Starting from:

$45

Home

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up) PDF

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up) PDF

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up)

FILE DETAILS:

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up)

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : WEAM007000

Total Pages : 234

DESCRIPTION:

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up)

FOREWORD:

- This manual is supplied by Komatsu Utility S.p.A. in order to provide customers with all the necessary information on the machine and the safety regulations related to it, together with the use and maintenance instructions that enable the operator to exploit the capacity of the machine with optimal results and to keep the machine efficient over time.

- The operation manual, together with the spare parts catalogue, is an integral part of the machine and must accompany it, even when it is resold, until its final disposal.

- The manual must be handled with the greatest care and always kept on board the machine, so that it can be consulted at any moment; it must be placed in the appropriate compartment, where also the ownership documents and the logbook are usually kept.

- This manual must be given to the persons who have to use the machine and carry out the routine maintenance operations; they must read the contents carefully more than once, in such a way as to clearly understand what are the correct operating conditions and the dangerous conditions that must be avoided. In case of loss or damage, request a new copy to Komatsu or to your Komatsu Dealer.

- The illustrations contained in this manual may represent machine configurations that are available on request. Komatsu machines are constantly improved in order to increase their efficiency and reliability; this manual sums up all the information regarding the most recent techniques applied at the moment in which the machine is marketed. For any updated information, contact your Komatsu Dealer.

- Punctual periodic annotations regarding the maintenance operations that have been carried out are important to have a clear prospect of the situation and to know exactly what has been done and what has to be done after the next maintenance interval. Therefore, it is advisable to consult either the hour meter and the maintenance plan frequently.

- Over the years Komatsu Dealers have gathered considerable experience in customer service. If more information is needed, do not hesitate to contact your Komatsu Utility Dealer: he always knows how to get the best performance from the machine, he can suggest the use of the equipment that is most suitable for specific needs and can provide the technical assistance necessary for any change that may be required to conform the machine to the safety standards and traffic rules. Furthermore, Komatsu Dealers also ensure their assistance for the supply of Komatsu genuine spare parts, which alone guarantee safety and interchangeability.

- The table included in this manual must be filled in with the machine data, which are the data that must always be indicated to the Dealer when requiring assistance and ordering spare parts.

TABLE OF CONTENTS:

Komatsu PC20MR-2 Galeo Hydraulic Excavator Operation & Maintenance Manual (15001 and up)

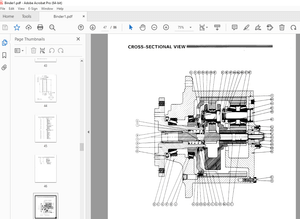

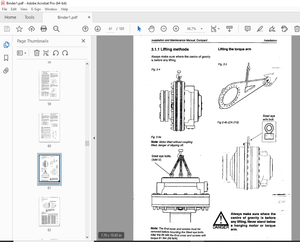

1.1 FOREWORD............................................................................................. 3 1.2 INFORMATION ON SAFETY................................................................................ 4 1.3 INTRODUCTION......................................................................................... 6 1.3.1 INTENDED USES.................................................................................. 6 1.3.2 IMPROPER OR UNAUTHORIZED USES.................................................................. 6 1.3.3 MAIN CHARACTERISTICS........................................................................... 6 1.3.4 RUNNING-IN..................................................................................... 7 1.3.5 DIRECTIONS OF MACHINE.......................................................................... 7 1.4 PRODUCT IDENTIFICATION............................................................................... 8 1.4.1 MACHINE SERIAL NUMBER.......................................................................... 8 1.4.2 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)........................... 8 1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE............................................ 9 1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER............................................................ 9 1.4.5 SWING REDUCTION GEAR SERIAL NUMBER............................................................. 10 1.4.6 CAB SERIAL NUMBER.............................................................................. 10 1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS............................................................ 11 TABLE OF CONTENTS........................................................................................ 12 2.1 SAFETY, NOISE AND VIBRATION PLATES................................................................... 20 2.1.1 POSITION OF THE SAFETY PLATES.................................................................. 20 2.1.2 PICTOGRAMS AND RELEVANT MEANINGS............................................................... 21 2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB.............................................. 26 2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY........................................... 27 2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED.................................................. 27 2.2 GENERAL PRECAUTIONS.................................................................................. 28 2.2.1 GENERAL SAFETY RULES........................................................................... 28 2.2.2 SAFETY DEVICES AND GUARDS...................................................................... 28 2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS......................................................... 28 2.2.4 UNAUTHORIZED MODIFICATIONS..................................................................... 29 2.2.5 LEAVING THE OPERATOR’S SEAT.................................................................... 29 2.2.6 GETTING ON AND OFF THE MACHINE................................................................. 30 2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL........................................................... 31 2.2.8 PREVENTING BURNS............................................................................... 31 2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER....................................................... 32 2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT................................................ 32 2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT.......................................................... 33 2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE...................................................... 33 2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT.......................................................... 33 2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE................................................... 34 2.3.1 SAFETY ON THE WORK SITE........................................................................ 34 2.3.2 FIRE PREVENTION................................................................................ 34 2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB................................................. 34 2.3.4 ROOM VENTILATION............................................................................... 35 2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS......................................................... 35 2.3.6 CLEANING THE WINDOWS - CHECKING THE WINDSHIELD WIPER BLADES.................................... 35 2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING................................................................. 36 2.4.1 STARTING THE ENGINE............................................................................ 36 2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE................................................ 36 2.4.3 CHECKS FOR TRAVELLING IN REVERSE............................................................... 37 2.4.4 MOVING THE MACHINE............................................................................. 37 2.4.5 MOVING ON SLOPES............................................................................... 38 2.4.6 WORKING ON SLOPES.............................................................................. 39 2.4.7 UNAUTHORIZED OPERATIONS........................................................................ 39 2.4.8 PREVENTING ELECTROCUTION....................................................................... 41 2.4.9 VISIBILITY..................................................................................... 41 2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES....................................................... 41 2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT................................................ 42 2.4.12 WORKING ON LOOSE GROUND....................................................................... 42 2.4.13 PARKING THE MACHINE........................................................................... 42 2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES........................................................... 43 2.5.1 LOADING AND UNLOADING.......................................................................... 43 2.5.2 TRANSPORT...................................................................................... 43 2.6 BATTERY.............................................................................................. 44 2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY................................................ 44 2.6.2 STARTING WITH BOOSTER CABLES................................................................... 44 2.7 PRECAUTIONS FOR THE REMOVAL.......................................................................... 45 2.8 PRECAUTIONS FOR MAINTENANCE.......................................................................... 46 2.8.1 WARNING PLATES................................................................................. 46 2.8.2 TOOLS.......................................................................................... 46 2.8.3 PERSONNEL...................................................................................... 46 2.8.4 EQUIPMENT...................................................................................... 47 2.8.5 WORKING UNDER THE MACHINE...................................................................... 47 2.8.6 CLEANING THE MACHINE........................................................................... 47 2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS................................................ 48 2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY.................................... 48 2.8.9 STOP THE ENGINE BEFORE CARRY ING OUT ANY MAINTENANCE OPER ATION OR INSPECTION.................. 48 2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP............................................ 49 2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR.................................................... 49 2.8.12 USING LAMPS................................................................................... 49 2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR......................................... 50 2.8.14 PRECAUTIONS CONCERNING THE STARTER............................................................ 50 2.8.15 HANDLING HIGH-PRESSURE PIPES.................................................................. 50 2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL....................................... 51 2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERA TURES AND HIGH PRESSURE................ 51 2.8.18 PRECAUTIONS TO BE TAKEN WHEN USING HIGH-PRESSURE GREASE TO ADJUST THE TRACK TENSION........... 52 2.8.19 DO NOT REMOVE THE SHOCK ABSORBING SPRING FROM THE SHOCK ABSORBER UNIT......................... 52 2.8.20 HYDRAULIC ACCUMULATOR......................................................................... 52 2.8.21 COOLING FAN AND BELT.......................................................................... 53 2.8.22 WASTE MATERIALS............................................................................... 53 2.8.23 COMPRESSED AIR................................................................................ 53 2.8.24 PRECAUTIONS FOR THE USE OF THE synthetic biodegrada ble oil type HEES......................... 53 3.1 MACHINE VIEW ILLUSTRATIONS........................................................................... 56 3.1.1 OVERALL MACHINE VIEW........................................................................... 56 3.1.2 CONTROLS AND GAUGES............................................................................ 57 3.2 DETAILED CONTROLS AND GAUGES......................................................................... 58 3.2.1 MONITORING SYSTEM.............................................................................. 58 3.2.1.1 EMERGENCY MONITORS....................................................................... 59 3.2.1.2 METER DISPLAY PORTION.................................................................... 61 3.2.1.3 PILOT LAMPS.............................................................................. 63 3.2.1.4 MONITOR SWITCHES PORTION................................................................. 64 3.2.2 SWITCHES....................................................................................... 66 3.2.3 CONTROL LEVERS AND PEDALS...................................................................... 69 3.2.4 WINDSHIELD (Machines equipped with cab)........................................................ 76 3.2.5 SLIDING DOOR (Machines equipped with cab)...................................................... 80 3.2.6 SLIDING WINDOW (Machines equipped with cab).................................................... 80 3.2.7 EMERGENCY ESCAPE HAMMER (Machines equipped with cab)........................................... 81 3.2.8 CAPS AND COVERS WITH LOCK...................................................................... 82 3.2.9 ENGINE REAR COVER.............................................................................. 83 3.2.10 COOLING COVER................................................................................. 84 3.2.11 TANK COVER.................................................................................... 85 3.2.12 METHOD OF OPENING (TILTING) FLOOR............................................................. 86 3.2.13 FUSE.......................................................................................... 90 3.2.14 BLOCK FUSE.................................................................................... 90 3.2.15 OPERATION MANUAL STORAGE...................................................................... 91 3.2.16 TOOL BOX...................................................................................... 91 3.2.17 GREASE GUN HOLDER............................................................................. 91 3.2.18 ASHTRAY (Machines equipped with cab).......................................................... 91 3.3 MACHINE OPERATIONS AND CONTROLS...................................................................... 92 3.3.1 BEFORE STARTING ENGINE......................................................................... 92 3.3.1.1 WALK-AROUND CHECKS....................................................................... 92 3.3.1.2 CHECKS BEFORE STARTING................................................................... 94 3.3.1.3 ADJUSTMENT...............................................................................100 3.3.1.4 OPERATIONS BEFORE STARTING ENGINE........................................................103 3.3.1.5 STARTING ENGINE..........................................................................105 3.3.2 AFTER STARTING ENGINE..........................................................................108 3.3.2.1 BREAKING-IN THE NEW MACHINE..............................................................108 3.3.2.2 WARMING-UP OPERATION.....................................................................108 3.3.3 STOPPING THE ENGINE............................................................................110 3.3.4 MACHINE OPERATION..............................................................................111 3.3.4.1 PREPARATIONS FOR MOVING THE MACHINE OFF..................................................111 3.3.4.2 MOVING MACHINE FORWARD...................................................................111 3.3.4.3 MOVING MACHINE BACKWARD..................................................................113 3.3.4.4 STOPPING MACHINE.........................................................................114 3.3.5 STEERING THE MACHINE...........................................................................115 3.3.5.1 STEERING.................................................................................115 3.3.6 SWINGING.......................................................................................117 3.3.7 WORK EQUIPMENT CONTROLS AND OPERATIONS.........................................................118 3.3.8 PROHIBITED OPERATIONS..........................................................................120 3.3.9 GENERAL OPERATION INFORMATION..................................................................122 3.3.10 TRAVELING ON SLOPES...........................................................................124 3.3.11 ESCAPE FROM MUD...............................................................................126 3.3.12 WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR...............................................127 3.3.13 CHANGING THE BUCKET...........................................................................129 3.3.14 PARKING MACHINE...............................................................................130 3.3.15 CHECK AFTER SHUT OFF ENGINE...................................................................131 3.3.16 MACHINE INSPECTION AFTER DAILY WORK...........................................................131 3.3.17 LOCKING.......................................................................................131 3.3.18 RUBBER SHOES (Machines equipped only with rubber shoes).......................................132 3.3.18.1 OPTIMAL USE OF THE RUBBER SHOES.........................................................132 3.3.18.2 RUBBER SHOE WARRANTY....................................................................132 3.3.18.3 USING THE RUBBER SHOES..................................................................132 3.4 TRANSPORTATION.......................................................................................136 3.4.1 TRANSPORTATION PROCEDURE.......................................................................136 3.4.2 LOADING AND UNLOADING WITH TRAILER.............................................................136 3.4.3 LIFTING MACHINE................................................................................142 3.5 COLD WEATHER OPERATION...............................................................................144 3.5.1 COLD WEATHER OPERATION INFORMATION.............................................................144 3.5.1.1 FUEL AND LUBRICANTS......................................................................144 3.5.1.2 COOLING SYSTEM COOLANT...................................................................144 3.5.1.3 BATTERY..................................................................................145 3.5.2 CAB HEATER IN COLD WEATHER (Machines equipped with cab)........................................145 3.5.3 AFTER DAILY WORK COMPLETION....................................................................146 3.5.4 AFTER COLD WEATHER SEASON......................................................................146 3.6 LONG TERM STORAGE....................................................................................147 3.6.1 BEFORE STORAGE.................................................................................147 3.6.2 DURING STORAGE.................................................................................147 3.6.3 AFTER STORAGE..................................................................................147 3.7 TROUBLES AND ACTIONS.................................................................................148 3.7.1 RUNNING OUT OF FUEL............................................................................148 3.7.2 PHENOMENA THAT ARE NOT FAILURES................................................................148 3.7.3 TOWING THE MACHINE.............................................................................148 3.7.4 SEVERE JOB CONDITION...........................................................................149 3.7.5 DISCHARGED BATTERY.............................................................................149 3.7.5.1 BATTERY REMOVAL AND INSTALLATION.........................................................150 3.7.5.2 BATTERY CHARGES..........................................................................150 3.7.5.3 STARTING ENGINE WITH BOOSTER CABLES......................................................151 3.7.6 OTHER TROUBLE..................................................................................153 3.7.6.1 ELECTRICAL SYSTEM........................................................................153 3.7.6.2 CHASSIS..................................................................................154 3.7.6.3 ENGINE...................................................................................154 4.1 MAINTENANCE INFORMATION..............................................................................158 4.2 LUBRICANTS, COOLANT AND FILTERS......................................................................161 4.2.1 HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC.........................................161 4.2.1.1 OIL......................................................................................161 4.2.1.2 FUEL.....................................................................................161 4.2.1.3 COOLING SYSTEM COOLANT...................................................................162 4.2.1.4 GREASE...................................................................................162 4.2.1.5 CARRYING OUT KOWA (KOMATSU OIL WEAR ANALYSIS)............................................163 4.2.1.6 OIL AND FUEL STORAGE.....................................................................164 4.2.1.7 FILTERS..................................................................................164 4.2.2 ELECTRIC SYSTEM MAINTENANCE....................................................................165 4.2.3 HANDLING HYDRAULIC SYSTEM......................................................................165 4.3 WEAR PARTS...........................................................................................166 4.3.1 WEAR PARTS LIST................................................................................166 4.4 LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS..........................................................167 4.4.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS............................................171 4.5 TIGHTENING TORQUE SPECIFICATIONS.....................................................................172 4.5.1 TIGHTENING TORQUE LIST.........................................................................172 4.6 LUBRICATION..........................................................................................173 4.6.1 LUBRICATION DIAGRAM............................................................................173 4.7 SAFETY CRITICAL PARTS................................................................................174 4.7.1 SAFETY CRITICAL PARTS LIST.....................................................................174 4.8 MAINTENANCE SCHEDULE.................................................................................175 4.8.1 MAINTENANCE SCHEDULE CHART.....................................................................175 4.8.2 MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER.....................................................176 4.8.2.a CHANGING THE HYDRAULIC OIL FIL TER.......................................................176 4.8.2.b CHANGING THE HYDRAULIC OIL...............................................................176 4.9 MAINTENANCE PROCEDURE................................................................................177 4.9.1 WHEN REQUIRED..................................................................................177 4.9.1.a CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT.............................................177 4.9.1.b CLEAN INSIDE OF COOLING SYSTEM...........................................................179 4.9.1.c CHECK LEVEL OF BATTERY ELECTROLYTE.......................................................182 4.9.1.d CLEANING THE FUEL FILTER (WITH WATER SEPARATOR)..........................................184 4.9.1.e DRAIN WATER AND SEDIMENT FROM FUEL TANK..................................................184 4.9.1.f CHECK AND ADJUST TRACK TENSION (Machines equipped with steel shoes)......................185 4.9.1.g CHECKING THE RUBBER SHOES (Machines equipped with rubber shoes)..........................187 4.9.1.h CHECK AND ADJUST RUBBER SHOE TENSION (Machine equipped with rubber shoes)................189 4.9.1.i REPLACE RUBBER SHOES (Machine equipped with rubber shoes)................................191 4.9.1.j CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID (Machine equipped with cab)...................193 4.9.1.k CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER (Machine equipped with cab)....194 4.9.1.l BLEEDING AIR FROM HYDRAULIC SYSTEM.......................................................194 4.9.2 CHECK BEFORE STARTING..........................................................................195 4.9.3 EVERY 500 HOURS MAINTENANCE....................................................................196 4.9.3.a LUBRICATING..............................................................................196 4.9.3.b CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE........................198 4.9.3.c CHANGING THE FUEL FILTER ELEMENT (WITH WATER SEPARATOR)..................................199 4.9.3.d CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL.............................................200 4.9.3.e REPLACE FEED PUMP PRE-FILTER.............................................................201 4.9.3.f CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS......................................201 4.9.3.g CHECK AND ADJUST COOLING FAN BELT TENSION................................................202 4.9.4 EVERY 1000 HOURS MAINTENANCE...................................................................203 4.9.4.a CHANGING THE HYDRAULIC OIL FILTER ELEMENT................................................203 4.9.4.b CHANGE OIL IN FINAL DRIVE CASE...........................................................204 4.9.4.c CHECK ENGINE VALVE CLEARANCE, ADJUST.....................................................204 4.9.5 EVERY 2000 HOURS MAINTENANCE...................................................................205 4.9.5.a CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER.............................................205 4.9.5.b CHECK ALTERNATOR, STARTING MOTOR.........................................................206 5.1 SPECIFICATIONS.......................................................................................208 5.2 LIFTING CAPACITIES...................................................................................210 5.2.1 LIFTING CAPACITIES (WITH CANOPY)...............................................................210 5.2.2 LIFTING CAPACITIES (WITH CABIN)................................................................213 6.1 ATTACHMENTS AND OPTIONS - GENERAL INFORMATION........................................................218 6.1.1 SAFETY FIRST...................................................................................218 6.1.2 ATTACHMENT INSTALLATION........................................................................219 6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT......................................................220 6.1.3.1 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT................................................220 6.2 MACHINE READY FOR ATTACHMENT.........................................................................221 6.2.1 LOCATIONS......................................................................................221 6.2.2 HYDRAULIC CIRCUIT..............................................................................223 6.2.2.1 ASSEMBLYING AND CONNECTING THE EQUIPMENT.................................................223 6.2.2.2 MAINTENANCE..............................................................................224 6.2.2.3 BLEEDING AIR.............................................................................224 6.3 ATTACHMENT OPERATIONS................................................................................225 6.3.1 LONG TERM STORAGE..............................................................................226 6.3.2 SPECIFICATIONS.................................................................................226 6.4 ATTACHMENT GUIDE.....................................................................................227 6.4.1 ATTACHMENT COMBINATIONS........................................................................227 6.5 RECOMMENDED ATTACHMENT OPERATIONS....................................................................228 6.5.1 HYDRAULIC BREAKER..............................................................................228

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE:

1 file (8.6MB)