$45

Komatsu PC210-6K, PC210LC-6K, PC240LC-6K, PC240NLC-6K Hydraulic Excavator Shop Manual - PDF

Komatsu PC210-6K, PC210LC-6K, PC240LC-6K, PC240NLC-6K Hydraulic Excavator Shop Manual (K32001 and up)

FILE DETAILS:

Komatsu PC210-6K, PC210LC-6K, PC240LC-6K, PC240NLC-6K Hydraulic Excavator Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : EEBD001801

Total Pages : 665

DESCRIPTION:

Komatsu PC210-6K, PC210LC-6K, PC240LC-6K, PC240NLC-6K Hydraulic Excavator Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters: these chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs , as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the order to be followed when removing, installing, disassembling or assembling eachr component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD:

This section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

Komatsu PC210-6K, PC210LC-6K, PC240LC-6K, PC240NLC-6K Hydraulic Excavator Shop Manual

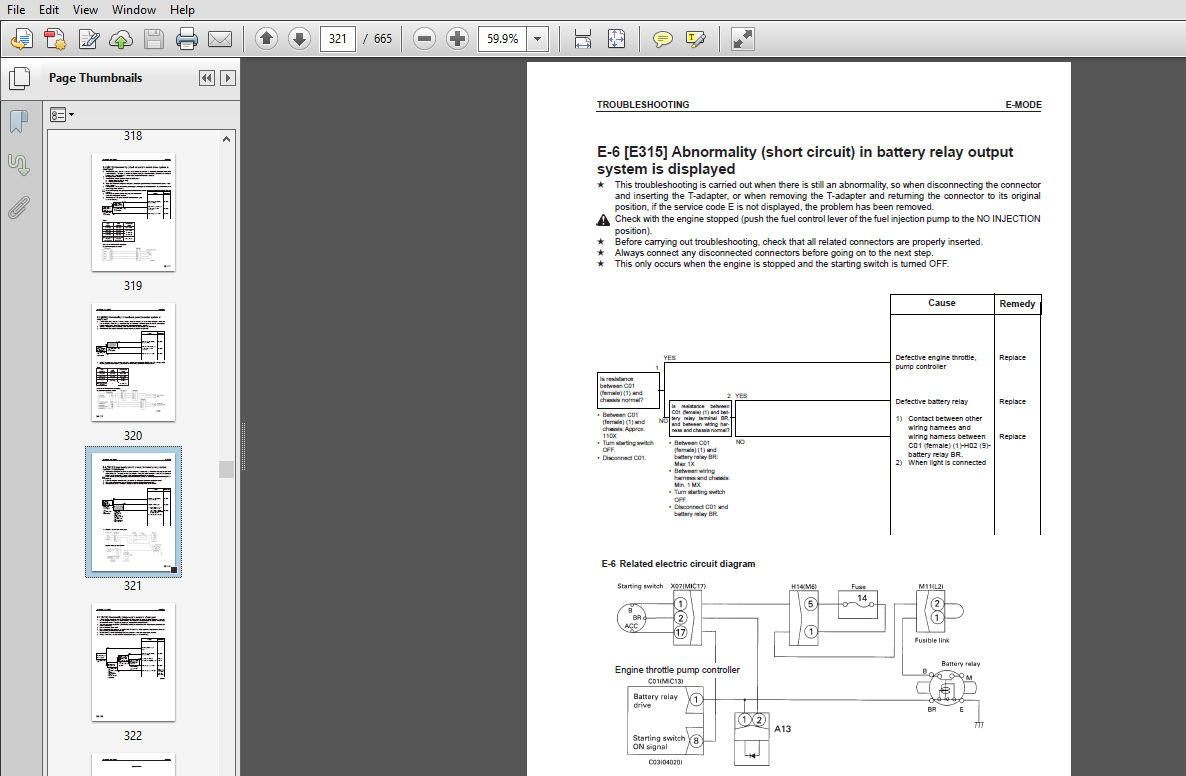

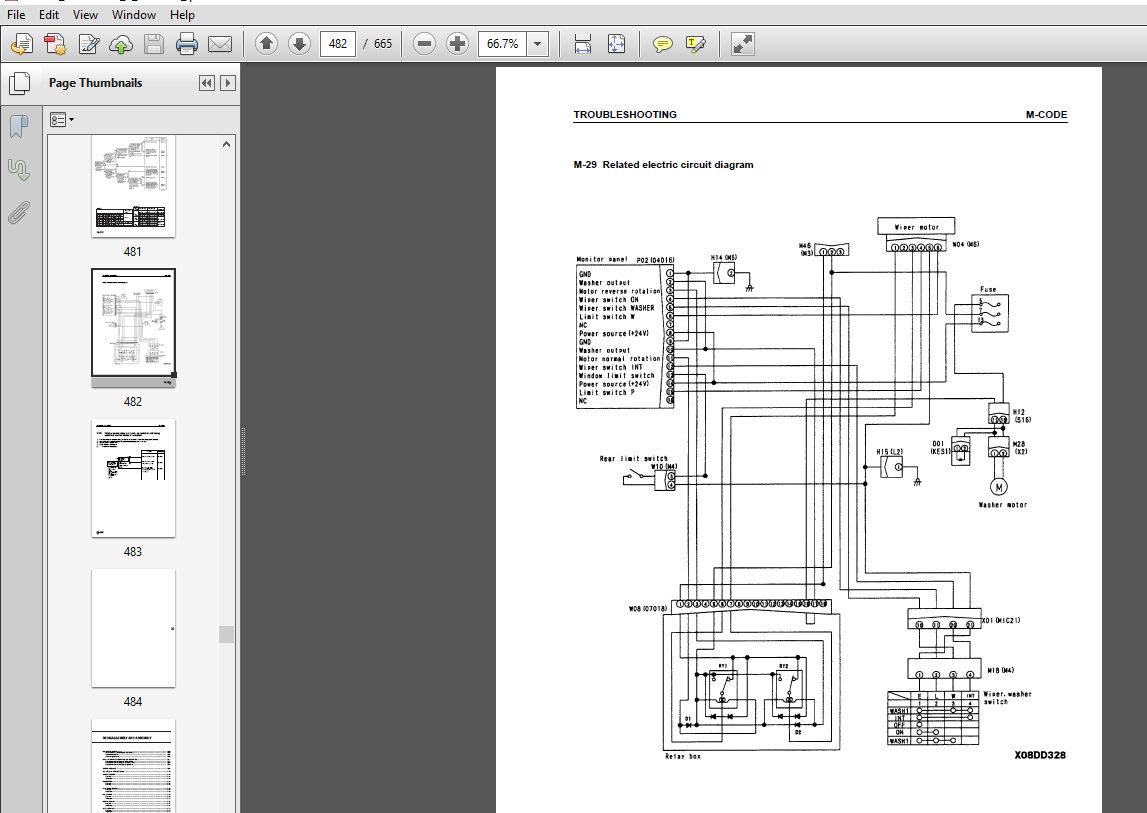

10 STRUCTURE AND FUNCTION ............................................................................................................................................................................................ 24 ENGINE RELATED PARTS ............................................................................................................................................................................................. 29 RADIATOR OIL COOLER ............................................................................................................................................................................................ 30 POWER TRAIN ...................................................................................................................................................................................................... 31 FINAL DRIVE ...................................................................................................................................................................................................... 32 SWING CIRCLE ..................................................................................................................................................................................................... 33 SWING MACHINERY .................................................................................................................................................................................................. 34 TRACK FRAME, RECOIL SPRING ....................................................................................................................................................................................... 35 TRACK SHOE ....................................................................................................................................................................................................... 36 HYDRAULIC TANK ................................................................................................................................................................................................... 38 HYDRAULIC TANK ................................................................................................................................................................................................... 39 HYDRAULIC PUMP ................................................................................................................................................................................................... 40 CONTROL VALVE .................................................................................................................................................................................................... 59 SAFETY- SUCTION VALVE FOR SERVICE VALVE .......................................................................................................................................................................... 67 SELF- REDUCING PRESSURE VALVE .................................................................................................................................................................................... 68 CLSS ............................................................................................................................................................................................................. 73 SWING MOTOR ......................................................................................................................................................................................................115 CENTER SWIVEL JOINT TRAVEL MOTOR .................................................................................................................................................................................119 VALVE CONTROL WORK EQUIPMENT SWING PPC VALVE ...................................................................................................................................................................129 TRAVEL PPC VALVE .................................................................................................................................................................................................133 SERVICE PPC VALVE ................................................................................................................................................................................................137 SAFETY LOCK VALVE PPC ACCUMULATOR STRAIGHT- TRAVEL SYSTEM ........................................................................................................................................................142 EPC SOLENOID VALVE ...............................................................................................................................................................................................143 OVERLOAD WARNING DEVICE ..........................................................................................................................................................................................145 HOSE BURST PROTECTION VALVE (BOOM) ...............................................................................................................................................................................147 WORK EQUIPMENT ENGINE CONTROL SYSTEM .............................................................................................................................................................................156 ELECTRONIC CONTROL SYSTEM ........................................................................................................................................................................................162 MACHINE MONITOR SYSTEM ...........................................................................................................................................................................................187 20 TESTING AND ADJUSTING .............................................................................................................................................................................................201 TESTING AND ADJUSTING STANDARD VALUE TABLE .......................................................................................................................................................................207 For engine - PC210- 6k .......................................................................................................................................................................................207 For engine - PC240- 6k For chassis ...........................................................................................................................................................................209 STANDARD VALUE TABLE FOR ELECTRICAL PARTS ........................................................................................................................................................................218 MEASURING ENGINE SPEED ...........................................................................................................................................................................................227 MEASURING EXHAUST GAS COLOR ......................................................................................................................................................................................228 ADJUSTING VALVE CLEARANCE ........................................................................................................................................................................................229 MEASURING COMPRESSION PRESSURE ...................................................................................................................................................................................230 MEASURING BLOW- BY PRES-SURE .....................................................................................................................................................................................230 TESTING AND ADJUSTING FUEL INJECTION TIMING ......................................................................................................................................................................231 MEASURE ENGINE OIL PRESSURE ......................................................................................................................................................................................232 TESTING AND ADJUSTING FAN BELT TENSION ...........................................................................................................................................................................233 MEASURING SPEED SENSOR ...........................................................................................................................................................................................234 TESTING AND ADJUSTING GOV-ERNOR MOTOR LEVER STROKE ...............................................................................................................................................................235 TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUIT .............................................................................................................................236 TESTING AND ADJUSTING PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRES-SURE) ....................................................................................................................................239 TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE AND LS DIFFERENTIAL PRESSURE) ........................................................................................................240 TESTING AND ADJUSTING CONTROL CIRCUIT OIL PRESSURE ...............................................................................................................................................................243 TESTING SOLENOID VALVE OUT-PUT PRESSURE ..........................................................................................................................................................................244 MEASURING PPC VALVE OUTPUT PRESSURE ..............................................................................................................................................................................246 Pressure switch piping diagram ...............................................................................................................................................................................247 ADJUSTING WORK EQUIPMENT SWING PPC VALVE .......................................................................................................................................................................248 ADJUSTMENT OF FLOW CON-TROL SYSTEM ...............................................................................................................................................................................249 Graph of PPC Pressure Against HCU Circuit Oil Flow ...............................................................................................................................................................251 TESTING TRAVEL DEVIATION .........................................................................................................................................................................................252 TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT ......................................................................................................................................................253 MEASURE OIL LEAKAGE ..............................................................................................................................................................................................255 RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT ................................................................................................................................................................257 TESTING CLEARANCE OF SWING CIRCLE BEARING ........................................................................................................................................................................257 TESTING AND ADJUSTING TRACK SHOE TENSION .........................................................................................................................................................................258 BLEEDING AIR .....................................................................................................................................................................................................259 SEQUENCE OF EVENTS IN TROUBLESHOOTING ............................................................................................................................................................................261 POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE .................................................................................................................................................................262 CHECKS BEFORE TROUBLESHOOTING ....................................................................................................................................................................................270 CONNECTOR TYPES AND MOUNTING LOCATIONS ...........................................................................................................................................................................272 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS .......................................................................................................................................................................277 EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM ...........................................................................................................................................................285 DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL ............................................................................................................................................................286 METHOD OF USING JUDGEMENT TABLE ..................................................................................................................................................................................295 METHOD OF USING TROUBLESHOOTING CHARTS ...........................................................................................................................................................................297 DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE .........................................................................................................................................................299 SERVICE CODE TABLE ...............................................................................................................................................................................................304 TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE) .....................................................................................................................................................305 TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROLLER (GOVERNOR CONTROL SYSTEM) (E MODE) ..........................................................................................................................307 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE .......................................................................................................................................308 JUDGEMENT TABLE FOR ENGINE THROTTLE PUMP GOVERNOR (GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS ...........................................................................................................312 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE SYSTEM .....................................................................................................................................................................314 E- 1 Abnormality in engine throttle pump controller power source (controller LED is OFF) .......................................................................................................................316 E- 2 [E308] Abnormality in fuel control dial input value is displayed ............................................................................................................................................317 E- 3 [E317] Abnormality (disconnection) in motor drive system is displayed .......................................................................................................................................318 E- 4 [E318] Abnormality (short circuit) in motor drive system is displayed .......................................................................................................................................319 E- 5 [E306] Abnormality in feedback potentiometer system is displayed ............................................................................................................................................320 E- 6 [E315] Abnormality (short circuit) in battery relay output system is displayed ..............................................................................................................................321 E- 7 [E316] Abnormality (step- out) in motor is displayed ........................................................................................................................................................322 E- 8 Engine does not start .......................................................................................................................................................................................324 E- 8 Related electric circuit diagram E- 9 Engine speed is irregular .........................................................................................................................................327 E- 10 Lack of output (engine high idling speed is too low) ...................................................................................................................................................331 E- 11 Engine does not stop ...................................................................................................................................................................................333 E- 12 Defective operation of battery relay system (engine does not stop) .....................................................................................................................................335 TROUBLESHOOTING OF ENGINE SYSTEM (S MODE) ........................................................................................................................................................................337 S- 1 Starting performance is poor (starting always takes time) ...............................................................................................................................................342 S- 2 Engine does not start ...................................................................................................................................................................................344 S- 3 Engine does not pick up smoothly (follow- up is poor) ...................................................................................................................................................347 S- 4 Engine stops during operations ..........................................................................................................................................................................348 S- 5 Engine does not rotate smoothly (hunting) ...............................................................................................................................................................349 S- 6 Engine lacks output (no power) ..........................................................................................................................................................................350 S- 7 Exhaust smoke is black (incomplete combustion) ..........................................................................................................................................................351 S- 8 Oil consumption is excessive (or exhaust smoke is blue) .................................................................................................................................................352 S- 9 Oil becomes contaminated quickly ........................................................................................................................................................................353 S- 10 Fuel consumption is excessive ..........................................................................................................................................................................354 S- 11 Oil is in coolant, or coolant spurts black, or coolant level goes down .................................................................................................................................355 S- 12 Oil pressure caution lamp lights up (drop in oil pressure) .............................................................................................................................................356 S- 13 Oil level rises (coolant, fuel in oil) .................................................................................................................................................................357 S- 14 Coolant temperature becomes too high (overheating) .....................................................................................................................................................358 S- 15 Abnormal noise is made .................................................................................................................................................................................359 S- 16 Vibration is excessive .................................................................................................................................................................................360 TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROLLER (PUMP CONTROL SYSTEM) (C- MODE) .............................................................................................................................361 POINTS TO REMEMBER WHEN TROUBLESHOOTING PUMP CONTROLLER SYSTEM ...............................................................................................................................................361 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE .......................................................................................................................................362 JUDGEMENT TABLE FOR ENGINE THROTTLE PUMP CONTROLLER (PUMP CONTROL SYSTEM) AND HYDRAULIC RELATED PARTS ELECTICAL CIRCUIT DIAGRAM FOR C MODE AND F MODE ..........................................................372 C- 1 Abnormality in controller power source system (controller LED is OFF) .......................................................................................................................................374 C- 2 [E232] Short circuit in pump EPC solenoid system is displayed ...............................................................................................................................................375 C- 3 [E233] Disconnection in PC- EPC solenoid system is displayed ................................................................................................................................................377 C- 4 [213] Disconnection in swing holding brake solenoid system is displayed .....................................................................................................................................379 C- 5 [E203] Short circuit in swing holding brake solenoid system is displayed ....................................................................................................................................381 C- 6 [E204] Short circuit in pump merge/ divider solenoid system is displayed ....................................................................................................................................383 C- 7 [E214] Disconnection in pum merge/ divider solenoid system is displayed .....................................................................................................................................384 C- 8 [E207] Short circuit in active mode solenoid system is displayed ............................................................................................................................................385 C- 9 [E208] Disconnection in active mode solenoid system is displayed ............................................................................................................................................386 C- 10 [E206] Short circuit in travel speed solenoid system is displayed ..........................................................................................................................................387 C- 13 [E215] Disconnection in 2- stage relief solenoid system is displayed .......................................................................................................................................388 C- 14 [E217] Model selection input error is displayed ............................................................................................................................................................389 C- 15 [E222] Short circuit in LS- EPC solenoid system is displayed ...............................................................................................................................................391 C- 16 [E223] Disconnection in LS- EPC solenoid system is displayed ...............................................................................................................................................392 C- 17 [E224] Abnormality in front pump pressure sensor system is displayed .......................................................................................................................................393 C- 18 [E225] Abnormality in rear pump pressure sensor system is displayed ........................................................................................................................................394 C- 19 [E226] Abnormality in pressure sensor power source system is displayed .....................................................................................................................................395 C- 20 [E227] Abnormality in engine speed sensor system is displayed ..............................................................................................................................................396 TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE) ..............................................................................................................................397 F- 1 Bit pattern 20 - (1) Swing oil pressure switch does not light up ........................................................................................................................................397 F- 2 Bit pattern 20-( 2) Travel oil pressure switch does not light up ............................................................................................................................................398 F- 3 Bit pattern 20-( 3) Boom LOWER oil pressure switch does not light up ........................................................................................................................................400 F- 4 Bit pattern 20-( 4) Boom RAISE oil pressure switch does not light up ........................................................................................................................................401 F- 5 Bit pattern 20-( 5) Arm IN oil pressure switch does not light up ............................................................................................................................................402 F- 6 Bit pattern 20-( 6) Arm OUT oil pressure switch does not light up ...........................................................................................................................................403 F- 7 Bit pattern 21-( 1) Bucket CURL oil pressure switch does not light up .......................................................................................................................................404 F- 8 Bit pattern 21-( 2) Bucket DUMP oil pressure switch does not light up .......................................................................................................................................405 F- 9 Bit pattern 21-( 3) Swing lock switch does not light up .....................................................................................................................................................406 F- 10 Bit pattern 22-( 5) Kerosene mode connection does not light up .............................................................................................................................................407 F- 11 Bit pattern 22-( 6) L. H. knob switch does not light up ....................................................................................................................................................408 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H- MODE) .....................................................................................................................................................409 PUMP MERGE/ DIVIDER LOGIC ........................................................................................................................................................................................413 SOLENOID ACTUATION TABLE .........................................................................................................................................................................................414 H- 1 Speeds of all work equipment, swing, travel are slow ........................................................................................................................................................415 H- 3 No work equipment, travel, swing move H- 2 There is excessive drop in engine speed, or engine stalls ........................................................................................................417 H- 4 Abnormal noise generated (around pump) ......................................................................................................................................................................418 H- 5 Auto- deceleration does not work (when PPC shuttle valve) ...................................................................................................................................................418 H- 6 Fine control ability is poor or response is poor ............................................................................................................................................................419 H- 7 Boom is slow or lacks power .................................................................................................................................................................................421 H- 8 Arm is slow or lacks power ..................................................................................................................................................................................423 H- 9 Bucket is slow or lacks power ...............................................................................................................................................................................425 H- 10 Work equipment (boom, arm, bucket) does not move (but travel and swing are normal) .........................................................................................................................426 H- 11 Excessive hydraulic drift (boom, arm, bucket) ..............................................................................................................................................................426 H- 12 Excessive time lag (engine at low idling) ..................................................................................................................................................................427 H- 13 Other equipment moves when single circuit is relieved ......................................................................................................................................................427 M- 30 Related electric circuit diagram H- 14 Lack of power when pressure rises ...................................................................................................................................430 H- 16 In compound operations, work equipment with larger load is slow ............................................................................................................................................431 H- 15 In L/ O, F/ O modes, work equipment speed is faster than specified speed ...................................................................................................................................431 H- 17 In swing + boom RAISE, boom RAISE is slow ..................................................................................................................................................................432 H- 18 In swing + travel, travel speed drops excessively ..........................................................................................................................................................432 H- 19 Travel deviation ...........................................................................................................................................................................................432 H- 20 Travel speed is slow .......................................................................................................................................................................................433 H- 21 Steering does not turn easily or lacks power ...............................................................................................................................................................435 H- 23 Travel does not move (one side only) .......................................................................................................................................................................437 H- 22 Travel speed does not switch or is faster than specified speed .............................................................................................................................................437 H- 24 Does not swing .............................................................................................................................................................................................438 H- 25 Swing acceleration is poor or swing speed is slow ..........................................................................................................................................................439 H- 26 Excessive overrun when stopping swing ......................................................................................................................................................................441 H- 27 Excessive shock when stopping wing (one direction only) H- 28 Excessive abnormal noise when stopping swing .................................................................................................442 H- 29 Excessive hydraulic drift of swing .........................................................................................................................................................................442 H- 30 Swing speed is faster than specified speed in L/ O and F/ O modes ..........................................................................................................................................443 TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M CODE ) ..............................................................................................................................................................444 ACTION TAKEN BY MONITOR PANEL WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE ................................................................................................................................444 ELECTRICAL CIRCUIT DIAGRAM FOR M MODE SYSTEM M- 1 [E101] Abnormality in error data is displayed [E102] Error in clock data is displayed ..........................................................................448 M- 2 [E103] Short circuit in buzzer output or contact of 24V wiring harness with buzzer drive harness is displayed ...............................................................................................449 M- 3 [E104] Air clogging detected is displayed ...................................................................................................................................................................450 M- 4 [E108] Engine coolant temperature 105° C detected is displayed ..............................................................................................................................................450 M- 5 When starting switch is turned ON, none of the lamps on the monitor panel light up for 3 seconds ............................................................................................................451 M- 6 When starting switch is turned ON, monitor panel lamps all stay lit up and do not go out M- 7 When starting switch is turned ON, items lit up on monitor panel are different from actual machine (model) ....453 M- 8 When starting switch is turned ON (engine stopped), basic check items flashes ...............................................................................................................................454 M- 9 Preheating is not being used but (preheating monitor) lights up .............................................................................................................................................457 M- 10 When starting switch is turned ON and engine is started, basic check items flash ...........................................................................................................................458 M- 11 When starting switch is turned ON (engine stopped), caution items, emergency items flash (battery, engine oil pressure lamps do not light up) ..............................................................460 M- 12 When starting switch is turned ON and engine is started, caution items, emergency items flash (then there is no abnormality in engine or items to check before troubleshooting) ............................462 M- 13 When starting switch is turned ON (engine stopped), buzzer does not sound for 1 second Caution item flashes but buzzer does not sound ......................................................................465 M- 14 No abnormality is displayed on monitor but buzzer sounds ...................................................................................................................................................465 M- 15 Night lighting on monitor panel does not light up (liquid crystal display is normal) .......................................................................................................................466 M- 16 Coolant temperature gauge does not rise ....................................................................................................................................................................467 M- 17 Coolant temperature gauge does not give any display (none of the gauge lamps light up during operation) ....................................................................................................468 M- 18 Fuel level gauge always displays FULL ......................................................................................................................................................................469 M- 19 Fuel level gauge does not give display .....................................................................................................................................................................469 M- 20 Swing lock switch is turned ON (LOCK) but (swing lock monitor) does not light up ...........................................................................................................................470 M- 21 Swing prolix switch is turned ON (prolix), but (swing lock monitor) does not flash .........................................................................................................................471 M- 22 Service meter does not advance while engine is running M- 23 When starting switch is at OFF and time switch is pressed, time and service meter are not displayed ...........................................472 M- 24 Defective fuel level sensor system .........................................................................................................................................................................473 M- 25 Defective coolant temperature sensor system ................................................................................................................................................................474 M- 26 Defective engine oil sensor system .........................................................................................................................................................................475 M- 27 Defective coolant level sensor system ......................................................................................................................................................................476 M- 28 Defective hydraulic oil level sensor system ................................................................................................................................................................477 M- 29 Wiper does not work or switch is not being used but wiper is actuated ......................................................................................................................................478 M- 30 Washer motor does not work, or switch is not being used but washer motor is actuated .......................................................................................................................483 30 DISASSEMBLY AND ASSEMBLY ..........................................................................................................................................................................................485 METHOD OF USING MANUAL ...........................................................................................................................................................................................490 SPECIAL TOOL LIST ................................................................................................................................................................................................493 SKETCHES OF SPECIAL TOOLS ........................................................................................................................................................................................497 STARTING MOTOR ...............................................................................................................................................................................................498 ALTERNATOR .......................................................................................................................................................................................................499 FUEL INJECTION PUMP ..............................................................................................................................................................................................500 WATER PUMP .......................................................................................................................................................................................................503 NOZZLE HOLDER ....................................................................................................................................................................................................505 TURBOCHARGER .....................................................................................................................................................................................................506 THERMOSTAT .......................................................................................................................................................................................................507 GOVERNOR MOTOR ...................................................................................................................................................................................................509 CYLINDER HEAD ASSEMBLY ...........................................................................................................................................................................................510 RADIATOR HYDRAULIC OIL COOLER ..................................................................................................................................................................................518 ENGINE, MAIN PUMP ................................................................................................................................................................................................520 DAMPER ...........................................................................................................................................................................................................524 FUEL TANK ........................................................................................................................................................................................................525 CENTER SWIVEL JOINT ..............................................................................................................................................................................................526 FINAL DRIVE ......................................................................................................................................................................................................529 SPROCKET .........................................................................................................................................................................................................538 SWING MOTOR ......................................................................................................................................................................................................539 SWING MACHINERY ..................................................................................................................................................................................................540 SWING MACHINERY ..................................................................................................................................................................................................541 REVOLVING FRAME ..................................................................................................................................................................................................548 REMOVAL OF SWING CIRCLE ASSEMBLY .................................................................................................................................................................................550 INSTALLATION OF SWING CIRCLE ASSEMBLY ............................................................................................................................................................................551 REMOVAL OF IDLER RECOIL SPRING ASSEMBLY ........................................................................................................................................................................552 INSTALLATION OF IDLER RECOIL SPRING ASSEMBLY ...................................................................................................................................................................552 DISASSEMBLY OF RECOIL SPRING ASSEMBLY ............................................................................................................................................................................553 ASSEMBLY OF RECOIL SPRING ASSEMBLY ...............................................................................................................................................................................554 DISASSEMBLY OF IDLER ASSEMBLY ....................................................................................................................................................................................555 ASSEMBLY OF IDLER ASSEMBLY .......................................................................................................................................................................................556 REMOVAL OF TRACK ROLLER ASSEMBLY .................................................................................................................................................................................558 INSTALLATION OF TRACK ROLLER ASSEMBLY ............................................................................................................................................................................558 DISASSEMBLY OF TRACK ROLLER ASSEMBLY .............................................................................................................................................................................559 ASSEMBLY OF TRACK ROLLER ASSEMBLY ................................................................................................................................................................................560 REMOVAL OF CARRIER ROLLER ASSEMBLY ...............................................................................................................................................................................562 INSTALLATION OF CARRIER ROLLER ASSEMBLY ..........................................................................................................................................................................562 DISASSEMBLY OF CARRIER ROLLER ASSEMBLY ...........................................................................................................................................................................563 ASSEMBLY OF CARRIER ROLLER ASSEMBLY ..............................................................................................................................................................................564 REMOVAL OF TRACK SHOE ASSEMBLY ...................................................................................................................................................................................566 INSTALLATION OF TRACK SHOE ASSEMBLY ..............................................................................................................................................................................566 HYDRAULIC TANK ...................................................................................................................................................................................................567 MAIN PUMP ........................................................................................................................................................................................................569 MAIN PUMP INPUT SHAFT OIL SEAL ...................................................................................................................................................................................572 CONTROL VALVE ....................................................................................................................................................................................................573 PUMP MERGE- DIVIDER VALVE ........................................................................................................................................................................................582 MAIN RELIEF VALVE ................................................................................................................................................................................................583 PC VALVE .........................................................................................................................................................................................................584 LS VALVE .........................................................................................................................................................................................................585 PC, LS- EPC VALVE ................................................................................................................................................................................................586 SOLENOID VALVE ...................................................................................................................................................................................................587 REMOVAL OF WORK EQUIPMENT SWING PPC VALVE ASSEMBLY .............................................................................................................................................................588 INSTALLATION OF WORK EQUIPMENT SWING PPC VALVE ASSEMBLY ........................................................................................................................................................588 TRAVEL PPC VALVE .................................................................................................................................................................................................591 REMOVAL OF BOOM CYLINDER ASSEMBLY ................................................................................................................................................................................593 INSTALLATION OF BOOM CYLINDER ASSEMBLY ...........................................................................................................................................................................594 REMOVAL OF ARM CYLINDER ASSEMBLY .................................................................................................................................................................................595 INSTALLATION OF ARM CYLINDER ASSEMBLY ............................................................................................................................................................................596 REMOVAL OF BUCKET CYLINDER ASSEMBLY ..............................................................................................................................................................................597 INSTALLATION OF BUCKET CYLINDER ASSEMBLY .........................................................................................................................................................................598 DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY .......................................................................................................................................................................599 ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY ..........................................................................................................................................................................601 WORK EQUIPMENT ...................................................................................................................................................................................................604 BUCKET ...........................................................................................................................................................................................................606 ARM ..............................................................................................................................................................................................................608 BUCKET - ARM .....................................................................................................................................................................................................610 BOOM .............................................................................................................................................................................................................612 REMOVAL OF OPERATOR™S CAB ASSEMBLY ...............................................................................................................................................................................614 INSTALLATION OF OPERATOR™S CAB ASSEMBLY ..........................................................................................................................................................................616 COUNTERWEIGHT ....................................................................................................................................................................................................617 REMOVAL OF ENGINE THROTTLE CONTROLLER ASSEMBLY ...................................................................................................................................................................618 MONITOR ..........................................................................................................................................................................................................619 40 MAINTENANCE STANDARD ..............................................................................................................................................................................................622 SWING MACHINERY ..................................................................................................................................................................................................625 SWING CIRCLE FINAL DRIVE .........................................................................................................................................................................................628 TRACK FRAME, RECOIL SPRING .......................................................................................................................................................................................630 IDLER ............................................................................................................................................................................................................631 CARRIER ROLLER ...................................................................................................................................................................................................633 TRACK ROLLER .....................................................................................................................................................................................................634 TRACK SHOE .......................................................................................................................................................................................................635 HYDRAULIC PUMP ...................................................................................................................................................................................................637 CONTROL VALVE ....................................................................................................................................................................................................638 VARIABLE PRESSURE COMPENSATION VALVE .............................................................................................................................................................................644 SAFETY- SUCTION VALVE FOR SERVICE VALVE ..........................................................................................................................................................................645 SELF- REDUCING PRESSURE VALVE ....................................................................................................................................................................................646 SWING MOTOR ......................................................................................................................................................................................................647 TRAVEL MOTOR .....................................................................................................................................................................................................648 TRAVEL PPC VALVE WORK EQUIPMENT SWING PPC VALVE EPC SOLENOID VALVE .............................................................................................................................................651 CENTER SWIVEL JOINT HYDRAULIC CYLINDER ...........................................................................................................................................................................653 WORK EQUIPMENT DIMENSIONS OF WORK EQUIPMENT ......................................................................................................................................................................661

IMAGES PREVIEW OF THE MANUAL: