$38

Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 – PDF DOWNLOAD

Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 – PDF DOWNLOAD

Language : English

Pages : 493

Downloadable : Yes

File Type : PDF

Size: 51.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 – PDF DOWNLOAD

SERIAL NUMBERS PC3000-6 6224

The Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 is a comprehensive guide that provides detailed information on the maintenance and repair of the Komatsu PC3000-6 Hydraulic Mining Shovel. This manual is designed to be used by maintenance personnel who are responsible for the safe and efficient maintenance and repair of the machine.

- The manual is divided into several sections, each providing valuable information on specific aspects of the machine’s maintenance and repair. The first section provides an overview of the machine’s features and specifications, including its engine, hydraulic system, electrical system, and structural components. This section also includes information on the machine’s safety features and important safety guidelines for maintenance and repair personnel.

- The second section of the manual provides detailed information on the disassembly and assembly of the machine. This includes instructions for disassembling and assembling the machine’s various components and systems, including the engine, hydraulic system, electrical system, and structural components. This section also includes information on how to align and adjust the various components and systems to ensure proper operation and performance.

- The third section of the manual provides information on the testing and adjustment of the machine’s components and systems. This includes procedures for testing and adjusting the engine, hydraulic system, electrical system, and other components of the machine to ensure proper operation and performance.

- The fourth section of the manual provides information on troubleshooting and repairing the machine. This includes procedures for diagnosing and repairing common problems, as well as information on how to replace worn or damaged parts. This section also includes information on how to perform welding and other fabrication work on the machine’s structural components.

- The manual also includes several appendices that provide additional information on topics such as specifications and dimensions, hydraulic system diagrams, and electrical system diagrams. These appendices can be especially useful for maintenance personnel who are responsible for maintaining and repairing the machine.

- Overall, the Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 is an essential resource for anyone involved in the maintenance and repair of this machine. Its detailed information and step-by-step procedures can help ensure the safe and efficient maintenance and repair of the machine, and its troubleshooting procedures can help minimize downtime and increase productivity.

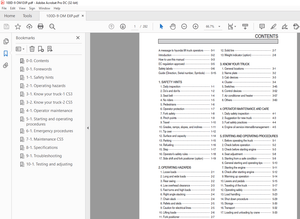

TABLE OF CONTENTS:

