING AND BEING TOWED……………………………………………………………………………………….. 47

LIFTING OPERATION BY USING BUCKET WITH HOOK………………………………………………………………………………………. 47

PRECAUTIONS FOR LIFTING OPERATIONS…………………………………………………………………………………………… 47

PRECAUTIONS FOR MAINTENANCE………………………………………………………………………………………………………… 49

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE…………………………………………………………………………….. 49

DISPLAY WARNING TAG DURING INSPECTION AND MAINTENANCE………………………………………………………………………….. 49

KEEP WORK PLACE CLEAN AND TIDY………………………………………………………………………………………………. 50

SELECT SUITABLE PLACE FOR INSPECTION AND MAINTENANCE…………………………………………………………………………… 50

ONLY AUTHORIZED PERSONNEL…………………………………………………………………………………………………… 50

APPOINT LEADER WHEN WORKING WITH OTHERS………………………………………………………………………………………. 50

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE……………………………………………………………………… 50

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…………………………………………………………………………….. 51

PRECAUTIONS WHEN INSTALLING, REMOVING, OR STORING ATTACHMENTS…………………………………………………………………… 51

PRECAUTIONS FOR WORKING AT HIGH PLACES……………………………………………………………………………………….. 52

PRECAUTIONS WHEN WORKING ON MACHINE………………………………………………………………………………………….. 52

PRECAUTIONS WHEN WORKING UNDER MACHINE OR WORK EQUIPMENT……………………………………………………………………….. 52

USE PROPER TOOLS…………………………………………………………………………………………………………… 53

PRECAUTIONS FOR CHECK AND MAINTENANCE……………………………………………………………………………………………. 54

TURN BATTERY ISOLATOR SWITCH TO OFF POSITION………………………………………………………………………………….. 54

PRECAUTIONS FOR WELDING…………………………………………………………………………………………………….. 54

HANDLE BATTERY…………………………………………………………………………………………………………….. 54

PRECAUTIONS WHEN USING HAMMER……………………………………………………………………………………………….. 55

PRECAUTIONS FOR HIGH-TEMPERATURE COOLANT……………………………………………………………………………………… 56

PRECAUTIONS FOR HIGH-TEMPERATURE OIL…………………………………………………………………………………………. 56

PRECAUTIONS FOR HIGH-TEMPERATURE PARTS……………………………………………………………………………………….. 56

PRECAUTIONS FOR HIGH-PRESSURE OIL……………………………………………………………………………………………. 56

PRECAUTIONS FOR HIGH-PRESSURE FUEL…………………………………………………………………………………………… 57

HANDLE HIGH-PRESSURE HOSES AND PIPING………………………………………………………………………………………… 57

PRECAUTIONS FOR HIGH VOLTAGE………………………………………………………………………………………………… 57

PRECAUTIONS FOR NOISE………………………………………………………………………………………………………. 57

PRECAUTIONS FOR HIGH-PRESSURE GREASE WHEN ADJUSTING TRACK TENSION……………………………………………………………….. 58

HANDLE ACCUMULATOR AND GAS SPRING……………………………………………………………………………………………. 58

PRECAUTIONS FOR COMPRESSED AIR………………………………………………………………………………………………. 58

MAINTENANCE OF AIR CONDITIONER………………………………………………………………………………………………. 58

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS………………………………………………………………………………….. 59

METHOD FOR SELECTING WINDOW WASHER FLUID……………………………………………………………………………………… 59

PERIODIC INSPECTION OF DEFINED LIFE PARTS…………………………………………………………………………………….. 59

OPERATION……………………………………………………………………………………………………………………………. 60

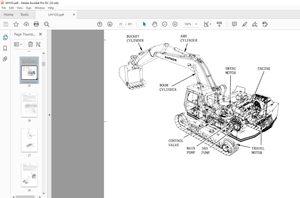

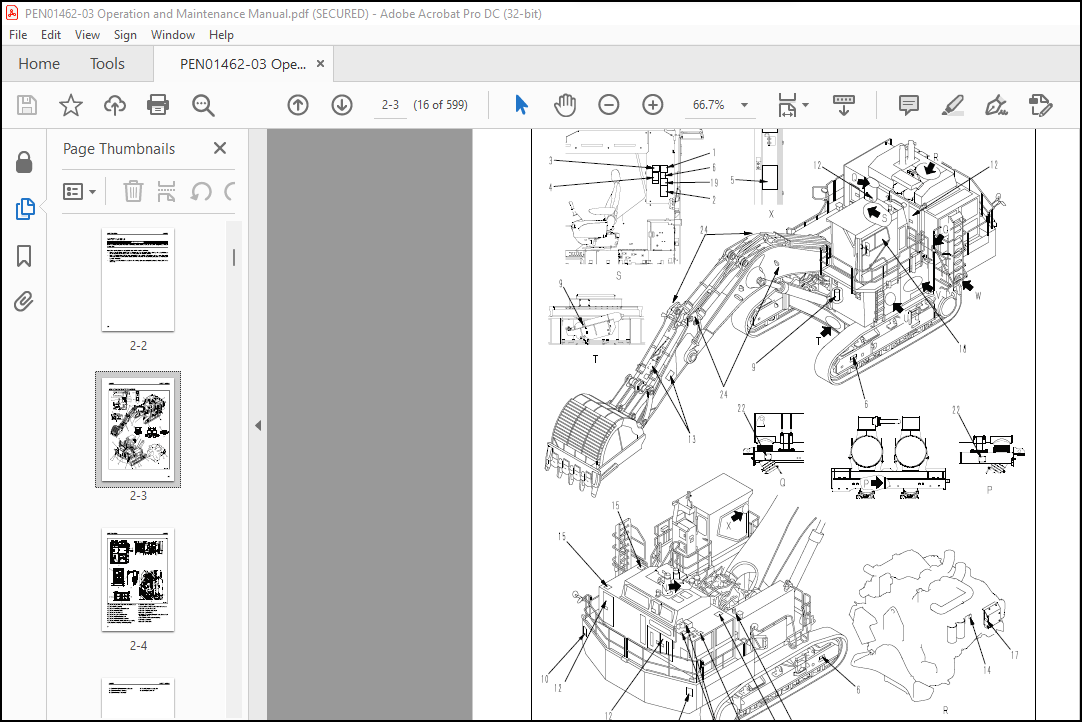

GENERAL VIEW……………………………………………………………………………………………………………………… 61

MACHINE EQUIPMENT NAME…………………………………………………………………………………………………………. 61

CAB EQUIPMENT NAMES……………………………………………………………………………………………………………. 64

CONTROLS AND GAUGES NAMES………………………………………………………………………………………………………. 65

MACHINE MONITOR EQUIPMENT NAME………………………………………………………………………………………………. 67

EXPLANATION OF COMPONENTS………………………………………………………………………………………………………….. 71

EXPLANATION OF MACHINE MONITOR EQUIPMENT…………………………………………………………………………………………. 71

BASIC OPERATION OF MACHINE MONITOR…………………………………………………………………………………………… 73

WARNING DISPLAY……………………………………………………………………………………………………………. 80

ACTION LEVEL DISPLAY……………………………………………………………………………………………………….. 82

ENGINE COOLANT TEMPERATURE CAUTION LAMP………………………………………………………………………………………. 87

HYDRAULIC OIL TEMPERATURE CAUTION LAMP……………………………………………………………………………………….. 87

FUEL LEVEL CAUTION LAMP…………………………………………………………………………………………………….. 88

PTO OIL TEMPERATURE CAUTION LAMP…………………………………………………………………………………………….. 88

ENGINE OIL TEMPERATURE CAUTION LAMP………………………………………………………………………………………….. 88

ENGINE OIL PRESSURE CAUTION LAMP…………………………………………………………………………………………….. 89

SYSTEM CAUTION LAMP………………………………………………………………………………………………………… 89

HYDRAULIC SYSTEM CAUTION LAMP……………………………………………………………………………………………….. 90

MAIN PUMP OUTPUT SYSTEM CAUTION LAMP…………………………………………………………………………………………. 90

ENGINE SYSTEM CAUTION LAMP………………………………………………………………………………………………….. 91

ENGINE SUDDEN STOP BY AUTO IDLE STOP CAUTION LAMP……………………………………………………………………………… 91

FAN CONTROL SYSTEM CAUTION LAMP……………………………………………………………………………………………… 92

ENGINE OIL PRESSURE CAUTION LAMP…………………………………………………………………………………………….. 92

ENGINE OIL LEVEL CAUTION LAMP……………………………………………………………………………………………….. 92

ENGINE OVERRUN CAUTION LAMP…………………………………………………………………………………………………. 93

RADIATOR COOLANT LEVEL CAUTION LAMP………………………………………………………………………………………….. 93

CHARGE LEVEL CAUTION LAMP…………………………………………………………………………………………………… 93

HYDRAULIC OIL LEVEL CAUTION LAMP…………………………………………………………………………………………….. 94

HYDRAULIC OIL FILTER CLOGGING CAUTION LAMP……………………………………………………………………………………. 94

AIR CLEANER CLOGGING CAUTION LAMP……………………………………………………………………………………………. 95

MAINTENANCE TIME CAUTION LAMP……………………………………………………………………………………………….. 96

SEATBELT CAUTION LAMP………………………………………………………………………………………………………. 96

CAMERA SYSTEM CAUTION LAMP………………………………………………………………………………………………….. 97

AUTO-GREASING CAUTION LAMP………………………………………………………………………………………………….. 97

AUTO-GREASING LEVEL CAUTION LAMP…………………………………………………………………………………………….. 98

WATER SEPARATOR CAUTION LAMP………………………………………………………………………………………………… 98

PILOT DISPLAY AND METER DISPLAY………………………………………………………………………………………………100

MONITOR SWITCHES……………………………………………………………………………………………………………117

FUNCTION SWITCHES…………………………………………………………………………………………………………..127

USER MENU………………………………………………………………………………………………………………….131

SWITCHES (INSIDE OF CAB)………………………………………………………………………………………………………..165

STARTING SWITCH…………………………………………………………………………………………………………….166

FUEL CONTROL DIAL…………………………………………………………………………………………………………..166

EMERGENCY ENGINE STOP SWITCH…………………………………………………………………………………………………167

CIGARETTE LIGHTER…………………………………………………………………………………………………………..167

SWING LOCK SWITCH…………………………………………………………………………………………………………..168

WORKING LAMP SWITCH…………………………………………………………………………………………………………168

HORN SWITCH………………………………………………………………………………………………………………..169

ROOM LAMP SWITCH……………………………………………………………………………………………………………169

REVOLVING LAMP SWITCH……………………………………………………………………………………………………….169

ENGINE SHUTDOWN SECONDARY SWITCH……………………………………………………………………………………………..170

SEAT HEATER SWITCH………………………………………………………………………………………………………….171

MACHINE PUSH-UP SWITCH………………………………………………………………………………………………………171

STAIRCASE LIGHTING SWITCH……………………………………………………………………………………………………171

BOOM SHOCK ABSORBING CONTROL SWITCH…………………………………………………………………………………………..172

SERVICE CENTER SWITCH……………………………………………………………………………………………………….172

ADDITIONAL LAMP SWITCH………………………………………………………………………………………………………173

GREASING MODE SELECTOR SWITCH………………………………………………………………………………………………..174

TRUCK COUNTER SWITCH………………………………………………………………………………………………………..174

SWITCH FOR MIRROR WITH HEATED WIRE……………………………………………………………………………………………174

SWITCHES (INSIDE CAB BASE ROOM)………………………………………………………………………………………………….175

ROOM LAMP SWITCH (INSIDE CAB BASE ROOM)……………………………………………………………………………………….175

PUMP SECONDARY DRIVE SWITCH………………………………………………………………………………………………….176

SWING PARKING BRAKE CANCEL SWITCH…………………………………………………………………………………………….177

LOCK LEVER AUTOMATIC LOCK CANCEL SWITCH……………………………………………………………………………………….177

SWITCHES (OUTSIDE OF MACHINE)……………………………………………………………………………………………………178

ENGINE ROOM LAMP SWITCH……………………………………………………………………………………………………..179

PUMP ROOM LAMP SWITCH……………………………………………………………………………………………………….179

EMERGENCY ENGINE STOP SWITCH…………………………………………………………………………………………………180

STAIRWAY RAISE SWITCH……………………………………………………………………………………………………….183

STAIRWAY LOWER SWITCH……………………………………………………………………………………………………….184

STAIRCASE LIGHTING SWITCH……………………………………………………………………………………………………185

NIGHTTIME MAINTENANCE LAMP SWITCH…………………………………………………………………………………………….186

BATTERY ISOLATOR SWITCH……………………………………………………………………………………………………..187

STARTING MOTOR ISOLATOR SWITCH……………………………………………………………………………………………….188

CAUTION LAMP…………………………………………………………………………………………………………………..189

EMERGENCY ENGINE STOP INDICATOR………………………………………………………………………………………………190

STAIRWAY WARNING LAMP……………………………………………………………………………………………………….191

SYSTEM OPERATING LAMP……………………………………………………………………………………………………….191

CONTROL LEVERS AND PEDALS……………………………………………………………………………………………………….192

LOCK LEVER…………………………………………………………………………………………………………………192

TRAVEL LEVER……………………………………………………………………………………………………………….194

WORK EQUIPMENT CONTROL LEVER…………………………………………………………………………………………………195

OTHER EQUIPMENT………………………………………………………………………………………………………………..196

EMERGENCY ESCAPE HAMMER……………………………………………………………………………………………………..196

EMERGENCY LADDER……………………………………………………………………………………………………………197

METHOD FOR USING DOOR LOCK…………………………………………………………………………………………………..200

CAP AND COVER WITH LOCK……………………………………………………………………………………………………..200

MAGAZINE BOX……………………………………………………………………………………………………………….200

CUP HOLDER…………………………………………………………………………………………………………………200

ASHTRAY……………………………………………………………………………………………………………………201

HOOK………………………………………………………………………………………………………………………201

UTILITY BOX………………………………………………………………………………………………………………..201

POWER SUPPLY OUTLET…………………………………………………………………………………………………………202

FUSE………………………………………………………………………………………………………………………203

CIRCUIT BREAKER…………………………………………………………………………………………………………….206

CONTROLLER…………………………………………………………………………………………………………………209

TOOL BOX…………………………………………………………………………………………………………………..210

FIRE EXTINGUISHER…………………………………………………………………………………………………………..210

GREASE PUMP………………………………………………………………………………………………………………..211

ACCUMULATOR………………………………………………………………………………………………………………..219

KOMTRAX Plus……………………………………………………………………………………………………………….221

MACHINE OPERATIONS AND CONTROLS……………………………………………………………………………………………………..222

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE………………………………………………………………………………………222

METHOD FOR WALK-AROUND CHECK…………………………………………………………………………………………………222

METHOD FOR CHECKING BEFORE STARTING…………………………………………………………………………………………..224

METHOD FOR ADJUSTING………………………………………………………………………………………………………..246

METHOD FOR OPERATIONS AND CHECKS BEFORE STARTING ENGINE…………………………………………………………………………268

METHOD FOR STARTING ENGINE………………………………………………………………………………………………………272

METHOD FOR MANUAL PREHEATING WHEN STARTING ENGINE………………………………………………………………………………274

METHOD FOR STARTING ENGINE IN COLD WEATHER…………………………………………………………………………………….275

TURBOCHARGER PROTECTION FUNCTION……………………………………………………………………………………………..276

METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE……………………………………………………………………………..276

METHOD FOR CHECKING STARTING CONDITION AND UNUSUAL NOISE OF ENGINE……………………………………………………………….277

METHOD FOR CHECKING LOW-SPEED RUN AND ACCELERATION OF ENGINE…………………………………………………………………….277

METHOD FOR RUNNING-IN THE NEW MACHINE…………………………………………………………………………………………277

METHOD FOR ENGINE WARM-UP OPERATION…………………………………………………………………………………………..277

METHOD FOR HYDRAULIC SYSTEM WARM-UP OPERATION………………………………………………………………………………….280

AIR CONDITIONER WARM-UP OPERATION…………………………………………………………………………………………….284

METHOD FOR OPERATION AFTER COMPLETION OF WARM-UP OPERATION………………………………………………………………………285

METHOD FOR STOPPING ENGINE………………………………………………………………………………………………………286

STOP ENGINE IN EMERGENCY…………………………………………………………………………………………………….288

STOP ENGINE IF FIRE OCCURS…………………………………………………………………………………………………..294

METHOD FOR STARTING MACHINE (TRAVEL FORWARD AND REVERSE) AND STOPPING MACHINE…………………………………………………………296

PREPARATIONS FOR MOVING MACHINE………………………………………………………………………………………………296

METHOD FOR TRAVELING FORWARD…………………………………………………………………………………………………297

METHOD FOR TRAVELING REVERSE…………………………………………………………………………………………………297

METHOD FOR STOPPING MACHINE………………………………………………………………………………………………….298

METHOD FOR STEERING MACHINE……………………………………………………………………………………………………..299

METHOD FOR STEERING (CHANGE THE DIRECTION) MACHINE……………………………………………………………………………..299

METHOD FOR SWINGING MACHINE……………………………………………………………………………………………………..301

METHOD FOR OPERATING WORK EQUIPMENT………………………………………………………………………………………………302

HANDLE WORKING MODE…………………………………………………………………………………………………………….303

METHOD FOR SELECTING WORKING MODE…………………………………………………………………………………………….303

PROHIBITED OPERATIONS…………………………………………………………………………………………………………..304

PROHIBITION OF OPERATIONS USING SWING FORCE……………………………………………………………………………………304

PROHIBITION OF OPERATIONS USING TRAVEL FORCE…………………………………………………………………………………..304

PROHIBITION OF OPERATIONS USING HYDRAULIC CYLINDERS TO STROKE END………………………………………………………………..304

DO NOT PERFORM THE WORK IF FOREIGN MATERIAL IS ACCUMULATED AROUND HYDRAULIC CYLINDER……………………………………………….305

PROHIBITION OF OPERATIONS USING BUCKET DROPPING FORCE…………………………………………………………………………..305

PROHIBITION OF OPERATIONS USING BUCKET AS LEVER………………………………………………………………………………..305

PROHIBITION OF OPERATIONS USING MACHINE DROPPING FORCE………………………………………………………………………….306

PROHIBITION OF DIGGING OPERATION AT AN ANGLE WITHOUT ENGAGING TEETH………………………………………………………………306

PROHIBITION OF DIGGING OPERATION ON HARD ROCKY GROUND…………………………………………………………………………..306

PROHIBITION OF OPERATIONS WHEN MACHINE IS NOT STABLE……………………………………………………………………………307

PROHIBITION OF SWINGING OR TRAVELING WHEN ROCK IS ON TOP OF TRACK ASSEMBLY………………………………………………………..307

PROHIBITION OF SUDDEN LEVER OR PEDAL SHIFT DURING HIGH SPEED TRAVEL………………………………………………………………307

PROHIBITION OF HIGH-SPEED TRAVEL OPERATIONS ON ROUGH GROUND……………………………………………………………………..308

DO NOT TRAVEL LONG -TIME CONTINUOUSLY…………………………………………………………………………………………308

PRECAUTIONS FOR OPERATION……………………………………………………………………………………………………….309

PRECAUTIONS FOR TRAVELING……………………………………………………………………………………………………309

PRECAUTIONS WHEN PERFORMING OPERATIONS CONTINUOUSLY WITH THE WORK EQUIPMENT IN THE SAME POSTURE……………………………………..309

PERMISSIBLE DEPTH OF WATER, SOIL AND DIRT……………………………………………………………………………………..309

PRECAUTIONS FOR WORKING ON SLOPE…………………………………………………………………………………………………310

METHOD FOR ESCAPING FROM MUD…………………………………………………………………………………………………….311

RECOMMENDED APPLICATIONS………………………………………………………………………………………………………..312

DIGGING WORK……………………………………………………………………………………………………………….312

LOADING WORK……………………………………………………………………………………………………………….312

EFFECTIVE USE OF HYDRAULIC EXCAVATOR……………………………………………………………………………………………..313

METHOD FOR CHANGING BUCKET………………………………………………………………………………………………………314

METHOD FOR PARKING MACHINE………………………………………………………………………………………………………315

METHOD FOR CHECKING AFTER FINISHING WORK………………………………………………………………………………………….317

LOCK………………………………………………………………………………………………………………………….318

METHOD FOR OPENING AND CLOSING CAP WITH LOCK…………………………………………………………………………………..318

METHOD FOR OPENING AND CLOSING COVER WITH LOCK…………………………………………………………………………………319

METHOD FOR OPENING AND CLOSING CAB DOOR……………………………………………………………………………………….320

HANDLE AIR CONDITIONER……………………………………………………………………………………………………………..321

EXPLANATION OF AIR CONDITIONER EQUIPMENT………………………………………………………………………………………….322

OFF SWITCH…………………………………………………………………………………………………………………322

FAN SWITCH…………………………………………………………………………………………………………………322

TEMPERATURE CONTROL SWITCH…………………………………………………………………………………………………..323

VENT SELECTOR SWITCH………………………………………………………………………………………………………..324

AUTO SWITCH………………………………………………………………………………………………………………..327

FRESH/RECIRC AIR SELECTOR SWITCH……………………………………………………………………………………………..327

DISPLAY MONITOR…………………………………………………………………………………………………………….327

AIR CONDITIONER SWITCH………………………………………………………………………………………………………328

DEFROSTER SELECTOR SWITCH……………………………………………………………………………………………………328

SUNLIGHT SENSOR…………………………………………………………………………………………………………….328

METHOD FOR OPERATING AIR CONDITIONER……………………………………………………………………………………………..329

METHOD FOR AUTOMATIC OPERATION……………………………………………………………………………………………….329

METHOD FOR STOPPING AUTOMATIC OPERATION……………………………………………………………………………………….330

METHOD FOR MANUAL OPERATION………………………………………………………………………………………………….330

METHOD FOR STOPPING MANUAL OPERATION………………………………………………………………………………………….331

METHOD FOR OPERATING DEFROSTER……………………………………………………………………………………………….332

FUNCTIONS OF AIR CONDITIONER AND OTHERS…………………………………………………………………………………………..332

SELF-DIAGNOSIS FUNCTION OF AIR CONDITIONER…………………………………………………………………………………….332

FUNCTION OF SWITCHING SET TEMPERATURE DISPLAY………………………………………………………………………………….334

HANDLING RADIO…………………………………………………………………………………………………………………….335

EXPLANATION OF RADIO EQUIPMENT…………………………………………………………………………………………………..335

POWER BUTTON……………………………………………………………………………………………………………….335

BAND/AUX SELECTOR BUTTON…………………………………………………………………………………………………….335

VOLUME CONTROL BUTTON……………………………………………………………………………………………………….335

TUNING/TIME ADJUSTMENT BUTTON………………………………………………………………………………………………..335

PRESET BUTTON………………………………………………………………………………………………………………336

DISPLAY SELECTOR BUTTON……………………………………………………………………………………………………..336

SOUND CONTROL BUTTON………………………………………………………………………………………………………..336

DISPLAY……………………………………………………………………………………………………………………336

AUX……………………………………………………………………………………………………………………….336

METHOD FOR CONTROLLING RADIO…………………………………………………………………………………………………….337

METHOD FOR ADJUSTING FREQUENCY……………………………………………………………………………………………….337

METHOD FOR ADJUSTING FREQUENCY (AUTO PRESETTING)……………………………………………………………………………….338

METHOD FOR CALLING PRESET……………………………………………………………………………………………………338

METHOD FOR REGISTERING PRESET………………………………………………………………………………………………..338

METHOD FOR ADJUSTING SOUND BALANCE……………………………………………………………………………………………339

METHOD FOR ADJUSTING HIGH REGISTER RANGE (TREBLE)………………………………………………………………………………339

METHOD FOR ADJUSTING LOW REGISTER RANGE (BASS)…………………………………………………………………………………339

METHOD FOR ADJUSTING CLOCK…………………………………………………………………………………………………..339

STOW ANTENNA…………………………………………………………………………………………………………………..340

KomVision…………………………………………………………………………………………………………………………341

PRECAUTIONS WHEN USING KomVision…………………………………………………………………………………………………341

EXPLANATION OF KomVision COMPONENTS………………………………………………………………………………………………342

KomVision MONITOR EQUIPMENT NAME…………………………………………………………………………………………………343

EXPLANATION OF KomVision MONITOR EQUIPMENT………………………………………………………………………………………..344

MENU BUTTON………………………………………………………………………………………………………………..345

KomVision MONITOR DISPLAY……………………………………………………………………………………………………348

SYSTEM STATUS LAMP………………………………………………………………………………………………………….351

HANDLE ANCHOR POINT FOR TIE-OFF……………………………………………………………………………………………………..352

HANDLE AUTO-GREASING SYSTEM…………………………………………………………………………………………………………353

MACHINE OPERATIONS AND CONTROLS………………………………………………………………………………………………….353

METHOD FOR CHECKING BEFORE STARTING OPERATION………………………………………………………………………………….353

METHOD FOR OPERATING GREASING MODE SELECTOR SWITCH……………………………………………………………………………..353

TROUBLES AND ACTIONS……………………………………………………………………………………………………………355

AUTO-GREASING CAUTION LAMP…………………………………………………………………………………………………..356

INJECTOR ACTION INDICATOR……………………………………………………………………………………………………356

CHECK AND MAINTENANCE…………………………………………………………………………………………………………..358

METHOD FOR REPLACING GREASE CAN………………………………………………………………………………………………358

METHOD FOR BLEEDING AIR FROM GREASE LINE………………………………………………………………………………………358

INJECTOR POSITION IN AUTO-GREASING SYSTEM AND METHOD FOR GREASING………………………………………………………………..360

HANDLE THE HYDRAULICALLY OPERATED STAIRWAY……………………………………………………………………………………………362

PROCEDURE FOR OPERATING THE HYDRAULICALLY OPERATED STAIRWAY…………………………………………………………………………362

PROCEDURE FOR LOWERING STAIRWAY BY OPERATING FROM MACHINE……………………………………………………………………….363

PROCEDURE FOR STORING STAIRWAY BY OPERATING FROM MACHINE………………………………………………………………………..363

ACTIONS IF MACHINE DOES NOT MOVE BY PROXIMITY SWITCH FAILURE ETC…………………………………………………………………364

METHOD FOR CHECKING AND ADJUSTING PROXIMITY SWITCH……………………………………………………………………………..364

ACTIONS IF PROXIMITY SWITCH HAS FAILED………………………………………………………………………………………..366

STAIRWAY CAUTION LAMP……………………………………………………………………………………………………….366

TRANSPORTATION…………………………………………………………………………………………………………………….367

PRECAUTIONS FOR TRANSPORTING MACHINE……………………………………………………………………………………………..367

SELECT TRANSPORTATION METHOD…………………………………………………………………………………………………….367

METHOD FOR LIFTING THE UNITS FOR TRANSPORTATION……………………………………………………………………………………367

MACHINE CONFIGURATION FOR TRANSPORTATION………………………………………………………………………………………….367

COLD WEATHER OPERATION……………………………………………………………………………………………………………..368

COLD WEATHER OPERATION INFORMATION……………………………………………………………………………………………….368

FUEL AND LUBRICANTS…………………………………………………………………………………………………………368

COOLANT……………………………………………………………………………………………………………………368

BATTERY……………………………………………………………………………………………………………………369

PRECAUTIONS AFTER DAILY WORK COMPLETION IN COLD WEATHER…………………………………………………………………………….370

AFTER COLD WEATHER SEASON……………………………………………………………………………………………………….370

PRECAUTIONS FOR LONG-TERM STORAGE……………………………………………………………………………………………………371

PREPARATION FOR LONG-TERM STORAGE………………………………………………………………………………………………..371

MAINTENANCE DURING LONG-TERM STORAGE……………………………………………………………………………………………..371

STARTING MACHINE AFTER LONG-TERM STORAGE………………………………………………………………………………………….372

TROUBLES AND ACTIONS……………………………………………………………………………………………………………….373

ACTIONS WHEN RUNNING OUT OF FUEL…………………………………………………………………………………………………373

PROCEDURES FOR BLEEDING AIR FROM FUEL CIRCUIT………………………………………………………………………………….373

PHENOMENA THAT ARE NOT FAILURES………………………………………………………………………………………………….374

PRECAUTIONS FOR TOWING MACHINE…………………………………………………………………………………………………..375

PRECAUTIONS FOR SEVERE JOB CONDITION……………………………………………………………………………………………..375

PRECAUTIONS FOR DISCHARGED BATTERY……………………………………………………………………………………………….376

METHOD FOR REMOVING AND INSTALLING BATTERY…………………………………………………………………………………….376

PRECAUTIONS FOR CHARGING BATTERY……………………………………………………………………………………………..377

START ENGINE WITH JUMPER CABLES………………………………………………………………………………………………378

OTHER TROUBLE………………………………………………………………………………………………………………….380

PHENOMENA AND ACTIONS FOR ELECTRICAL SYSTEM……………………………………………………………………………………380

PHENOMENA AND ACTIONS FOR CHASSIS…………………………………………………………………………………………….381

PHENOMENA AND ACTIONS FOR ENGINE RELATED PARTS…………………………………………………………………………………383

IF MACHINE MONITOR SHOWS WARNING DISPLAY………………………………………………………………………………………385

MAINTENANCE…………………………………………………………………………………………………………………………..386

PRECAUTIONS FOR MAINTENANCE…………………………………………………………………………………………………………387

CHECK SERVICE METER READING……………………………………………………………………………………………………..387

KOMATSU GENUINE REPLACEMENT PARTS………………………………………………………………………………………………..387

KOMATSU GENUINE LUBRICANTS………………………………………………………………………………………………………387

ALWAYS USE CLEAN WASHER FLUID……………………………………………………………………………………………………387

FRESH AND CLEAN LUBRICANTS………………………………………………………………………………………………………387

CHECK DRAINED OIL AND USED FILTER………………………………………………………………………………………………..387

PRECAUTIONS FOR REFILLING OIL OR FUEL…………………………………………………………………………………………….387

PRECAUTIONS FOR WELDING…………………………………………………………………………………………………………387

DO NOT DROP THINGS INSIDE MACHINE………………………………………………………………………………………………..387

DUSTY JOBSITES…………………………………………………………………………………………………………………388

AVOID MIXING OIL……………………………………………………………………………………………………………….388

LOCK INSPECTION COVERS………………………………………………………………………………………………………….388

BLEED AIR FROM HYDRAULIC CIRCUIT…………………………………………………………………………………………………388

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES……………………………………………………………………………………….388

CHECKS AFTER INSPECTION AND MAINTENANCE…………………………………………………………………………………………..389

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE……………………………………………………………………………….389

OUTLINE OF MAINTENANCE……………………………………………………………………………………………………………..390

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC……………………………………………………………………………….391

OIL……………………………………………………………………………………………………………………….391

FUEL………………………………………………………………………………………………………………………392

BIO-FUEL…………………………………………………………………………………………………………………..392

PARAFFIN-BASED FUEL…………………………………………………………………………………………………………393

COOLANT AND WATER FOR DILUTION……………………………………………………………………………………………….394

GREASE…………………………………………………………………………………………………………………….394

PERFORM KOWA (Komatsu Oil Wear Analysis)………………………………………………………………………………………395

STORE OIL AND FUEL………………………………………………………………………………………………………….396

FILTER…………………………………………………………………………………………………………………….396

HANDLE ELECTRICAL COMPONENTS…………………………………………………………………………………………………….396

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS…………………………………………………………………………………………397

MAINTENANCE SCHEDULE……………………………………………………………………………………………………………….399

MAINTENANCE SCHEDULE TABLE………………………………………………………………………………………………………399

MAINTENANCE PROCEDURE………………………………………………………………………………………………………………401

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)………………………………………………………………………401

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)………………………………………………………………………401

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)………………………………………………………………………401

INITIAL 4000 HOURS MAINTENANCE (ONLY AFTER THE FIRST 4000 HOURS)…………………………………………………………………….401

WHEN REQUIRED………………………………………………………………………………………………………………….401

METHOD FOR CHECKING, CLEANING AND REPLACING AIR CLEANER…………………………………………………………………………401

METHOD FOR CLEANING INSIDE OF COOLING SYSTEM…………………………………………………………………………………..409

CHECK KOMATSU MAINTENANCE-FREE BATTERY INDICATOR……………………………………………………………………………….413

METHOD FOR CHECKING LOOSENESS AND TIGHTENING TRACK SHOE BOLTS……………………………………………………………………414

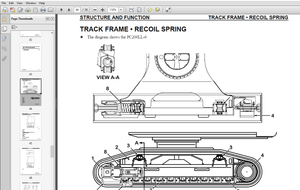

METHOD FOR CHECKING AND ADJUSTING TRACK TENSION………………………………………………………………………………..415

METHOD FOR REPLACING BUCKET TEETH (K PRIME)……………………………………………………………………………………420

METHOD FOR REMOVING SLING……………………………………………………………………………………………………426

METHOD FOR CHECKING WINDOW WASHER FLUID LEVEL, ADDING FLUID……………………………………………………………………..427

METHOD FOR CHECKING AND MAINTENANCE AIR CONDITIONER…………………………………………………………………………….429

METHOD FOR BLEEDING AIR FROM HYDRAULIC CIRCUIT…………………………………………………………………………………429

METHOD FOR BLEEDING AIR FROM FUEL CIRCUIT……………………………………………………………………………………..437

METHOD FOR RELEASING PRESSURE IN ACCUMULATOR FOR HYDRAULIC CONTROL CIRCUIT………………………………………………………..437

METHOD FOR CLEANING LINE FILTER AND REMOVING DIRT………………………………………………………………………………438

METHOD FOR CHECKING SEALANT AROUND ENGINE COOLING SYSTEM………………………………………………………………………..439

METHOD FOR CHECKING CAMERA VISIBILITY…………………………………………………………………………………………440

CHECK OIL LEVEL IN GREASE PUMP CRANKCASE, ADD AND CHANGE OIL…………………………………………………………………….441

METHOD FOR CHECKING AND CLEANING GREASE REFILL FILTER…………………………………………………………………………..442

CHECKS BEFORE STARTING………………………………………………………………………………………………………….443

EVERY 250 HOURS MAINTENANCE……………………………………………………………………………………………………..444

METHOD FOR CHECKING OIL LEVEL IN FINAL DRIVE CASE, ADDING OIL……………………………………………………………………444

METHOD FOR CHECKING BATTERY ELECTROLYTE LEVEL………………………………………………………………………………….444

METHOD FOR CHECKING AND ADJUSTING ALTERNATOR DRIVE BELT TENSION………………………………………………………………….447

METHOD FOR CHECKING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION…………………………………………………………449

METHOD FOR CHECKING LOOSENESS AND TIGHTENING TRACK FRAME AND AXLE CONNECTING BOLTS…………………………………………………451

EVERY 500 HOURS MAINTENANCE……………………………………………………………………………………………………..452

METHOD FOR CHANGING OIL IN ENGINE OIL PAN, REPLACING ENGINE OIL FILTER CARTRIDGE…………………………………………………..452

METHOD FOR REPLACING FUEL PREFILTER CARTRIDGE………………………………………………………………………………….454

CHECK AND CLEAN RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS, FUEL COOLER FINS, PTO COOLER FINS, AND AIR CONDITIONER CONDENSER FINS….457

METHOD FOR CLEANING AIR CONDITIONER FRESH/RECIRC FILTERS………………………………………………………………………..460

CHECK REFRIGERANT (GAS) LEVEL FOR AIR CONDITIONER AND ADD REFRIGERANT…………………………………………………………….463

METHOD FOR CLEANING AIR CONDITIONER CONDENSER………………………………………………………………………………….465

METHOD FOR REPLACING PILOT FILTER CARTRIDGE……………………………………………………………………………………466

METHOD FOR CHECKING AND REPLACING HYDRAULIC PUMP DRAIN FILTER CARTRIDGE…………………………………………………………..466

METHOD FOR REPLACING SWING AND TRAVEL MOTOR DRAIN FILTER CARTRIDGE……………………………………………………………….467

EVERY 1000 HOURS MAINTENANCE…………………………………………………………………………………………………….468

METHOD FOR REPLACING HYDRAULIC OIL FILTER ELEMENT………………………………………………………………………………468

METHOD FOR CHANGE OIL IN SWING MACHINERY CASE………………………………………………………………………………….469

METHOD FOR CHANGING OIL IN PTO CASE…………………………………………………………………………………………..471

METHOD FOR CLEANING PTO LUBRICATION FILTER STRAINER…………………………………………………………………………….473

METHOD FOR REPLACING FUEL MAIN FILTER CARTRIDGE………………………………………………………………………………..474

METHOD FOR REPLACING FUEL TANK BREATHER ELEMENT………………………………………………………………………………..476

METHOD FOR CHECKING ALL TIGHTENING POINTS OF ENGINE INTAKE PIPE CLAMPS……………………………………………………………476

METHOD FOR CHECKING WELDED STRUCTURE………………………………………………………………………………………….477

CHECK FUNCTION OF ACCUMULATOR FOR CONTROL CIRCUIT AND RELEASE INTERNAL PRESSURE IN HYDRAULIC CIRCUIT…………………………………480

METHOD FOR REPLACING HYDRAULIC TANK BREATHER ELEMENT……………………………………………………………………………483

METHOD FOR REPLACING SWING MOTOR COOLING FILTER ELEMENT…………………………………………………………………………484

METHOD FOR CHECKING EMERGENCY LADDER………………………………………………………………………………………….486

METHOD FOR LUBRICATING THE HYDRAULICALLY OPERATED STAIRWAY………………………………………………………………………486

METHOD FOR LUBRICATING FUEL SHUT OFF LEVER…………………………………………………………………………………….487

EVERY 2000 HOURS MAINTENANCE…………………………………………………………………………………………………….488

METHOD FOR CHANGING OIL IN FINAL DRIVE CASE……………………………………………………………………………………488

METHOD FOR CHECKING SWING PINION GREASE LEVEL, ADD GREASE……………………………………………………………………….489

METHOD FOR CHECKING ALTERNATOR AND STARTING MOTOR………………………………………………………………………………489

METHOD FOR CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE………………………………………………………………………..489

EVERY 4000 HOURS MAINTENANCE…………………………………………………………………………………………………….490

METHOD FOR LUBRICATING ENGINE MOUNT…………………………………………………………………………………………..490

METHOD FOR CHECKING WATER PUMP……………………………………………………………………………………………….490

METHOD FOR CHECKING FOR LOOSENESS OF ENGINE HIGH-PRESSURE PIPING CLAMP, HARDENING OF RUBBER…………………………………………491

METHOD FOR CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER…………………………………………………….492

METHOD FOR REPLACING COOLANT FILTER CARTRIDGE………………………………………………………………………………….493

METHOD FOR CHANGING COOLANT………………………………………………………………………………………………….493

METHOD FOR CHECKING AIR CONDITIONER COMPRESSOR OPERATION………………………………………………………………………..493

REPLACE CAP OF COOLING SYSTEM………………………………………………………………………………………………..494

EVERY 5000 HOURS MAINTENANCE…………………………………………………………………………………………………….496

METHOD FOR CHANGING OIL IN HYDRAULIC TANK, CLEANING HYDRAULIC TANK STRAINER……………………………………………………….496

EVERY 8000 HOURS MAINTENANCE…………………………………………………………………………………………………….500

METHOD FOR REPLACING ENGINE HIGH-PRESSURE PIPING CLAMP………………………………………………………………………….500

METHOD FOR REPLACING FUEL SPRAY PREVENTION CAP…………………………………………………………………………………500

METHOD FOR REPLACING INJECTOR ASSEMBLY………………………………………………………………………………………..500

EVERY 9000 HOURS MAINTENANCE…………………………………………………………………………………………………….500

METHOD FOR REPLACING FUEL SPRAY PREVENTION CAP ON FUEL DOSER PIPING………………………………………………………………500

EVERY 6 MONTHS MAINTENANCE………………………………………………………………………………………………………500

CHECK ANCHOR POINT FOR TIE-OFF……………………………………………………………………………………………….500

SPECIFICATIONS………………………………………………………………………………………………………………………..502

SPECIFICATIONS…………………………………………………………………………………………………………………….503

SPECIFICATIONS: PC2000-11R………………………………………………………………………………………………………503

ATTACHMENTS AND OPTIONS………………………………………………………………………………………………………………..506

PRECAUTIONS FOR USING ATTACHMENT AND OPTIONS………………………………………………………………………………………….507

PRECAUTIONS WHEN SELECTING………………………………………………………………………………………………………507

READ THE OPERATION AND MAINTENANCE MANUAL THOROUGHLY……………………………………………………………………………….507

PRECAUTIONS WHEN REMOVING AND INSTALLING………………………………………………………………………………………….507

PRECAUTIONS FOR USING…………………………………………………………………………………………………………..508

ATTACHMENTS AND OPTIONS…………………………………………………………………………………………………………….509

INSTALL ATTACHMENT……………………………………………………………………………………………………………..509

TRACK SHOES SELECTION…………………………………………………………………………………………………………..510

ADJUST HEATED MIRROR……………………………………………………………………………………………………………….511

HANDLE EXTERNAL POWER SUPPLY ENGINE PREHEATER…………………………………………………………………………………………513

INSTALLATION PROCEDURES FOR EXTERNAL POWER SUPPLY SYSTEM FOR EXTERNAL POWER SUPPLY ENGINE PREHEATER……………………………………..513

FABRICATE EXTERNAL POWER SUPPLY CABLE…………………………………………………………………………………………….514

INSTALL EXTERNAL POWER SUPPLY SYSTEM……………………………………………………………………………………………..516

PROCEDURE FOR HANDLING EXTERNAL POWER SUPPLY ENGINE PREHEATER……………………………………………………………………….519

METHOD FOR OPERATING EXTERNAL POWER SUPPLY HEATER………………………………………………………………………………519

HANDLE MOVABLE DIESEL PREHEATER……………………………………………………………………………………………………..521

GENERAL VIEW…………………………………………………………………………………………………………………..524

EXPLANATION OF MOVABLE DIESEL PREHEATER EQUIPMENT………………………………………………………………………………….527

OPERATION OF MOVABLE DIESEL PREHEATER…………………………………………………………………………………………….530

PREPARATION………………………………………………………………………………………………………………..531

METHOD FOR STARTING OPERATION………………………………………………………………………………………………..533

METHOD FOR STOPPING OPERATION………………………………………………………………………………………………..535

IF FUEL IS NOT SUPPLIED NORMALLY……………………………………………………………………………………………..537

CAUSE OF TROUBLE AND ACTIONS…………………………………………………………………………………………………….539

HANDLE FUEL QUICK CHARGE SYSTEM……………………………………………………………………………………………………..541

GENERAL VIEW…………………………………………………………………………………………………………………..541

ADD FUEL………………………………………………………………………………………………………………………542

REPLACE FUEL TANK BREATHER ELEMENT……………………………………………………………………………………………….543

ACTIONS IF MACHINE DOES NOT MOVE BY PROXIMITY SWITCH FAILURE ETC…………………………………………………………………….544

CHECK AND ADJUST PROXIMITY SWITCH…………………………………………………………………………………………….544

ACTIONS IF PROXIMITY SWITCH HAS FAILURE……………………………………………………………………………………….546

HANDLE SERVICE CENTER………………………………………………………………………………………………………………548

EXPLANATION OF SERVICE CENTER COMPONENTS………………………………………………………………………………………….548

OPERATE SERVICE ARM…………………………………………………………………………………………………………….549

METHOD FOR LOWERING SERVICE ARM………………………………………………………………………………………………549

METHOD FOR STOWING SERVICE ARM……………………………………………………………………………………………….550

DRAIN OR ADD OIL, GREASE AND COOLANT THROUGH SERVICE PANEL………………………………………………………………………….551

METHOD FOR DRAINING AND ADDING ENGINE OIL……………………………………………………………………………………..552

METHOD FOR DRAINING AND ADDING FRONT SWING MACHINERY CASE OIL……………………………………………………………………553

METHOD FOR DRAINING AND ADDING REAR SWING MACHINERY CASE OIL…………………………………………………………………….555

METHOD FOR DRAINING AND ADDING PTO CASE OIL……………………………………………………………………………………556

METHOD FOR DRAINING AND ADDING HYDRAULIC OIL…………………………………………………………………………………..557

METHOD FOR DRAINING AND ADDING COOLANT………………………………………………………………………………………..559

METHOD FOR ADDING FUEL………………………………………………………………………………………………………562

EVERY 1000 HOURS MAINTENANCE…………………………………………………………………………………………………….563

METHOD FOR LUBRICATING SERVICE ARM……………………………………………………………………………………………563

METHOD FOR REPLACING FUEL TANK BREATHER ELEMENT………………………………………………………………………………..564

ACTIONS IF MACHINE DOES NOT MOVE BY PROXIMITY SWITCH FAILURE ETC…………………………………………………………………….565

METHOD FOR CHECKING AND ADJUSTING PROXIMITY SWITCH……………………………………………………………………………..565

ACTIONS IF PROXIMITY SWITCH HAS FAILED……………………………………………………………………………………………566

SERVICE CENTER CAUTION LAMP……………………………………………………………………………………………………..566

HANDLE JUMP START RECEPTACLE………………………………………………………………………………………………………..567

EXPLANATION OF JUMP START RECEPTACLE COMPONENTS……………………………………………………………………………………567

METHOD FOR CONNECTING EXTERNAL POWER SUPPLY……………………………………………………………………………………….567

RADIO(Bluetooth®)………………………………………………………………………………………………………………….569

RADIO EQUIPMENT………………………………………………………………………………………………………………..569

RADIO BAND SELECTOR SWITCH…………………………………………………………………………………………………..569

AUX SELECTOR SWITCH…………………………………………………………………………………………………………569

DISPLAY……………………………………………………………………………………………………………………570

VOLUME CONTROL SWITCH……………………………………………………………………………………………………….570

DISPLAY SELECTOR SWITCH……………………………………………………………………………………………………..570

POWER SWITCH……………………………………………………………………………………………………………….570

TUNING/TIME SETTING SWITCH…………………………………………………………………………………………………..571

PRESET/AUDIO SWITCH…………………………………………………………………………………………………………571

MENU SWITCH………………………………………………………………………………………………………………..571

USB TERMINAL FOR CHARGE……………………………………………………………………………………………………..571

Bluetooth®…………………………………………………………………………………………………………………571

OPERATE RADIO………………………………………………………………………………………………………………….572

OPERATE RADIO WHEN YOU LISTEN………………………………………………………………………………………………..572

PLAY MUSIC WITH Bluetooth® CONNECTED………………………………………………………………………………………….573

RADIO SETTING………………………………………………………………………………………………………………….573

SOUND BALANCE SETTING……………………………………………………………………………………………………….574

HIGH REGISTER RANGE (TREBLE) SETTING………………………………………………………………………………………….574

LOW REGISTER RANGE (BASS) SETTING…………………………………………………………………………………………….575

LOUDNESS SETTING……………………………………………………………………………………………………………575

CLOCK SETTING………………………………………………………………………………………………………………576

PAIRING……………………………………………………………………………………………………………………577

CHECK PRESET REGION OF RADIO…………………………………………………………………………………………………578

CHECK VERSION OF RADIO………………………………………………………………………………………………………578

REPLACEMENT PARTS……………………………………………………………………………………………………………………..580

DEFINED LIFE PARTS…………………………………………………………………………………………………………………581

DEFINED LIFE PARTS LIST…………………………………………………………………………………………………………581

CONSUMABLE PARTS…………………………………………………………………………………………………………………..582

CONSUMABLE PARTS LIST…………………………………………………………………………………………………………..582

RECOMMENDED FUEL, COOLANT, AND LUBRICANT……………………………………………………………………………………………..584

LUBRICATION CHART………………………………………………………………………………………………………………586

USE OF FUEL, COOLANT AND LUBRICANTS TO ACCORDING TO AMBIENT TEMPERATURE………………………………………………………………587

RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS…………………………………………………………………….589

INDEX…………………………………………………………………………………………………………………………………590