$45

Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Operation & Maintenance Manual PDF

Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Operation & Maintenance Manual

FILE DETAILS:

Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Operation & Maintenance Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Product Code : EEAM008000

Total Pages : 258

DESCRIPTION:

Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Operation & Maintenance Manual

FOREWORD:

- This manual provides rules and guidelines which will help you use this machine safely and effectively. Keep this manual handy and have all personnel read it periodically. If this manual has been lost or has become dirty and can not be read, request a replacement manual from Komatsu or your Komatsu distributor.

- If you sell the machine, be sure to give this manual to the new owners. Continuing improvements in the design of this machine can lead to changes in detail which may not be reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information for your machine or for questions regarding information in this manual.

TABLE OF CONTENTS:

Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Operation & Maintenance Manual

1 Foreword 0-1

2 Safety information 0-2

3 Introduction 0-4

4 Location of plates, table to enter serial No and distributor 0-5

SAFETY

6 General Precautions 1-2

7 Precautions during operation 1-8

71 Before starting engine 1-8

72 Operating machine 1-10

73 Transportation 1-15

74 Battery 1-16

75 Towing 1-17

76 Bucket with hook 1-18

8 Precautions for maintenance 1-21

81 Before carrying out maintenance 1-21

82 During maintenance 1-24

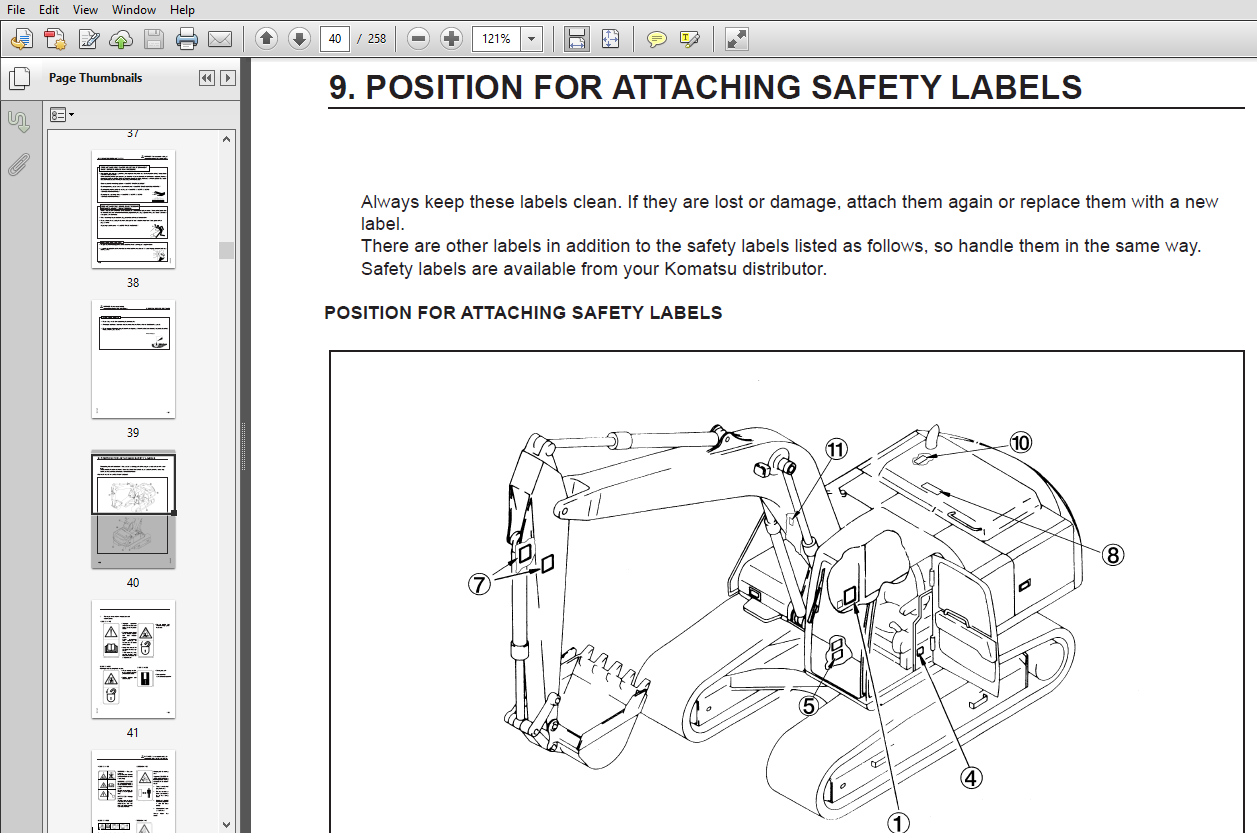

9 Position for attaching safety labels 1-28

OPERATION

10 General view

101 General view of machine 2-2

102 General view of controls and gauges 2-3

11 Explanation of components

111 Machine monitor 2-4

112 Switches 2-15

113 Control levers, pedals 2-19

114 Roof hatch 2-24

115 Front window 2-25

116 Door lock 2-27

117 Cap, cover with lock 2-28

118 Luggage box 2-29

119 Ashtray 2-29

1110 Heater 2-29

1111 Air conditioner 2-30

1112 Car radio 2-33

1113 Fuse 2-34

1114 Fusible link 2-35

1115 Controllers 2-35

1116 Tool box 2-35

1117 Refuelling pump 2-35

1118 Handling the accumulator 2-36

0-8

PC340-ENG

12 Operation

121 Check before starting engine 2-38

122 Starting engine 2-48

123 Operations and checks after starting engine 2-51

124 Moving machine off 2-57

125 Steering machine 2-60

126 Stopping machine 2-62

127 Swinging 2-63

128 Operation of work equipment 2-64

129 Working mode selection 2-65

1210 Prohibitions for operation 2-67

1211 Precaution for operation 2-69

1212 Precaution when travelling up or down hills 2-70

1213 How to escape from mud 2-72

1214 Work possible using hydraulic excavator 2-73

1215 Replacement and inversion of bucket 2-74

1216 Parking the machine 2-76

1217 Check after finishing work 2-77

1218 Stopping engine 2-78

1219 Check after stopping engine 2-79

1220 Locking 2-79

1221 Overload warning device 2-79

13 Transportation

131 Loading, unloading work 2-80

132 Precautions for loading 2-82

133 Precautions for transportation 2-83

134 Lifting the machine 2-83

14 Cold weather operation

141 Precaution for low temperature 2-85

142 Precautions after completion of work 2-86

143 After cold weather 2-86

15 Long-term storage

151 Before storage 2-87

152 During storage 2-88

153 After storage 2-88

154 Starting machine after long-term storage 2-88

16 Troubleshooting

161 Phenomena that are not failures 2-89

162 Method of towing machine 2-89

163 Using method for light-weight towing hole 2-89

164 Precautions on particular jobsites 2-90

165 If battery is discharged 2-90

166 Other trouble 2-94

5 CONTENTS

0-9 PC340-ENG

MAINTENANCE

17 Guides to maintenance 3-2

18 Outlines of service 3-5

181 Outline of oil, fuel, coolant 3-5

182 Outline of electric system 3-9

183 Outline of hydraulic system 3-10

19 Wear parts list 3-11

20 Use of fuel, coolant and lubricants according to ambient temperature 3-12

21 Standard tightening torques for bolts and nuts 3-16

211 Introduction of necessary tools 3-16

212 Torque list 3-17

22 Periodic replacement of safety critical parts 3-18

23 Maintenance schedule chart 3-20

231 Maintenance schedule chart 3-20

232 Maintenance interval when using hydraulic breaker 3-22

24 Service procedure 3-23

241 Initial 250 hours service 3-23

242 When required 3-24

243 Check before starting 3-45

244 Every 50 hours service 3-49

245 Every 100 hours service 3-51

246 Every 250 hours service 3-54

247 Every 500 hours service 3-61

248 Every 1000 hours service 3-67

249 Every 2000 hours service 3-73

2410 Every 4000 hours 3-80

SPECIFICATIONS

25 SPECIFICATIONS 4-2

251 Machine specifications 4-2

252 Explanation of lifting capacity chart 4-5

5 CONTENTS

0-10

PC340-ENG

OPTIONS AND ATTACHMENTS

26 General Precautions 5-2

261 General precautions related to safety 5-2

262 Precautions when installing attachments 5-3

27 Handling bucket with hook 5-4

271 Checking for damage to bucket with hook 5-4

272 Prohibited operations 5-4

273 Precautions during operation 5-4

28 Machine ready for attachments 5-5

281 Explanation of components 5-5

282 Hydraulic circuit 5-7

283 Attachment mounting / dismounting procedure 5-9

284 Operation 5-11

285 Long-term storage 5-12

286 Specifications 5-12

29 Introduction of attachments 5-13

291 Specification, use 5-13

292 Attachment installing combination table 5-14

293 Selection of track shoes 5-15

294 Selection of bucket teeth 5-16

295 Handling trapezoidal bucket 5-17

296 Handling extension arm 5-18

30 Extending machine service life 5-19

301 Hydraulic breaker 5-19

302 Power ripper 5-22

303 Fork grab 5-23

304 Grapple bucket 5-24

305 Scrap grapple 5-25

306 Crusher & cutter 5-26

307 Hydraulic pile driver 5-27

308 Hydraulic excavator with multi-purpose crane 5-28

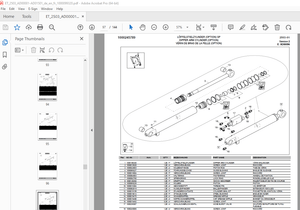

IMAGES PREVIEW OF THE MANUAL: