$35

Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 – PDF DOWNLOAD

Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 – PDF DOWNLOAD

Language : English

Pages : 479

Downloadable : Yes

File Type : PDF

Size: 17.5 MB

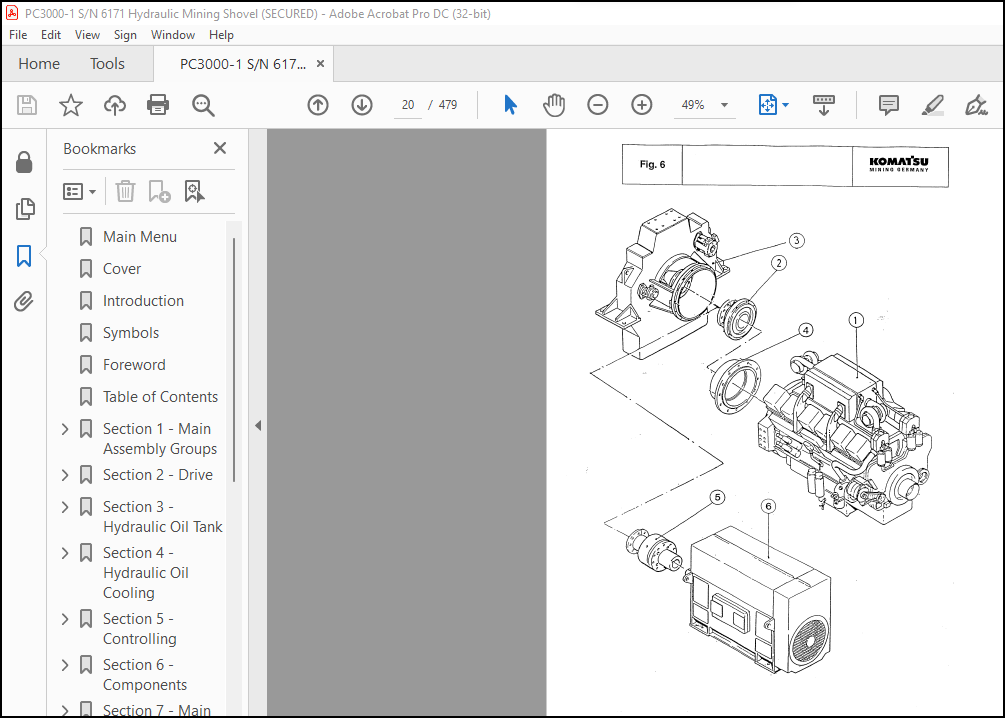

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 – PDF DOWNLOAD

SERIAL NUMBERS PC3000-1 6171

The Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 is a comprehensive guide that provides in-depth information on the maintenance and repair of the Komatsu PC3000-1 Hydraulic Mining Shovel. This manual is designed to be used by mechanics and technicians who are responsible for servicing and repairing the machine.

- The manual is divided into several sections, each providing valuable information on specific aspects of the machine. The first section provides an overview of the machine and its specifications, including its engine, hydraulic system, electrical system, and structural components. This section also includes information on the safety features of the machine and important safety guidelines for working on the machine.

- The second section of the manual provides detailed information on the maintenance and servicing of the machine. This includes recommended maintenance schedules, procedures for routine maintenance, and troubleshooting procedures for identifying and fixing common problems. This section also includes information on how to service the machine’s engine, hydraulic system, and electrical system, as well as how to perform inspections and replace worn or damaged parts.

- The third section of the manual provides detailed information on the repair and replacement of components and systems. This includes step-by-step procedures for disassembling and reassembling the machine, as well as instructions for repairing or replacing specific components such as the engine, hydraulic system, electrical system, and structural components.

- The fourth section of the manual provides information on testing and adjusting the machine’s components and systems. This includes procedures for testing and adjusting the engine, hydraulic system, electrical system, and other components of the machine to ensure proper operation and performance.

- The manual also includes several appendices that provide additional information on topics such as specifications and dimensions, hydraulic system diagrams, and electrical system diagrams. These appendices can be especially useful for mechanics and technicians who are responsible for maintaining and repairing the machine.

- Overall, the Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 is an essential resource for anyone involved in the maintenance and repair of this machine. Its detailed information and step-by-step procedures can help ensure the safe and efficient operation of the machine, and its troubleshooting procedures can help minimize downtime and increase productivity.

TABLE OF CONTENTS:

Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171 – PDF DOWNLOAD

Main Menu…………………………………………………………… 0

Cover………………………………………………………………. 1

Introduction………………………………………………………… 2

Symbols…………………………………………………………….. 3

Foreword……………………………………………………………. 4

Table of Contents……………………………………………………. 6

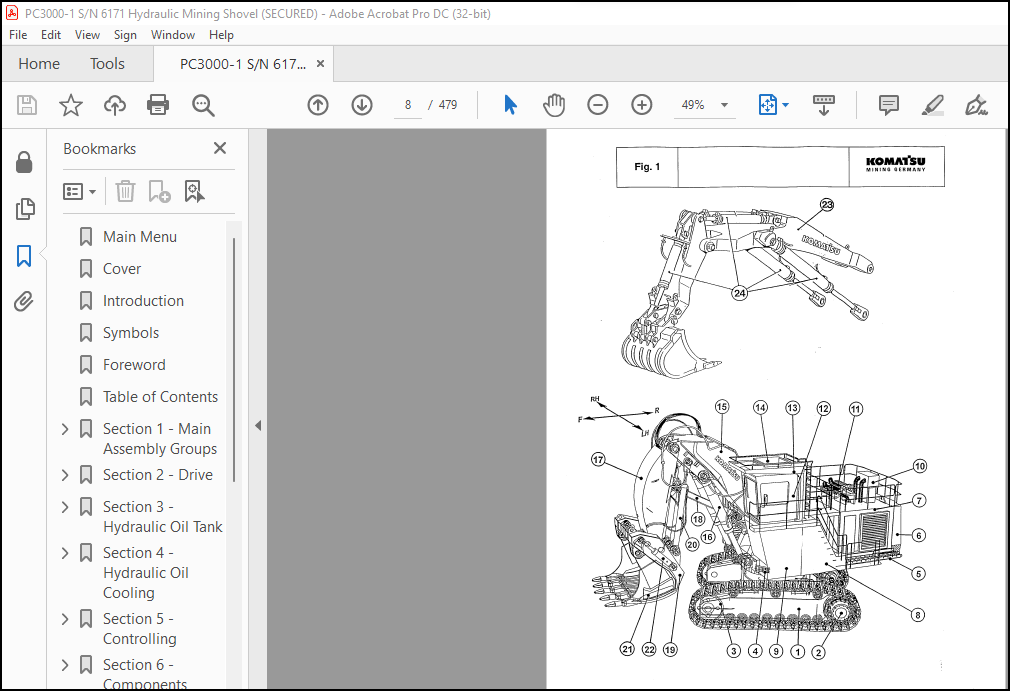

Section 1 – Main Assembly Groups………………………………………. 7

Table of Contents, Section 1………………………………………. 7

General Layout……………………………………………….. 9

Drive……………………………………………………….. 11

Control Blocks, Slew Gear……………………………………… 13

Undercarriage, Travel Drive……………………………………. 15

Driver’s Cab…………………………………………………. 17

Section 2 – Drive……………………………………………………. 19

Table of Contents, Section 2………………………………………. 19

Prime Drive Assembly………………………………………….. 21

Engine Mounts………………………………………………… 23

Fan Drive and Cooler Assy……………………………………… 25

Coupling…………………………………………………….. 27

Air Filter…………………………………………………… 29

Pump Distributor Gear…………………………………………. 31

Pump Spline – Lubrication……………………………………… 33

PTO – Gear Ludrication………………………………………… 35

Section 3 – Hydraulic Oil Tank………………………………………… 41

Table of Contents, Section 3………………………………………. 41

Main Oil Tank………………………………………………… 43

Return and Leak Oil Filter…………………………………….. 45

Breather Filter………………………………………………. 47

Location of Pressure Switches and Sensors……………………….. 49

Section 4 – Hydraulic Oil Cooling……………………………………… 51

Table of Contents, Section 4………………………………………. 51

General……………………………………………………… 53

Hydraulic Oil Cooling Circuit………………………………….. 55

Measuring / Setting the Back Pressure Valve……………………… 57

Fan Drive……………………………………………………. 61

Axial Piston Pump…………………………………………….. 65

Measuring and Setting of the Fan Speed………………………….. 67

Function Check for RPM-Control…………………………………. 71

Section 5 – Controlling………………………………………………. 73

Table of Contents, Section 5………………………………………. 73

Pilot Pressure Supplu…………………………………………. 75

General………………………………………………….. 75

Function…………………………………………………. 77

Checks and Adjustment of Pilot Pressure…………………………. 79

Measuring and Adjustment of Control Pressure…………………….. 81

Checking of Accumulator Function……………………………. 81

Checking of Accumulator Pre-charge Pressure………………….. 81

Travel Parking Brake………………………………………….. 83

Function Check of Travel Parking Brake………………………….. 85

Slew Parking (House) Brake…………………………………….. 87

Section 6 – Components……………………………………………….. 89

Table of Content…………………………………………………. 89

Main Control Blocks and High Pressure Filter (Bull-Clam Attachment…. 91

Main Control Blocks and High Pressure Filter (Back Hoe Attachment….. 93

Distributor Manifold (Bull-Clam Attachment)……………………… 95

Distributor Manifold (Back Hoe Attachment……………………….. 97

Restrictor Block with Pressure Valve……………………………. 99

Restrictor Block………………………………………………101

Anti Cavitation Valve Block…………………………………….103

Proportional Solenoid Valve…………………………………….105

Pressure Filter……………………………………………….107

Control Blocks………………………………………………..109

Control Blocks and Valves…………………………………..111

Valve at the Control Block………………………………….115

Load Holding Valve…………………………………………117

Travel Brake Valve…………………………………………….119

Pressure Reducing Valve………………………………………..121

Directional Control Valve (Solenoid Valve)……………………….123

Hydraulic Cylinder…………………………………………….125

Auxiliary Pumps, Fan Drive……………………………………..127

Auxiliary Gear Pumps…………………………………………..129

Slew Ring…………………………………………………….131

Section 7 – Main Hydraulic Pumps and Pump Regulation……………………..133

Table of Content………………………………………………….133

Main Hydraulic Pump A7V / HD D………………………………….135

SL-Bearing……………………………………………………139

Function of the Pump Governor…………………………………..141

Pump Bearing Lubrication……………………………………….147

Pump Governor Adjustments………………………………………151

Pump Regulation, General……………………………………….161

Determination of Peak Point (Engine Performance Test)……………..167

Hydraulic Regulation Adjustment, Stop Gap Operation……………….169

Detailed Explanation for Electronic Pump Regulation……………….171

Adjustments / Checks for Electronic Pump Regulation……………….173

Adjusting the RPM Sensor (MPU)………………………………….175

Adjustments at the ELL – Module, Normal Fine Tuning……………….177

Checks / Function Test / Fault Finding at JOBSITE…………………181

EPM – Module, Function and Test…………………………………183

ERM – Module, Function and Test…………………………………185

ELL – Module, Function and Test…………………………………189

Amplifier Module, Function and Test……………………………..193

Simplified Trouble Shooting of Electronic Regulation………………195

Section 8 – Operating Hydraulic………………………………………..199

Table of Content………………………………………………….199

Hydraulic for Attachment Cylinder……………………………….201

Adjustments for Attachment Cylinder Hydraulic…………………….205

Slew Circuit, General………………………………………….223

Slew Motor……………………………………………………227

Slew Gear and House Brake………………………………………231

Slew Brake Valve………………………………………………235

Slew Function…………………………………………………240

Checks and Adjustments…………………………………………251

Travel Citcuit………………………………………………..259

Rotary Distributor…………………………………………….263

Travel Motor (Axial Piston Motor A2FM)…………………………..265

Travel Gear and House Brake…………………………………….269

Travel Gear……………………………………………….269

Travel Gear House Brake…………………………………….271

Travel, Function………………………………………………273

Anti-Cavitation Circuit………………………………………..277

Adjustments / Checks…………………………………………..279

Section 9 – Hydraulic Tank Tension System……………………………….285

Table of Content………………………………………………….285

Hydraulic Track Tension System………………………………….287

Function………………………………………………….289

Pressure Increasing Valve…………………………………..293

Pressure Relief Valve, Direct Operated……………………….295

Adjustments / Pressure Checks……………………………….297

Section 10 – Hints for the Hydraulic Circuit Diagram……………………..305

Table of Content………………………………………………….305

Hints for Reading Circuit Diagrams………………………………309

Legend of the Hydraulic Circuit Diagram………………………….310

Pressure Check Points………………………………………….314

How to Read the Circuit Diagram…………………………………316

Hydraulic Diagram (1/3)……………………………………………317

Hydraulic Diagram (2/3)……………………………………………318

Hydraulic Diagram (3/3)……………………………………………319

Section 11 – Hints for the Electric Circuit Diagram………………………321

Table of Content………………………………………………….321

Markings of Electrical Components in Circuit Diagrams……………..323

Symbols………………………………………………………325

KGM Circuit Diagrams…………………………………………..329

General Information………………………………………..329

Explanation of the Drawing Concept…………………………..331

Terminal Plans…………………………………………….333

Location of Main Terminal Boxes and Important Components……….335

Reading a Circuit Diagram…………………………………..337

Adjustments…………………………………………………..341

Component List / Function………………………………………342

Electrical Diagrams……………………………………………….348

Electrical Diagrams – 897 818 40 (1/49)………………………….348

Electrical Diagrams – 897 818 40 (2/49)………………………….349

Electrical Diagrams – 897 818 40 (3/49)………………………….350

Electrical Diagrams – 897 818 40 (4/49)………………………….351

Electrical Diagrams – 897 818 40 (5/49)………………………….352

Electrical Diagrams – 897 818 40 (6/49)………………………….353

Electrical Diagrams – 897 818 40 (7/49)………………………….354

Electrical Diagrams – 897 818 40 (8/49)………………………….355

Electrical Diagrams – 897 818 40 (9/49)………………………….356

Electrical Diagrams – 897 818 40 (10/49)…………………………357

Electrical Diagrams – 897 818 40 (11/49)…………………………358

Electrical Diagrams – 897 818 40 (12/49)…………………………359

Electrical Diagrams – 897 818 40 (13/49)…………………………360

Electrical Diagrams – 897 818 40 (14/49)…………………………361

Electrical Diagrams – 897 818 40 (15/49)…………………………362

Electrical Diagrams – 897 818 40 (16/49)…………………………363

Electrical Diagrams – 897 818 40 (17/49)…………………………364

Electrical Diagrams – 897 818 40 (18/49)…………………………365

Electrical Diagrams – 897 818 40 (19/49)…………………………366

Electrical Diagrams – 897 818 40 (20/49)…………………………367

Electrical Diagrams – 897 818 40 (21/49)…………………………368

Electrical Diagrams – 897 818 40 (22/49)…………………………369

Electrical Diagrams – 897 818 40 (23/49)…………………………370

Electrical Diagrams – 897 818 40 (24/49)…………………………371

Electrical Diagrams – 897 818 40 (25/49)…………………………372

Electrical Diagrams – 897 818 40 (26/49)…………………………373

Electrical Diagrams – 897 818 40 (27/49)…………………………374

Electrical Diagrams – 897 818 40 (28/49)…………………………375

Electrical Diagrams – 897 818 40 (29/49)…………………………376

Electrical Diagrams – 897 818 40 (30/49)…………………………377

Electrical Diagrams – 897 818 40 (31/49)…………………………378

Electrical Diagrams – 897 818 40 (32/49)…………………………379

Electrical Diagrams – 897 818 40 (33/49)…………………………380

Electrical Diagrams – 897 818 40 (34/49)…………………………381

Electrical Diagrams – 897 818 40 (35/49)…………………………382

Electrical Diagrams – 897 818 40 (36/49)…………………………383

Electrical Diagrams – 897 818 40 (37/49)…………………………384

Electrical Diagrams – 897 818 40 (38/49)…………………………385

Electrical Diagrams – 897 818 40 (39/49)…………………………386

Electrical Diagrams – 897 818 40 (40/49)…………………………387

Electrical Diagrams – 897 818 40 (41/49)…………………………388

Electrical Diagrams – 897 818 40 (42/49)…………………………389

Electrical Diagrams – 897 818 40 (43/49)…………………………390

Electrical Diagrams – 897 818 40 (44/49)…………………………391

Electrical Diagrams – 897 818 40 (45/49)…………………………392

Electrical Diagrams – 897 818 40 (46/49)…………………………393

Electrical Diagrams – 897 818 40 (47/49)…………………………394

Electrical Diagrams – 897 818 40 (48/49)…………………………395

Electrical Diagrams – 897 818 40 (49/49)…………………………396

Section 12 – Electronic Text Monitoring System…………………………..398

Table of Content………………………………………………….398

Introduction………………………………………………….399

Function……………………………………………………..402

Lay Out of Dash Board………………………………………….408

Text Monitoring System…………………………………………416

Frequency / Voltage Converter (EFD-Module)……………………….476