$42

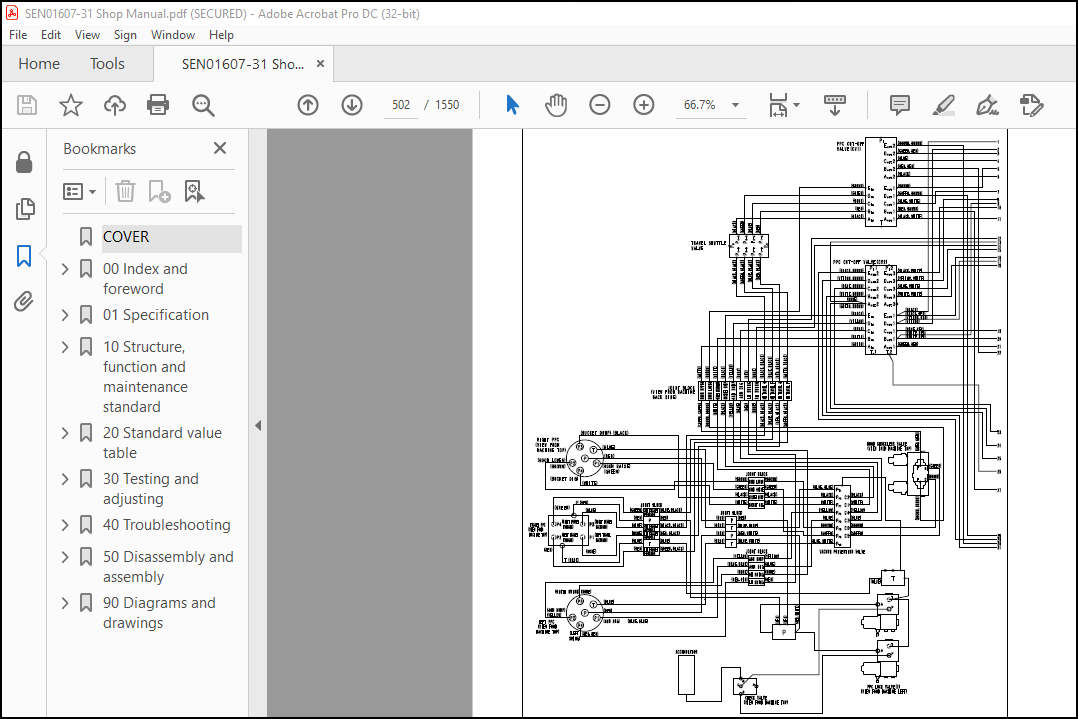

Komatsu PC2000-8 Hydraulic Excavator Shop Manual SEN01607-31 – PDF DOWNLOAD

Komatsu PC2000-8 Hydraulic Excavator Shop Manual SEN01607-31 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC2000-8 Hydraulic Excavator Shop Manual SEN01607-31 – PDF DOWNLOAD

Language : English

Pages : 1550

Downloadable : Yes

File Type : PDF

Size: 98.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC2000-8 Hydraulic Excavator Shop Manual SEN01607-31 – PDF DOWNLOAD

- The Komatsu PC2000-8 Hydraulic Excavator Shop Manual is a comprehensive guide that provides detailed information and instructions for the maintenance, repair, and overhaul of the Komatsu PC2000-8 hydraulic excavator. This manual is designed to help users understand the various systems and components of the excavator, and provides step-by-step instructions for performing routine maintenance tasks, as well as more complex repair and overhaul procedures.

- The manual is organized into sections that correspond to the various systems and components of the excavator, including the engine, hydraulic system, electrical system, undercarriage, and more. Within each section, the manual provides detailed information about the components, including specifications, procedures for disassembly and reassembly, and troubleshooting tips. The manual also includes exploded view illustrations that show the relationship between the parts, making it easier to understand the components and how they work together.

- One of the key benefits of the Komatsu PC2000-8 Hydraulic Excavator Shop Manual is its focus on preventative maintenance. The manual provides detailed information about the recommended maintenance procedures for each component, as well as guidelines for monitoring the health of the excavator and addressing potential issues before they become major problems. This can help users extend the lifespan of the excavator, minimize downtime, and reduce repair costs.

- In addition to providing information about the excavator itself, the Komatsu PC2000-8 Hydraulic Excavator Shop Manual also includes important safety information, including guidelines for working around the excavator, handling hazardous materials, and using the excavator safely and efficiently.

- Overall, the Komatsu PC2000-8 Hydraulic Excavator Shop Manual is a valuable resource for anyone who needs to maintain, repair, or overhaul the Komatsu PC2000-8 hydraulic excavator. With its clear and concise language, step-by-step instructions, and detailed illustrations, this manual is an essential tool for anyone who is involved in the maintenance and repair of this important piece of heavy machinery.

TABLE OF CONTENTS:

Komatsu PC2000-8 Hydraulic Excavator Shop Manual SEN01607-31 – PDF DOWNLOAD

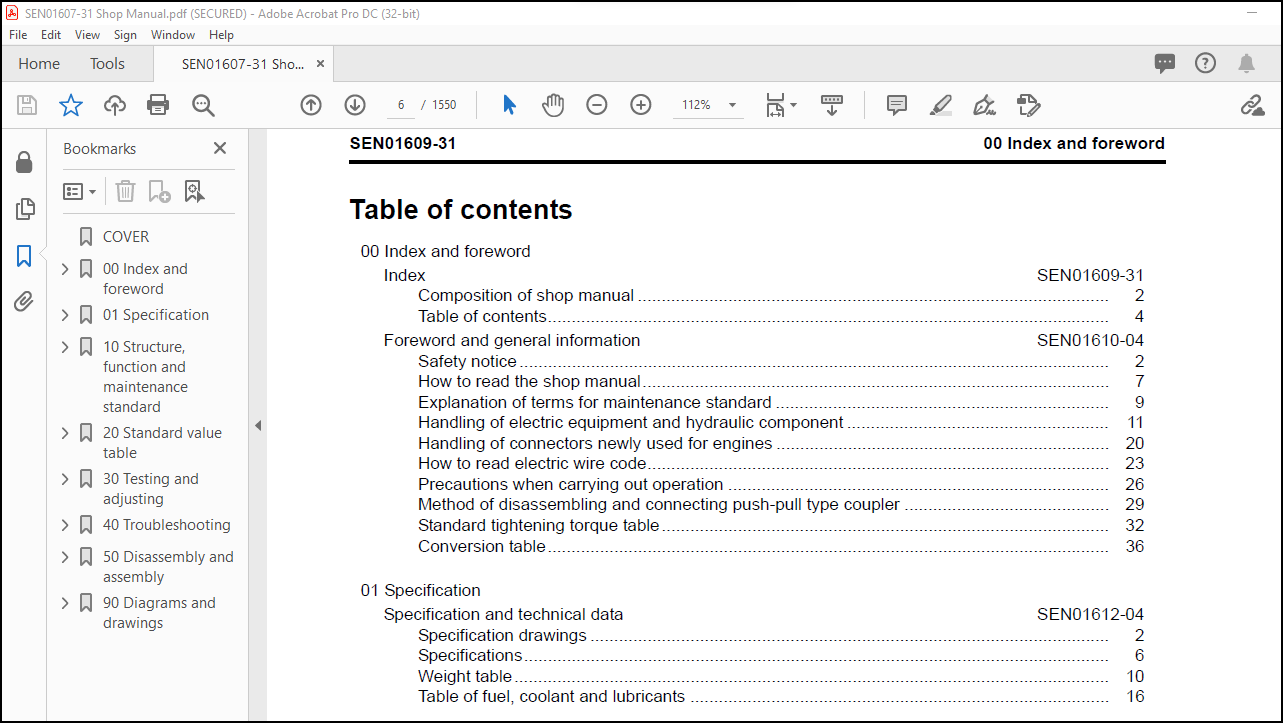

COVER……………………………………………………………………………………………….. 1

00 Index and foreword…………………………………………………………………………………. 3

Index……………………………………………………………………………………………. 3

Composition of shop manual……………………………………………………………………… 4

Table of contents……………………………………………………………………………… 6

Foreword and general information……………………………………………………………………. 19

Safety notice…………………………………………………………………………………. 20

How to read the shop manual…………………………………………………………………….. 25

Explanation of terms for maintenance standard…………………………………………………….. 27

Handling of electric equipment and hydraulic component…………………………………………….. 29

Handling of connectors newly used for engines…………………………………………………….. 38

How to read electric wire code………………………………………………………………….. 41

Precautions when carrying out operation………………………………………………………….. 44

Method of disassembling and connecting push-pull type coupler………………………………………. 47

Standard tightening torque table………………………………………………………………… 50

Conversion table………………………………………………………………………………. 54

01 Specification……………………………………………………………………………………… 61

Specification and technical data……………………………………………………………………. 61

Specification drawings…………………………………………………………………………. 62

Specifications………………………………………………………………………………… 66

Weight table………………………………………………………………………………….. 70

Table of fuel, coolant and lubricants……………………………………………………………. 76

10 Structure, function and maintenance standard………………………………………………………….. 79

Engine and cooling system………………………………………………………………………….. 79

Radiator and oil cooler………………………………………………………………………… 80

PTO………………………………………………………………………………………….. 82

PTO lubrication system…………………………………………………………………………. 84

Power train………………………………………………………………………………………. 87

Power train…………………………………………………………………………………… 88

Swing machinery……………………………………………………………………………….. 90

Swing circle………………………………………………………………………………….. 92

Final drive…………………………………………………………………………………… 94

Sprocket……………………………………………………………………………………… 96

Undercarriage and frame……………………………………………………………………………. 99

Track frame…………………………………………………………………………………… 100

Idler………………………………………………………………………………………… 102

Carrier roller………………………………………………………………………………… 104

Track roller………………………………………………………………………………….. 105

Track shoe……………………………………………………………………………………. 106

HIC system……………………………………………………………………………………. 111

Hydraulic system, Part 1…………………………………………………………………………… 119

Hydraulic piping drawing……………………………………………………………………….. 122

Hydraulic tank………………………………………………………………………………… 126

Oil cooler……………………………………………………………………………………. 128

Line oil filter……………………………………………………………………………….. 130

Pilot oil filter………………………………………………………………………………. 131

Return oil filter……………………………………………………………………………… 132

Motor drain oil filter…………………………………………………………………………. 133

Pump drain filter……………………………………………………………………………… 134

Accumulator…………………………………………………………………………………… 135

Travel junction valve………………………………………………………………………….. 137

Solenoid valve………………………………………………………………………………… 140

Hydraulic cylinder…………………………………………………………………………….. 148

Greasing system……………………………………………………………………………….. 152

Center swivel joint……………………………………………………………………………. 162

Hydraulic ladder system………………………………………………………………………… 163

Service center system………………………………………………………………………….. 168

Hydraulic system, Part 2…………………………………………………………………………… 175

Hydraulic system, Part 2……………………………………………………………………….. 176

Control valve……………………………………………………………………………… 176

Electronic OLSS system……………………………………………………………………… 204

Swing motor……………………………………………………………………………….. 208

Cooling fan motor (For radiator and oil cooler)……………………………………………….. 216

Cooling fan pump…………………………………………………………………………… 222

Hydraulic system, Part 3…………………………………………………………………………… 237

Travel motor………………………………………………………………………………….. 238

Hydraulic pump………………………………………………………………………………… 250

PPC valve…………………………………………………………………………………….. 270

Variable back pressure valve……………………………………………………………………. 282

Suction selector valve…………………………………………………………………………. 286

PPC cut-off valve……………………………………………………………………………… 290

Work equipment……………………………………………………………………………………. 299

Work equipment………………………………………………………………………………… 300

Dimensions of work equipment……………………………………………………………………. 304

Cab and its attachments……………………………………………………………………………. 309

Air conditioner piping…………………………………………………………………………. 310

Cab………………………………………………………………………………………….. 311

Electrical system…………………………………………………………………………………. 315

Engine control………………………………………………………………………………… 316

Electrical control system………………………………………………………………………. 327

Monitor system………………………………………………………………………………… 369

Sensor……………………………………………………………………………………….. 397

ORBCOMM terminal………………………………………………………………………………. 409

20 Standard value table……………………………………………………………………………….. 411

Standard service value table……………………………………………………………………….. 411

Standard service value table for engine………………………………………………………….. 412

Standard service value table for chassis (Backhoe specification)……………………………………. 413

Standard service value table for chassis (Loading shovel specification)……………………………… 424

30 Testing and adjusting………………………………………………………………………………. 437

Testing and adjusting, Part 1………………………………………………………………………. 437

Tools for testing, adjusting, and troubleshooting…………………………………………………. 439

Measuring engine speed…………………………………………………………………………. 442

Testing air boost pressure……………………………………………………………………… 443

Testing exhaust temperature…………………………………………………………………….. 444

Testing exhaust color………………………………………………………………………….. 445

Adjusting valve clearance………………………………………………………………………. 447

Testing compression pressure……………………………………………………………………. 449

Testing blow-by pressure……………………………………………………………………….. 451

Testing engine oil pressure…………………………………………………………………….. 452

Handling fuel system parts……………………………………………………………………… 453

Releasing residual pressure in fuel system……………………………………………………….. 453

Testing fuel pressure………………………………………………………………………….. 454

Reduced cylinder mode operation…………………………………………………………………. 455

No-injection cranking………………………………………………………………………….. 455

Testing leakage from pressure limiter and return rate from injector…………………………………. 456

Bleeding air from fuel circuit………………………………………………………………….. 459

Bleeding air from fuel circuit (lowgrade fuel specification)……………………………………….. 463

Testing fuel system for leakage…………………………………………………………………. 465

Testing and adjusting alternator belt tension…………………………………………………….. 466

Testing and adjusting air conditioner compressor belt tension………………………………………. 467

Handling controller high-voltage circuit…………………………………………………………. 468

Testing and adjusting, Part 2………………………………………………………………………. 471

Testing swing circle bearing clearance…………………………………………………………… 473

Remaining pressure relief from HIC circuit……………………………………………………….. 474

Gas filling in HIC circuit accumulator…………………………………………………………… 475

Bleeding air from HIC circuit and supplying oil to it……………………………………………… 478

Testing and adjusting track shoe tension…………………………………………………………. 482

Testing and adjusting work equipment, swing and travel circuit oil pressures…………………………. 486

Testing and adjusting control circuit oil pressure (output pressure of self pressure reducing valve)……. 490

Testing and adjusting main pump control signal……………………………………………………. 492

Measuring fan speed……………………………………………………………………………. 495

Measuring fan pump EPC solenoid current………………………………………………………….. 496

Measuring fan pump EPC solenoid valve output pressure……………………………………………… 497

Oil pressure measuring points for pump discharge pressure or jet sensor differential pressure………….. 499

Measuring PPC valve output pressure……………………………………………………………… 500

Measuring solenoid valve outlet pressure…………………………………………………………. 504

Adjusting work equipment and swing PPC valve……………………………………………………… 506

Testing and adjusting travel deviation…………………………………………………………… 507

Testing work equipment hydraulic drift cause portion………………………………………………. 509

Testing oil leakage……………………………………………………………………………. 510

Remaining pressure relief from hydraulic circuit………………………………………………….. 513

Air bleeding from each component………………………………………………………………… 514

Testing and adjusting auto grease system…………………………………………………………. 520

Adjusting mirrors……………………………………………………………………………… 523

Testing and adjusting clearance of hydraulic ladder proximity switch………………………………… 525

Testing and adjusting position of hydraulic ladder position sensor plate…………………………….. 527

Testing and adjusting clearance to service arm proximity switch…………………………………….. 528

Testing and adjusting, Part 3………………………………………………………………………. 531

Special functions of machine monitor…………………………………………………………….. 532

Handling controller voltage circuit……………………………………………………………… 587

Testing and adjusting, Part 4………………………………………………………………………. 589

VHMS controller initial setting procedure………………………………………………………… 590

Precautions for replacing VHMS controller………………………………………………………… 609

Preparation work for troubleshooting of electrical system………………………………………….. 615

Pm-clinic service……………………………………………………………………………… 617

Measurement procedure………………………………………………………………………….. 618

40 Troubleshooting……………………………………………………………………………………. 637

Failure code table and fuse locations……………………………………………………………….. 637

Failure code table…………………………………………………………………………….. 638

Before carrying out troubleshooting of electrical system…………………………………………… 645

General information on troubleshooting………………………………………………………………. 653

Points to remember when troubleshooting………………………………………………………….. 654

Sequence of events in troubleshooting……………………………………………………………. 655

Checks before troubleshooting…………………………………………………………………… 656

Classification and procedures of troubleshooting………………………………………………….. 657

Connection table for connector pin numbers……………………………………………………….. 661

T- branch box and T- branch adapter table………………………………………………………… 697

Troubleshooting by failure code, Part 1……………………………………………………………… 701

Failure code [0410KA] Fuel LV. Sensor Failure…………………………………………………….. 704

Failure code [0410KB] Fuel LV. Sensor Failure…………………………………………………….. 706

Failure code [6014NX] Hydraulic Oil Filter Clogging (or change of VHMS-LED display from n5 to 51)………. 708

Failure code [8800ZG] Auto grease abnormally……………………………………………………… 709

Failure code [7@HAZL] VR1/P1F Relief Press Abnormality…………………………………………….. 710

Failure code [7@HBZL] VL1/P1R Relief Press Abnormality…………………………………………….. 711

Failure code [7@HCZL] VR2/P2F Relief Press Abnormality…………………………………………….. 712

Failure code [7@HDZL] VL2/P2R Relief Press Abnormality…………………………………………….. 714

Failure code [AA10NX] Aircleaner Clogging………………………………………………………… 716

Failure code [AB00KE] Charge Voltage Low…………………………………………………………. 718

Failure code [aB00KE] Low Upper ALR Charge Voltage (or change of VHMS-LED display from n9 to 11)……….. 720

Failure code [B@BAZG] Eng. Oil Press. Low………………………………………………………… 722

Failure code [B@BAZK] Eng. Oil Level Low…………………………………………………………. 724

Failure code [B@BCNS] Eng. Water Overheat………………………………………………………… 726

Failure code [B@BCZK] Eng. Water Lvl Low…………………………………………………………. 728

Failure code [B@CBNS] PTO Oil Overheat (or change of VHMS-LED display from n5 to 61)………………….. 730

Failure code [B@HANS] Hydr. Oil Overheat…………………………………………………………. 732

Failure code [B@HAZK] Low Hydraulic Oil Level (or change of VHMSLED display from n5 to 52)…………….. 734

Failure code [CA111] ECM Critical Internal Failure………………………………………………… 736

Failure code [CB111] ECM Critical Internal Failure………………………………………………… 738

Failure code [CA115] Eng. Ne and Bkup Speed Sens Error…………………………………………….. 740

Failure code [CB115] Eng. Ne and Bkup Speed Sens Error…………………………………………….. 741

Failure code [CA122] Chg Air Press Sensor High Error………………………………………………. 742

Failure code [CA123] Chg Air Press Sensor Low Error……………………………………………….. 744

Failure code [CA131] Throttle Sensor High Error…………………………………………………… 746

Failure code [CA132] Throttle Sensor Low Error……………………………………………………. 748

Failure code [CA135] Eng Oil Press Sensor High Error………………………………………………. 750

Failure code [CA141] Eng Oil Press Sensor Low Error……………………………………………….. 752

Failure code [CA144] Coolant Temp Sens High Error…………………………………………………. 754

Failure code [CA145] Coolant Temp Sens Low Error………………………………………………….. 756

Failure code [CA153] Chg Air Temp Sensor High Error……………………………………………….. 758

Failure code [CA154] Chg Air Temp Sensor Low Error………………………………………………… 760

Failure code [CA187] Sens Supply 2 Volt Low Error…………………………………………………. 762

Failure code [CB187] Sens Supply 2 Volt Low Error…………………………………………………. 762

Failure code [CA212] Eng Oil Temp Sensor High Error……………………………………………….. 764

Failure code [CA213] Eng Oil Temp Sensor Low Error………………………………………………… 766

Troubleshooting by failure code, Part 2……………………………………………………………… 769

Failure code [CA221] Ambient Press Sens High Error………………………………………………… 772

Failure code [CA222] Ambient Press Sens Low Error…………………………………………………. 774

Failure code [CA227] Sens Supply 2 Volt High Error………………………………………………… 776

Failure code [CB227] Sens Supply 2 Volt High Error………………………………………………… 778

Failure code [CA234] Eng Over Speed……………………………………………………………… 780

Failure code [CA238] Ne Speed Sens Supply Volt Error………………………………………………. 782

Failure code [CB238] Ne Speed Sens Supply Volt Error………………………………………………. 784

Failure code [CA263] Fuel Temp Sensor High Error………………………………………………….. 786

Failure code [CB263] Fuel Temp Sensor High Error………………………………………………….. 788

Failure code [CA265] Fuel Temp Sensor Low Error…………………………………………………… 789

Failure code [CB265] Fuel Temp Sensor Low Error…………………………………………………… 789

Failure code [CA271] IMV/PCV1 Short Error………………………………………………………… 790

Failure code [CB271] IMV/PCV1 Short Error………………………………………………………… 792

Failure code [CA272] IMV/PCV1 Open Error…………………………………………………………. 794

Failure code [CB272] IMV/PCV1 Open Error…………………………………………………………. 796

Failure code [CA273] PCV2 Short Error……………………………………………………………. 798

Failure code [CB273] PCV2 Short Error……………………………………………………………. 800

Failure code [CA274] PCV2 Open Error…………………………………………………………….. 802

Failure code [CB274] PCV2 Open Error…………………………………………………………….. 804

Failure code [CA322] Inj #1(L/B#1) Open/Short Error……………………………………………….. 806

Failure code [CA323] Inj #5(L/B#5) Open/Short Error……………………………………………….. 808

Failure code [CA324] Inj #3(L/B#3) Open/Short Error……………………………………………….. 810

Failure code [CA325] Inj #6(L/B#6) Open/Short Error……………………………………………….. 812

Failure code [CA331] Inj #2(L/B#2) Open/Short Error……………………………………………….. 814

Failure code [CA332] Inj #4(L/B#4) Open/Short Error……………………………………………….. 816

Failure code [CA342] Calibration Code Incompatibility……………………………………………… 818

Failure code [CB342] Calibration Code Incompatibility……………………………………………… 818

Failure code [CA351] Injectors Drive Circuit Error………………………………………………… 820

Failure code [CB351] Injectors Drive Circuit Error………………………………………………… 822

Failure code [CA352] Sens Supply 1 Volt Low Error…………………………………………………. 824

Failure code [CB352] Sens Supply 1 Volt Low Error…………………………………………………. 824

Failure code [CA386] Sens Supply 1 Volt High Error………………………………………………… 826

Failure code [CB386] Sens Supply 1 Volt High Error………………………………………………… 828

Failure code [CA441] Battery Voltage Low Error……………………………………………………. 830

Failure code [CB441] Battery Voltage Low Error……………………………………………………. 830

Failure code [CA442] Battery Voltage High Error…………………………………………………… 831

Failure code [CB442] Battery Voltage High Error…………………………………………………… 831

Failure code [CA449] Rail Press Very High Error…………………………………………………… 832

Failure code [CB449] Rail Press Very High Error…………………………………………………… 832

Troubleshooting by failure code, Part 3……………………………………………………………… 835

Failure code [CA451] Rail Press Sensor High Error…………………………………………………. 838

Failure code [CB451] Rail Press Sensor High Error…………………………………………………. 840

Failure code [CA452] Rail Press Sensor Low Error………………………………………………….. 842

Failure code [CB452] Rail Press Sensor Low Error………………………………………………….. 842

Failure code [CA553] Rail Press High Error……………………………………………………….. 843

Failure code [CB553] Rail Press High Error……………………………………………………….. 844

Failure code [CA554] Rail Press Sensor In Range Error……………………………………………… 845

Failure code [CB554] Rail Press Sensor In Range Error……………………………………………… 845

Failure code [CA559] Rail Press Low Error………………………………………………………… 846

Failure code [CB559] Rail Press Low Error………………………………………………………… 850

Failure code [CA689] Eng Ne Speed Sensor Error……………………………………………………. 854

Failure code [CB689] Eng Ne Speed Sensor Error……………………………………………………. 856

Failure code [CA691] Intake Air Temp Sens High Error………………………………………………. 858

Failure code [CA692] Intake Air Temp Sens Low Error……………………………………………….. 860

Failure code [CA731] Eng Bkup Speed Sens Phase Error………………………………………………. 861

Failure code [CB731] Eng Bkup Speed Sens Phase Error………………………………………………. 861

Failure code [CA757] All Persistent Data Lost Error……………………………………………….. 862

Failure code [CB757] All Persistent Data Lost Error……………………………………………….. 862

Failure code [CA778] Eng Bkup Speed Sensor Error………………………………………………….. 864

Failure code [CB778] Eng Bkup Speed Sensor Error………………………………………………….. 866

Failure code [CA781] CEN Communication Error……………………………………………………… 868

Failure code [CB781] CEN Communication Error……………………………………………………… 870

Failure code [CA1257] Harness Key Error………………………………………………………….. 872

Failure code [CB1257] Harness Key Error………………………………………………………….. 873

Failure code [CB1548] Inj #7(R/B#1) Open/Short Error………………………………………………. 874

Failure code [CB1549] Inj #8(R/B#2) Open/Short Error………………………………………………. 876

Failure code [CB1551] Inj #10(R/B#4) Open/Short Error……………………………………………… 878

Failure code [CB1552] Inj #11(R/B#5) Open/Short Error……………………………………………… 880

Failure code [CB1553] Inj #12(R/B#6) Open/Short Error……………………………………………… 882

Failure code [CB1622] Inj #9(R/B#3) Open/Short Error………………………………………………. 884

Failure code [CA1633] KOMNET Data link Time out Error……………………………………………… 886

Failure code [CA2185] Throt Sens Sup Volt High Error………………………………………………. 888

Failure code [CA2186] Throt Sens Sup Volt Low Error……………………………………………….. 890

Failure code [CA2249] Rail Press Very Low Error…………………………………………………… 891

Failure code [CB2249] Rail Press Very Low Error…………………………………………………… 891

Failure code [CA2555] Grid Heater Relay Volt Low Error…………………………………………….. 892

Failure code [CA2556] Grid Heater Relay Volt High Error……………………………………………. 894

Troubleshooting by failure code, Part 4……………………………………………………………… 897

Failure code [D110KB] Battery Relay Drive S/C…………………………………………………….. 900

Failure code [D163KB] Flash Light Relay S/C………………………………………………………. 902

Failure code [D195KA] Step Light Relay Disc………………………………………………………. 904

Failure code [D195KY] Step Light Relay S/C……………………………………………………….. 906

Failure code [D1E9KB] Wiper Drive Relay 1 S/C…………………………………………………….. 908

Failure code [D1EAKB] Wiper Drive Relay 2 S/C…………………………………………………….. 910

Failure code [D1EBKB] Lower Wiper Brake Relay Short Circuit………………………………………… 912

Failure code [D1ECKB] Upper Wiper Brake Relay Short Circuit………………………………………… 914

Failure code [DA22KK] Pump 1 Solenoid Power Low Error……………………………………………… 916

Failure code [dA22KK] Pump 2 Solenoid Power Low Error……………………………………………… 918

Failure code [DA25KP] Pump 1 Sens Supply Vol Low Error…………………………………………….. 920

Failure code [dA25KP] Pump 2 Sens Supply Vol Low Error…………………………………………….. 922

Failure code [DA26KP] 5V Sensor 2 Power Abnormality……………………………………………….. 924

Failure code [DA29KQ] Pump 1 Model Select Abnormality……………………………………………… 926

Failure code [dA29KQ] Pump 2 Model Select Abnormality……………………………………………… 928

Failure code [DA2RMC] CAN Discon (Pump 1 Con Detected)…………………………………………….. 930

Failure code [dA2RMC] CAN Discon (Pump 2 Con Detected)…………………………………………….. 932

Failure code [DAFRMC] CAN Discon (Monitor Detected)……………………………………………….. 934

Failure code [DA2TMC] Pump Comm. ECM Child Abnormality…………………………………………….. 936

Failure code [DBB0KK] VHMS Source Voltage Error (or change of VHMS-LED display from n9 to 01)………….. 938

Failure code [DBB0KQ] VHMS Connector Mismatch (or change of VHMS-LED display from nF to 11)……………. 940

Failure code [DBB5KP] VHMS 5V source sys Error (or change of VHMSLED display from n9 to 04)……………. 942

Failure code [DBB6KP] VHMS 24V source sys Error (or change of VHMS-LED display from n9 to 02)………….. 944

Failure code [DBBQKR] KOM-NET/c error (or change of VHMS-LED display from n8 to 02)…………………… 946

Failure code [DGE5KX] Ambient Air Temp Sensor Failure (or change of VHMS-LED display from n4 to 01)…….. 948

Failure code [DGH2KB] Hydr. Oil Temp. Sensor S/C………………………………………………….. 950

Failure code [DGT3KZ] PTO Temp Sensor Failure (or change of VHMSLED display from n5 to 01)…………….. 952

Troubleshooting by failure code, Part 5……………………………………………………………… 955

Failure code [DGT5KA] Exhaust Temp. Sensor LBF Failure (or change of VHMS-LED display from n3 to 12)……. 958

Failure code [dGT5KA] Exhaust Temp. Sensor LBR Failure (or change of VHMS-LED display from n3 to 22)……. 960

Failure code [DGT5KB] Exhaust Temp. Sensor LBF Failure (or change of VHMS-LED display from n3 to 11)……. 962

Failure code [dGT5KB] Exhaust Temp. Sensor LBR Failure (or change of VHMS-LED display from n3 to 21)……. 964

Failure code [DGT6KA] Exhaust Temp. Sensor RBF Failure (or change of VHMS-LED display from n3 to 24)……. 966

Failure code [dGT6KA] Exhaust Temp. Sensor RBR Failure (or change of VHMS-LED display from n3 to 26)……. 968

Failure code [DGT6KB] Exhaust Temp. Sensor RBF Failure (or change of VHMS-LED display from n3 to 23)……. 970

Failure code [dGT6KB] Exhaust Temp. Sensor RBR Failure (or change of VHMS-LED display from n3 to 26)……. 972

Failure code [DH25KX] VR1/P1F J/S Dif Press Sensor Abnormality……………………………………… 974

Failure code [DH26KX] VL1/P1R J/S Dif Press Sensor Abnormality……………………………………… 976

Failure code [DH27KX] VR2/P2F J/S Dif Press Sensor Abnormality……………………………………… 978

Failure code [DH28KX] VL2/P2R J/S Dif Press Sensor Abnormality……………………………………… 980

Failure code [DHE5KB] Blowby Pres. Sensor Failure (or change of VHMS-LED display from n3 to 32)………… 982

Failure code [DHE5KY] Blowby Pres. Sensor Failure (or change of VHMS-LED display from n3 to 31)………… 984

Failure code [DHH2KA] Hydraulic oil filter Sensor Failure (or change of VHMS-LED display from n5 to 53)…. 986

Failure code [DHPEKX] VR1/P1F Pump P. Sensor Abnormality…………………………………………… 988

Failure code [DHPFKX] VL1/P1R Pump P. Sensor Abnormality…………………………………………… 990

Failure code [DHPGKX] VR2/P2F Pump P. Sensor Abnormality…………………………………………… 992

Failure code [DHPHKX] VL2/P2R Pump P. Sensor Abnormality…………………………………………… 994

Failure code [DHPSKX] Auto Grease Press Sensor Abnormality…………………………………………. 996

Failure code [DHPTKX] Fan(RAD) Pump P. Sensor Open Circuit…………………………………………. 998

Failure code [DHPUKX] Fan(O/C) Pump P. Sensor Open Circuit………………………………………….1000

Failure code [DHS3KX] Arm Dig PPC Press Sensor Abnormality………………………………………….1002

Failure code [DHS4KX] Bucket Curl PPC Press Sensor Abnormality………………………………………1004

Failure code [DHS8KX] Boom Raise PPC Press Sensor Abnormality……………………………………….1006

Failure code [DHS9KX] Boom Lower PPC Press Sensor Abnormality……………………………………….1008

Failure code [DHSAKX] Swing Right PPC Press Sensor Abnormality………………………………………1010

Failure code [DHSBKX] Swing Left PPC Press Sensor Abnormality……………………………………….1012

Failure code [DHSCKX] Arm Dump PPC Press Sensor Abnormality…………………………………………1014

Failure code [DHSDKX] Bucket Dump PPC Press Sensor Abnormality………………………………………1016

Troubleshooting by failure code, Part 6………………………………………………………………1019

Failure code [DUM3KB] Auto Grease Caution LED Short Circuit…………………………………………1021

Failure code [DUM4KB] FAN Reverse LED Short Circuit………………………………………………..1022

Failure code [DV20KB] Travel Alarm S/C……………………………………………………………1023

Failure code [DW41KA] Swing Priority Sol Open Circuit………………………………………………1025

Failure code [DW41KB] Swing Priority Sol Short Circuit……………………………………………..1027

Failure code [DW45KA] Swing Brake Sol. Disc……………………………………………………….1029

Failure code [DW45KB] Swing Brake Sol. S/C………………………………………………………..1032

Failure code [DW91KA] Straight-Travel Sol. Disc……………………………………………………1034

Failure code [DW91KB] Straight-Travel Sol. S/C…………………………………………………….1036

Failure code [DW4XKA] Bucket Curl Hi Cancel Sol. Disc………………………………………………1038

Failure code [DW4XKB] Bucket Curl Hi Cancel Sol. S/C……………………………………………….1039

Failure code [DW7BKA] Fan Motor (RAD) Reverse Sol Open Circuit………………………………………1040

Failure code [DW7BKB] Fan Motor (RAD) Reverse Sol. S/C……………………………………………..1042

Failure code [DW7HKA] Fan Motor(O/C) Reverse Sol Open Circuit……………………………………….1044

Failure code [DW7HKB] Fan Motor(O/C) Reverse Sol Short Circuit………………………………………1046

Failure code [DWA3KA] Arm throttle Valve/L Sol Open Circuit…………………………………………1048

Failure code [DWA3KB] Arm throttle Valve/L Sol Short Circuit………………………………………..1050

Failure code [DWA4KA] Arm throttle Valve/R Sol Open Circuit…………………………………………1052

Failure code [DWA4KB] Arm throttle Valve/R Sol Short Circuit………………………………………..1054

Failure code [DWA5KA] Auto Grease Sol Open Circuit…………………………………………………1056

Failure code [DWA5KB] Auto Grease Sol Short Circuit………………………………………………..1058

Failure code [DWA6KA] Boom throttle Valve Sol Open Circuit………………………………………….1059

Failure code [DWA6KB] Boom throttle Valve Sol Short Circuit…………………………………………1061

Failure code [DWK0KA] 2-stage Relief Sol. Disc…………………………………………………….1063

Failure code [DWK0KB] 2-stage Relief Sol. S/C……………………………………………………..1065

Failure code [DWK2KA] Back Press Comp Valve Sol Open Circuit………………………………………..1066

Failure code [DWK2KB] Back Press Comp Valve Sol Short Circuit……………………………………….1067

Troubleshooting by failure code, Part 7………………………………………………………………1069

Failure code [DWN5KA] Fan(RAD) Pump EPC Sol Open Circuit……………………………………………1071

Failure code [DWN5KB] Fan(RAD) Pump EPC Sol Short Circuit…………………………………………..1072

Failure code [DWNCKA] Fan(O/C) Pump EPC Sol Open Circuit……………………………………………1073

Failure code [DWNCKB] Fan(O/C) Pump EPC Sol Short Circuit…………………………………………..1074

Failure code [DXAAKA] P1F EPC Sol Disc……………………………………………………………1076

Failure code [DXAAKB] P1F EPC Sol S/C…………………………………………………………….1078

Failure code [DXABKA] P1R Pump EPC Sol. Disc………………………………………………………1080

Failure code [DXABKB] P1R Pump EPC Sol. S/C……………………………………………………….1082

Failure code [DXACKA] P2F Pump EPC Sol. Disc………………………………………………………1084

Failure code [DXACKB] P2F Pump EPC Sol. S/C……………………………………………………….1086

Failure code [DXADKA] P2R Pump EPC Sol. Disc………………………………………………………1088

Failure code [DXADKB] P2R Pump EPC Sol. S/C……………………………………………………….1090

Failure code [DY2CKB] Washer Drive S/C……………………………………………………………1092

Failure code [DY20MA] Low Wiper Working Abnormality………………………………………………..1094

Failure code [DY2FMA] Upper Wiper Working Abnormality………………………………………………1097

Failure code [F@BBZL] High Blowby Pressure (or change of VHMS-LED display from n3 to 38)……………….1100

Failure code [F@BYNR] Very High LBF CYL Exhaust Temp (or change of VHMS-LED display from n3 to 62)………1102

Failure code [f@BYNR] Very High LBR CYL Exhaust Temp (or change of VHMS-LED display from n3 to 72)………1104

Failure code [F@BYNS] High LBF CYL Exhaust Temp (or change of VHMS-LED display from n3 to 61)…………..1106

Failure code [f@BYNS] High LBR CYL Exhaust Temp (or change of VHMS-LED display from n3 to 71)…………..1108

Failure code [F@BZNR] Very High RBF CYL Exhaust Temp (or change of VHMS-LED display from n3 to 82)………1110

Failure code [f@BZNR] Very High RBR CYL Exhaust Temp (or change of VHMS-LED display from n3 to 92)………1112

Failure code [F@BZNS] High RBF CYL Exhaust Temp (or change of VHMS-LED display from n3 to 81)…………..1114

Failure code [f@BZNS] High RBR CYL Exhaust Temp (or change of VHMS-LED display from n3 to 91)…………..1116

Failure code [LA10ZL] RAD system fan pump relief pressure high error…………………………………1118

Failure code [LA20ZL] O/C system pump relief pressure high error…………………………………….1120

Troubleshooting of electrical system (E-mode)…………………………………………………………1123

Before carrying out troubleshooting of electrical system……………………………………………1125

Contents of troubleshooting table………………………………………………………………..1132

E-1 When starting switch is turned ON, machine monitor displays nothing………………………………1134

E-2 When starting switch turned ON (before starting engine), basic check item lights up………………..1136

E-3 Engine does not start (Engine does not turn)…………………………………………………..1138

E-4 Auto-decelerator does not operate…………………………………………………………….1142

E-5 Automatic warm-up system does not operate……………………………………………………..1143

E-6 Preheater does not work……………………………………………………………………..1144

E-7 Whole work equipment, swing operation and machine travel operation are disabled……………………1146

E-8 Machine push-up function does not work………………………………………………………..1148

E-9 Boom shockless function cannot be released…………………………………………………….1150

E-10 Machine monitor does not display some items…………………………………………………..1152

E-11 Contents of display by machine monitor are different from applicable machine……………………..1153

E-12 Fuel level monitor lights up in red while engine is running…………………………………….1154

E-13 Hydraulic oil temperature gauge does not indicate normally……………………………………..1155

E-14 Fuel level gauge does not indicate normally…………………………………………………..1156

E-15 Swing lock monitor does not indicate normally…………………………………………………1158

E-16 Machine monitor display anything even when operated on monitor switch section…………………….1160

E-17 Wiper does not work………………………………………………………………………..1161

E-18 Monitoring function does not display “Travel” normally…………………………………………1168

E-19 Travel alarm does not sound…………………………………………………………………1170

E-20 All of room lamp, headlamp and working lamp do not light up…………………………………….1171

E-21 Air conditioner does not work……………………………………………………………….1176

E-22 Step light does not light up or goes off……………………………………………………..1178

Troubleshooting of hydraulic and mechanical system (H-mode)…………………………………………….1183

Before troubleshooting for hydraulic and mechanical systems…………………………………………1185

Table of failure modes and causes………………………………………………………………..1190

Information in troubleshooting table……………………………………………………………..1192

H-1 Speed or power of whole work equipment, travel, and swing is low…………………………………1193

H-2 Engine speed lowers remarkably or engine stalls………………………………………………..1195

H-3 Work equipment, swing, and travel mechanism do not move…………………………………………1196

H-4 Abnormal noise comes from around hydraulic pump………………………………………………..1198

H-5 Speed or power of boom is low………………………………………………………………..1199

H-6 Speed or power of arm is low…………………………………………………………………1201

H-7 Speed or power of bucket is low………………………………………………………………1202

H-8 Boom does not move………………………………………………………………………….1203

H-9 Arm does not move…………………………………………………………………………..1203

H-10 Bucket does not move……………………………………………………………………….1203

H-11 Hydraulic drift of work equipment is large……………………………………………………1204

H-12 Time lag of work equipment is large………………………………………………………….1205

H-13 Heavy lift function does not work or is not reset……………………………………………..1206

H-14 Machine push-up function does not work or is not reset…………………………………………1206

H-15 Boom shockless function does not work or is not reset………………………………………….1206

H-16 Machine gradually deviates during traveling…………………………………………………..1208

H-17 Machine deviates excessively when started to travel……………………………………………1211

H-18 Machine deviates excessively during multiple operations………………………………………..1212

H-19 Traveling speed or power is low……………………………………………………………..1212

H-20 Travel system does not move (only one side)…………………………………………………..1213

H-21 Upper structure does not swing………………………………………………………………1214

H-22 Swing speed or acceleration is low…………………………………………………………..1216

H-23 In compound operation of work equipment, swing speed or acceleration is low………………………1218

H-24 Upper structure overruns remarkably when it stops swinging……………………………………..1219

H-25 Large shock is made when upper structure stops swinging………………………………………..1220

H-26 Large abnormal sound comes from when upper structure stops swinging……………………………..1221

H-27 Hydraulic drift of work equipment is large in swing operation…………………………………..1222

H-28 Fan rotation is abnormal (large noise or vibration of fans, or fan overheating)…………………..1223

H-29 Bottom dump speed or power is lower (Loading shovel specification)………………………………1224

H-30 Bottom dump cylinder does not move (Loading shovel specification)……………………………….1225

Troubleshooting of mechanical system (S-mode)…………………………………………………………1227

Method of using troubleshooting charts……………………………………………………………1229

S-1 Starting performance is poor…………………………………………………………………1232

S-2 Engine does not start……………………………………………………………………….1233

S-3 Engine does not pick up smoothly……………………………………………………………..1236

S-4 Engine stops during operations……………………………………………………………….1237

S-5 Engine does not rotate smoothly………………………………………………………………1238

S-6 Engine lacks output (or lacks power)………………………………………………………….1240

S-7 Exhaust smoke is black (incomplete combustion)…………………………………………………1242

S-8 Oil consumption is excessive (or exhaust smoke is blue)…………………………………………1243

S-9 Oil becomes contaminated quickly……………………………………………………………..1244

S-10 Fuel consumption is excessive……………………………………………………………….1245

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)……………………………1246

S-12 Oil pressure drops…………………………………………………………………………1247

S-13 Oil level rises (Entry of coolant or fuel)……………………………………………………1248

S-14 Coolant temperature becomes too high (overheating)…………………………………………….1249

S-15 Abnormal noise is made……………………………………………………………………..1250

S-16 Vibration is excessive……………………………………………………………………..1251

50 Disassembly and assembly…………………………………………………………………………….1253

General information on disassembly and assembly……………………………………………………….1253

How to read this manual…………………………………………………………………………1254

Coating materials list………………………………………………………………………….1256

Special tool list………………………………………………………………………………1259

Sketches of special tools……………………………………………………………………….1263

Engine and cooling system…………………………………………………………………………..1267

Removal and installation of power container assembly……………………………………………….1268

Removal and installation of engine, PTO and hydraulic pump assembly………………………………….1273

Removal and installation of radiator assembly……………………………………………………..1285

Removal and installation of aftercooler assembly…………………………………………………..1286

Removal and installation of hydraulic oil cooler assembly…………………………………………..1288

Removal and installation of fuel cooler assembly…………………………………………………..1289

Removal and installation of cooling assembly………………………………………………………1290

Removal and installation of fan motor assembly…………………………………………………….1294

Removal and installation of fuel tank assembly…………………………………………………….1295

Engine……………………………………………………………………………………………1299

Removal and installation of fuel supply pump assembly………………………………………………1300

Removal and installation of cylinder head assembly…………………………………………………1304

Removal and installation of fuel injector…………………………………………………………1318

Removal and installation of engine front oil seal………………………………………………….1329

Removal and installation of engine rear oil seal…………………………………………………..1332

Power train……………………………………………………………………………………….1337

Removal and installation of PTO assembly………………………………………………………….1338

Disassembly and assembly of PTO assembly………………………………………………………….1339

Removal and installation of swing motor and swing machinery assembly…………………………………1343

Disassembly and assembly of swing machinery assembly……………………………………………….1345

Removal and installation of swing circle assembly………………………………………………….1355

Removal and installation of final drive assembly…………………………………………………..1356

Disassembly and assembly of final drive assembly…………………………………………………..1358

Undercarriage and frame…………………………………………………………………………….1371

Removal and installation of track shoe assembly……………………………………………………1372

Removal and installation of idler assembly………………………………………………………..1374

Disassembly and assembly of idler assembly………………………………………………………..1375

Disassembly and assembly of idler adjust cylinder assembly………………………………………….1377

Removal and installation of idler cushion cylinder assembly…………………………………………1378

Disassembly and assembly of idler cushion cylinder assembly…………………………………………1379

Removal and installation of track roller assembly………………………………………………….1380

Disassembly and assembly of track roller assembly………………………………………………….1381

Removal and installation of carrier roller assembly………………………………………………..1383

Disassembly and assembly of carrier roller assembly………………………………………………..1384

Removal and installation of revolving frame assembly……………………………………………….1388

Removal and installation of counterweight assembly…………………………………………………1391

Removal and installation of hydraulic ladder………………………………………………………1392

Hydraulic system…………………………………………………………………………………..1395

Removal and installation of hydraulic tank assembly………………………………………………..1396

Removal and installation of hydraulic pump assembly………………………………………………..1399

Removal and installation of hydraulic pump input shaft oil seal……………………………………..1404

Removal and installation of control valve assembly…………………………………………………1405

Disassembly and assembly of control valve assembly…………………………………………………1412

Removal and installation of center swivel joint assembly……………………………………………1416

Disassembly and assembly of center swivel joint assembly……………………………………………1417

Removal and installation of swing motor assembly…………………………………………………..1418

Removal and installation of travel motor assembly………………………………………………….1419

Disassembly and assembly of work equipment PPC valve assembly……………………………………….1420

Disassembly and assembly of travel PPC valve assembly………………………………………………1422

Disassembly and assembly of hydraulic cylinder assembly (Backhoe specification)……………………….1425

Disassembly and assembly of hydraulic cylinder assembly (Loading shovel specification)…………………1432

Removal and installation of grease pump…………………………………………………………..1437

Disassembly and assembly of grease pump…………………………………………………………..1441

Work equipment…………………………………………………………………………………….1451

Removal and installation of bucket cylinder assembly (Backhoe specification)………………………….1452

Removal and installation of bucket cylinder assembly (Loading shovel specification)……………………1454

Removal and installation of bucket assembly (Backhoe specification)………………………………….1456

Removal and installation of bucket assembly (Loading shovel specification)……………………………1458

Removal and installation of arm cylinder (Backhoe specification)…………………………………….1460

Removal and installation of arm cylinder (Loading shovel specification)………………………………1462

Removal and installation of arm assembly (Backhoe specification)…………………………………….1463

Removal and installation of arm assembly (Loading shovel specification)………………………………1465

Removal and installation of boom cylinder assembly (Backhoe specification)……………………………1466

Removal and installation of boom cylinder assembly (Loading shovel specification)……………………..1468

Removal and installation of boom assembly (Backhoe specification)……………………………………1470

Removal and installation of boom assembly (Loading shovel specification)……………………………..1472

Removal and installation of bottom dump cylinder assembly (Loading shovel specification)……………….1474

Cab and its attachments…………………………………………………………………………….1477

Removal and installation of operator cab assembly………………………………………………….1478

Removal and installation of operator cab glass (adhesion glass)……………………………………..1481

Removal and installation of operator cab (assembly-type)……………………………………………1488

Removal and installation of cab base assembly……………………………………………………..1489

Removal and installation of service center………………………………………………………..1491

Electrical system………………………………………………………………………………….1495

Removal and installation of air conditioner unit assembly…………………………………………..1496

Removal and installation of monitor assembly………………………………………………………1500

Removal and installation of engine controller assembly……………………………………………..1501

Removal and installation of pump controller assembly……………………………………………….1502

Removal and installation of VHMS controller assembly……………………………………………….1503

Removal and installation of Orbcomm terminal assembly for VHMS………………………………………1503

90 Diagrams and drawings……………………………………………………………………………….1505

Hydraulic diagrams and drawings……………………………………………………………………..1505

Hydraulic circuit diagram (Backhoe specification) Serial No.: 20001 – 20197…………………………..1507

Hydraulic circuit diagram (Backhoe specification) Serial No.: 20198 and up……………………………1509

Hydraulic circuit diagram (Loading shovel specification) Serial No.: 20001 – 20197…………………….1511

Hydraulic circuit diagram (Loading shovel specification) Serial No.: 20198 and up……………………..1513

Electrical diagrams and drawings…………………………………………………………………….1517

Electrical circuit diagram (1/14)………………………………………………………………..1519

Electrical circuit diagram (2/14)………………………………………………………………..1521

Electrical circuit diagram (3/14)………………………………………………………………..1523

Electrical circuit diagram (4/14)………………………………………………………………..1525

Electrical circuit diagram (5/14)………………………………………………………………..1527

Electrical circuit diagram (6/14)………………………………………………………………..1529

Electrical circuit diagram (7/14)………………………………………………………………..1531

Electrical circuit diagram (8/14)………………………………………………………………..1533

Electrical circuit diagram (9/14)………………………………………………………………..1535

Electrical circuit diagram (10/14)……………………………………………………………….1537

Electrical circuit diagram (11/14)……………………………………………………………….1539

Electrical circuit diagram (12/14)……………………………………………………………….1541

Electrical circuit diagram (13/14)……………………………………………………………….1543

Electrical circuit diagram (14/14)……………………………………………………………….1545

Connector list and stereogram……………………………………………………………………1547