$45

Komatsu PC290LC-8, PC290NLC-8 Hydraulic Excavator Shop Manual - PDF

Komatsu PC290LC-8, PC290NLC-8 Hydraulic Excavator Shop Manual

FILE DETAILS:

Komatsu PC290LC-8, PC290NLC-8 Hydraulic Excavator Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : UEN00001-01

Total Pages : 1050

DESCRIPTION:

Komatsu PC290LC-8, PC290NLC-8 Hydraulic Excavator Shop Manual

HOW TO READ THE SHOP MANUAL:

1. Composition of shop manual:

This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections.

00. Index and foreword:

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification:

This section explains the specifications of the machine.

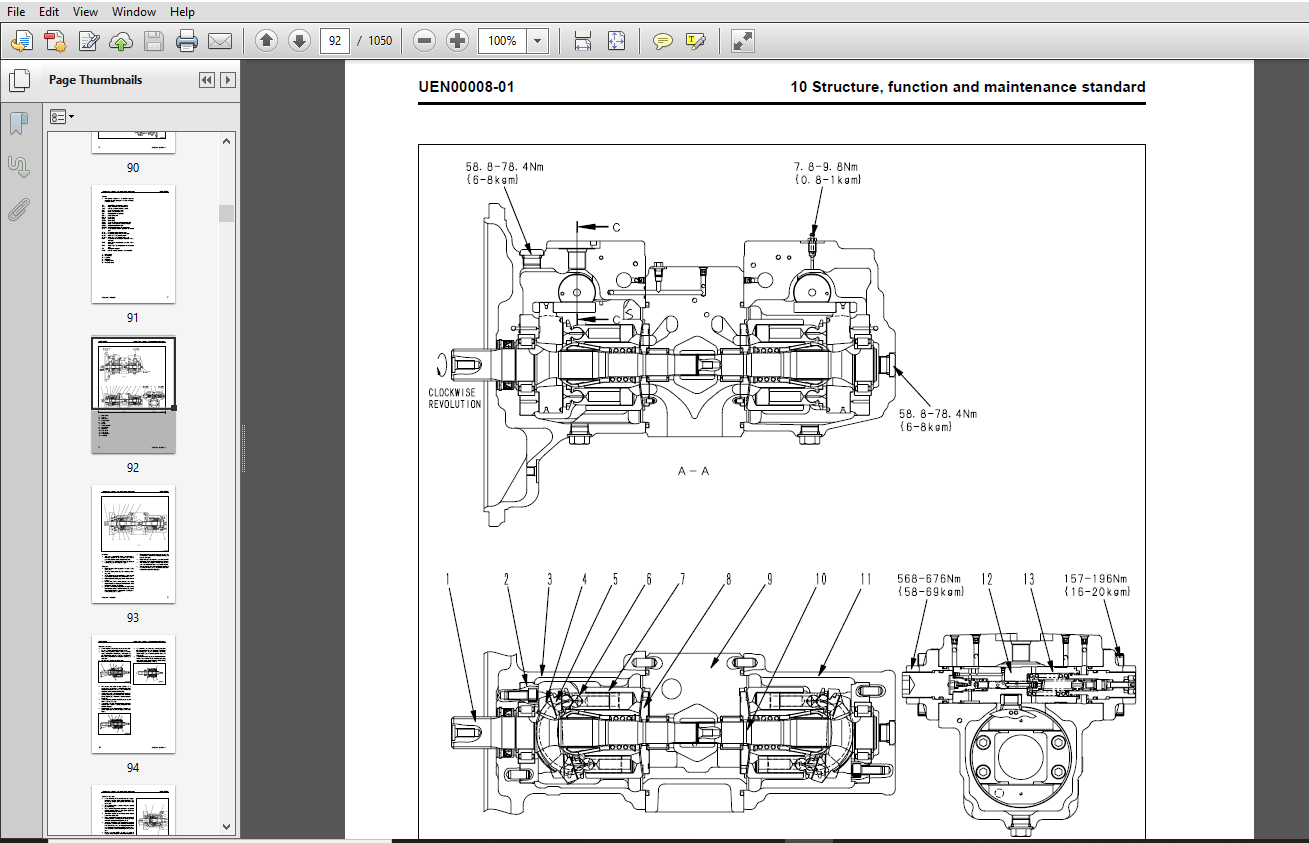

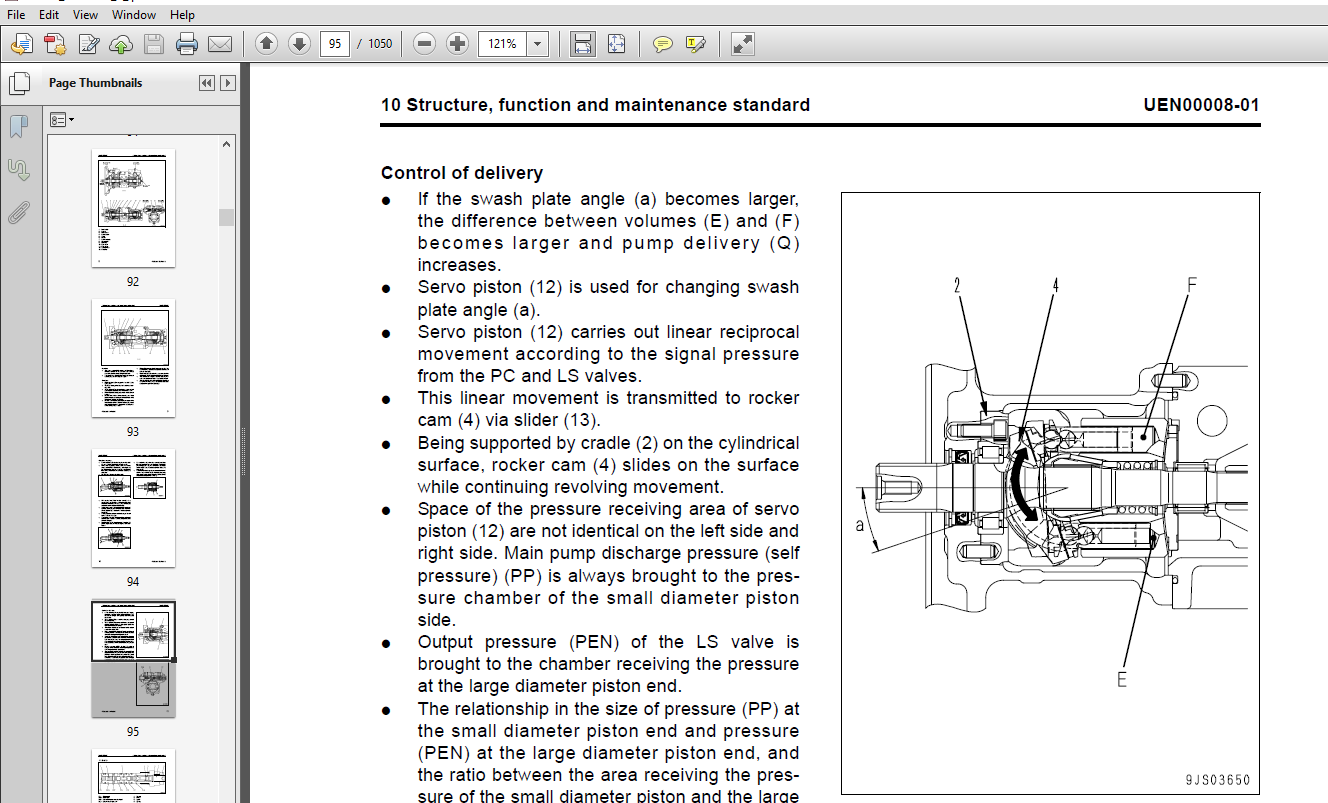

10. Structure, function and maintenance standard:

This section explains the structure, function, and maintenance standard values of each component. The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

20. Standard value table:

This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting:

This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

40. Troubleshooting:

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly:

This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume):

- Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams. - Engine volume

This section explains the method of reproducing, repairing, and replacing parts

TABLE OF CONTENTS:

Komatsu PC290LC-8, PC290NLC-8 Hydraulic Excavator Shop Manual

00 Index and foreword........................................................................................ 3 Index.................................................................................................... 3 Organization list of the shop manual................................................................. 4 Table of contents.................................................................................... 6 00 Index and foreword........................................................................................ 15 Foreword and general information......................................................................... 15 Foreword and general information..................................................................... 16 Safety notice.................................................................................... 16 How to read the shop manual...................................................................... 20 Explanation of terms for maintenance standard.................................................... 22 Handling electric equipment and hydraulic component.............................................. 24 How to read electric wire code................................................................... 32 Method of disassembling and connecting push-pull type coupler.................................... 35 Standard tightening torque table................................................................. 38 Conversion table................................................................................. 42 01 Specification............................................................................................. 49 Specification and technical data......................................................................... 49 Specification and technical data..................................................................... 50 Specification dimension drawings................................................................. 50 Working range diagram............................................................................ 51 Specifications................................................................................... 52 Weight table..................................................................................... 54 Table of fuel, coolant and lubricants............................................................ 56 10 Structure, function and maintenance standard.............................................................. 59 Engine and cooling system................................................................................ 59 Engine and cooling system............................................................................ 60 Engine related parts............................................................................. 60 Radiator, oil cooler, aftercooler and fuel cooler................................................ 61 10 Structure, function and maintenance standard.............................................................. 63 Power train.............................................................................................. 63 Power train.......................................................................................... 64 Power train...................................................................................... 64 Final drive...................................................................................... 66 Swing machinery.................................................................................. 68 Swing circle..................................................................................... 70 10 Structure, function and maintenance standard.............................................................. 73 Undercarriage and frame.................................................................................. 73 Undercarriage and frame.............................................................................. 74 Track frame and recoil spring.................................................................... 74 Idler............................................................................................ 76 Carrier roller................................................................................... 78 Track roller..................................................................................... 79 Track shoe....................................................................................... 80 10 Structure, function and maintenance standard.............................................................. 85 Hydraulic system, Part 1................................................................................. 85 Hydraulic system, Part 1............................................................................. 86 Hydraulic equipment layout drawing............................................................... 86 Hydraulic tank and filter........................................................................ 88 Hydraulic pump................................................................................... 90 Pilot oil filter................................................................................. 112 10 Structure, function and maintenance standard.............................................................. 115 Hydraulic system, Part 2................................................................................. 115 Hydraulic system, Part 2............................................................................. 116 Control valve.................................................................................... 116 CLSS............................................................................................. 127 Functions and operation by valve................................................................. 132 Hydraulic drift prevention valve................................................................. 157 10 Structure, function and maintenance standard.............................................................. 169 Hydraulic system, Part 3................................................................................. 169 Hydraulic system, Part 3............................................................................. 171 Swing motor...................................................................................... 171 Center swivel joint.............................................................................. 180 Travel motor..................................................................................... 183 PPC valve........................................................................................ 196 Valve control.................................................................................... 218 ATT EPC Valve Assembly........................................................................... 220 Solenoid valve................................................................................... 222 PPC Accumulator.................................................................................. 224 Return oil filter................................................................................ 225 Attachment circuit selector valve................................................................ 226 Quick coupler control valve...................................................................... 228 Quick coupler control valve...................................................................... 230 Hydraulic cylinder............................................................................... 232 10 Structure, function and maintenance standard.............................................................. 235 Work equipment........................................................................................... 235 Work equipment....................................................................................... 236 Dimensions of components......................................................................... 236 10 Structure, function and maintenance standard.............................................................. 243 Cab and its attachments.................................................................................. 243 Cab and its attachments.............................................................................. 244 Air conditioner piping........................................................................... 244 10 Structure, function and maintenance standard.............................................................. 247 Electrical system........................................................................................ 247 Electrical system.................................................................................... 249 Engine control................................................................................... 249 Electrical control system........................................................................ 258 Monitor system................................................................................... 283 Sensor........................................................................................... 314 PPC Levers....................................................................................... 317 KOMTRAX terminal system.......................................................................... 319 20 Standard value table...................................................................................... 323 Standard service value table............................................................................. 323 Standard service value table......................................................................... 324 Standard value table for engine related parts.................................................... 324 Standard value table for chassis related parts................................................... 325 30 Testing and adjusting..................................................................................... 337 Testing and adjusting, Part 1............................................................................ 337 Testing and adjusting, Part 1........................................................................ 339 Tools for testing, adjusting, and troubleshooting................................................ 339 Measuring engine speed........................................................................... 342 Measuring intake air pressure (boost pressure)................................................... 343 Checking exhaust gas color....................................................................... 344 Adjusting valve clearance........................................................................ 345 Measuring compression pressure................................................................... 347 Measuring blow-by pressure....................................................................... 349 Measuring engine oil pressure.................................................................... 350 Handling fuel system parts....................................................................... 351 Releasing residual pressure from fuel system..................................................... 351 Measuring fuel pressure.......................................................................... 352 Measuring fuel return rate and leakage........................................................... 354 Bleeding air from fuel circuit................................................................... 356 Checking fuel circuit for leakage................................................................ 358 Checking and adjusting air conditioner compressor belt tension................................... 359 Measuring swing circle bearing clearance......................................................... 360 Checking and adjusting track shoe tension........................................................ 361 Measuring and adjusting oil pressure in work equipment, swing, and travel circuits............... 363 Measuring control circuit basic pressure......................................................... 366 Measuring and adjusting oil pressure in pump PC control circuit.................................. 367 Measuring and adjusting oil pressure in pump LS control circuit.................................. 370 Measuring solenoid valve output pressure......................................................... 374 Measuring PPC valve output pressure.............................................................. 377 Adjusting play of work equipment and swing PPC valves............................................ 379 Measuring and adjusting quick coupler control valve output pressure.............................. 380 Checking parts which cause hydraulic drift of work equipment..................................... 381 Releasing residual pressure from hydraulic circuit............................................... 382 Measuring oil leakage............................................................................ 383 Bleeding air from each part...................................................................... 386 Checking cab tipping stopper..................................................................... 388 Adjusting mirrors................................................................................ 390 30 Testing and adjusting..................................................................................... 393 Testing and adjusting, Part 2............................................................................ 393 Testing and adjusting, Part 2........................................................................ 394 Special functions of machine monitor............................................................. 394 30 Testing and adjusting..................................................................................... 451 Testing and adjusting, Part 3............................................................................ 451 Testing and adjusting, Part 3........................................................................ 452 Handling high-voltage circuit of engine controller............................................... 452 Preparation work for troubleshooting of electrical system........................................ 453 Procedure for testing diodes..................................................................... 457 Pm Clinic service................................................................................ 459 40 Troubleshooting........................................................................................... 467 General information on troubleshooting................................................................... 467 General information on troubleshooting............................................................... 468 Points to remember when troubleshooting.......................................................... 468 Sequence of events in troubleshooting............................................................ 469 Check before troubleshooting..................................................................... 470 Classification and procedures for troubleshooting................................................ 471 How to read electric wire code................................................................... 475 Connection table for connector pin numbers....................................................... 478 T-boxes and T-adapters table..................................................................... 501 40 Troubleshooting........................................................................................... 505 Troubleshooting by failure code (Display of code), Part 1................................................ 505 Troubleshooting by failure code (Display of code), Part 1............................................ 507 Failure codes table.............................................................................. 507 Before carrying out troubleshooting when failure code is displayed............................... 512 Information in troubleshooting table............................................................. 516 Failure code [989L00] Engine Controller Lock Caution 1........................................... 518 Failure code [989M00] Engine Controller Lock Caution 2........................................... 518 Failure code [989N00] Engine Controller Lock Caution 3........................................... 519 Failure code [AA10NX] Air Cleaner Clogging....................................................... 519 Failure code [AB00KE] Charge Voltage Low......................................................... 520 Failure code [B@BAZG] Eng Oil Press. Low......................................................... 522 Failure code [B@BAZK] Eng Oil Level Low.......................................................... 522 Failure code [B@BCNS] Eng Water Overheat......................................................... 523 Failure code [B@BCZK] Eng Water Level Low........................................................ 523 Failure code [B@HANS] Hydr Oil Overheat.......................................................... 524 Failure code [CA111] EMC Critical Internal Failure............................................... 524 Failure code [CA115] Eng Ne and Bkup Speed Sens Error............................................ 525 Failure code [CA122] Chg Air Press Sensor High Error............................................. 526 Failure code [CA123] Chg Air Press Sensor Low Error.............................................. 528 Failure code [CA131] Throttle Sensor High Error.................................................. 530 Failure code [CA132] Throttle Sensor Low Error................................................... 532 Failure code [CA144] Coolant Temp Sens High Error................................................ 534 Failure code [CA145] Coolant Temp Sens Low Error................................................. 536 Failure code [CA153] Chg Air Temp Sensor High Error.............................................. 538 Failure code [CA154] Chg Air Temp Sensor Low Error............................................... 540 Failure code [CA155] Chg Air Temp High Speed Derate.............................................. 542 Failure code [CA187] Sens Supply 2 Volt Low Error................................................ 544 Failure code [CA221] Ambient Press Sens High Error............................................... 546 Failure code [CA222] Ambient Press Sens Low Error................................................ 548 Failure code [CA227] Sens Supply 2 Volt High Error............................................... 550 Failure code [CA234] Eng Overspeed............................................................... 551 Failure code [CA238] Ne Speed Sens Supply Volt Error............................................. 552 Failure code [CA271] IMV/PCV1 Short Error........................................................ 553 Failure code [CA272] IMV/PCV1 Open Error......................................................... 554 Failure code [CA322] Inj #1 (L#1) Open/Short Error............................................... 556 Failure code [CA323] Inj #5 (L#5) Open/Short Error............................................... 558 Failure code [CA324] Inj #3 (L#3) Open/Short Error............................................... 560 Failure code [CA325] Inj #6 (L#6) Open/Short Error............................................... 562 Failure code [CA331] Inj #2 (L#2) Open/Short Error............................................... 564 Failure code [CA332] Inj #4 (L#4) Open/Short Error............................................... 566 40 Troubleshooting........................................................................................... 569 Troubleshooting by failure code (Display of code), Part 2................................................ 569 Troubleshooting by failure code (Display of code), Part 2............................................ 571 Failure code [CA342] Calibration Code Incompatibility............................................ 571 Failure code [CA351] Injectors Drive Circuit Error............................................... 572 Failure code [CA352] Sens Supply 1 Volt Low Error................................................ 574 Failure code [CA386] Sens Supply 1 Volt High Error............................................... 576 Failure code [CA428] Water in Fuel Sensor High Error............................................. 578 Failure code [CA429] Water in Fuel Sensor Low Error.............................................. 580 Failure code [CA435] Eng Oil Press Sw Error...................................................... 582 Failure code [CA441] Battery Voltage Low Error................................................... 583 Failure code [CA442] Battery Voltage High Error.................................................. 586 Failure code [CA449] Rail Press Very High Error.................................................. 588 Failure code [CA451] Rail Press Sensor High Error................................................ 590 Failure code [CA452] Rail Press Sensor Low Error................................................. 592 Failure code [CA488] Chg Air Temp High Torque Derate............................................. 594 Failure code [CA553] Rail Press High Error....................................................... 594 Failure code [CA559] Rail Press Low Error........................................................ 595 Failure code [CA689] Eng Ne Speed Sensor Error................................................... 596 Failure code [CA731] Eng Bkup Speed Sens Phase Error............................................. 598 Failure code [CA757] All Continuous Data Lost Error.............................................. 600 Failure code [CA778] Eng Bkup Speed Sensor Error................................................. 602 Failure code [CA1633] KOMNET Datalink Timeout Error.............................................. 604 Failure code [CA2185] Throt Sens Sup Volt High Error............................................. 606 Failure code [CA2186] Throt Sens Sup Volt Low Error.............................................. 607 Failure code [CA2249] Rail Press Very Low Error.................................................. 608 Failure code [CA2311] IMV Solenoid Error......................................................... 610 Failure code [CA2555] Grid Htr Relay Volt High Error............................................. 612 Failure code [CA2556] Grid Htr Relay Volt Low Error.............................................. 614 Failure code [D19JKZ] Personal Code Relay Abnormality............................................ 616 Failure code [D862KA] GPS Antenna Discon......................................................... 618 Failure code [DA25KP] 5V Sensor 1 Power Abnormality.............................................. 619 Failure code [DA29KQ] Model Selection Abnormality................................................ 626 40 Troubleshooting........................................................................................... 629 Troubleshooting by failure code (Display of code), Part 3................................................ 629 Troubleshooting by failure code (Display of code), Part 3............................................ 632 Failure code [DA2RMC] CAN Discon (Pump Con Detected)............................................. 632 Failure code [DAFGMC] GPS Module Error........................................................... 634 Failure code [DAFRMC] CAN Discon (Monitor Detected).............................................. 636 Failure code [DGH2KB] Hydr Oil Sensor Short...................................................... 638 Failure code [DHPAMA] F Pump Press Sensor Abnormality............................................ 640 Failure code [DHPBMA] R Pump Press Sensor Abnormality............................................ 642 Failure code [DHS3MA] Arm Curl PPC Press Sensor Abnormality...................................... 644 Failure code [DHS4MA] Bucket Curl PPC Press Sensor Abnormality................................... 646 Failure code [DHS8MA] Boom Raise PPC Press Sensor Abnormality.................................... 648 Failure code [DHSAMA] Swing RH PPC Press Sensor Abnormality...................................... 650 Failure code [DHSBMA] Swing LH PPC Press Sensor Abnormality...................................... 652 Failure code [DHSDMA] Bucket Dump PPC Press Sensor Abnormality................................... 654 Failure code [DHX1MA] Overload Sensor Abnormality (Analog)....................................... 656 Failure code [DW43KA] Travel Speed Sol Discon.................................................... 658 Failure code [DW43KB] Travel Speed Sol Short..................................................... 660 Failure code [DW45KA] Swing Brake Sol Discon..................................................... 662 Failure code [DW45KB] Swing Brake Sol Short...................................................... 664 Failure code [DW91KA] Travel Junction Sol Discon................................................. 666 Failure code [DW91KB] Travel Junction Sol Short.................................................. 668 Failure code [DWA2KA] Service Sol Discon......................................................... 670 Failure code [DWA2KB] Service Sol Short.......................................................... 671 Failure code [DWK0KA] 2-stage Relief Sol Discon.................................................. 672 Failure code [DWK0KB] 2-stage Relief Sol Short................................................... 674 40 Troubleshooting........................................................................................... 677 Troubleshooting by failure code (Display of code), Part 4................................................ 677 Troubleshooting by failure code (Display of code), Part 4............................................ 680 Failure code [DXA8KA] PC-EPC (F) Sol Discon...................................................... 680 Failure code [DXA8KB] PC-EPC (F) Sol Short....................................................... 682 Failure code [DXA9KA] PC-EPC (R) Sol Discon...................................................... 684 Failure code [DXA9KB] PC-EPC (R) Sol Short....................................................... 686 Failure code [DXE0KA] LS-EPC Sol Discon.......................................................... 688 Failure code [DXE0KB] LS-EPC Sol Short........................................................... 690 Failure code [DXE4KA] Service Current EPC Discon................................................. 692 Failure code [DXE4KB] Service Current EPC Short.................................................. 694 Failure code [DXE5KA] Merge-divider Main Sol Discon.............................................. 696 Failure code [DXE5KB] Merge-divider Main Sol Short............................................... 698 Failure code [DXE6KA] Merge-divider LS Sol Discon................................................ 700 Failure code [DXE6KB] Merge-divider LS Sol Short................................................. 702 Failure code [DY20KA] Wiper Working Abnormality.................................................. 704 Failure code [DY20MA] Wiper Parking Abnormality.................................................. 706 Failure code [DY2CKA] Washer Drive Discon........................................................ 708 Failure code [DY2CKB] Washer Drive Short......................................................... 710 Failure code [DY2DKB] Wiper Drive (For) Short.................................................... 712 Failure code [DY2EKB] Wiper Drive (Rev) Short.................................................... 714 40 Troubleshooting........................................................................................... 717 Troubleshooting of electrical system (E-mode)............................................................ 717 Troubleshooting of electrical system (E-mode)........................................................ 719 Before carrying out troubleshooting of electrical system......................................... 719 Information in troubleshooting table............................................................. 721 E-1 When starting switch turned ON, machine monitor displays nothing............................. 722 E-2 When starting switch turned ON (before starting engine), basic check item lights up.......... 724 E-3 Engine does not start (Engine does not turn)................................................. 727 E-4 Preheater does not operate................................................................... 730 E-5 Automatic warm-up system does not operate (in cold season)................................... 732 E-6 All work equipment, swing, and travel mechanism do not move or cannot be locked.............. 734 E-7 Precaution lights up while engine is running................................................. 736 E-8 Emergency stop item lights up while engine is running........................................ 741 E-9 Engine coolant temperature gauge does not indicate normally.................................. 742 E-10 Hydraulic oil temperature gauge does not indicate normally.................................. 743 E-11 Fuel level gauge does not indicate normally................................................. 745 E-12 Contents of display by machine monitor are different from applicable machine................ 747 E-13 Machine monitor does not display some items................................................. 747 E-14 Function switch does not work............................................................... 747 E-15 Auto-decelerator does not operate normally.................................................. 748 E-16 Working mode does not change................................................................ 749 E-17 Travel speed does not change................................................................ 750 E-18 Alarm buzzer cannot be stopped.............................................................. 751 E-19 Windshield wiper and window washer do not operate........................................... 752 E-20 Power maximizing function does not operate normally......................................... 754 E-21 Swing holding brake does not operate normally............................................... 756 E-22 Travel alarm does not sound or does not stop sounding....................................... 758 E-23 Air conditioner does not operate normally (including air conditioner abnormality record).... 760 E-24 When starting switch is turned OFF, service meter is not displayed.......................... 772 E-25 Machine monitor cannot be set in service mode............................................... 772 E-26 Monitoring function does not display lever control signal normally.......................... 773 E-27 KOMTRAX system does not operate normally.................................................... 781 40 Troubleshooting........................................................................................... 783 Troubleshooting of hydraulic and mechanical system (H-mode).............................................. 783 Troubleshooting of hydraulic and mechanical system (H-mode).......................................... 786 System diagram of hydraulic and mechanical system................................................ 786 Information in troubleshooting table............................................................. 788 H-1 Speed or power of whole work equipment, swing, and travel is low............................. 789 H-2 Engine speed lowers extremely or engine stalls............................................... 791 H-3 Work equipment, swing, and travel systems do not work........................................ 792 H-4 Abnormal sound comes out from around hydraulic pump.......................................... 792 H-5 Auto-decelerator does not operate............................................................ 793 H-6 Fine control performance or response is low.................................................. 793 H-7 Speed or power of boom is low................................................................ 794 H-8 Speed or power of arm is low................................................................. 795 H-9 Speed or power of bucket is low.............................................................. 796 H-10 Work equipment does not move singly......................................................... 796 H-11 Hydraulic drift of work equipment is large.................................................. 797 H-12 Time lag of work equipment is large......................................................... 799 H-13 When part of work equipment is relieved singly, other parts of work equipment move.......... 799 H-14 Power maximizing function does not work..................................................... 800 H-15 In compound operation of work equipment, speed of part loaded more is low................... 800 H-16 When machine swings and raises boom simultaneously, boom rising speed is low................ 801 H-17 When machine swings and travels simultaneously, travel speed lowers largely................. 801 H-18 Machine deviates during travel.............................................................. 802 H-19 Travel speed is low......................................................................... 803 H-20 Machine is not steered well or steering power is low........................................ 804 H-21 Travel speed does not change or travel speed is low/high.................................... 805 H-22 Travel system does not move (only one side)................................................. 806 H-23 Upper structure does not swing.............................................................. 807 H-24 Swing acceleration or swing speed is low.................................................... 809 H-25 Upper structure overruns remarkably when it stops swinging.................................. 810 H-26 Large shock is made when upper structure stops swinging..................................... 811 H-27 Large sound is made when upper structure stops swinging..................................... 811 H-28 Hydraulic drift of swing is large........................................................... 812 H-29 Attachment circuit is not changed........................................................... 813 H-30 Oil flow in attachment circuit cannot be controlled......................................... 813 Quick coupler.................................................................................... 814 40 Troubleshooting........................................................................................... 817 Troubleshooting of engine (S-mode)....................................................................... 817 Troubleshooting of engine (S-mode)................................................................... 819 Method of using troubleshooting chart............................................................ 819 S-1 Starting performance is poor................................................................. 822 S-2 Engine does not start........................................................................ 823 S-3 Engine does not pick up smoothly............................................................. 826 S-4 Engine stops during operations............................................................... 827 S-5 Engine does not rotate smoothly.............................................................. 828 S-6 Engine lack output (or lacks power).......................................................... 829 S-7 Exhaust smoke is black (incomplete combustion)............................................... 830 S-8 Oil consumption is excessive (or exhaust smoke is blue)...................................... 831 S-9 Oil becomes contaminated quickly............................................................. 832 S-10 Fuel consumption is excessive............................................................... 833 S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)....................... 834 S-12 Oil pressure drops.......................................................................... 835 S-13 Oil level rises (Entry of coolant/fuel)..................................................... 836 S-14 Coolant temperature becomes too high (overheating).......................................... 837 S-15 Abnormal noise is made...................................................................... 838 S-16 Vibration is excessive...................................................................... 839 50 Disassembly and assembly.................................................................................. 841 General information on disassembly and assembly.......................................................... 841 General information on disassembly and assembly...................................................... 842 How to read this manual.......................................................................... 842 Coating materials list........................................................................... 844 Special tool list................................................................................ 847 Sketches of special tools........................................................................ 852 50 Disassembly and assembly.................................................................................. 855 Engine and cooling system................................................................................ 855 Engine and cooling system............................................................................ 856 Removal and installation of fuel supply pump assembly............................................ 856 Removal and installation of fuel injector assembly............................................... 858 Removal and installation of engine front seal.................................................... 865 Removal and installation of engine rear seal..................................................... 868 Removal and installation of cylinder head assembly............................................... 871 Removal and installation of radiator assembly.................................................... 883 Removal and installation of hydraulic oil cooler assembly........................................ 886 Removal and installation of aftercooler assembly................................................. 888 Removal and installation of fuel cooler assembly................................................. 890 Removal and installation of engine and hydraulic pump assembly................................... 891 50 Disassembly and assembly.................................................................................. 901 Power train.............................................................................................. 901 Power train.......................................................................................... 902 Removal and installation of final drive assembly................................................. 902 Disassembly and assembly of final drive assembly................................................. 903 Removal and installation of swing motor and swing machinery assembly............................. 912 Disassembly and assembly of swing motor and swing machinery assembly............................. 914 Removal and installation of swing circle assembly................................................ 923 50 Disassembly and assembly.................................................................................. 925 Undercarriage and frame.................................................................................. 925 Undercarriage and frame.............................................................................. 926 Disassembly and assembly of carrier roller assembly.............................................. 926 Disassembly and assembly of track roller assembly................................................ 927 Disassembly and assembly of idler assembly....................................................... 928 Disassembly and assembly of recoil spring assembly............................................... 931 Removal and installation of sprocket............................................................. 933 Expansion and installation of track shoe assembly................................................ 934 Removal and installation of revolving frame assembly............................................. 936 Removal and installation of counterweight assembly............................................... 938 50 Disassembly and assembly.................................................................................. 941 Hydraulic system......................................................................................... 941 Hydraulic system..................................................................................... 942 Removal and installation of center swivel joint assembly......................................... 942 Disassembly and assembly of center swivel joint assembly......................................... 944 Removal and installation of hydraulic tank assembly.............................................. 945 Removal and installation of control valve assembly............................................... 948 Disassembly and assembly of control valve assembly............................................... 953 Removal and installation of hydraulic pump assembly.............................................. 957 Removal and installation of oil seal in hydraulic pump input shaft............................... 961 Disassembly and assembly of work equipment PPC valve assembly.................................... 962 Disassembly and assembly of travel PPC valve assembly............................................ 963 Disassembly and assembly of hydraulic cylinder assembly.......................................... 964 Disassembly and Assembly of Quick Coupler Valve.................................................. 970 50 Disassembly and assembly.................................................................................. 973 Work equipment........................................................................................... 973 Work equipment....................................................................................... 974 Removal and installation of work equipment assembly.............................................. 974 50 Disassembly and assembly.................................................................................. 979 Cab and its attachments.................................................................................. 979 Cab and its attachments.............................................................................. 980 Removal and installation of operator's cab assembly.............................................. 980 Removal and installation of operator cab glass (stuck glass)..................................... 983 Removal and installation of front window assembly................................................ 993 Removal and installation of floor frame assembly.................................................1000 50 Disassembly and assembly..................................................................................1005 Electrical system........................................................................................1005 Electrical system....................................................................................1006 Removal and installation of air conditioner unit assembly........................................1006 Removal and installation of KOMTRAX communication modem assembly.................................1009 Removal and installation of monitor assembly.....................................................1010 Removal and installation of pump controller assembly.............................................1012 Removal and installation of engine controller assembly...........................................1013 90 Diagrams and drawings.....................................................................................1015 Hydraulic diagrams and drawings..........................................................................1015 Hydraulic diagrams and drawings (For PC290-8 K50001 ~ K50104)........................................1017 Hydraulic circuit diagram 1/2....................................................................1017 Hydraulic circuit diagram 2/2....................................................................1019 Hydraulic diagrams and drawings (For PC290-8 K50105 and up)).........................................1021 Hydraulic circuit diagram 1/2....................................................................1021 Hydraulic circuit diagram 2/2....................................................................1023 90 Diagrams and drawings.....................................................................................1027 Electrical diagrams and drawings.........................................................................1027 Electrical circuit diagram (For PC290-8 K50001 ~ K50104).............................................1029 Electrical circuit diagram (1/5).................................................................1029 Electrical circuit diagram (2/5).................................................................1031 Electrical circuit diagram (3/5).................................................................1033 Electrical circuit diagram (4/5).................................................................1035 Electrical circuit diagram (5/5).................................................................1037 Electrical diagrams and drawings (For PC290 K50105 and up)...........................................1039 Electrical circuit diagram (1/5).................................................................1039 Electrical circuit diagram (2/5).................................................................1041 Electrical circuit diagram (3/5).................................................................1043 Electrical circuit diagram (4/5).................................................................1045 Electrical circuit diagram (5/5).................................................................1047

IMAGES PREVIEW OF THE MANUAL: