$37

Komatsu PC3000-1 Hydraulic Mining Shovel Operation & Maintenance Manual OMPC30006194 – PDF DOWNLOAD

Komatsu PC3000-1 Hydraulic Mining Shovel Operation & Maintenance Manual OMPC30006194 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC3000-1 Hydraulic Mining Shovel Operation & Maintenance Manual OMPC30006194 – PDF DOWNLOAD

Language : English

Pages : 507

Downloadable : Yes

File Type : PDF

Size: 16.3 MB

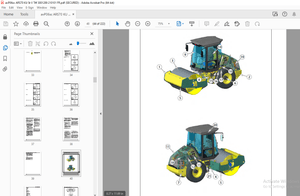

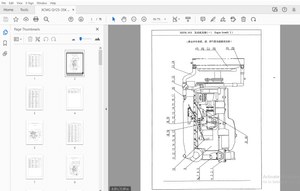

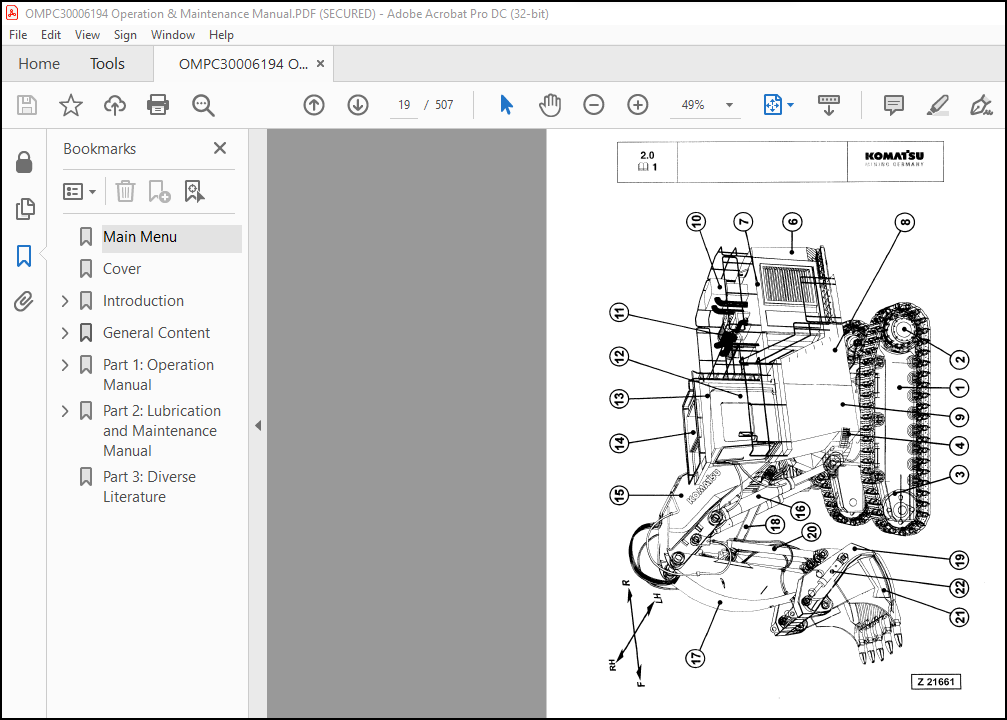

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC3000-1 Hydraulic Mining Shovel Operation & Maintenance Manual OMPC30006194 – PDF DOWNLOAD

The Komatsu PC3000-1 Hydraulic Mining Shovel is a large excavator used in the mining industry to extract materials such as coal, copper, iron ore, and more. The operation and maintenance of this machine are critical to ensuring its efficient and safe use in mining operations.

- The Operation & Maintenance Manual for the Komatsu PC3000-1 Hydraulic Mining Shovel is a comprehensive guide that provides detailed information on the operation and maintenance of the machine. This manual contains valuable information on the machine’s features, controls, and operating procedures, as well as recommended maintenance procedures and schedules.

- The manual is divided into several sections, each providing valuable information on specific aspects of the machine. The first section provides an overview of the machine’s features and specifications, including its engine, hydraulic system, and electrical system. This section also provides information on the machine’s safety features and important safety guidelines for operating the machine.

- The second section of the manual provides a detailed description of the machine’s controls and how to operate them. This includes information on the operation of the machine’s boom, bucket, and cab, as well as its various sensors, gauges, and monitors. This section also includes information on how to start and stop the machine, as well as how to use the various modes and settings available.

- The third section of the manual provides information on maintenance and servicing of the machine. This section includes recommended maintenance schedules, procedures for routine maintenance, and troubleshooting procedures for identifying and fixing common problems. It also includes information on how to service the machine’s engine, hydraulic system, and electrical system, as well as how to perform inspections and replace worn or damaged parts.

- The manual also includes several appendices that provide additional information on topics such as specifications and dimensions, hydraulic system diagrams, and electrical system diagrams. These appendices can be especially useful for mechanics and technicians who are responsible for maintaining and servicing the machine.

- Overall, the Operation & Maintenance Manual for the Komatsu PC3000-1 Hydraulic Mining Shovel is an essential resource for anyone involved in the operation and maintenance of this machine. Its detailed information and step-by-step procedures can help ensure the safe and efficient use of the machine in mining operations, and its troubleshooting procedures can help minimize downtime and increase productivity.

TABLE OF CONTENTS:

Komatsu PC3000-1 Hydraulic Mining Shovel Operation & Maintenance Manual OMPC30006194 – PDF DOWNLOAD

Main Menu…………………………………… 0

Cover………………………………………. 1

Introduction………………………………… 2

Introduction…………………………….. 2

General Content……………………………… 8

Table of Contents………………………… 8

Part 1: Operation Manual……………………… 14

Table of Contents………………………… 14

Foreword………………………………… 18

Construction of the Excavator……………… 20

Safety Instructions………………………. 34

Operator’s Cab-Controls…………………… 77

Operator’s Cab-Monitors…………………… 87

Operator’s Instructions……………………177

Working Instructions………………………239

Parking the Excavator……………………..24

Refilling System………………………….247

Exchange of Attachment and/or Components…….264

Transportation and Lifting of the Excavator….266

Retrieval Procedure……………………….268

Part 2: Lubrication and Maintenance Manual………270

Subject………………………………….270

Table of Contents…………………………270

Foreword…………………………………272

Safety Instructions……………………….288

Fuel and Lubricants……………………….292

Filling Capacities………………………..296

Lubrication and Maintenance Schedule………..298

Lubrication and Maintenance Work……………319

Excavator Storage…………………………496

Troubleshooting…………………………..502

Part 3: Diverse Literature…………………….507