$42

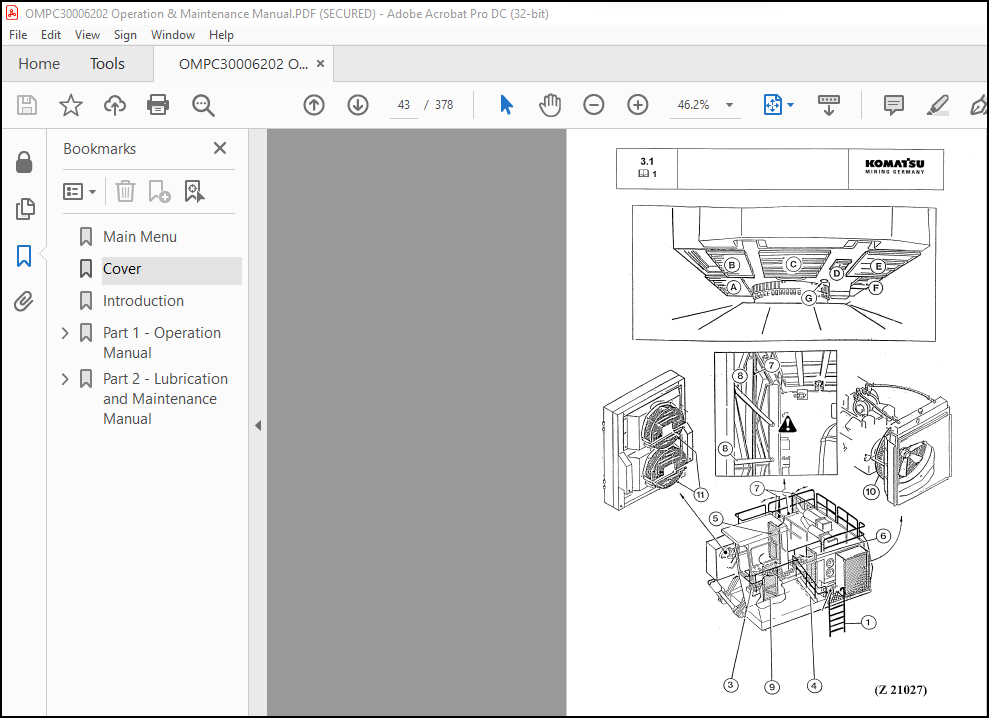

Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 – PDF

Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 – PDF DOWNLOAD

Language : English

Pages : 378

Downloadable : Yes

File Type : PDF

Size: 13.9 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 – PDF DOWNLOAD

SERIAL NUMBERS PC3000-1 6202

The Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 is a comprehensive guide that provides detailed information on the operation and maintenance of the Komatsu PC3000-1 Hydraulic Mining Excavator. This manual is designed to be used by operators and maintenance personnel who are responsible for the safe and efficient operation of the machine.

- The manual is divided into several sections, each providing valuable information on specific aspects of the machine. The first section provides an overview of the machine’s features and specifications, including its engine, hydraulic system, electrical system, and structural components. This section also includes information on the machine’s safety features and important safety guidelines for operating the machine.

- The second section of the manual provides a detailed description of the machine’s controls and how to operate them. This includes information on the operation of the machine’s boom, bucket, and cab, as well as its various sensors, gauges, and monitors. This section also includes information on how to start and stop the machine, as well as how to use the various modes and settings available.

- The third section of the manual provides information on maintenance and servicing of the machine. This section includes recommended maintenance schedules, procedures for routine maintenance, and troubleshooting procedures for identifying and fixing common problems. It also includes information on how to service the machine’s engine, hydraulic system, and electrical system, as well as how to perform inspections and replace worn or damaged parts.

- The fourth section of the manual provides information on troubleshooting and diagnosing problems with the machine. This includes procedures for identifying and fixing common problems with the engine, hydraulic system, electrical system, and other components of the machine.

- The manual also includes several appendices that provide additional information on topics such as specifications and dimensions, hydraulic system diagrams, and electrical system diagrams. These appendices can be especially useful for mechanics and technicians who are responsible for maintaining and servicing the machine.

- Overall, the Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 is an essential resource for anyone involved in the operation and maintenance of this machine. Its detailed information and step-by-step procedures can help ensure the safe and efficient use of the machine in mining operations, and its troubleshooting procedures can help minimize downtime and increase productivity.

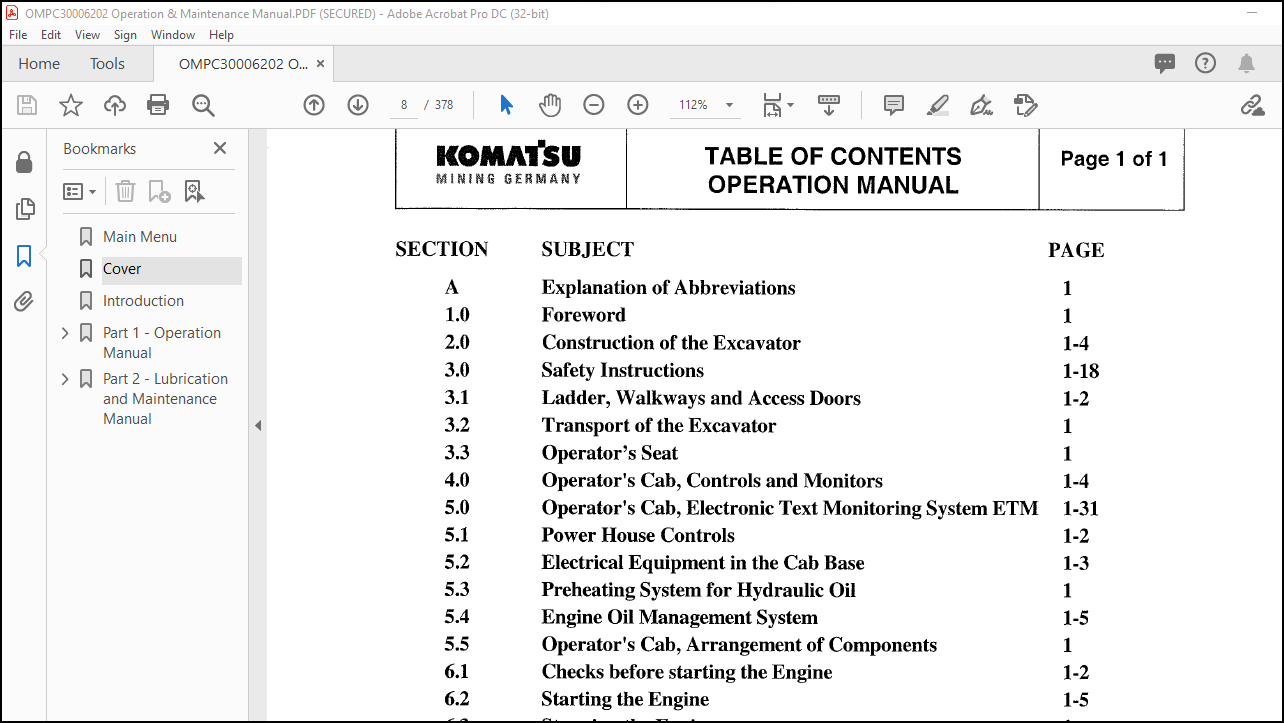

TABLE OF CONTENTS:

Komatsu PC3000-1 Hydraulic Mining Excavator Operation & Maintenance Manual OMPC30006202 – PDF DOWNLOAD

Main Menu……………………………………………………………………… 0

Cover…………………………………………………………………………. 1

Introduction…………………………………………………………………… 2

Part 1 – Operation Manual……………………………………………………….. 8

Table of Contents – Operation Manual………………………………………….. 8

Section A – Explanation of Abbreviations Used in this Manual…………………….. 10

Section 1.0 – Foreward………………………………………………………. 12

Section 2.0 – Construction of the Excavator……………………………………. 14

2. – Overall View……………………………………………………….. 14

2.1 – Superstructure…………………………………………………….. 16

2.3 – Attachment………………………………………………………… 20

Backhoe Attachment…………………………………………………… 20

Section 3.0 – Safety Instructions…………………………………………….. 22

Fundamental Safety Instructions…………………………………………… 23

1.1 – Warnings and Symbols……………………………………………. 23

1.2 – Basic Operation and Designated Use of Hydraulic Excavator…………… 23

1.3 – Organizational Measures…………………………………………. 24

1.4 – Selection and Qualification of Personal…………………………… 26

1.5 – Safety Instructions Governing Specific Operational Phases…………… 27

1.6 – Warning of Special Dangers………………………………………. 32

1.7 – Transporting and Towing – Recommissioning…………………………. 35

1.8 – Special Safety Equipment………………………………………… 36

Safety Harness………………………………………………………….. 38

Instructions for Use…………………………………………………. 38

Prior to Using Harness……………………………………………….. 40

Recommendations for Use of Holding Hooks and Hold-Back Hooks……………… 42

Instructions for Use of Strap-Type Fall Absorber………………………… 42

Section 3.1 – Ladder, Walkways, and Access Doors……………………………….. 44

Superstructure………………………………………………………….. 44

Sea Protection Covers……………………………………………………. 47

Section 3.2 – Transport of Excavator………………………………………….. 48

Short Transport with Calm Sea Conditions Drawing……………………………. 49

Long Transport with Rough Sea Conditions Drawing……………………………. 50

Location of Plug Socket for Hydraulic Oil Heating System…………………….. 51

Section 3.3 – Operator’s Seat………………………………………………… 54

Section 4.0 – Operator’s Cab – Controls and Monitors……………………………. 56

Control Levers and Control Pedals…………………………………………. 56

Safety Circuit for Controls………………………………………………. 56

Switch Board……………………………………………………………. 60

Instruments and Pontoon Controls………………………………………….. 62

Section 5.0 – Electronic Text Monitoring System Komatsu ETM……………………… 64

Introduction……………………………………………………………. 64

Further Features of the ETM System…………………………………….. 64

Messages are Divided into Two Main Groups………………………………. 64

Function of the Keys (1 to 8) of Keyboard………………………………. 66

System Components……………………………………………………. 68

Switches for Adjustment of the ETM…………………………………….. 70

Message Classification……………………………………………….. 70

Functions of the ETM System…………………………………………… 72

Display the Content of Record (PROTOCOL) Memory…………………………. 78

Display the Content of Static Memory…………………………………… 80

Print Out Content of Static Memory…………………………………….. 82

Print Out Content of Record (PROTOCOL) Memory…………………………… 82

Change-over from English to German Language…………………………….. 88

Change-over from German to English Language…………………………….. 88

Several Massage Conditions Occur at Same Time…………………………… 90

Setting the Display Unit……………………………………………… 92

Erase Record (PROTOCOL) and STATISTICS Memory…………………………… 94

Return to System Level……………………………………………….. 96

Setting Screen Brightness…………………………………………….. 96

Table of Messages……………………………………………………. 97

Basic Display (Message Page no. 0)…………………………………. 97

Message Page Number 1 to 5………………………………………… 97

Message Page Number 6 to 11……………………………………….. 98

Message Page Number 12 to 18………………………………………. 99

Message Page Number 19 to 26……………………………………….100

Message Page Number 27 to 30……………………………………….101

Message Page Number 31 to 38……………………………………….102

Message Page Number 39 to 44……………………………………….103

Message Page Number 45 to 52……………………………………….104

Message Page Number 53 to 64……………………………………….105

Grouping Messages According to their Priority……………………………107

1st Priority Group………………………………………………..107

2nd Priority Group………………………………………………..108

3rd Priority Group………………………………………………..108

4th Priority Group………………………………………………..109

Explanation of the Statics Print-Out……………………………………110

Time Diagram of Statics Print………………………………………….111

Section 5.1 – Power House Controls…………………………………………….114

Section 5.2 – Electrical Equipment in Cab Base………………………………….118

Main Switch X2 in Cab Base………………………………………………..120

Diagnostic Fault Codes of Engine Centry System………………………………120

Switch Box X7 for Cab Heating and Air Conditioning…………………………..122

Section 5.3 – Preheating System for Hydraulic Oil……………………………….124

General…………………………………………………………………124

Operating the Heating System………………………………………………124

Section 5.4 – Engine Oil Management System……………………………………..126

General…………………………………………………………………126

Centinel Diagnostic Lamps…………………………………………………128

Check Centinel Diagnostic Lamps for Faults………………………………….128

Clearing Active Faults and Reset the Centinel System…………………………130

Resetting the Centinel System is Necessary………………………………….130

Check the Centinel System for Proper Operation………………………………130

Calibration Plug for Engine Oil Quality…………………………………….130

Oil Burning System Centinel Combined with Reverse System……………………..131

Eliminator Engine Oil Filter………………………………………………132

Section 5.5 – Operator’s Cab Arrangement of Components…………………………..134

Section 6.1 – Ceheck Before Starting the Engine…………………………………136

Section 6.2 – Starting the Engine……………………………………………..140

Before Starting………………………………………………………….140

Starting Procedure……………………………………………………….140

Cold Weather Starting…………………………………………………….142

After Starting…………………………………………………………..142

Automatic Engine Shut-Down System (Safety Chain)…………………………….144

Untitled………………………………………………………………..146

Engine Warm-Up…………………………………………………………..146

Hydraulic Oil Warm-Up…………………………………………………….146

Hydraulic Oil Viscosity and Temperature Chart……………………………….148

Section 6.3 – Stopping the Engine……………………………………………..150

Stopping Procedure……………………………………………………….150

Section 6.4 – Pontoon Operation……………………………………………….152

Warping of the Pontoon……………………………………………………154

Float Position of Backhoe Attachment……………………………………….154

Determination of Directions……………………………………………….154

Shut-off Cocks for the Pontoon Hydraulic System……………………………..156

Section 6.5 – Slewing and Braking the Superstructure…………………………….158

6.5.1 – Rotating the Superstructure………………………………………..158

6.5.2 – Swing Angle Limitation System………………………………………158

6.5.3 – Braking the Superstructure…………………………………………158

6.5.4 – Swing Parking Brake……………………………………………….160

Section 6.6 – Working with the Attachment………………………………………162

Section 6.7 – Combined Operation Cycles………………………………………..166

Section 6.8 – Operating the Heater, Ventilation, and Air Conditioning……………..168

Heating…………………………………………………………………168

Air Conditioning (Special Equipment………………………………………..170

Combined Operation of Air Conditioning and Heating…………………………..170

Section 6.11 – Automatic Lubrication Systems……………………………………172

Central Lubrication System and Swing Ring Gear Lubrication System……………..172

Controls of Automatic Lubrication Systems…………………………………..172

Factory Adjustments………………………………………………………174

Section 6.13 – Fire Detection and Suppression System (Special Equipment)…………..176

Section 6.15 – Transfer Pump for Hydraulic Oil Reservoir…………………………184

Functions of the Transfer Pump…………………………………………….184

Transfer Procedure……………………………………………………….186

Section 7.0 – Working Instructions…………………………………………….190

Excavator Operation………………………………………………………190

Barge Warping……………………………………………………………190

Pontoon Warping………………………………………………………….192

Maintaining the Pontoon in the Flow………………………………………..192

Slowing Down Pontoon Motions………………………………………………192

Working Ashore or at Banks from the Pontoon…………………………………192

Working in Shallow Waters…………………………………………………192

Depositing the Attachment During Working Breaks……………………………..194

Section 7.1 – Emergency Operation System……………………………………….196

Section 9.0 – Refueling the Excavator………………………………………….198

Section 10.0 – Exchange of Attachment and/or Components………………………….200

Part 2 – Lubrication and Maintenance Manual………………………………………..202

Table of Contents – Lubrication and Maintenance Manual…………………………..202

Section 1.0 – Foreward……………………………………………………….204

Section Contents…………………………………………………………204

Definitions……………………………………………………………..205

Section 1.1 – Fire Prevention…………………………………………………208

Section 1.2 – Repair Welding………………………………………………….212

Section 2.0 – Safety Instructions……………………………………………..220

Section 3.0 – Fuel and Lubricants……………………………………………..222

Section 4.0 – Filling Capacities………………………………………………224

Section 5.0 – Lubrication and Maintenance Schedule………………………………226

5.1 – Initial Servicing…………………………………………………..226

5.2 – Periodic Servicing Intervals…………………………………………226

Service Interval Chart………………………………………………..227

Replacement of Hydraulic Hose Lines…………………………………….232

Inspection of Hydraulic Hose Lines……………………………………..232

5.3 – Extended Service Intervals for Engines with Engine Oil Management System….234

Servicing Intervals…………………………………………………..234

Every 10 Operating Hours…………………………………………..234

Every 500 Operating Hours………………………………………….236

Every 4000 Operating Hours…………………………………………236

Engine Oil Reserve Tank……………………………………………236

5.3.1 – Resetting of Engine Oil Burning System Centinel…………………..238

5.4 – Maintenance of Engine……………………………………………….238

5.5 – Maintenance of Eliminator Oil Filtration System………………………..238

Lubrication Point and Maintence Chart………………………………………239

Section 6.1 – Every 10 Operating Hours or Daily…………………………………242

1. – Visual Inspection……………………………………………………242

1.1 – Central Lubrication System……………………………………….246

Backhoe Attachment………………………………………………..246

Bullclam Bucket Attachment…………………………………………248

Slweing Connection………………………………………………..250

1.2 – Grease Injectors, Corrective Actions………………………………250

1.3 – Check Slew Ring Teeth for Proper Lubrication……………………….252

2. – Maintenance of Engines……………………………………………….254

3. – Lubrication of Attachment…………………………………………….254

3.1 – Lubrication of Backhoe Attachment…………………………………254

3.2 – Lubrication of Front Loader Attachment…………………………….254

4. – Lubrication of Slewing Connection……………………………………..256

5. – Engine Air Cleaners………………………………………………….258

6. – Not Used……………………………………………………………258

7. – Radiator – Check Coolant Level………………………………………..260

8. – Track Groups………………………………………………………..260

9. – Fuel System, Water Separator………………………………………….260

Section 6.2 – Every 50 Operating Hours or Weekly………………………………..262

10. – Slew Gear and Motor Adapter Housing…………………………………..262

11. – Not Used…………………………………………………………..264

12. – Pump Distributor Geat (PTO) and Oil Reservoirs…………………………264

13. – Radiator and Hydraulic Oil Coolers……………………………………268

14. – Air Conditioning……………………………………………………268

15. – Maintenance of Engines………………………………………………268

Section 6.3 – Every 250 Operating Hours or Monthly………………………………270

50. – Engine…………………………………………………………….270

51. – Drive Belts………………………………………………………..270

52. – Not Used…………………………………………………………..278

53. – Not Used…………………………………………………………..278

54. – Hydraulic Oil Cooler – Lubricate Fan Bearings………………………….278

55. – Not Used…………………………………………………………..278

56. – Not Used…………………………………………………………..278

57. – Compressor for Signal Horn…………………………………………..280

58. – Automatic Lubrication Systems, Clean In-Line-Grease-Filters……………..282

59. – Air Cleaner for Operator’s Cab……………………………………….284

60. – Air Conditioning……………………………………………………284

61. – Not Used…………………………………………………………..284

62. – Not Used…………………………………………………………..284

63. – Air Conditioning Refrigerant Compressor……………………………….286

Section 6.4 – Every 500 Operating Hours or Every 3 Months………………………..288

70. – Engine…………………………………………………………….288

71. – Batteries………………………………………………………….288

72. – Fuel Tank, Drain Water and Sediments………………………………….290

73. – Flexible Drive Coupling……………………………………………..292

74. – Rotary Distributor Lubrication……………………………………….294

Section 6.5 – Every 1000 Operating Hours or Every 6 Months……………………….296

80. – High-Strength Bolt Connections……………………………………….296

Bolt Torque Chart………………………………………………………..320

81. – Maintenance of Engines………………………………………………322

82. – Hydraulic System……………………………………………………322

83. – Pump Distributor Gears, Slew Gears, and Travel Gears……………………336

84. – Compressor for Signal Horn…………………………………………..338

85. – Not Used…………………………………………………………..338

86. – Air Conditioning……………………………………………………338

Section 6.6 – Every 2000 Operating Hours or Yearly………………………………340

100. – Hydraulic System…………………………………………………..340

Section 6.7 – Every 3000 operating operating Hours but at Least Once a Year………..348

111. – Slew Gear and Motor Adapter Housing………………………………….348

111. – Pump Distributor Gear (PTO)…………………………………………352

Section – 6.8 – When Necessary………………………………………………..356

120. – Servicing the Engine Air Cleaners……………………………………356

121. – Additional Fuel System Water Separator……………………………….362

122. – Slew Gear…………………………………………………………364

123. – Automatic Lubrication Systems with Replaceable Grease Barrels…………..366

124. – Not Used………………………………………………………….368

125. – Not Used………………………………………………………….368

126. – Not Used………………………………………………………….368

127. – Not Used………………………………………………………….368

128. – Hydraulic System…………………………………………………..368

129. – Cold Starting Aid, Replace Fluid Cylinder…………………………….368

130. – Electrical Switch Board (X2)………………………………………..370

Section 7.0 – Excavator Storage……………………………………………….372

General…………………………………………………………………372

1. Preparing for Storage………………………………………………….372

2. One Month Repetitive Service Peroid……………………………………..373

3. Six Month Repetitive Service Period……………………………………..373

4. Preparing for Operation………………………………………………..374

Section 8.0 – Troubleshooting…………………………………………………376

General…………………………………………………………………376

Engine………………………………………………………………….376

Hydraulic System…………………………………………………………377

Travel and Slew Gears…………………………………………………….378

Crawler Tracks…………………………………………………………..378