$36

Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:\

Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 496

Downloadable : Yes

File Type : PDF

Size: 21.4 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

SERIAL NUMBER 06320

The Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual is a comprehensive guide that provides detailed information on the operation and maintenance of the Komatsu PC3000E-6 Hydraulic Mining Shovel. This manual is designed to be used by operators and maintenance personnel who are responsible for the safe and efficient operation of the machine.

- The manual is divided into several sections, each providing valuable information on specific aspects of the machine’s operation and maintenance. The first section provides an overview of the machine’s features and specifications, including its engine, hydraulic system, electrical system, and structural components. This section also includes information on the machine’s safety features and important safety guidelines for operating and maintaining the machine.

- The second section of the manual provides detailed information on the operation of the machine. This includes instructions for starting, operating, and shutting down the machine, as well as guidelines for operating the machine’s various components and systems. This section also includes information on how to use the machine’s monitoring and control systems to ensure proper operation and performance.

- The third section of the manual provides detailed information on the maintenance and servicing of the machine. This includes recommended maintenance schedules, procedures for routine maintenance, and troubleshooting procedures for identifying and fixing common problems. This section also includes information on how to service the machine’s engine, hydraulic system, and electrical system, as well as how to perform inspections and replace worn or damaged parts.

- The fourth section of the manual provides information on testing and adjusting the machine’s components and systems. This includes procedures for testing and adjusting the engine, hydraulic system, electrical system, and other components of the machine to ensure proper operation and performance.

- The manual also includes several appendices that provide additional information on topics such as specifications and dimensions, hydraulic system diagrams, and electrical system diagrams. These appendices can be especially useful for maintenance personnel who are responsible for maintaining and repairing the machine.

- Overall, the Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual is an essential resource for anyone involved in the operation and maintenance of this machine. Its detailed information and step-by-step procedures can help ensure the safe and efficient operation of the machine, and its troubleshooting procedures can help minimize downtime and increase productivity.

TABLE OF CONTENTS:

Komatsu PC3000E-6 Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

1 FOREWORD…………………………………………………………………………………………………………………………………… 3

1.1 BEFORE READING THIS MANUAL……………………………………………………………………………………………………………… 4

1.2 EC DECLARATION OF CONFORMITY……………………………………………………………………………………………………………. 5

1.3 DIRECTIONS OF THE MACHINE………………………………………………………………………………………………………………. 6

1.4 SPECIFICATION AND SERIAL PLATE………………………………………………………………………………………………………….. 7

1.4.1 PRODUCT IDENTIFICATION NUMBER……………………………………………………………………………………………………… 7

1.5 DIVISION OF THE BINDER…………………………………………………………………………………………………………………. 8

1.6 DESIGNATED USE OF THE SHOVEL……………………………………………………………………………………………………………. 9

1.7 DELIVERY OF THE SHOVEL…………………………………………………………………………………………………………………. 10

1.7.1 SPARE PARTS……………………………………………………………………………………………………………………… 10

1.7.2 SERVICE…………………………………………………………………………………………………………………………. 10

1.8 EXPLANATION OF ABBREVIATIONS……………………………………………………………………………………………………………. 11

1.9 CONTENTS……………………………………………………………………………………………………………………………… 13

2 SAFETY…………………………………………………………………………………………………………………………………….. 19

2.1 SAFETY INFORMATION…………………………………………………………………………………………………………………….. 20

2.2 OVERVIEW……………………………………………………………………………………………………………………………… 21

2.2.1 NORMAL OPERATIONS………………………………………………………………………………………………………………… 21

2.2.2 REGULAR MAINTENANCE………………………………………………………………………………………………………………. 21

2.2.3 TROUBLESHOOTING, ADJUSTMENTS AND REPAIR…………………………………………………………………………………………….. 21

2.2.4 ADDITIONAL SAFETY PRECAUTIONS……………………………………………………………………………………………………… 21

2.3 SOUND PRESSURE AND VIBRATION LEVELs IN THE OPERATOR’S CAB………………………………………………………………………………….. 22

2.3.1 SOUND…………………………………………………………………………………………………………………………… 22

2.3.2 VIBRATION……………………………………………………………………………………………………………………….. 22

2.4 GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR…………………………………………………………………………………… 23

2.4.1 UNDERSTANDING THE MACHINE…………………………………………………………………………………………………………. 23

2.4.2 PRECAUTIONS BEFORE STARTING OPERATION ON THE EXCAVATOR……………………………………………………………………………….. 23

2.4.2.1 ENSURING SAFE OPERATION……………………………………………………………………………………………………… 23

2.4.3 PREPARATIONS FOR SAFE OPERATION……………………………………………………………………………………………………. 23

2.4.3.1 PRECAUTIONS REGARDING SAFETY RELATED EQUIPMENT…………………………………………………………………………………. 23

2.4.3.2 INSPECTING THE MACHINE………………………………………………………………………………………………………. 23

2.4.3.3 WEAR WELL FITTING CLOTHES AND PROTECTIVE EQUIPMENT……………………………………………………………………………… 24

2.4.3.4 KEEP MACHINE CLEAN………………………………………………………………………………………………………….. 24

2.4.3.5 PRECAUTIONS INSIDE OPERATOR’S COMPARTMENT……………………………………………………………………………………… 24

2.4.3.6 PROVIDE FIRE EXTINGUISHER AND FIRST AID KIT……………………………………………………………………………………. 25

2.4.3.7 IF A PROBLEM IS FOUND……………………………………………………………………………………………………….. 25

2.4.4 FIRE PREVENTION………………………………………………………………………………………………………………….. 25

2.4.4.1 PRECAUTIONS TO PREVENT FIRE………………………………………………………………………………………………….. 25

2.4.4.2 ACTION IF FIRE OCCURS……………………………………………………………………………………………………….. 27

2.4.4.3 EMERGENCY EXIT FROM OPERATOR’S CAB……………………………………………………………………………………………. 27

2.4.5 PRECAUTIONS WHEN GETTING ON OR OFF THE MACHINE………………………………………………………………………………………. 28

2.4.5.1 USE HANDRAILS AND STEPS WHEN GETTING ON OR OFF THE MACHINE………………………………………………………………………. 28

2.4.5.2 NO JUMPING ON OR OFF THE MACHINE……………………………………………………………………………………………… 28

2.4.5.3 NO PEOPLE ON THE ATTACHMENT………………………………………………………………………………………………….. 28

2.4.5.4 WORKING IN HIGH PLACES………………………………………………………………………………………………………. 28

2.4.5.5 LEAVING OPERATOR’S SEAT WITH LOCK…………………………………………………………………………………………….. 29

2.4.5.6 LEAVING THE MACHINE…………………………………………………………………………………………………………. 29

2.4.6 BURN PREVENTION………………………………………………………………………………………………………………….. 29

2.4.6.1 Hot coolant………………………………………………………………………………………………………………… 29

2.4.6.2 Hot oil……………………………………………………………………………………………………………………. 30

2.4.7 PRECAUTIONS WHEN CLEANING CAB GLASS………………………………………………………………………………………………… 30

2.4.8 PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES………………………………………………………………………………………… 30

2.4.8.1 UNAUTHORIZED MODIFICATION……………………………………………………………………………………………………. 31

2.4.8.2 PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS…………………………………………………………………………………. 31

2.4.9 ELECTROMAGNETIC COMPATIBILITY (EMC)………………………………………………………………………………………………… 31

2.4.10 PRECAUTIONS AT JOBSITE…………………………………………………………………………………………………………… 32

2.4.10.1 VISIBILITY FROM OPERATOR’S SEAT……………………………………………………………………………………………… 33

2.4.10.2 CAMERA SYSTEM WITH MONITORS…………………………………………………………………………………………………. 33

2.4.10.3 ENSURE GOOD VISIBILITY……………………………………………………………………………………………………… 33

2.4.10.4 CHECKING SIGNS AND SIGNALMAN’S SIGNALS……………………………………………………………………………………….. 33

2.4.10.5 INVESTIGATE AND CONFIRM JOBSITE CONDITIONS……………………………………………………………………………………. 34

2.4.10.6 DO NOT GO CLOSE TO HIGH VOLTAGE CABLES……………………………………………………………………………………….. 34

2.4.10.7 WORKING ON LOOSE GROUND…………………………………………………………………………………………………….. 35

2.4.10.8 GAS, DUST, STEAM AND SMOKE………………………………………………………………………………………………….. 35

2.4.10.9 VENTILATION OF ENCLOSED AREAS……………………………………………………………………………………………….. 36

2.4.11 STARTING motor………………………………………………………………………………………………………………….. 37

2.4.11.1 WARNING TAG……………………………………………………………………………………………………………….. 37

2.4.11.2 CHECKS BEFORE STARTING motor………………………………………………………………………………………………… 37

2.4.11.3 PRECAUTION WHEN STARTING motor………………………………………………………………………………………………. 37

2.4.11.4 PRECAUTION IN COLD AREAS……………………………………………………………………………………………………. 38

2.4.12 OPERATION………………………………………………………………………………………………………………………. 38

2.4.12.1 CHECKS BEFORE OPERATION…………………………………………………………………………………………………….. 38

2.4.12.2 PRECAUTIONS WHEN TRAVELLING IN FORWARD OR REVERSE……………………………………………………………………………… 39

2.4.12.3 PRECAUTIONS WHEN travelling…………………………………………………………………………………………………. 40

2.4.12.4 TRAVELLING ON SLOPES……………………………………………………………………………………………………….. 41

2.4.12.5 OPERATIONS ON SLOPES……………………………………………………………………………………………………….. 42

2.4.12.6 PROHIBITED OPERATIONS………………………………………………………………………………………………………. 42

2.4.12.7 TRAVELLING ON FROZEN OR SNOW COVERED SURFACES…………………………………………………………………………………. 43

2.4.12.8 PARKING THE MACHINE………………………………………………………………………………………………………… 43

2.4.12.9 TRANSPORTATION…………………………………………………………………………………………………………….. 43

2.5 PRECAUTION FOR MAINTENANCE……………………………………………………………………………………………………………… 44

2.5.1 GENERAL PRECAUTIONS………………………………………………………………………………………………………………. 44

2.5.1.1 SELECTION AND QUALIFICATION OF PERSONNEL – BASIC RESPONSIBILITIES………………………………………………………………… 45

2.5.1.2 STOP motor FOR MAINTENANCE…………………………………………………………………………………………………… 46

2.5.1.3 WARNING TAG………………………………………………………………………………………………………………… 47

2.5.1.4 KEEP WORKPLACE CLEAN AND TIDY………………………………………………………………………………………………… 48

2.5.1.5 APPOINT LEADER WHEN WORKING WITH OTHERS……………………………………………………………………………………….. 48

2.5.1.6 TWO WORKERS FOR MAINTENANCE WHEN THE MACHINE IS RUNNING…………………………………………………………………………. 49

2.5.1.7 INSTALLING, REMOVING OR STORING ATTACHMENTS……………………………………………………………………………………. 49

2.5.1.8 PRECAUTIONS WHEN WORKING UNDER THE MACHINE OR EQUIPMENT…………………………………………………………………………. 50

2.5.1.9 NOISE……………………………………………………………………………………………………………………… 50

2.5.1.10 WHEN USING A HAMMER………………………………………………………………………………………………………… 50

2.5.1.11 PROPER TOOLS………………………………………………………………………………………………………………. 51

2.5.1.12 ACCUMULATOR……………………………………………………………………………………………………………….. 51

2.5.1.13 PERSONNEL…………………………………………………………………………………………………………………. 51

2.5.2 PRECAUTIONS FOR INSPECTION AND MAINTENANCE………………………………………………………………………………………….. 52

2.5.2.1 PRECAUTION WHEN WELDING……………………………………………………………………………………………………… 52

2.5.2.2 BATTERY HANDLING……………………………………………………………………………………………………………. 52

2.5.3 PRECAUTIONS WITH HIGH PRESSURE FLUID……………………………………………………………………………………………….. 53

2.5.3.1 PRECAUTIONS WITH HIGH FUEL PRESSURE…………………………………………………………………………………………… 53

2.5.3.2 HANDLING HIGH PRESSURES HOSES OR PIPES………………………………………………………………………………………… 54

2.5.3.3 REPLACEMENT OF HOSE LINES……………………………………………………………………………………………………. 54

2.5.3.4 INSPECTION OF HOSE LINES…………………………………………………………………………………………………….. 54

2.5.3.5 PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS………………………………………………………………………………….. 55

2.5.3.6 PRECAUTIONS FOR HIGH VOLTAGE…………………………………………………………………………………………………. 55

2.5.3.7 AIR CONDITIONING MAINTENANCE…………………………………………………………………………………………………. 55

2.5.3.8 COMPRESSED AIR……………………………………………………………………………………………………………… 56

2.5.3.9 WASTE MATERIALS…………………………………………………………………………………………………………….. 56

2.6 ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS…………………………………………………………………………… 57

2.6.1 INSPECTION OF THE HYDRAULIC SYSTEM…………………………………………………………………………………………………. 57

2.6.2 TWO WORKERS ONLY WHEN THE MACHINE IS RUNNING DURING ADJUSTMENTS……………………………………………………………………….. 57

2.6.3 AREAS OF POTENTIAL DANGER AROUND THE EXCAVATOR………………………………………………………………………………………. 57

2.7 SPECIAL SAFETY EQUIPMENT……………………………………………………………………………………………………………….. 58

2.7.1 FRONT GUARD PROTECTIVE STRUCTUR ’FOPS’ FOR OPERATOR’S CAB…………………………………………………………………………….. 59

2.7.2 OBJECT HANDLING………………………………………………………………………………………………………………….. 59

2.7.3 LIGHTING………………………………………………………………………………………………………………………… 59

2.7.4 WARNING BEACON…………………………………………………………………………………………………………………… 59

2.7.5 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD)………………………………………………………………………….. 59

2.7.5.1 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD)…………………………………………………………………….. 59

2.7.5.2 INSTRUCTIONS FOR USE………………………………………………………………………………………………………… 61

2.7.5.3 PRIOR TO USING THE HARNESS (1), THE WEARER SHALL……………………………………………………………………………….. 63

2.7.5.4 RECOMMENDATIONS FOR USE OF THE HOLDING HOOKS AND HOLD- BACK HOOKS OF THE SAFETY HARNESS…………………………………………….. 63

2.7.5.5 INSTRUCTIONS FOR USE………………………………………………………………………………………………………… 65

2.8 HIGH VOLTAGE SAFETY INSTRUCTIONS FOR MACHINES WITH ELECTRIC MOTOR…………………………………………………………………………… 67

2.8.1 QUALIFICATION OF PERSONNEL………………………………………………………………………………………………………… 67

2.8.2 ELECTRICAL TOOLS…………………………………………………………………………………………………………………. 67

2.8.3 GENERAL PREPARATION BEFORE WORKING ON ELECTRICAL EQUIPMENT……………………………………………………………………………. 68

2.8.4 CONNECTION OF PILOT LINE (GROUND CHECK WIRE)………………………………………………………………………………………… 68

2.8.5 PREPARATION BEFORE WORKING ON THE CABLE DRUM………………………………………………………………………………………… 68

2.8.6 PREPARATION BEFORE WORKING ON THE CABLE GUIDE……………………………………………………………………………………….. 69

2.8.7 MODIFICATION OF THE ELECTRICAL SYSTEM………………………………………………………………………………………………. 69

2.8.8 FIRE……………………………………………………………………………………………………………………………. 69

2.8.9 GENERAL INSTRUCTIONS……………………………………………………………………………………………………………… 70

2.9 SAFETY WARNING SIGNS…………………………………………………………………………………………………………………… 71

2.9.1 LOCATION AND DESCRIPTION OF THE SIGNS………………………………………………………………………………………………. 72

3 OPERATION………………………………………………………………………………………………………………………………….. 87

3.1 FOREWORD……………………………………………………………………………………………………………………………… 88

3.2 CONSTRUCTION OF THE SHOVEL……………………………………………………………………………………………………………… 89

3.2.1 OVERALL VIEW…………………………………………………………………………………………………………………….. 89

3.2.2 UNDERCARRIAGE AND SUPERSTRUCTURE…………………………………………………………………………………………………… 90

3.2.2.1 SUPERSTRUCTURE – TOP VIEW……………………………………………………………………………………………………. 92

3.2.2.2 Undercarriage………………………………………………………………………………………………………………. 95

3.2.2.3 Attachment…………………………………………………………………………………………………………………. 97

3.2.3 HYDRAULICALLY OPERATED ACCESS LADDER……………………………………………………………………………………………….. 98

3.2.3.1 Operating the hydraulic Access Ladder…………………………………………………………………………………………. 99

3.2.4 EMERGENCY ESCAPE LADDER……………………………………………………………………………………………………………102

3.2.5 EMERGENCY ESCAPE LADDER AND ESCAPE HATCH IN THE MACHINERY HOUSE (SPECIAL EQUIPMENT)………………………………………………………104

3.2.6 motor SHUTDOWN FROM GROUND MAN OR OPERATOR WARNING SYSTEM……………………………………………………………………………..106

3.2.6.1 motor Shutdown System actuated from Ground Man (Special Equipment)………………………………………………………………..107

3.2.6.2 Operator Warning System (Special Equipment)…………………………………………………………………………………….107

3.2.7 OPERATOR’S CAB WITH INTEGRATED FALLING OBJECT PROTECTIVE STRUCTURE (FOPS)……………………………………………………………….108

3.2.7.1 Operator’s Seat Adjustment……………………………………………………………………………………………………113

3.2.7.2 Co-driver’s Seat…………………………………………………………………………………………………………….114

3.2.7.3 INSTRUCTIONS TO using and looking after THE SEAT BELTS…………………………………………………………………………..115

3.3 OPERATOR’S CAB – CONTROLS……………………………………………………………………………………………………………….116

3.3.1 CONTROLS WITH BACKHOE ATTACHMENT……………………………………………………………………………………………………116

3.3.1.1 Hydraulic Control System……………………………………………………………………………………………………..117

3.3.1.2 Safety Circuit for Controls…………………………………………………………………………………………………..117

3.3.1.3 EURO Control Pattern…………………………………………………………………………………………………………119

3.3.2 CONTROLS WITH BOTTOM DUMP BUCKET……………………………………………………………………………………………………120

3.3.2.1 Hydraulic Control System……………………………………………………………………………………………………..121

3.3.2.2 Safety Circuit for Controls…………………………………………………………………………………………………..121

3.3.2.3 Automatic Float Position for Boom and Stick…………………………………………………………………………………….121

3.3.2.4 EURO Control Pattern…………………………………………………………………………………………………………123

3.3.3 OPERATOR’S CONSOLE………………………………………………………………………………………………………………..125

3.3.3.1 Control Panel……………………………………………………………………………………………………………….127

3.3.3.2 Rear Panel Controls………………………………………………………………………………………………………….131

3.4 ELECTRONIC TEXT MONITORING SYSTEM ETM…………………………………………………………………………………………………….132

3.4.1 INTRODUCTION……………………………………………………………………………………………………………………..133

3.4.2 SYSTEM COMPONENTS…………………………………………………………………………………………………………………135

3.4.3 STRUCTURE AND FUNCTIONS OF THE CONTROL MENU………………………………………………………………………………………….139

3.4.4 Fault and Information Message Classification…………………………………………………………………………………………139

3.4.4.1 DISPLAYING THE CONTENTS OF THE RECORD (PROTOCOL) MEMORY………………………………………………………………………….141

3.4.4.2 Display the Contents of Statistics Memory………………………………………………………………………………………143

3.4.4.3 Transfering the data of the Statistics Memory and the Protocol Memory……………………………………………………………..145

3.4.4.4 Downloading the Data…………………………………………………………………………………………………………145

3.4.4.5 Changing the Input Language…………………………………………………………………………………………………..147

3.4.4.6 Settings of the Display Unit………………………………………………………………………………………………….147

3.4.4.7 TABLE OF MESSAGES……………………………………………………………………………………………………………148

3.4.4.8 Explanation of statistics download information………………………………………………………………………………….163

3.4.4.9 Time Diagram of Statistics Print………………………………………………………………………………………………163

3.5 CAMERA SYSTEM WITH MONITORs (SPECIAL EQUIPMENT)……………………………………………………………………………………………166

3.5.1 LOCATION OF MONITOR AND CONTROL UNIT………………………………………………………………………………………………..167

3.5.1.1 Operating the Monitors……………………………………………………………………………………………………….169

3.5.1.2 Typical Arrangement of the Cameras…………………………………………………………………………………………….171

3.6 OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING……………………………………………………………………………………..172

3.6.1 Digital Display…………………………………………………………………………………………………………………..172

3.7 MACHINERY HOUSE………………………………………………………………………………………………………………………..176

3.7.1 EMERGENCY motor SHUTDOWN SWITCHES…………………………………………………………………………………………………..177

3.8 ELECTRICAL EQUIPMENT IN CAB BASE…………………………………………………………………………………………………………178

3.8.1 CAB BASE…………………………………………………………………………………………………………………………181

3.8.1.1 Access Cover for the Headlights mounted on Cab Base……………………………………………………………………………..183

3.8.2 SWITCH BOX (X2) IN CAB BASE………………………………………………………………………………………………………..185

3.8.3 Medium Voltage Switch Cabinet………………………………………………………………………………………………………187

3.8.3.1 Medium Voltage Switch Cabinet…………………………………………………………………………………………………189

3.8.4 PREHEATING SYSTEM…………………………………………………………………………………………………………………193

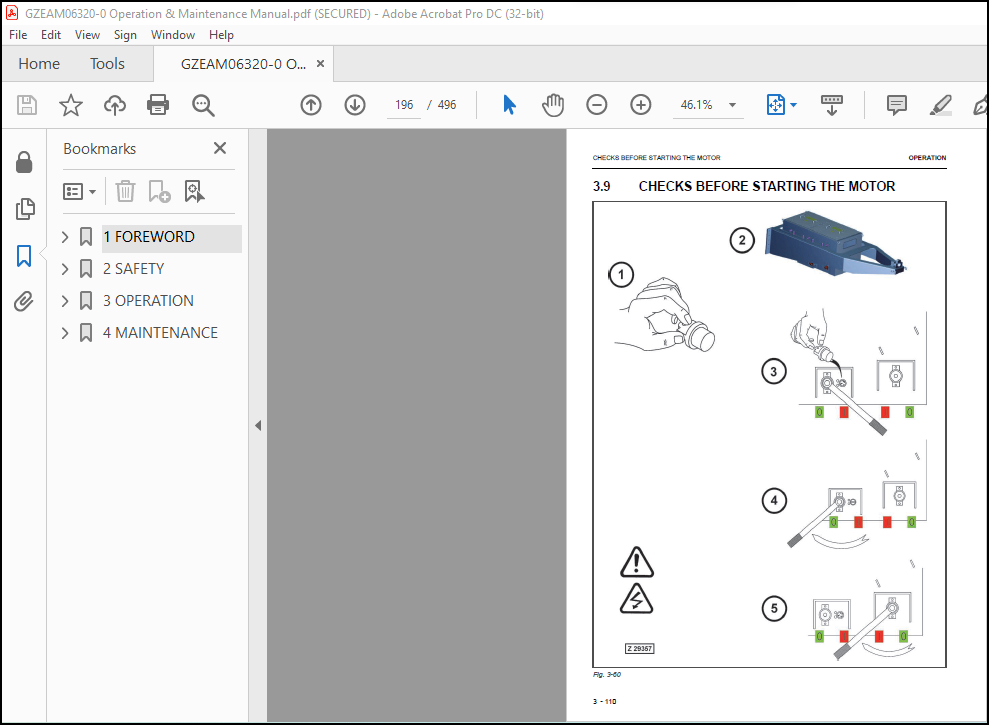

3.9 CHECKS BEFORE STARTING THE MOTOR…………………………………………………………………………………………………………196

3.9.1 WALK AROUND INSPECTION…………………………………………………………………………………………………………….197

3.9.2 TURNING ON THE POWER SUPPLY………………………………………………………………………………………………………..197

3.9.2.1 HYDRAULIC SYSTEM – CHECK OIL LEVEL…………………………………………………………………………………………….199

3.9.2.2 OPERATOR’S SEAT ADJUSTMENT……………………………………………………………………………………………………199

3.10 STARTING THE MOTOR…………………………………………………………………………………………………………………….200

3.10.1 STARTING PROCEDURE AT AMBIENT TEMPERATURE UP TO -25°C………………………………………………………………………………..203

3.10.2 STARTING PROCEDURES AT AMBIENT TEMPERATURES FROM -25°C TO -40°C……………………………………………………………………….205

3.10.2.1 Hydraulic Oil Viscosity and Temperature Chart………………………………………………………………………………….209

3.11 MOVING THE SHOVEL……………………………………………………………………………………………………………………..210

3.11.1 TRAVEL CONTROL WITH FOOT PEDALS……………………………………………………………………………………………………210

3.11.1.1 PARKING BRAKE………………………………………………………………………………………………………………212

3.11.1.2 TRAVEL ALARM / BACK-UP ALARM…………………………………………………………………………………………………212

3.11.2 TRAVELLING INSTRUCTIONS…………………………………………………………………………………………………………..212

3.11.2.1 TRAVELLING LONG DISTANCES……………………………………………………………………………………………………215

3.12 SLEWING AND BRAKING THE SUPERSTRUCTURE…………………………………………………………………………………………………..216

3.12.1 SLEWING THE SUPERSTRUCTURE………………………………………………………………………………………………………..216

3.12.1.1 MACHINES WITH “EURO” CONTROL…………………………………………………………………………………………………216

3.12.1.2 MACHINES WITH “KMG” CONTROLBraking the………………………………………………………………………………………..217

3.12.1.3 BRAKING THE SUPERSTRUCTURE…………………………………………………………………………………………………..217

3.12.1.4 Hydraulic slew brake actuated by hydraulic access Ladder and Service Arm of Central Refilling System…………………………………218

3.12.1.5 Important Instructions for Slewing the Superstructure…………………………………………………………………………..218

3.13 WORKING WITH THE ATTACHMENT…………………………………………………………………………………………………………….220

3.13.1 MACHINES EQUIPPED WITH ”EURO” CONTROL SYSTEM………………………………………………………………………………………..220

3.13.1.1 BACKHOE……………………………………………………………………………………………………………………220

3.13.1.2 FACE SHOVEL………………………………………………………………………………………………………………..220

3.13.2 MACHINES EQUIPPED WITH ”KMG” CONTROL SYSTEM…………………………………………………………………………………………221

3.13.2.1 BACKHOE……………………………………………………………………………………………………………………221

3.13.2.2 FACE SHOVEL………………………………………………………………………………………………………………..221

3.13.2.3 BOTTOM DUMP BUCKET………………………………………………………………………………………………………….222

3.13.2.4 OPERATING THE BUCKET CLAM……………………………………………………………………………………………………222

3.13.2.5 SAFETY DEVICES (SPECIAL EQUIPMENT)……………………………………………………………………………………………224

3.13.2.6 WORKING HINTS………………………………………………………………………………………………………………224

3.13.3 COMBINED OPERATION CYCLES…………………………………………………………………………………………………………225

3.14 WORKING INSTRUCTIONS…………………………………………………………………………………………………………………..227

3.14.1 STABILITY OF THE SHOVEL…………………………………………………………………………………………………………..227

3.14.2 SHOVEL OPERATION…………………………………………………………………………………………………………………227

3.15 PARKING THE SHOVEL…………………………………………………………………………………………………………………….230

3.15.0.1 CLEANING THE TRACK GROUPS……………………………………………………………………………………………………….230

3.16 STOPPING THE MOTOR…………………………………………………………………………………………………………………….232

3.16.1 RELIEVE PRESSURE IN THE HYDRAULIC SYSTEM……………………………………………………………………………………………235

3.17 GROUNDING PROCEDURE FOR THE HIGH VOLTAGE SYSTEM…………………………………………………………………………………………..236

3.17.1 ISOLATING THE POWER SUPPLY………………………………………………………………………………………………………..239

3.17.2 PROCEDURE FOR ISOLATING THE POWER SUPPLY……………………………………………………………………………………………241

3.17.3 PERFORMING GROUNDING PROCEDURES……………………………………………………………………………………………………243

3.18 AUTOMATIC LUBRICATION SYSTEMS…………………………………………………………………………………………………………..248

3.18.1 OPERATION OF THE AUTOMATIC LUBRICATION SYSTEMS………………………………………………………………………………………249

3.19 FIRE DETECTION AND SUPPRESSION SYSTEM……………………………………………………………………………………………………252

3.19.0.1 FIRE DETECTION AND SUPPRESSION SYSTEMS……………………………………………………………………………………………253

3.19.0.2 FIRE DETECTION AND SUPPRESSION SYSTEM…………………………………………………………………………………………….255

3.19.1 HIGH LEVEL ALARM -FIRE-…………………………………………………………………………………………………………..257

3.19.2 Motor shut-down………………………………………………………………………………………………………………….257

3.19.3 ACTUATION MODES OF THE FIRE SUPPRESSION SYSTEM………………………………………………………………………………………257

3.19.3.1 MANUAL ACTUATION……………………………………………………………………………………………………………257

3.19.3.2 AUTOMATIC ACTUATION…………………………………………………………………………………………………………257

3.19.4 INDICATION OF OPERATIONAL MODES AT CONTROL MODULE, AFTER AUTOMATIC ACTUATION OF THE FIRE SUPPRESSION SYSTEM………………………………..259

3.20 CENTRAL REFILLING SYSTEM……………………………………………………………………………………………………………….260

3.20.1 REFILLING SYSTEM FOR HYDRAULIC OIL RESERVOIR, GREASE BARRELS OF THE CENTRAL REFILLING SYSTEM AND SLEW RING GEAR LUBRICATION SYSTEM……………261

3.20.2 REFILLING PROCEDURE………………………………………………………………………………………………………………263

3.20.3 REFILLABLE GREASE CONTAINERS OF THE AUTOMATIC LUBRICATION SYSTEMS……………………………………………………………………..265

3.21 TRANSFER PUMP FOR HYDRAULIC OIL…………………………………………………………………………………………………………266

3.21.1 OPERATING THE TRANSFER PUMP……………………………………………………………………………………………………….267

3.21.2 FUNCTIONS OF THE TRANSFER PUMP…………………………………………………………………………………………………….267

3.22 CABLE GUIDE (IF SO EQUIPPED)……………………………………………………………………………………………………………271

3.22.1 LIFTING DEVICE FOR THE POWER CABLE…………………………………………………………………………………………………271

3.23 WORK ON THE LOADER ATTACHMENT…………………………………………………………………………………………………………..272

3.23.0.1 OBSERVE THE FOLLOWING INSTRUCTIONS……………………………………………………………………………………………….272

3.24 TRANSPORTATION AND LIFTING OF THE SHOVEL…………………………………………………………………………………………………273

3.24.1 DISASSEMBLING OF THE SHOVEL……………………………………………………………………………………………………….273

3.24.2 TRANSPORTATION AND LIFTING………………………………………………………………………………………………………..273

3.25 RETRIEVAL PROCEDURE……………………………………………………………………………………………………………………274

3.25.1 GENERAL…………………………………………………………………………………………………………………………274

3.26 SHOVEL STORAGE………………………………………………………………………………………………………………………..275

3.26.1 GENERAL…………………………………………………………………………………………………………………………275

3.26.2 PREPARING FOR STORAGE…………………………………………………………………………………………………………….275

3.26.3 ONE MONTH REPETITIVE SERVICE PERIOD………………………………………………………………………………………………..275

3.26.4 SIX MONTH REPETITIVE SERVICE PERIOD………………………………………………………………………………………………..275

3.26.5 PREPARING FOR OPERATION…………………………………………………………………………………………………………..276

3.27 TROUBLE SHOOTING………………………………………………………………………………………………………………………277

3.27.1 GENERAL…………………………………………………………………………………………………………………………277

3.27.2 MAIN DRIVE ELECTRIC MOTOR…………………………………………………………………………………………………………277

3.27.3 HYDRAULIC SYSTEM…………………………………………………………………………………………………………………278

3.27.4 FINAL DRIVES AND SWING GEAR……………………………………………………………………………………………………….279

3.27.5 CRAWLER TRACKS…………………………………………………………………………………………………………………..279

4 MAINTENANCE…………………………………………………………………………………………………………………………………281

4.1 FOREWORD………………………………………………………………………………………………………………………………282

4.1.1 DEFINITIONS………………………………………………………………………………………………………………………282

4.1.2 GENERAL RECOMMENDATIONS……………………………………………………………………………………………………………282

4.2 PRECAUTIONS FOR MAINTENANCE……………………………………………………………………………………………………………..283

4.3 FLUIDS AND LUBRICANTS…………………………………………………………………………………………………………………..284

4.3.1 LUBRICANTS FOR OPERATION IN COLD AND ARCTIC CLIMATES………………………………………………………………………………….284

4.3.2 FLUIDS AND LUBRICANTS FOR MODERATE AND HOT CLIMATES…………………………………………………………………………………..285

4.3.3 MAIN DRIVE ELECTRIC MOTORS – BEARING LUBRICATION……………………………………………………………………………………..286

4.3.3.1 Recommended Hydraulic Oils……………………………………………………………………………………………………287

4.3.3.2 General Information to selecting hydraulic oils…………………………………………………………………………………288

4.4 FILLING CAPACITIES……………………………………………………………………………………………………………………..290

4.5 STANDARD TORQUE LIST……………………………………………………………………………………………………………………291

4.5.1 Torque for Flange Joints…………………………………………………………………………………………………………..292

4.5.2 TORQUES FOR SPECIAL COMPONENTS……………………………………………………………………………………………………..293

4.6 LUBRICATION AND MAINTENANCE SCHEDULE……………………………………………………………………………………………………..295

4.6.1 INITIAL SERVICING…………………………………………………………………………………………………………………295

4.6.1.1 INITIAL RUNNING-IN…………………………………………………………………………………………………………..295

4.6.1.2 AFTER THE FIRST 250 OPERATING HOURS……………………………………………………………………………………………295

4.6.1.3 AFTER THE FIRST 1000 OPERATING HOURS…………………………………………………………………………………………..295

4.6.2 SERVICING THE CRITICAL BOLT CONNECTIONS……………………………………………………………………………………………..296

4.6.3 PERIODIC SERVICING INTERVALS……………………………………………………………………………………………………….296

4.6.4 PERIODIC SERVICING SCHEDULE………………………………………………………………………………………………………..296

4.6.4.1 WHEN NECESSARY………………………………………………………………………………………………………………296

4.6.4.2 EVERY 10 OPERATING HOURS OR DAILY……………………………………………………………………………………………..297

4.6.4.3 EVERY 50 OPERATING HOURS OR WEEKLY…………………………………………………………………………………………….297

4.6.4.4 EVERY 250 OPERATING HOURS OR MONTHLY…………………………………………………………………………………………..298

4.6.4.5 EVERY 500 OPERATING HOURS OR QUATERLY………………………………………………………………………………………….298

4.6.4.6 EVERY 1000 OPERATING HOURS OR 6 MONTHLY………………………………………………………………………………………..298

4.6.4.7 EVERY 2000 OPEARTING HOURS OR YEARLY…………………………………………………………………………………………..299

4.6.4.8 EVERY 3000 HOURS OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR…………………………………………………………………….300

4.6.4.9 EVERY 6000 HOURS OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR…………………………………………………………………….300

4.6.5 MAINTENANCE SCHEDULES OF FILTER ELEMENTS AND OTHER COMPONENTS OF THE HYDRAULIC SYSTEM…………………………………………………….301

4.6.6 Lubrication Chart…………………………………………………………………………………………………………………302

4.7 SAFETY CRITICAL PARTS…………………………………………………………………………………………………………………..303

4.7.1 REPLACEMENT OF HYDRAULIC HOSE LINES AND FUEL HOSE LINES……………………………………………………………………………….303

4.7.2 INSPECTION OF HOSE LINES…………………………………………………………………………………………………………..303

4.7.3 PERIODIC REPLACEMENT OF FURTHER SAFETY CRITICAL PARTS…………………………………………………………………………………303

4.8 INITIAL SERVICING………………………………………………………………………………………………………………………306

4.8.1 WORKING ATTACHMENT – INITIAL CHECKS FOR PROPER LUBRICATION…………………………………………………………………………….307

4.8.2 CAR BODY AND RACEWAY OF SLEW RING…………………………………………………………………………………………………..309

4.8.3 SWING CIRCLE – CHECK GREASE INJECTORS……………………………………………………………………………………………….311

4.8.4 SWING CIRCLE – CHECK TORQUE OF BOLT CONNECTIONS………………………………………………………………………………………313

4.8.5 RETIGHTENING PROCEDURE OF THE CRAWLER CARRIER MOUNTING BOLTS…………………………………………………………………………..315

4.8.5.1 PROCEDURE FOR ENSURING PROPER TIGHTENING OF THE CRAWLER CARRIER MOUNTING BOLTS……………………………………………………..317

4.9 WHEN NECESSARY…………………………………………………………………………………………………………………………322

4.9.1 SWING CIRCLE TOOTHING LUBRICATION…………………………………………………………………………………………………..323

4.9.2 AUTOMATIC LUBRICATION SYSTEMS FILL GREASE CONTAINERS………………………………………………………………………………….325

4.9.2.1 Service the Grease Filters for Refillable Grease Containers of the Central Lubrication System and Swing circle pinion Lubrication System….327

4.9.3 GUIDE WHEELS – REPLACE FLOATING SEALS……………………………………………………………………………………………….327

4.9.4 SLIP RING UNIT – VISUAL CHECK………………………………………………………………………………………………………328

4.10 EVERY 10 OPERATING HOURS OR DAILY……………………………………………………………………………………………………….330

4.10.1 WALKAROUND INSPECTION…………………………………………………………………………………………………………….331

4.10.1.1 BOOM – CHECK LADDER AND WALKWAY………………………………………………………………………………………………335

4.10.2 ELECTRICAL EQUIPMENT – CHECK CONDITION……………………………………………………………………………………………..335

4.11 EVERY 50 OPERATING HOURS OR WEEKLY………………………………………………………………………………………………………336

4.11.1 SWING GEAR AND MOTOR ADAPTER HOUSING – CHECK OIL LEVEL……………………………………………………………………………….337

4.11.1.1 CHECK SWING GEAR OIL LEVEL…………………………………………………………………………………………………..337

4.11.1.2 CHECK MOTOR ADAPTER HOUSING OIL LEVEL…………………………………………………………………………………………337

4.11.1.3 Swing Gear manufactured by “Siebenhaar” or “Mitsui”…………………………………………………………………………….339

4.11.2 TRAVEL GEARS, BRAKE HOUSINGS AND MOTOR ADAPTER HOUSINGS – CHECK OIL LEVELS……………………………………………………………..341

4.11.2.1 PLANETARY GEAR BOX – CHECK OIL LEVEL………………………………………………………………………………………….341

4.11.2.2 SPUR GEAR BOX – CHECK OIL LEVEL………………………………………………………………………………………………343

4.11.2.3 BRAKE HOUSINGS – CHECK OIL LEVEL……………………………………………………………………………………………..343

4.11.2.4 MOTOR ADAPTER HOUSING – CHECK OIL LEVEL……………………………………………………………………………………….343

4.11.2.5 MILEAGE INDICATOR (Special Equipment)…………………………………………………………………………………………343

4.11.3 PTO (PUMP DISTRIBUTOR GEAR) – CHECK OIL LEVEL……………………………………………………………………………………….345

4.11.3.1 Main Hydraulic Pumps – Check Oil Level in Drive Shaft Housings…………………………………………………………………..345

4.11.4 HYDRAULIC ACCESS LADDER – CHECK SAFETY SENSOR……………………………………………………………………………………….347

4.11.5 HYDRAULIC OIL COOLERS – INSPECT AND CLEAN IF NECESSARY……………………………………………………………………………….349

4.12 EVERY 250 OPERATING HOURS OR MONTHLY…………………………………………………………………………………………………….350

4.12.1 SIGNAL HORN COMPRESSOR – LUBRICATE…………………………………………………………………………………………………351

4.12.2 HYDRAULIC OIL COOLER FAN – CHECK CONDITION AND FASTENING……………………………………………………………………………..351

4.12.3 AUTOMATIC LUBRICATION SYSTEMS – CLEAN BREATHER FILTER………………………………………………………………………………..353

4.12.4 CAB AIR CLEANER – CLEAN OR REPLACE FILTER ELEMENT……………………………………………………………………………………355

4.12.4.1 Clean and inspect filter element (3) as follows:……………………………………………………………………………….355

4.12.5 WINDSHIELD WASHER RESERVOIR – CHECK FLUID LEVEL……………………………………………………………………………………..357

4.12.6 AIR CONDITIONING FOR OPERATOR’S CAB – CHECK REFRIGERANT LEVEL…………………………………………………………………………359

4.12.6.1 Checking the refrigerant level……………………………………………………………………………………………….359

4.12.7 AIR CONDITIONER UNIT FOR MEDIUM VOLTAGE AND HIGH VOLTAGE SWITCH CABINETS……………………………………………………………….361

4.12.8 CABLE GRIP – CHECK CONDITION………………………………………………………………………………………………………363

4.13 EVERY 500 OPERATING HOURS OR MONTHLY…………………………………………………………………………………………………….364

4.13.1 BATTERIES – CHECK FLUID LEVEL……………………………………………………………………………………………………..365

4.13.2 CRAWLER TRACK – INSPECTION………………………………………………………………………………………………………..367

4.13.2.1 CHECK ADJUSTING RANGE OF GUIDE WHEELS…………………………………………………………………………………………367

4.13.2.2 CHECK ADJUSTING RANGE FOR GUIDE WHEELS………………………………………………………………………………………..369

4.13.2.3 CHECK ADJUSTING RANGE FOR GUIDE WHEELS………………………………………………………………………………………..371

4.13.2.4 Bleeding the System…………………………………………………………………………………………………………371

4.13.2.5 GREASE INJECTORS – CHECK INDICATOR STEMS………………………………………………………………………………………372

4.13.2.6 CORRECTIVE ACTIONS………………………………………………………………………………………………………….372

4.13.3 EMERGENCY LOWERING OF ACCESS LADDER – Test FUNCTIONALITY……………………………………………………………………………..375

4.13.4 HIGH VOLTAGE SWITCH CABINET – VISUAL CHECK………………………………………………………………………………………….377

4.13.5 CYLINDER ROD PROTECTION (IF EQUIPPED), CHANGE SLIDING BLOCKS………………………………………………………………………….379

4.14 EVERY 1000 OPERATING HOURS OR EVERY 6 MONTH………………………………………………………………………………………………380

4.14.1 CRITICAL BOLT CONNECTIONS…………………………………………………………………………………………………………381

4.14.2 HYDRAULIC SYSTEM – FILTER SERVICE………………………………………………………………………………………………….387

4.14.2.1 FILTER SERVICE……………………………………………………………………………………………………………..389

4.14.3 PTO (PUMP DISTRIBUTOR GEAR), SWING GEAR AND TRAVEL GEARS – OIL SAMPLE ANALYSIS………………………………………………………….401

4.14.3.1 Oil drain plugs,……………………………………………………………………………………………………………401

4.14.3.2 PTO (PUMP DISTRIBUTOR GEAR)………………………………………………………………………………………………….401

4.14.3.3 SWING GEAR AND TRAVEL GEARS………………………………………………………………………………………………….401

4.14.4 SIGNAL HORN COMPRESSOR – CLEAN AND LUBRICATE………………………………………………………………………………………..403

4.14.5 HYDRAULIC TRACK TENSIONING SYSTEM – CHECK PRESSURE ACCUMULATORS……………………………………………………………………….405

4.14.6 HYDRAULIC OIL COOLER – INSPECT AND LUBRICATE DOOR HINGES……………………………………………………………………………..407

4.14.7 MACHINERY HOUSE DOORS – INSPECT AND LUBRICATE DOOR HINGES…………………………………………………………………………….407

4.14.8 SLIP RING UNIT – LUBRICATE………………………………………………………………………………………………………..409

4.14.8.1 Lubricate………………………………………………………………………………………………………………….409

4.14.9 EMERGENCY MOTOR SHUTDOWN SWITCHES – TEST FUNCTIONALITY……………………………………………………………………………….411

4.14.10 MOTOR SHUTDOWN PULL chains (SPECIAL EQUIPMENT) – TEST FUNCTIONALITY…………………………………………………………………..413

4.14.11 HIGH VOLTAGE SWITCH CABINET – CHECK SCREW CONNECTIONS……………………………………………………………………………….415

4.14.12 ELECTRICAL EQUIPMENT – MAINTENANCE………………………………………………………………………………………………..417

4.15 EVERY 2000 OPERATING HOURS OR YEARLY…………………………………………………………………………………………………….418

4.15.1 HYDRAULIC SYSTEM – CHANGE OIL, REPLACE SUCTION STRAINERS AND PULSATION DAMPER…………………………………………………………..419

4.15.1.1 Sequence of Servicing……………………………………………………………………………………………………….419

4.15.1.2 Filling the Hydraulic System…………………………………………………………………………………………………427

4.15.1.3 Hydraulic oil viscosity and adjustment of temperature switch units……………………………………………………………….429

4.15.1.4 Vent Suction Oil Reservoir and Hydraulic Pumps…………………………………………………………………………………431

4.15.2 EMERGENCY ESCAPE LADDER – INSPECTION……………………………………………………………………………………………….433

4.15.3 PREVENTATIVE MAINTENANCE (PM) CLINIC – PERFORM TEST………………………………………………………………………………….435

4.15.4 SLIP RING UNIT – MAINTENANCE………………………………………………………………………………………………………437

4.16 EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR……………………………………………………………………………………442

4.16.1 SWING GEAR AND MOTOR ADAPTER HOUSING – CHANGE OIL……………………………………………………………………………………443

4.16.1.1 Swing gear manufactured by “L&S”……………………………………………………………………………………………..443

4.16.1.2 SWING GEAR MANUFACTURED BY “SIEBENHAAR” or “MITSUI”…………………………………………………………………………….447

4.16.2 TRAVEL GEARS, BRAKE AND MOTOR ADAPTER HOUSINGS – CHANGE OIL…………………………………………………………………………..451

4.16.2.1 TRAVEL GEARS – CHANGE OIL……………………………………………………………………………………………………453

4.16.2.2 BRAKE HOUSINGS – CHANGE OIL………………………………………………………………………………………………….453

4.16.2.3 MOTOR ADAPTER HOUSINGS – CHANGE OIL…………………………………………………………………………………………..453

4.16.3 PTO (PUMP DISTRIBUTOR GEAR) – CHANGE OIL……………………………………………………………………………………………455

4.16.3.1 BLEEDING GEAR PUMP FOR PTO LUBRICATION………………………………………………………………………………………..457

4.16.4 PTO GEAR OIL VISCOSITY AND ADJUSTMENT OF TEMPERATURE SWITCH UNITS……………………………………………………………………..459

4.16.5 CRITICAL BOLT CONNECTIONS – CHECK TORQUE LOAD……………………………………………………………………………………….461

4.17 EVERY 6000 HOURS OR AT LEAST ONCE A YEAR…………………………………………………………………………………………………480

4.17.1 AUTOMATIC LUBRICATION SYSTEMS – Replace GREASE FILTERS……………………………………………………………………………….481

4.17.2 HYDRAULIC Oil TANK – CHECK LEAKAGE OIL SCREEN FILTER…………………………………………………………………………………483

4.18 FIRE PREVENTION……………………………………………………………………………………………………………………….484

4.18.1 PRECAUTIONS……………………………………………………………………………………………………………………..485

4.19 WELD REPAIRS………………………………………………………………………………………………………………………….486

4.19.1 GENERAL PROTECTIVE MEASURES……………………………………………………………………………………………………….487

4.19.2 WELD REPAIRS ON MAJOR COMPONENTS OF THE EXCAVATOR……………………………………………………………………………………487

4.19.2.1 COUNTERWEIGHT………………………………………………………………………………………………………………487

4.19.3 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE UNDERCARRIAGE………………………………………………………………….489

4.19.4 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE LOADER ATTACHMENT………………………………………………………………491

4.19.5 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE SUPERSTRUCTURE…………………………………………………………………493

4.19.5.1 Electrical Units in Cab Base…………………………………………………………………………………………………495

4.19.6 AFTER FINISHING THE WELD REPAIRS ON THE SUPERSTRUCTURE……………………………………………………………………………….495