$35

Komatsu PC3000-1E Hydraulic Mining Shovel Operation & Maintenance Manual SN 06251 - PDF DOWNLOAD

Komatsu PC3000-1E Hydraulic Mining Shovel Operation & Maintenance Manual SN 06251 - PDF DOWNLOAD

DESCRIPTION:

Komatsu PC3000-1E Hydraulic Mining Shovel Operation & Maintenance Manual SN 06251 - PDF DOWNLOAD

DIVISION OF THE BINDER:

Part 1:

Operation Manual

Part 2:

Lubrication- and Maintenance Manual

Part 3:

Depending on the volume of Part 3 a second Binder "Volume 2" is being delivered with the Shovel. This Binder contains the General Assembly Procedure Manual for the Shovel, Specification Booklet, Service Literature for the Power Unit (Diesel Engine or Electric Motor) and for Special Equipment. The Electrical- and Hydraulic Diagrams are attached in the pocket of the front cover.

DESIGNATED USE OF THE SHOVEL:

- This machine has been manufactured in accordance with advanced and up-to-date technology standards including recognized safety rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause damage to the machine and to other material property.

- The machine must only be used in technically perfect condition in accordance with its designated use and the instructions set out in the operation manual. Only trained safety-conscious operators who are fully aware of the risks involved should operate the machine. Any functional disorders, especially those affecting the safety of the machine, should, therefore, be rectified immediately.

- The hydraulic Shovel is designed exclusively for excavating, i.e. excavation of bulk material and natural soil structure (e.g. earth, clay, sand and stones ashore and off-shore). Observe local and national safety regulations. Special conditions at the worksite require additional safe working precautions, follow your company's safety instructions. Short traveling distances for changing the working site are considered as part of the designated use of the Shovel.

- Using the Shovel for purposes other than those mentioned above (such as object handling and use as a transport vehicle) is considered contrary to its designated use. The manufacturer/supplier cannot be held liable for any damage resulting from such use. The risk of such misuse lies entirely with the user.

TABLE OF CONTENTS:

Komatsu PC3000-1E Hydraulic Mining Shovel Operation & Maintenance Manual SN 06251 - PDF DOWNLOAD

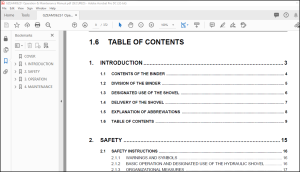

1 INTRODUCTION 3

1 1CONTENTS OF THE BINDER 4

1 2DIVISION OF THE BINDER 5

1 3DESIGNATED USE OF THE SHOVEL 6

1 4DELIVERY OF THE SHOVEL 7

1 5EXPLANATION OF ABBREVIATIONS 8

1 6TABLE OF CONTENTS 9

2 SAFETY 15

2 1SAFETY INSTRUCTIONS 16

2 1 1WARNINGS AND SYMBOLS 16

2 1 2BASIC OPERATION AND DESIGNATED USE OF THE HYDRAULIC SHOVEL 16

2 1 3ORGANIZATIONAL MEASURES 17

2 1 4SELECTION AND QUALIFICATION OF PERSONNEL - BASIC RESPONSIBILITIES 19

2 1 5SAFETY INSTRUCTIONS GOVERNING SPECIFIC OPERATIONAL PHASES 20

2 1 6WARNING OF SPECIAL DANGERS 23

2 1 7TRANSPORTING AND TOWING -RECOMMISSIONING 25

2 1 8SPECIAL SAFETY EQUIPMENT 25

2 1 9SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD) 29

3 OPERATION 37

3 1FOREWORD 38

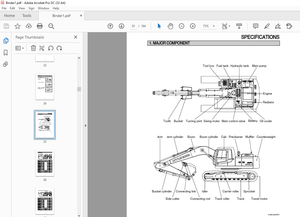

3 2CONSTRUCTION OF THE SHOVEL 39

3 2 1OVERALL VIEW 39

3 2 2UNDERCARRIAGE AND SUPERSTRUCTURE 42

3 2 3HYDRAULICALLY OPERATED ACCESS LADDER 48

3 2 4EMERGENCY ESCAPE LADDER 52

3 2 5EMERGENCY ESCAPE LADDER AND ESCAPE HATCH IN THE MACHINERY HOUSE (SPECIAL EQUIPMENT) 54

3 2 6EMERGENCY MOTOR SHUTDOWN FROM GROUND MAN OR OPERATOR WARNING SYSTEM 56

3 2 7OPERATOR’S CAB 58

3 3OPERATOR’S CAB - CONTROLS 62

3 3 1CONTROLS WITH BACKHOE ATTACHMENT 62

3 3 2CONTROLS WITH BOTTOM DUMP BUCKET 66

1 6 TABLE OF CONTENTS INTRODUCTION

3 4 ELECTRONIC TEXT MONITORING SYSTEM ETM 72

3 4 1INTRODUCTION 73

3 4 2SYSTEM COMPONENTS 77

3 4 3FUNCTIONS OF THE ETM SYSTEM 79

3 4 4SEVERAL MESSAGE CONDITIONS OCCUR AT THE SAME TIME 97

3 4 5SETTINGS OF THE TEXT DISPLAY UNIT (Z 20919) 99

3 5MACHINERY HOUSE 114

3 6ELECTRICAL SWITCH CABINET 120

3 6 1High Voltage switch cabinet, Illust (Z 25367) 121

3 6 2Medium Voltage Switch Cabinet, illust (Z 25369) 123

3 7CHECKS BEFORE STARTING THE MAIN MOTOR 128

3 8STARTING THE MAIN DRIVE MOTOR 132

3 9STOPPING THE MAIN DRIVE MOTORS 140

3 10MOVING THE EXCAVATOR 144

3 10 1Travel Control With Foot Pedals 145

3 10 2TRAVELLING INSTRUCTIONS 149

3 11SLEWING AND BRAKING THE SUPERSTRUCTURE 150

3 11 1SLEWING THE SUPERSTRUCTURE 151

3 12WORKING WITH THE ATTACHMENT 154

3 12 1MACHINES EQUIPPED WITH”EURO” CONTROL SYSTEM 154

3 12 2MACHINES EQUIPPED WITH”KMG” CONTROL SYSTEM 155

3 12 3BOTTOM DUMP BUCKET 156

3 12 4DROP BALL OPERATION 157

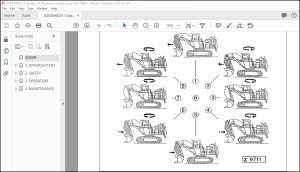

3 12 5COMBINED OPERATION CYCLES 160

3 13WORKING INSTRUCTIONS 162

3 13 1STABILITY OF THE SHOVEL 162

3 13 2SHOVEL OPERATION 162

3 14PARKING THE SHOVEL 165

3 15OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING 166

3 15 1Air conditioning (special equipment, illust ( Z 20423) 169

3 16OPERATION OF THE LUBRICATION SYSTEM 170

3 17FIRE DETECTION AND SUPPRESSION SYSTEM 178

3 18CENTRAL REFILLING SYSTEM 186

3 18 1Refilling system for hydraulic oil reservoir, grease barrels of the central lubrication system and slew ring gear lubrication system 187

3 18 2Refilling procedure 189

3 18 3Refilling the grease containers of the automatic lubrication system 191

INTRODUCTION 1 6 TABLE OF CONTENTS

11

3 19 WORK ON THE LOADER ATTACHMENT 192

3 20TRANSPORTATION AND LIFTING OF THE

SHOVEL 193

3 20 1DISASSEMBLING OF THE SHOVEL 193

3 20 2TRANSPORTATION AND LIFTING 193

3 21RETRIEVAL PROCEDURE 194

3 22SHOVEL STORAGE 195

3 22 1PREPARING FOR STORAGE 195

3 22 2ONE MONTH REPETITIVE SERVICE PERIOD 195

3 22 3SIX MONTH REPETITIVE SERVICE PERIOD 196

3 22 4PREPARING FOR OPERATION 196

3 23TROUBLE SHOOTING 197

3 23 1MAIN DRIVE ELECTRIC MOTOR 197

3 23 2HYDRAULIC SYSTEM 198

3 23 3FINAL DRIVES AND SWING GEAR 199

3 23 4CRAWLER TRACKS 199

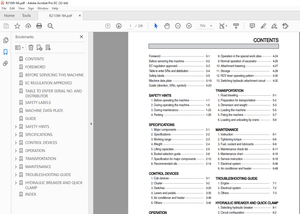

4 MAINTENANCE 201

4 1FOREWORD 202

4 2PRECAUTIONS FOR MAINTENANCE 203

4 3FLUIDS AND LUBRICANTS 205

4 3 1LUBRICANTS FOR OPERATION IN COLD AND ARCTIC CLIMATES 205

4 3 2FLUIDS AND LUBRICANTS FOR MODERATE AND HOT CLIMATES 206

4 3 3MAIN DRIVE ELECTRIC MOTORS – BEARING LUBRICATION 207

4 4FILLING CAPACITIES 210

4 5STANDARD TORQUE LIST 211

4 6LUBRICATION AND MAINTENANCE SCHEDULE 212

4 6 1INITIAL SERVICING 212

4 6 2PERIODIC SERVICING INTERVALS 212

4 6 3PERIODIC SERVICING SCHEDULE 213

4 6 4MAINTENANCE OF THE MAIN DRIVE MOTORS 216

4 6 5REPLACEMENT OF HYDRAULIC HOSE LINES 218

4 6 6PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS 219

4 7WHEN NECESSARY 222

4 7 1SWING CIRCLE TOOTHING LUBRICATION 223

4 7 2AUTOMATIC LUBRICATION SYSTEMS FILL GREASE CONTAINERS 225

4 7 3TRACK ROLLERS AND GUIDE WHEELS - REPLACE FLOATING SEALS 229

1 6 TABLE OF CONTENTS INTRODUCTION

4 8 EVERY 10 OPERATING HOURS OR DAILY 230

4 8 1WALK - AROUND INSPECTION 231

4 8 2Cleaning the track group, illust (Z 9550) 241

4 9EVERY 50 OPERATING HOURS OR WEEKLY 242

4 9 1SWING GEAR AND MOTOR ADAPTER HOUSING - CHECK OIL LEVEL 243

4 9 2TRAVEL GEARS, BRAKE HOUSINGS AND MOTOR ADAPTER HOUSINGS - CHECK OIL LEVELS 245

4 9 3PTO (PUMP DISTRIBUTOR GEAR) - CHECK OIL LEVEL 249

4 9 4Hydraulic Oil Cooler, illust (20009)

Inspect and clean if necessary: 253

4 9 5HYDRAULIC ACCESS LADDER - CHECK SAFETY SENSOR 255

4 10EVERY 250 OPERATING HOURS OR MONTHLY 256

4 10 1SIGNAL HORN COMPRESSOR - LUBRICATE 257

4 10 2HYDRAULIC OIL COOLER FAN BEARINGS - CHECK FOR LEAKAGE AND CLEAN BREATHER FILTER 257

4 10 3AUTOMATIC LUBRICATION SYSTEMS - CLEAN IN-LINE GREASE FILTER AND CHECK BREATHER FILTER 259

4 10 4CAB AIR CLEANER - CLEAN OR REPLACE FILTER ELEMENT 263

4 10 5WINDSHIELD WASHER RESERVOIR - CHECK FLUID LEVEL 265

4 10 6AIR CONDITIONING FOR OPERATOR’S CAB - CHECK REFRIGERANT LEVEL 265

4 11EVERY 500 OPERATING HOURS OR MONTHLY 266

4 11 1BATTERIES - CHECK FLUID LEVEL 267

4 11 2CRAWLER TRACK - INSPECTION 269

4 12EVERY 1000 OPERATING HOURS OR EVERY 6 MONTH 274

4 12 1HIGH STRENGTH BOLT CONNECTIONS - CHECK TORQUE LOAD 275

4 12 2HYDRAULIC SYSTEM - FILTER SERVICE 305

4 12 3Pump Distributor Gears, Slew Gears and Travel Gears 319

4 12 4SIGNAL HORN COMPRESSOR - CLEAN AND LUBRICATE 321

4 12 5HYDRAULIC TRACK TENSIONING SYSTEM - CHECK PRESSURE ACCUMULATORS 323

4 12 6HYDRAULIC OIL COOLER - INSPECT AND LUBRICATE DOOR HINGES 325

4 12 7MACHINERY HOUSE DOORS - INSPECT AND LUBRICATE DOOR HINGES 325

4 13EVERY 2000 OPERATING HOURS OR YEARLY 326

4 13 1HYDRAULIC SYSTEM - CHANGE OIL, REPLACE SUCTION STRAINERS AND PULSATION DAMPER 327

4 13 2EMERGENCY ESCAPE LADDER - INSPECTION 335

4 14EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR 336

4 14 1SWING GEAR AND MOTOR ADAPTER HOUSING - CHANGE OIL 337

4 14 2TRAVEL GEARS, BRAKE AND MOTOR ADAPTER HOUSINGS - CHANGE OIL 345

4 14 3PTO (PUMP DISTRIBUTOR GEAR) - CHANGE OIL 349

4 15FIRE PREVENTION 354

4 16WELD REPAIRS 356

4 16 1PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE

INTRODUCTION 1 6 TABLE OF CONTENTS

UNDERCARRIAGE 359

4 16 2PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE LOADER ATTACHMENT 361

4 16 3PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE SUPERSTRUCTURE 363

4 16 4AFTER FINISHING THE WELD REPAIRS ON THE SUPERSTRUCTURE 365

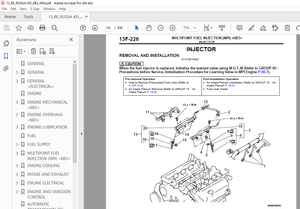

IMAGES PREVIEW OF THE MANUAL: