Starting from:

$40

Home

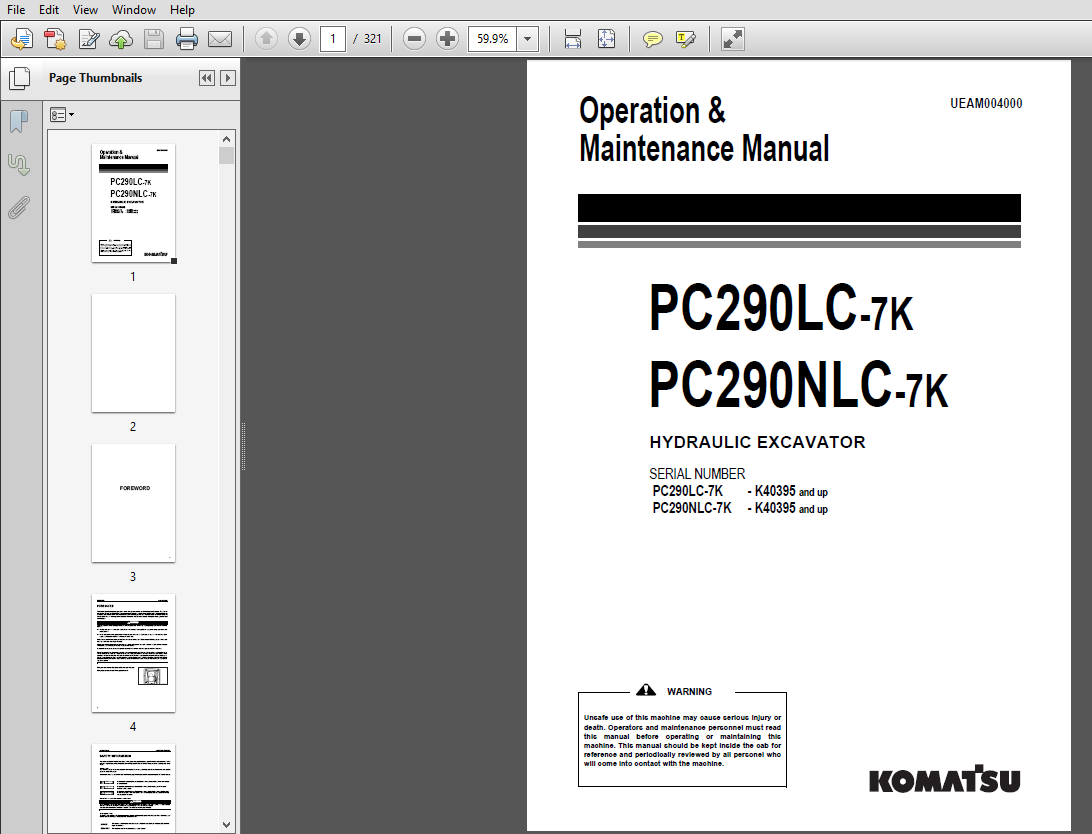

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual PDF

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual PDF

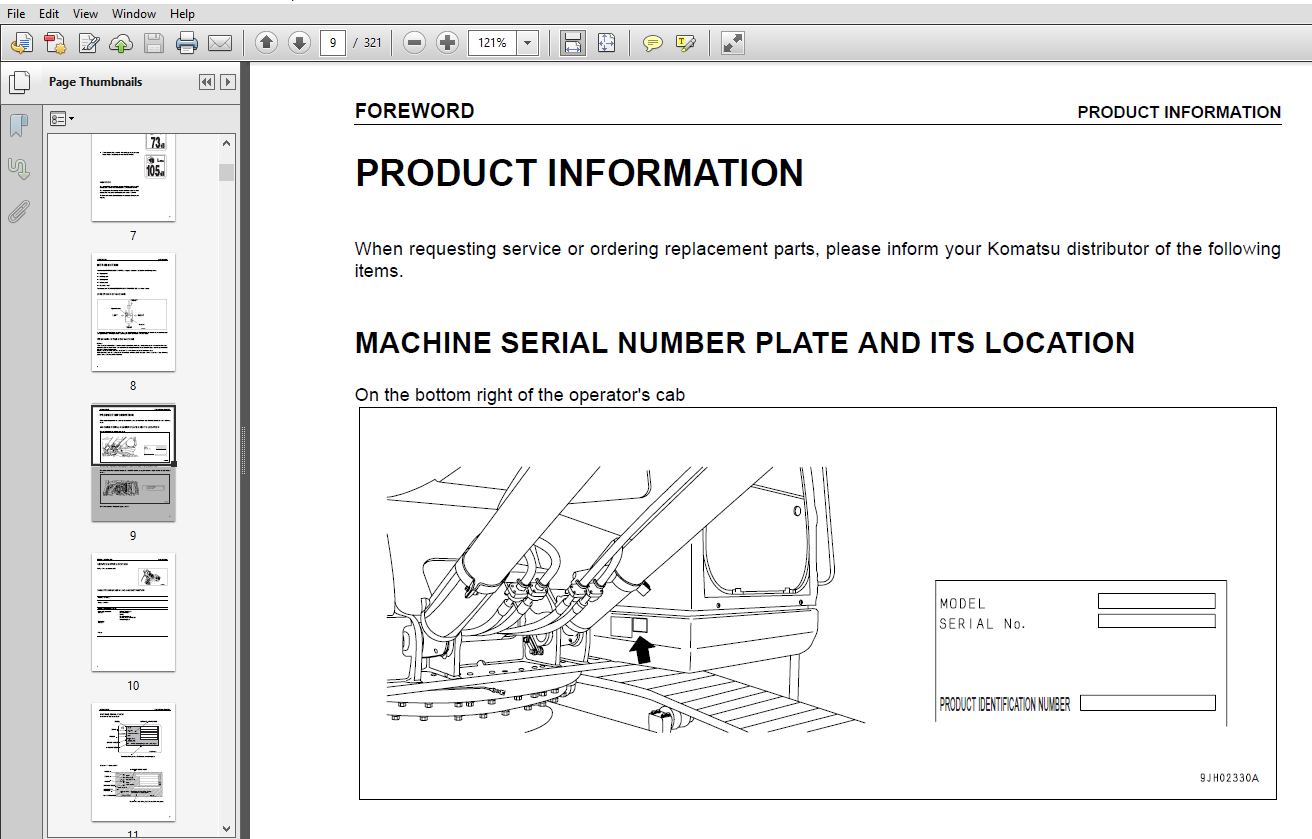

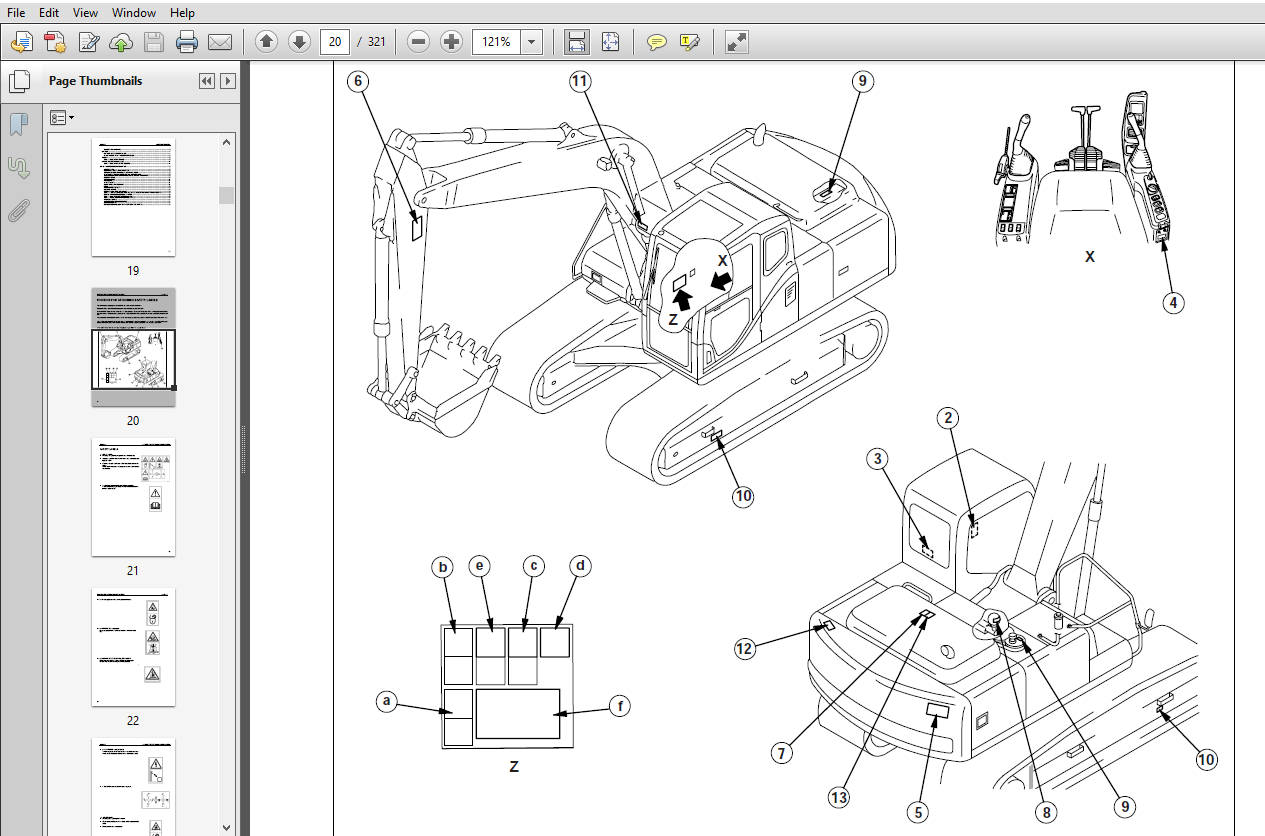

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual

FILE DETAILS:

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : UEAM004000

Total Pages : 321

DESCRIPTION:

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual

FOREWORD:

- This manual provides rules and guidelines which will help you use this machine safely and effectively. The precautions in this manual must be followed at all times while operating or performing maintenance .

- Most accidents are caused by the failure to follow fundamental safety rules for the operation and maintenance of machines. Accidents can be prevented by knowing beforehand conditions that may cause a hazard when performing operation and maintenance.

TABLE OF CONTENTS:

Komatsu PC290LC-7K, PC290NLC-7K Hydraulic Excavator Operation & Maintenance Manual

PC200-7_Sec01.pdf............................................................................................... 0

PC240LC-7K, PC240NLC-7K..................................................................................... 10

DIMENSIONS.................................................................................................. 10

WORKING RANGES.............................................................................................. 10

DIMENSIONS.................................................................................................. 11

Working ranges.............................................................................................. 11

PC240LC-7K, PC240NLC-7K..................................................................................... 14

SPECIFICATION DIMENSION DRAWINGS............................................................................ 8

PC210-7K, PC210LC-7K, PC210NLC-7K....................................................................... 8

DIMENSIONS.............................................................................................. 8

WORKING RANGES.......................................................................................... 8

DIMENSIONS.............................................................................................. 9

Working ranges.......................................................................................... 9

SPECIFICATIONS.............................................................................................. 12

PC210-7K, PC210LC-7K, PC210NLC-7K....................................................................... 12

WEIGHT TABLE................................................................................................ 16

pc210-7K, pc210lc-7K, PC210NLC-7K....................................................................... 16

pc240LC-7K, pc240Nlc-7K................................................................................. 18

FUEL, COOLANT, AND LUBRICANTs............................................................................... 20

PC200-7_Sec10.pdf............................................................................................... 0

ENGINE RELATED PARTS........................................................................................ 22

RADIATOR • OIL COOLER • AFTERCOOLER......................................................................... 23

POWER TRAIN................................................................................................. 24

This page left intentionally blank...................................................................... 25

FINAL DRIVE................................................................................................. 26

SWING MACHINERY............................................................................................. 28

PC210-7K, PC210LC-7K, PC210NLC-7K....................................................................... 28

SWING CIRCLE................................................................................................ 32

PC210-7K, PC210LC-7K, PC210NLC-7K....................................................................... 32

PC240LC-7K, PC240NLC-7K................................................................................. 33

TRACK FRAME • RECOIL SPRING................................................................................. 34

IDLER....................................................................................................... 36

CARRIER ROLLER.............................................................................................. 38

TRACK ROLLER................................................................................................ 39

TRACK SHOE.................................................................................................. 40

TRIPLE GROUSER SHOE, ROAD LINER, SWAMP SHOE, FLAT SHOE.................................................. 40

TRIPLE GROUSER SHOE..................................................................................... 43

SWAMP SHOE.............................................................................................. 43

hydraulic equipment layout drawing.......................................................................... 44

HYDRAULIC TANK.............................................................................................. 46

This page left intentionally blank...................................................................... 47

HYDRAULIC PUMP.............................................................................................. 48

HPV95 + 95(PC210/LC/NLC-7K)............................................................................. 48

HPV95 + 95(PC240LC/NLC-7K).............................................................................. 50

LS VALVE................................................................................................ 55

PC VALVE................................................................................................ 55

LS(pc)-EPC VALVE........................................................................................ 68

This page left intentionally blank...................................................................... 71

CONTROL VALVE............................................................................................... 72

pc210-7K, pc210lc-7K, PC210NLC-7K....................................................................... 73

This page left intentionally blank...................................................................... 82

CONTROL VALVE............................................................................................... 88

pc240LC-7K, pc240Nlc-7K................................................................................. 88

This page left intentionally blank...................................................................... 97

MAIN RELIEF VALVE (PC210/LC/NLC-7K).....................................................................107

Function............................................................................................107

MAIN RELIEF VALVE (PC240LC/NLC-7K)......................................................................108

Variable pressure compensation valve....................................................................109

CLSS........................................................................................................111

OUTLINE OF CLSS.........................................................................................111

SWING MOTOR.................................................................................................112

REVERSE PREVENTION VALVE....................................................................................117

CENTER SWIVEL JOINT.........................................................................................119

TRAVEL MOTOR................................................................................................120

TRAVEL JUNCTION VALVE.......................................................................................130

TRAVEL PPC SHUTTLE VALVE....................................................................................132

VALVE CONTROL...............................................................................................134

WORK EQUIPMENT • SWING PPC VALVE............................................................................136

TRAVEL PPC VALVE............................................................................................140

SERVICE PPC VALVE...........................................................................................149

SOLENOID VALVE..............................................................................................152

PPC ACCUMULATOR.............................................................................................154

return oil filter...........................................................................................155

For Breaker.............................................................................................155

BOOM HYDRAULIC DRIFT PREVENTION VALVE.......................................................................156

LIFT CHECK VALVE............................................................................................161

attachment circuit selector valve...........................................................................162

HYDRAULIC CYLINDER..........................................................................................164

pc210-7K, pc210lc-7K, PC210NLC-7K.......................................................................164

BOOM CYLINDER.......................................................................................164

ARM CYLINDER........................................................................................164

BUCKET CYLINDER.....................................................................................164

pc240LC-7K, pc240Nlc-7K.................................................................................166

BOOM CYLINDER.......................................................................................166

ARM CYLINDER........................................................................................166

BUCKET CYLINDER.....................................................................................166

work equipment..............................................................................................168

Pc210-7K, pc210lc-7K, PC210NLC-7K.......................................................................169

Pc240LC-7K, pc240Nlc-7K.................................................................................170

This page left intentionally blank......................................................................171

1. DIMENSION OF ARM.....................................................................................172

2. Dimension of bucket..................................................................................176

air conditioner.............................................................................................178

air conditioner piping..................................................................................178

ENGINE CONTROL..............................................................................................179

Governor motor..........................................................................................183

This page left intentionally blank......................................................................184

Engine throttle and pump controller.................................................................185

This page left intentionally blank......................................................................187

ELECTRONIC CONTROL SYSTEM...................................................................................188

This page left intentionally blank......................................................................189

machine control system diagram..........................................................................190

This page left intentionally blank......................................................................213

mULTI MONITOR SYSTEM........................................................................................214

SENSOR......................................................................................................237

PC240LC-7K, PC240NLC-7K................................................................................. 30

SELF PRESSURE REDUCING VALVE................................................................................103

20-001.pdf...................................................................................................... 0

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...............................................................242

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS..............................................................243

Flow control characteristic of PC valve (STD)...........................................................256

20_101.pdf...................................................................................................... 0

INSPECTION AND ADJUSTMENT OF ENGINE RPM.....................................................................258

MEASUREMENT OF EXHAUST GAS COLOR............................................................................260

ADJUSTMENT OF VALVE CLEARANCE...............................................................................261

MEASUREMENT OF COMPRESSION PRESSURE.........................................................................263

MEASUREMENT OF BLOW-BY PRESSURE.............................................................................264

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING..........................................................265

MEASUREMENT OF ENGINE OIL PRESSURE..........................................................................267

ADJUSTMENT OF ENGINE SPEED SENSOR...........................................................................268

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION....................................................268

EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM.......................................................269

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS...........................................................270

INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION.............................................................271

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN...........272

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE...................................................276

INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC240LC/NLC)..............................277

iNSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE(PC210/LC/NLC).............................280

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc240lc/nlc)..............................283

INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE(pc210/lc/nlc).............................287

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE...............................................................291

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE....................................................................294

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE............................................................295

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT................................................296

RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT..........................................................297

MEASUREMENT OF OIL LEAKAGE AMOUNT...........................................................................298

AIR BLEEDING OF VARIOUS PARTS...............................................................................300

INSPECTION PROCEDURES FOR DIODE.............................................................................302

SPECIAL FUNCTION OF MULTI-MONITOR PANEL.....................................................................303

Operation of Operator's Menu and Display (Outline)......................................................305

Table for Service and Failure Code Nos..................................................................310

Operation and Display of Service Menu...................................................................312

Table for Monitoring Items..............................................................................315

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM..........................................................327

Engine (PC240LC, 240NLC)................................................................................ 0

20_201.pdf...................................................................................................... 0

POINTS TO REMEMBER WHEN TROUBLESHOOTING.....................................................................340

SEQUENCE OF EVENTS IN TROUBLESHOOTING.......................................................................341

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE............................................................342

CHECKS BEFORE TROUBLESHOOTING...............................................................................350

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING................................................................351

Classification of troubleshooting.......................................................................351

Steps for troubleshooting...............................................................................351

Failure-looking Phenomenon and Troubleshooting No.......................................................352

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM...........................................356

Connector table.........................................................................................356

CONNECTOR LOCATION STEREOGRAM...........................................................................362

Monitor Panel System Circuit Diagram (M Circuit)........................................................368

Governor Control System Circuit Diagram (G Circuit) of Governor•Pump Controller.........................370

Pump Control System Circuit Diagram (P Circuit) of Governor•Pump Controller.............................372

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS..................................................................374

20_301.pdf...................................................................................................... 0

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..............................................................395

Service Code in Electrical System (Abnormal data in Error History)......................................391

Service Code in Electrical System (Short-circuiting in normal rotation system of windshield wiper.......404

Service Code in Electrical System (Short-circuiting in reverse rotation system of windshield wipe.......406

Service Code in Electrical System (Short-circuiting in window washer drive system)......................408

Service Code in Electrical System (Abnormal Windshield Wiper Motion)....................................410

Service Code in Electrical System (Abnormality in retracting windshield wiper)..........................412

Service Code in Electrical System (Short-circuiting in travel interlocking solenoid)....................310

Service Code in Electrical System (Short-circuiting in swing and parking brake solenoid - in gove.......416

Service Code in Electrical System (Short-circuiting in merge/divide solenoid)...........................418

Service Code in Electrical System (Short-circuiting in 2-stage relief solenoid).........................420

Service Code in Electrical System (Short-circuiting in travel speed shifting solenoid)..................422

Service Code in Electrical System (Disconnection in travel interlocking solenoid).......................424

Service Code in Electrical System (Disconnection in Swing Parking Brake Solenoid).......................426

Service Code in Electrical System (Disconnection of merge/divide solenoid)..............................428

Service Code in Electrical System (Disconnection in 2-stage relief solenoid)............................430

Service Code in Electrical System (Disconnection in travel speed shifting solenoid).....................432

Service Code in Electrical System (Abnormality in inputting model code).................................388

Service Code in Electrical System Disconnection of S-NET signal)........................................325

Service Code in Electrical System (Short-circuiting in LS-EPC solenoid).................................440

Service Code in Electrical System (Disconnection in LS-EPC solenoid system).............................262

Service Code in Electrical System (Abnormality in F pump pressure sensor)...............................442

Service Code in Electrical System (Abnormality in R pump pressure sensor)...............................444

Service Code in Electrical System (Abnormality in Pressure sensor power source).........................446

Service Code in Electrical System (Abnormality in engine rotation sensor in governor • pump contr.......448

Service Code in Electrical System (Short-circuiting in attachment return switching relay)...............449

Service Code in Electrical System (Short-circuiting in PC-EPC Solenoid..................................450

Service Code in Electrical System (Disconnection in PC-EPC solenoid system).............................452

Service Code in Electrical System (Disconnection in attachment return switching relay)..................454

Service Code in Electrical Equipment (Short-circuiting in attachment oil flow rate adjusting EPC).......456

Service Code in Electrical System (Disconnection in attachment oil flow rate adjusting EPC) (Mult.......457

Service Code in Electrical System (Incorrect nonvolatile memory data)...................................458

Service Code in Electrical System (Abnormality in governor potentiometer)...............................460

Service Code in Electrical System (Abnormality in fuel dial)............................................462

Service Code in Electrical System (Short-circuiting in battery relay)...................................464

Service Code in Electrical System (Step-out in governor motor)..........................................466

Service Code in Electrical System (Disconnection in governor motor Phase A and B).......................468

Service Code in Electrical System (Short-circuiting in governor motor Phase A and Phase B)..............361

Service Code in Electrical System ("Model Selection" function not provided yet).........................472

Service Mode in Electrical System (Model selecting signal fault)........................................473

Failure Code in Mechanical System (Out-of-rate engine rotation at high idling)..........................357

Failure Code in Mechanical System A000N2 (Out-of-rate engine rotation at low idling)....................358

Failure Code in Mechanical System (Air cleaner clogging)................................................475

Failure Code in Mechanical System (Abnormally lowered charging voltage).................................476

Failure Code in Mechanical System (Abnormally lowered engine oil pressure)..............................478

Failure Code in Mechanical System (Abnormally lowered engine oil level).................................479

Failure Code in Mechanical System (Engine cooling water overheating)....................................480

Failure Code in Mechanical System (Abnormally lowered radiator water level).............................481

Failure Code in Mechanical System (Hydraulic oil overheating)...........................................482

20_501.pdf...................................................................................................... 0

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..............................................................408

Relative Electrical Circuit Diagram.....................................................................484

E-1 Engine does not start (Engine does not rotate)......................................................485

Electrical Circuit Diagram for Engine Start, Stop and Battery Charging..............................487

E-2 Engine stops while in operation.....................................................................310

Electrical Circuit Diagram for Fuel Dial............................................................488

E-3 Engine speed is irregular, or there is hunting......................................................489

Electrical Circuit Diagram for Engine Start and Stop and Battery Charging...........................312

E-4 Engine does not stop................................................................................491

Electrical Circuit Diagram for Engine Start and Stop and Battery Charging...........................492

E-5 Auto-decelerator does not work......................................................................493

E-6 Auto engine warm-up device does not work............................................................494

E-7 Preheater does not work.............................................................................495

Electrical Circuit Diagram for Engine Preheater.....................................................496

E-8 All work equipment, swing and travel do not move....................................................497

Electrical Circuit Diagram for PPC Lock Solenoid....................................................498

E-9 One-touch Power Max Switch does not work............................................................499

Electric Circuit Diagram for One-Touch Power Max. Switch............................................499

E-10 No display in monitor panel at all.................................................................500

Electrical Circuit Diagram for Power Source in Monitor Panel........................................500

E-11 Part of display on monitor panel is missing........................................................501

E-12 Monitor panel displays contents irrelevant to the model............................................440

E-13 Fuel level monitor red lamp lights up while engine is running......................................502

Electrical Circuit Diagram for Fuel Level Sensor....................................................502

E-14 Engine cooling water temperature gauge does not indicate correctly.................................503

Electrical Circuit Diagram for Engine Cooling Water Temperature Sensor..............................503

E-15 Hydraulic oil temperature gauge does not display correctly.........................................504

Electrical Circuit Diagram for Hydraulic Oil Temperature Sensor.....................................504

E-16 Fuel gauge does not display correctly..............................................................505

Electrical Circuit Diagram for Fuel Level Sensor....................................................505

E-17 Swing lock monitor does not display correctly......................................................506

Electrical Circuit Diagram for Swing Lock Switch....................................................272

E-18 When the monitor switch is operated, no display appears............................................508

E-19 Windshield wiper does not work.....................................................................509

Electrical Circuit Diagram for Windshield Wiper Motor...............................................510

E-20 Alarming buzzer cannot be cancelled................................................................511

Electrical Circuit Diagram for Alarming Buzzer Cancellation Switch..................................511

E-21 "Boom RAISE" is not correctly displayed in monitor function........................................512

Electrical Circuit Diagram for Boom RAISE PPC Hydraulic Switch......................................306

E-22 "Boom LOWER" is not correctly displayed in monitor function........................................513

Electrical Circuit Diagram for Boom LOWER PPC Hydraulic Switch......................................513

E-23 "Arm DIGGING" is not correctly displayed in monitor function.......................................514

Electrical Circuit Diagram for Arm DIGGING PPC Hydraulic Switch.....................................514

E-24 "Arm DUMPING" is not correctly displayed in monitor function.......................................515

Electrical Circuit Diagram for Arm DUMPING PPC Hydraulic Switch.....................................515

E-25 "Bucket DIGGING" is not correctly displayed in monitor function....................................516

Electrical Circuit Diagram for Bucket DIGGING PPC hydraulic Switch..................................516

E-26 "Bucket DUMPING" is not correctly displayed in monitor function....................................517

Electrical Circuit Diagram for Bucket DUMPING PPC hydraulic Switch..................................353

E-27 "SWING" is not correctly displayed in monitor function.............................................518

Electrical Circuit Diagram for Right and Left Swing PPC hydraulic Switches..........................519

E-28 "TRAVEL" is not correctly displayed in monitor function............................................520

Electrical Circuit Diagram for Travel PPC hydraulic Switch and Travel Alarm.........................521

E-29 "Travel Differential Pressure" is not correctly displayed in monitor function......................522

Electrical Circuit Diagram for Travel and Steering PPC hydraulic Switch.............................523

E-30 "Service" is not correctly displayed in monitor function...........................................524

Electrical Circuit Diagram for Service PPC hydraulic Switch.........................................525

E-31 Air Conditioner does not work......................................................................526

Electrical Circuit Diagram for Air Conditioner......................................................526

E-32 Travel alarm does not sound........................................................................527

Electrical Circuit Diagram for Travel PPC Hydraulic Switch and Travel Alarm.........................528

20_601.pdf...................................................................................................... 0

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS...........................................................530

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..............................................................532

H-1 All work equipment lack power, or travel and swing speeds are slow..................................533

H-2 Engine speed sharply drops or engine stalls.........................................................534

H-3 No work equipment, travel or swing move.............................................................535

H-4 Abnormal noise is heard from around hydraulic pump..................................................535

H-5 Auto-decelerator does not work......................................................................536

H-6 Fine control mode does not function.................................................................536

H-7 Boom moves slowly or lacks power....................................................................537

H-8 Arm moves slowly or lacks power.....................................................................538

H-9 Bucket moves slowly or lacks power..................................................................539

H-10 Work equipment does not move in its single operation...............................................539

H-11 Work equipment has a bit too fast hydraulic drift..................................................540

H-12 Work equipment has big time lag....................................................................541

H-13 Other work equipment moves when relieving single circuit...........................................541

H-14 One-touch power max. switch does not operate.......................................................485

H-15 In compound operation, work equipment with larger load moves slowly................................542

H-16 In swing + boom RAISE operation, boom moves slowly.................................................542

H-17 In swing + travel, travel speed drops sharply......................................................542

H-18 Machine swerves in travel..........................................................................543

H-19 Machine travels slowly.............................................................................544

H-20 Machine cannot be easily steered or lacks power....................................................310

H-21 Travel speed does not shift, or it is too slow or fast.............................................489

H-22 Track shoe does not turn (on one side only)........................................................547

H-23 Machine does not swing.............................................................................548

H-24 Swing acceleration is poor, or swing speed is slow.................................................549

H-25 Excessive overrun when stopping swing..............................................................550

H-26 There is big shock when stopping swing.............................................................551

H-27 There is big abnormal noise caused when stopping swing.............................................551

H-28 Swing natural drift is too big.....................................................................315

Sec 30.pdf...................................................................................................... 0

HOW TO READ THIS MANUAL.....................................................................................555

REMOVAL AND INSTALLATION OF ASSEMBLIES..................................................................555

DisassemblY and assemblY OF assemblIES..................................................................556

PRECAUTIONS WHEN PERFORMING OPERATION.......................................................................557

STARTING MOTOR ASSEMBLY.....................................................................................559

REMOVAL.................................................................................................559

INSTALLATION............................................................................................559

FUEL INJECTION PUMP ASSEMBLY................................................................................560

ENGINE FRONT SEAL...........................................................................................564

ENGINE REAR SEAL............................................................................................566

CYLINDER HEAD ASSEMBLY......................................................................................568

RADIATOR ASSEMBLY...........................................................................................574

HYDRAULIC OIL COOLER ASSEMBLY...............................................................................576

ENGINE AND HYDRAULIC PUMP ASSEMBLIES........................................................................578

FINAL DRIVE ASSEMBLY........................................................................................584

FINAL DRIVE ASSEMBLY........................................................................................585

SKETCHES OF SPECIAL TOOLS...................................................................................592

SWING MOTOR AND SWING MACHINERY ASSEMBLY....................................................................593

SWING MOTOR AND SWING MACHINERY ASSEMBLY....................................................................594

CARRIER ROLLER ASSEMBLY.....................................................................................601

TRACK ROLLER ASSEMBLY.......................................................................................602

IDLER ASSEMBLY..............................................................................................603

RECOIL SPRING ASSEMBLY......................................................................................606

SPROCKET....................................................................................................608

TRACK SHOE ASSEMBLY.........................................................................................609

REMOVAL AND EXPANSION OF TRACK SHOE ASSEMBLY (IRON).....................................................609

REMOVal AND EXPANsion OF ROAD LINERS....................................................................611

INSTALLation OF ROAD LINERS.............................................................................612

SWING CIRCLE................................................................................................613

ASSEMBLY....................................................................................................613

REVOLVING FRAME ASSEMBLY....................................................................................614

CENTER SWIVEL JOINT ASSEMBLY................................................................................616

CENTER SWIVEL JOINT ASSEMBLY................................................................................618

HYDRAULIC TANK ASSEMBLY.....................................................................................619

CONTROL VALVE ASSEMBLY......................................................................................621

CONTROL VALVE ASSEMBLY......................................................................................624

HYDRAULIC PUMP ASSEMBLY.....................................................................................627

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT......................................................................630

WORK EQUIPMENT PPC VALVE ASSEMBLY...........................................................................631

TRAVEL PPC VALVE ASSEMBLY...................................................................................632

HYDRAULIC CYLINDER ASSEMBLY.................................................................................633

WORK EQUIPMENT ASSEMBLY.....................................................................................639

AIR CONDITIONER UNIT ASSEMBLY...............................................................................642

COUNTERWEIGHT ASSEMBLY......................................................................................645

OPERATOR’S CAB ASSEMBLY.....................................................................................646

MONITOR ASSEMBLY............................................................................................648

GOVERNOR PUMP CONTROLLER ASSEMBLY...........................................................................649

PC200-7_Sec90.pdf............................................................................................... 0

This page left intentionally blank..........................................................................652

PC200-7_Sec90_Body.pdf.......................................................................................... 0

hydraulic circuit diagram (1/2).............................................................................653

PC210-7K, PC210LC-7K, pc210nlc-7K.......................................................................653

This page left intentionally blank......................................................................654

hydraulic circuit diagram (2/2).............................................................................655

PC210-7K, PC210lc-7K, PC210nLC-7K.......................................................................655

This page left intentionally blank......................................................................656

HYDRAULIC diagram (1/1).....................................................................................657

pc240lc-7K, pc240nlc-7K.................................................................................657

This page left intentionally blank......................................................................658

electrical circuit diagram (1/4)............................................................................659

for multi monitor.......................................................................................659

pc210-7K, pc210lc-7K, pc210nlc-7K.......................................................................659

pc240lc-7K, pc240nlc-7K.................................................................................659

This page left intentionally blank......................................................................660

electrical circuit diagram (2/4)............................................................................661

for multi monitor.......................................................................................661

This page left intentionally blank......................................................................662

electrical circuit diagram (3/4)............................................................................663

for multi monitor.......................................................................................663

This page left intentionally blank......................................................................664

electrical circuit diagram (4/4)............................................................................665

for multi monitor.......................................................................................665

This page left intentionally blank......................................................................666

electrical circuit diagram for air conditioner..............................................................667

This page left intentionally blank......................................................................668

IMAGES PREVIEW OF THE MANUAL:

1 file (8.9MB)