Komatsu PC3000-6 Hydraulic Mining Shovel Shop Manual SMPC30006224 – PDF DOWNLOAD

MAIN MENU………………………………………………………………………………….. 0

COVER……………………………………………………………………………………… 1

I. INTRODUCTION…………………………………………………………………………….. 3

I.I CONTENTS OF BINDER…………………………………………………………………… 4

I.II FOREWARD…………………………………………………………………………… 5

I.III EXPLANATION OF ABBREVATIONS…………………………………………………………. 7

I.IV TABLE OF CONTENTS…………………………………………………………………… 8

II. SAFETY…………………………………………………………………………………. 15

II.I SAFETY INSTRUCTIONS…………………………………………………………………. 16

II.II GENERAL PRECAUTIONS………………………………………………………………… 17

II.III PREPARATIONS FOR WORK……………………………………………………………… 18

II.IV PRECAUTIONS DURING WORK…………………………………………………………….. 19

III. SPECIFICATIONS…………………………………………………………………………. 21

III.I LIFTING GEARS……………………………………………………………………… 22

III.II STANDARD TIGHTENING TORQUE CHART……………………………………………………. 24

III.III CONVERSION TABLE…………………………………………………………………. 25

III.IV EXPLANATION OF ABBREVATIONS………………………………………………………… 31

III.V GENERAL SPECIFICATIONS……………………………………………………………… 32

1. MAIN ASSEMBLY GROUPS……………………………………………………………………… 33

1.1 General layout………………………………………………………………………. 34

1.2 Superstructure………………………………………………………………………. 36

1.3 Power House…………………………………………………………………………. 38

1.4 Hydraulic Oil Reservoir………………………………………………………………. 40

1.5 Hydraulic Oil Cooler…………………………………………………………………. 42

1.6 Fuel tank (Fuel reservoir)……………………………………………………………. 44

1.7 Counter weight………………………………………………………………………. 46

1.8 Cab support…………………………………………………………………………. 48

1.9 Operators cab……………………………………………………………………….. 50

1.10 Control blocks……………………………………………………………………… 52

1.11 Swing gears………………………………………………………………………… 54

1.12 Under carriage……………………………………………………………………… 56

2. DRIVE…………………………………………………………………………………… 59

2.1 Prime drive assembly…………………………………………………………………. 60

2.2 Engine and gearbox mount……………………………………………………………… 62

2.3 Torque supports……………………………………………………………………… 65

2.4 Radiator fan Drive Assy………………………………………………………………. 66

2.5 Pump distributor gearbox (PTO)………………………………………………………… 68

2.5.1 Spline shaft housing……………………………………………………………. 70

2.5.2 PTO lubrication and cooling……………………………………………………… 72

2.5.3 PTO valve adjustments…………………………………………………………… 74

2.6 Coupling……………………………………………………………………………. 78

2.7 Air Filter………………………………………………………………………….. 80

3. HYDRAULIC OIL RESERVOIR…………………………………………………………………… 83

3.1 Hydraulic oil reservoir………………………………………………………………. 84

3.2 Return and leak oil filter……………………………………………………………. 88

3.3 Breather Filter……………………………………………………………………… 92

3.4 Location of electrical components……………………………………………………… 94

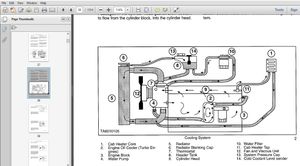

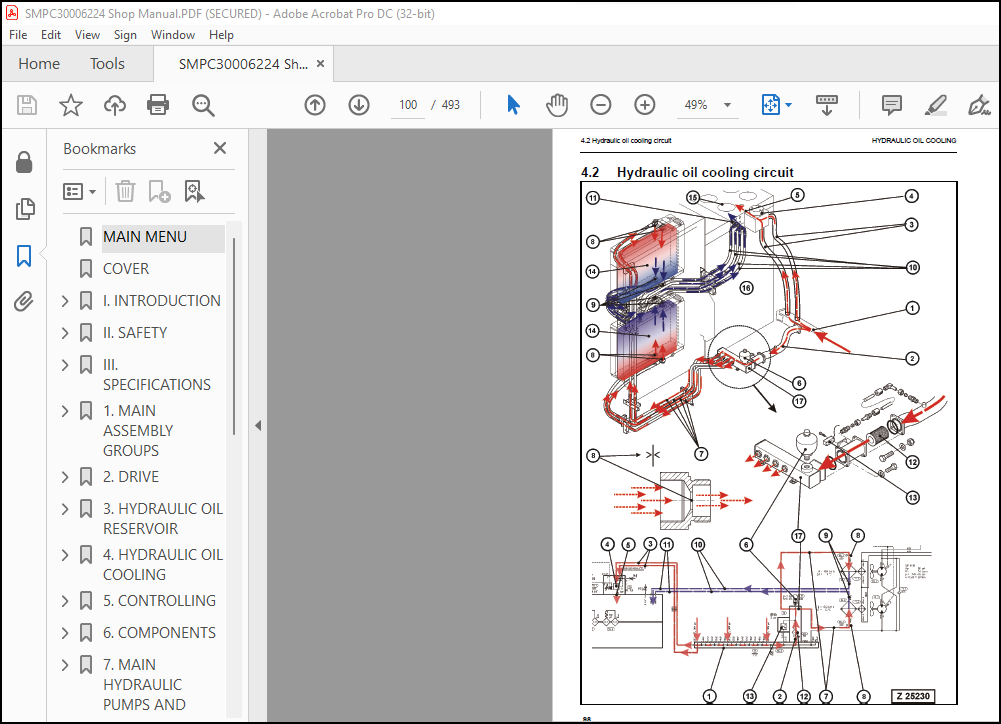

4. HYDRAULIC OIL COOLING…………………………………………………………………….. 97

4.1 General…………………………………………………………………………….. 98

4.2 Hydraulic oil cooling circuit………………………………………………………….100

4.3 Back pressure valve adjustment…………………………………………………………104

4.4 Fan drive……………………………………………………………………………106

4.4.1 Fan pump……………………………………………………………………….108

4.4.2 Pressure relieve valve…………………………………………………………..109

4.4.3 Temperature relay……………………………………………………………….111

4.5 Cooler fan drive adjustment……………………………………………………………112

5. CONTROLLING………………………………………………………………………………115

5.1 Pilot pressure supply and adjustment……………………………………………………116

5.1.1 Pilot control arrangement………………………………………………………..119

5.1.2 Pilot pressure adjustment………………………………………………………..121

5.1.3 Check of Control Pressure………………………………………………………..123

5.2 Slew brakes………………………………………………………………………….125

5.3 Travel parking brake………………………………………………………………….128

5.4 Check of the pilot control logic……………………………………………………….130

5.4.1 Check sheet BHA Page 1…………………………………………………………..132

5.4.2 Check sheet FSA Page 1…………………………………………………………..145

6. COMPONENTS……………………………………………………………………………….155

6.1 Main control block and valve arrangement………………………………………………..156

6.1.1 FSA arrangement…………………………………………………………………158

6.1.2 BHA arrangement…………………………………………………………………162

6.2 Distributor manifold………………………………………………………………….166

6.2.1 Front shovel attachment FSA………………………………………………………166

6.2.2 Back hoe attachment BHA………………………………………………………….168

6.2.3 SRV with throttle check valve…………………………………………………….170

6.2.4 Anti cavitation valve (check valve)……………………………………………….172

6.3 Main control block……………………………………………………………………174

6.3.1 Load holding valve………………………………………………………………182

6.3.2 High pressure filter auxiliary filter……………………………………………..184

6.3.3 High pressure filter auxiliary filter……………………………………………..186

6.3.4 High pressure filter auxiliary filter……………………………………………..188

6.4 Compact valve blocks………………………………………………………………….190

6.5 Compact valve blocks………………………………………………………………….192

6.6 Auxiliary gear pumps………………………………………………………………….194

6.7 Hydraulic cylinder……………………………………………………………………196

6.8 Swing ring…………………………………………………………………………..198

7. MAIN HYDRAULIC PUMPS AND PUMP REGULATION…………………………………………………….201

7.1 General……………………………………………………………………………..202

7.1.1 Pump location…………………………………………………………………..204

7.2 Main pump operating principles…………………………………………………………206

7.2.1 Main pump function………………………………………………………………211

7.3 Main pump checks and adjustments……………………………………………………….214

7.3.1 Peak point diesel engine test…………………………………………………….214

7.3.2 Pressure transducer test…………………………………………………………216

7.3.3 Cut off function………………………………………………………………..217

7.3.4 Pump regulation…………………………………………………………………219

7.3.5 Swing pump volume reduction………………………………………………………220

7.4 Electronic pump regulation…………………………………………………………….221

7.4.1 Pump Controller CR700……………………………………………………………223

7.4.2 Multi Monitor…………………………………………………………………..225

7.4.3 Multimonitor software instruction…………………………………………………227

7.4.4 Table of fault messages and adjustments……………………………………………234

7.5 Trouble shooting pump and pump regulation……………………………………………….243

8. OPERATING HYDRAULIC……………………………………………………………………….247

8.1 General layout……………………………………………………………………….248

8.2 Floating function of boom and stick only FSA…………………………………………….252

8.3 Check and Adjustments for MRV’s and SRV’s……………………………………………….254

8.3.1 Check and Adjustments for MRV…………………………………………………….256

8.3.2 Check and Adjustment for SRV’s……………………………………………………258

8.3.3 Check and adjustment of the throttle check valves…………………………………..266

8.4 Hydraulic for the swing circuit………………………………………………………..268

8.4.1 Hydraulic for the swing circuit…………………………………………………..272

8.4.2 Slew gear box L & S……………………………………………………………..276

8.4.3 Slew parking brake………………………………………………………………280

8.4.4 Slew service brake valve…………………………………………………………284

8.4.5 Checks and adjustment of the slew pressure valve……………………………………289

8.5 Travel circuit……………………………………………………………………….292

8.5.1 Rotary joint……………………………………………………………………294

8.5.2 Travel motor A2FMt………………………………………………………………296

8.5.3 Travel gear…………………………………………………………………….298

8.5.4 Travel parking brake…………………………………………………………….300

8.5.5 Travel control function………………………………………………………….302

9. TRACK TENSION SYSTEM………………………………………………………………………307

9.1 General layout……………………………………………………………………….308

9.2 Track tensioning function……………………………………………………………..310

9.2.1 Cushioning……………………………………………………………………..312

9.2.2 Pressure Increasing valve PIV…………………………………………………….314

9.3 Truck tensioning adjustment……………………………………………………………318

9.3.1 Truck tensioning function check…………………………………………………..320

10. ACCESS LADDER HYDRAULICALLY OPERATED……………………………………………………….323

10.1 Access ladder……………………………………………………………………….324

10.2 Access ladder functional description…………………………………………………..326

11. CENTRAL REFILLING SYSTEM………………………………………………………………….331

11.0.1 Functional description……………………………………………………………..332

12. HINTS FOR READING THE HYDRAULIC CIRCUIT DIAGRAM……………………………………………..337

12.1 General…………………………………………………………………………….338

12.2 Symbolic……………………………………………………………………………340

12.2.1 Lines, unions………………………………………………………………….341

12.2.2 Components, valves……………………………………………………………..343

12.2.3 Sensors……………………………………………………………………….343

12.2.4 Valves, valve components………………………………………………………..344

12.2.5 Pump, motor, cylinder…………………………………………………………..348

Hydraulic Diagrams – 938 367 40……………………………………………………………352

Hydraulic Diagrams – 938 367 40 (1/3)…………………………………………………..352

Hydraulic Diagrams – 938 367 40 (2/3)…………………………………………………..353

Hydraulic Diagrams – 938 367 40 (3/3)…………………………………………………..354

13. HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM………………………………………………356

13.1 Designation of electrical components…………………………………………………..358

13.2 Electric symbols…………………………………………………………………….359

13.3 Symbols…………………………………………………………………………….361

13.3.1 Drawing concept………………………………………………………………..363

13.3.2 Reading of the circuit diagram…………………………………………………..369

Electrical Diagrams………………………………………………………………………373

Electrical Diagrams – 938 368 40 (1/54)…………………………………………………373

Electrical Diagrams – 938 368 40 (2/54)…………………………………………………374

Electrical Diagrams – 938 368 40 (3/54)…………………………………………………375

Electrical Diagrams – 938 368 40 (4/54)…………………………………………………376

Electrical Diagrams – 938 368 40 (5/54)…………………………………………………377

Electrical Diagrams – 938 368 40 (6/54)…………………………………………………378

Electrical Diagrams – 938 368 40 (7/54)…………………………………………………379

Electrical Diagrams – 938 368 40 (8/54)…………………………………………………380

Electrical Diagrams – 938 368 40 (9/54)…………………………………………………381

Electrical Diagrams – 938 368 40 (10/54)………………………………………………..382

Electrical Diagrams – 938 368 40 (11/54)………………………………………………..383

Electrical Diagrams – 938 368 40 (12/54)………………………………………………..384

Electrical Diagrams – 938 368 40 (13/54)………………………………………………..385

Electrical Diagrams – 938 368 40 (14/54)………………………………………………..386

Electrical Diagrams – 938 368 40 (15/54)………………………………………………..387

Electrical Diagrams – 938 368 40 (16/54)………………………………………………..388

Electrical Diagrams – 938 368 40 (17/54)………………………………………………..389

Electrical Diagrams – 938 368 40 (18/54)………………………………………………..390

Electrical Diagrams – 938 368 40 (19/54)………………………………………………..391

Electrical Diagrams – 938 368 40 (20/54)………………………………………………..392

Electrical Diagrams – 938 368 40 (21/54)………………………………………………..393

Electrical Diagrams – 938 368 40 (22/54)………………………………………………..394

Electrical Diagrams – 938 368 40 (23/54)………………………………………………..395

Electrical Diagrams – 938 368 40 (24/54)………………………………………………..396

Electrical Diagrams – 938 368 40 (25/54)………………………………………………..397

Electrical Diagrams – 938 368 40 (26/54)………………………………………………..398

Electrical Diagrams – 938 368 40 (27/54)………………………………………………..399

Electrical Diagrams – 938 368 40 (28/54)………………………………………………..400

Electrical Diagrams – 938 368 40 (29/54)………………………………………………..401

Electrical Diagrams – 938 368 40 (30/54)………………………………………………..402

Electrical Diagrams – 938 368 40 (31/54)………………………………………………..403

Electrical Diagrams – 938 368 40 (32/54)………………………………………………..404

Electrical Diagrams – 938 368 40 (33/54)………………………………………………..405

Electrical Diagrams – 938 368 40 (34/54)………………………………………………..406

Electrical Diagrams – 938 368 40 (35/54)………………………………………………..407

Electrical Diagrams – 938 368 40 (36/54)………………………………………………..408

Electrical Diagrams – 938 368 40 (37/54)………………………………………………..409

Electrical Diagrams – 938 368 40 (38/54)………………………………………………..410

Electrical Diagrams – 938 368 40 (39/54)………………………………………………..411

Electrical Diagrams – 938 368 40 (40/54)………………………………………………..412

Electrical Diagrams – 938 368 40 (41/54)………………………………………………..413

Electrical Diagrams – 938 368 40 (42/54)………………………………………………..414

Electrical Diagrams – 938 368 40 (43/54)………………………………………………..415

Electrical Diagrams – 938 368 40 (44/54)………………………………………………..416

Electrical Diagrams – 938 368 40 (45/54)………………………………………………..417

Electrical Diagrams – 938 368 40 (46/54)………………………………………………..418

Electrical Diagrams – 938 368 40 (47/54)………………………………………………..419

Electrical Diagrams – 938 368 40 (48/54)………………………………………………..420

Electrical Diagrams – 938 368 40 (49/54)………………………………………………..421

Electrical Diagrams – 938 368 40 (50/54)………………………………………………..422

Electrical Diagrams – 938 368 40 (51/54)………………………………………………..423

Electrical Diagrams – 938 368 40 (52/54)………………………………………………..424

Electrical Diagrams – 938 368 40 (53/54)………………………………………………..425

Electrical Diagrams – 938 368 40 (54/54)………………………………………………..426

14. ELECTRONIC TEXT MONITORING SYSTEM ETM………………………………………………………428

14.1 General Function…………………………………………………………………….429

15. AUTOMATIC LUBRICATION SYSTEM………………………………………………………………432

15.1 General Function…………………………………………………………………….433

15.2 Function of a lubrication cycle……………………………………………………….435

15.3 Lubrication pump drive……………………………………………………………….443

15.4 Lubrication pump…………………………………………………………………….445

15.4.1 Adjustments lubricating pump speed……………………………………………….447

15.4.2 Adjustments lubricating pump pressure…………………………………………….449

15.5 Lubricant Injector (metering valve)……………………………………………………451

15.5.1 Connection of one or more injectors………………………………………………453

15.5.2 Function lubrication injector (metering valve)…………………………………….455

15.6 End line pressure switch……………………………………………………………..459

15.7 Lubricant in line filter……………………………………………………………..461

15.8 Lubricant level sensor……………………………………………………………….463

15.8.1 Capacitive digital type for machines with ETM……………………………………..463

15.8.2 Capacitive analog type for machines with PLC………………………………………465

15.9 Lubrication system function and controlling…………………………………………….468

15.9.1 Central Lubrication System (CLS) function and controlling with ETM system (PC 3000)……469

15.9.2 Swing ring lubrication system (SLS) function and controlling with ETM system (PC3000)….473

15.10 Adjustment of the lubrication system with ETM………………………………………….479

15.11 Trouble shooting lubricating system…………………………………………………..481

15.11.1 Lubrication pump cylinder does not move………………………………………….482

15.11.2 Lubricant pressure built up very slowly or not at all……………………………..484

15.11.3 Insufficient lubricant supply to one or more attachment bearings……………………484

15.11.4 Insufficient lubricant at the swing ring gear…………………………………….486