Starting from:

$45

Home

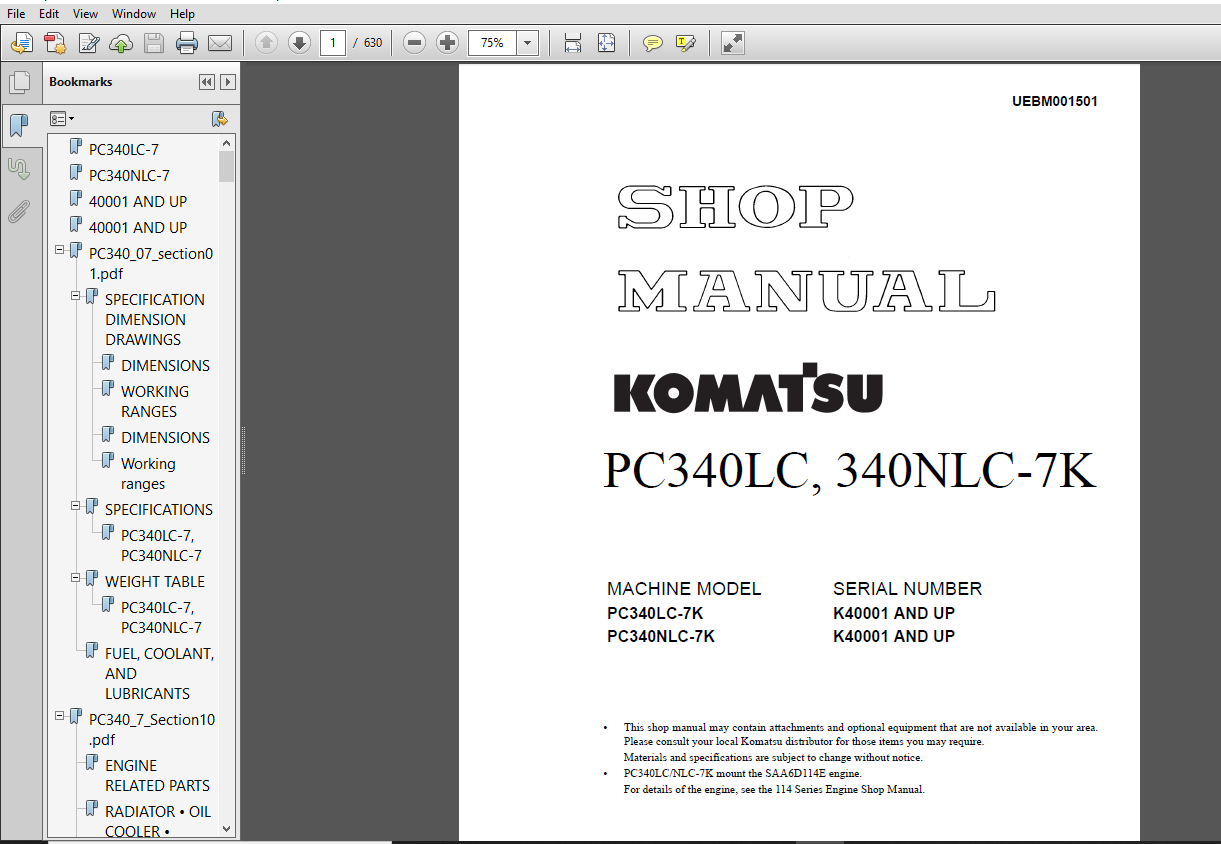

Komatsu PC340LC-7K, PC340NLC-7K Hydraulic Excavator Shop Manual - PDF DOWNLOAD

Komatsu PC340LC-7K, PC340NLC-7K Hydraulic Excavator Shop Manual - PDF DOWNLOAD

Komatsu PC340LC-7K, PC340NLC-7K Hydraulic Excavator Shop Manual

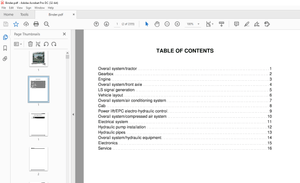

TABLE OF CONTENTS:

Komatsu PC340LC-7K, PC340NLC-7K Hydraulic Excavator Shop Manual

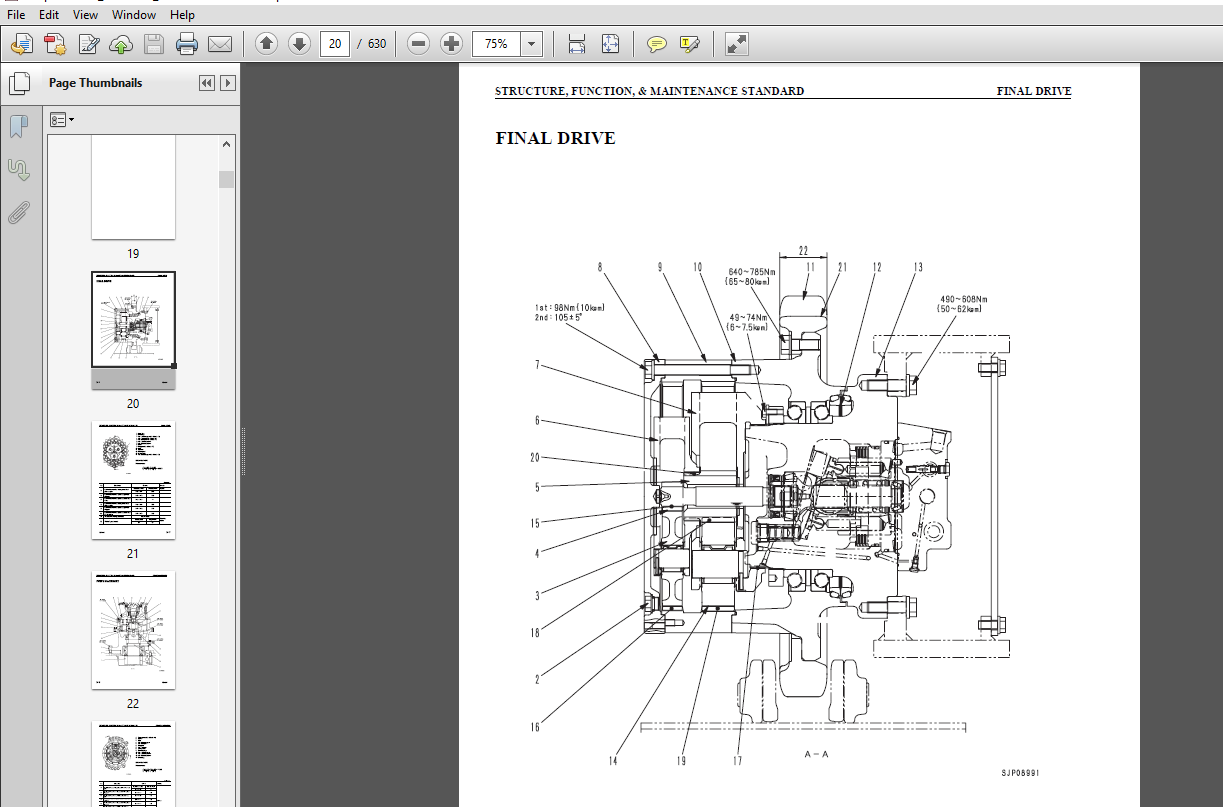

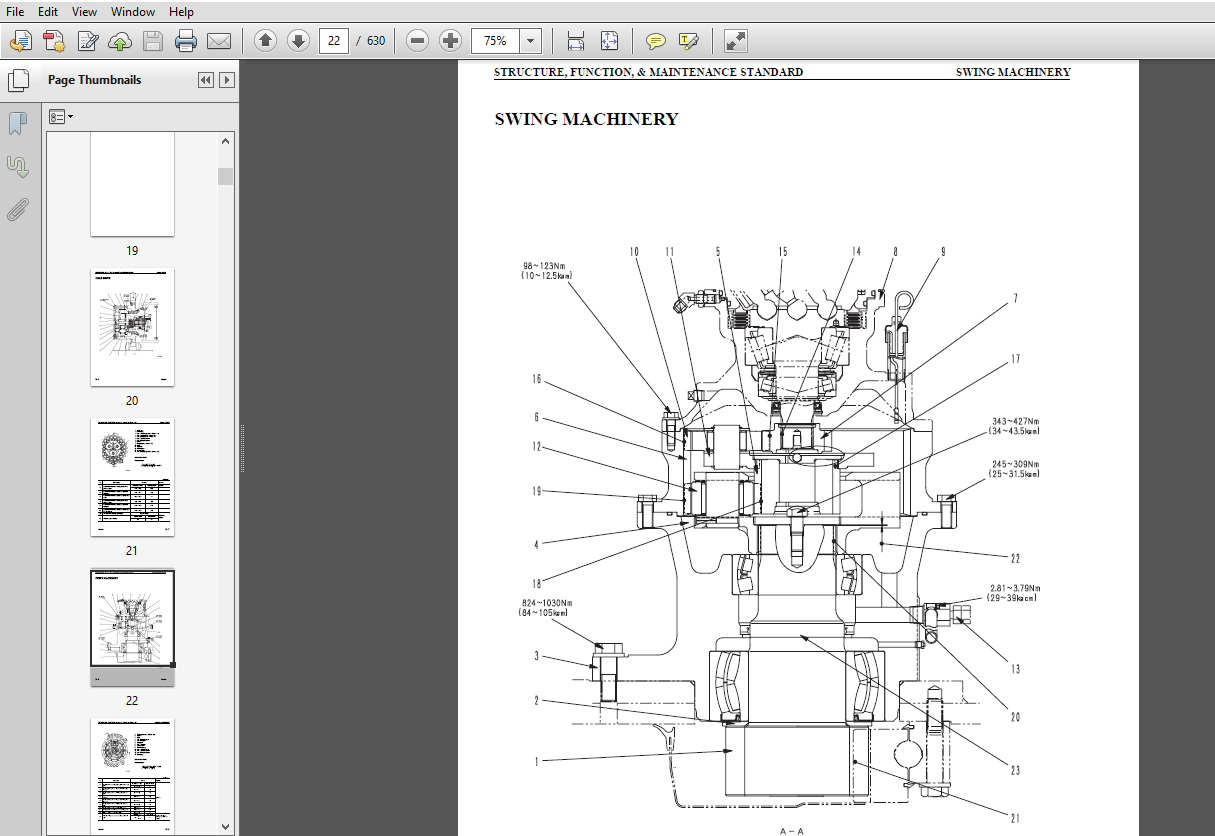

PC340LC-7................................................................................................... 0 PC340NLC-7.................................................................................................. 0 40001 AND UP................................................................................................ 0 40001 AND UP................................................................................................ 0 PC340_07_section01.pdf...................................................................................... 0 SPECIFICATION DIMENSION DRAWINGS........................................................................ 8 DIMENSIONS.......................................................................................... 8 WORKING RANGES...................................................................................... 8 DIMENSIONS.......................................................................................... 9 Working ranges...................................................................................... 9 SPECIFICATIONS.......................................................................................... 10 PC340LC-7, PC340NLC-7............................................................................... 10 WEIGHT TABLE............................................................................................ 12 PC340LC-7, PC340NLC-7............................................................................... 12 FUEL, COOLANT, AND LUBRICANTS........................................................................... 14 PC340_7_Section10.pdf....................................................................................... 0 ENGINE RELATED PARTS.................................................................................... 16 RADIATOR • OIL COOLER • AFTERCOOLER..................................................................... 17 POWER TRAIN............................................................................................. 18 FINAL DRIVE............................................................................................. 20 SWING MACHINERY......................................................................................... 22 SWING CIRCLE............................................................................................ 24 TRACK FRAME • RECOIL SPRING............................................................................. 26 IDLER................................................................................................... 28 CARRIER ROLLER.......................................................................................... 30 TRACK ROLLER............................................................................................ 31 TRACK SHOE.............................................................................................. 32 TRIPLE GROUSER SHOE................................................................................. 35 hydraulic equipment layout drawing...................................................................... 36 HYDRAULIC TANK.......................................................................................... 38 HYDRAULIC PUMP.......................................................................................... 40 HPV125 + 125........................................................................................ 40 LS VALVE............................................................................................ 45 PC VALVE............................................................................................ 45 LS(pc)-EPC VALVE.................................................................................... 58 variable volume valve................................................................................... 61 CONTROL VALVE........................................................................................... 64 MAIN RELIEF VALVE................................................................................... 78 Variable pressure compensation valve................................................................ 79 CLSS.................................................................................................... 80 OUTLINE OF CLSS..................................................................................... 80 SELF PRESSURE REDUCING VALVE............................................................................ 83 SWING MOTOR............................................................................................. 86 REVERSE PREVENTION VALVE................................................................................ 92 CENTER SWIVEL JOINT..................................................................................... 94 TRAVEL MOTOR............................................................................................ 95 TRAVEL JUNCTION VALVE...................................................................................105 TRAVEL PPC SHUTTLE VALVE................................................................................108 VALVE CONTROL...........................................................................................112 WORK EQUIPMENT • SWING PPC VALVE........................................................................113 TRAVEL PPC VALVE........................................................................................117 SERVICE PPC VALVE.......................................................................................126 SOLENOID VALVE..........................................................................................129 PPC ACCUMULATOR.........................................................................................131 return oil filter.......................................................................................132 For Breaker.........................................................................................132 BOOM HYDRAULIC DRIFT PREVENTION VALVE...................................................................134 quick return valve......................................................................................140 LIFT CHECK VALVE........................................................................................142 attachment circuit selector valve.......................................................................143 HYDRAULIC CYLINDER......................................................................................145 BOOM CYLINDER.......................................................................................145 ARM CYLINDER........................................................................................145 BUCKET CYLINDER.....................................................................................145 work equipment..........................................................................................148 2. Dimension of bucket..............................................................................152 air conditioner.........................................................................................154 air conditioner piping..............................................................................154 ENGINE CONTROL..........................................................................................155 Governor motor......................................................................................158 Engine throttle and pump controller.................................................................160 ELECTRONIC CONTROL SYSTEM...............................................................................163 Total system diagram................................................................................164 mULTI MONITOR SYSTEM....................................................................................187 SENSOR.................................................................................................. 0 20-001.pdf.................................................................................................. 0 1. The standard value for a new machine given in the table is the value used when shipping the ma.......213 2. The service limit value given in the tables is the estimated value for the shipped machine bas.......213 3. These standard values are not the standards used in dealing with claims..............................213 STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...........................................................214 STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS..........................................................215 20_101.pdf.................................................................................................. 0 INSPECTION AND ADJUSTMENT OF ENGINE RPM.................................................................224 MEASUREMENT OF AIR BOOST PRESSURE.......................................................................226 MEASUREMENT OF EXHAUST GAS COLOR........................................................................227 ADJUSTMENT OF VALVE CLEARANCE...........................................................................228 MEASUREMENT OF COMPRESSION PRESSURE.....................................................................230 MEASUREMENT OF BLOW-BY PRESSURE.........................................................................231 INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING......................................................232 MEASUREMENT OF ENGINE OIL PRESSURE......................................................................234 ADJUSTMENT OF ENGINE SPEED SENSOR.......................................................................235 INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION................................................235 EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM...................................................236 MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS.......................................................237 INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION.........................................................238 INSPECTION OF WEAR ON SPROCKET..........................................................................238 INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN.......239 INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE...............................................243 INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE.......................................244 INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE.......................................247 MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE...........................................................251 MEASUREMENT OF PPC VALVE OUTPUT PRESSURE................................................................254 ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE........................................................255 INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT............................................256 RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT......................................................257 MEASUREMENT OF OIL LEAKAGE AMOUNT.......................................................................258 AIR BLEEDING OF VARIOUS PARTS...........................................................................260 INSPECTION PROCEDURES FOR DIODE.........................................................................262 SPECIAL FUNCTION OF MULTI-MONITOR PANEL.................................................................263 DISPLAY METHOD AND SPECIAL FUNCTIONS OF 7-SEGMENT MONITOR PANEL.........................................287 PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM......................................................300 20_201.pdf.................................................................................................. 0 POINTS TO REMEMBER WHEN TROUBLESHOOTING.................................................................306 SEQUENCE OF EVENTS IN TROUBLESHOOTING...................................................................307 POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE........................................................308 CHECKS BEFORE TROUBLESHOOTING...........................................................................316 CLASSIFICATION AND STEPS FOR TROUBLESHOOTING............................................................317 CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM.......................................322 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS..............................................................340 20_301.pdf.................................................................................................. 0 INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..........................................................361 20_501.pdf.................................................................................................. 0 INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..........................................................374 30.pdf...................................................................................................... 0 HOW TO READ THIS MANUAL.................................................................................525 REMOVAL AND INSTALLATION OF ASSEMBLIES..............................................................525 DisassemblY and assemblY OF assemblIES..............................................................526 PRECAUTIONS WHEN PERFORMING OPERATION...................................................................527 REMOVAL AND INSTALLATION OF STARTING MOTOR ASSEMBLY.....................................................529 REMOVAL.............................................................................................529 INSTALLATION........................................................................................529 REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY................................................530 REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL...........................................................534 REMOVAL AND INSTALLATION OF ENGINE REAR SEAL............................................................535 REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY......................................................537 REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY...........................................................543 REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY...............................................545 REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLIES........................................547 REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY........................................................551 DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY........................................................552 SKETCHES OF SPECIAL TOOLS...........................................................................561 REMOVAL AND INSTALLATION OF SWING MOTOR, SWING MACHINERY ASSEMBLY.......................................562 DISASSEMBLY AND ASSEMBLY OF SWING MOTOR, SWING MACHINERY ASSEMBLY.......................................563 SKETCHES OF SPECIAL TOOLS...........................................................................570 DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY.....................................................571 DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY.......................................................572 DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY..............................................................573 DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY......................................................576 REMOVAL AND INSTALLATION OF TRACK SHOE ASSEMBLY.........................................................579 EXPANSION OF TRACK SHOE.............................................................................579 REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY.......................................................581 REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY....................................................582 REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY................................................585 DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY................................................587 REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY.....................................................588 REMOVAL AND INSTALLATION OF CONTROL VALVE ASSEMBLY......................................................590 DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY......................................................593 REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY.....................................................595 REMOVAL AND INSTALLATION OF OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT......................................598 DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY...........................................599 DISASSEMBLY AND ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY...................................................600 DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY.................................................601 REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY.....................................................607 REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY...............................................610 REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY......................................................613 REMOVAL AND INSTALLATION OF OPERATOR’S CAB ASSEMBLY.....................................................614 REMOVAL AND INSTALLATION OF MONITOR ASSEMBLY............................................................616 REMOVAL AND INSTALLATION OF GOVERNOR PUMP CONTROLLER ASSEMBLY...........................................617 20_601.pdf.................................................................................................. 0 TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).............................................363 SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS...................................................500 INFORMATION CONTAINED IN TROUBLESHOOTING TABLE......................................................502 H-1 All work equipment lack power, or travel and swing speeds are slow..........................503 H-2 Engine speed sharply drops or engine stalls.................................................504 H-3 No work equipment, travel or swing move.....................................................505 H-4 Abnormal noise is heard from around hydraulic pump..........................................505 H-5 Auto-decelerator does not work..............................................................506 H-6 Fine control mode does not function.........................................................506 H-7 Boom moves slowly or lacks power............................................................507 H-8 Arm moves slowly or lacks power.............................................................508 H-9 Bucket moves slowly or lacks power..........................................................509 H-10 Work equipment does not move in its single operation.......................................509 H-11 Work equipment has a bit too fast hydraulic drift..........................................510 H-12 Work equipment has big time lag............................................................511 H-13 Other work equipment moves when relieving single circuit...................................511 H-14 One-touch power max. switch does not operate...............................................511 H-15 In compound operation, work equipment with larger load moves slowly........................512 H-16 In swing + boom RAISE operation, boom moves slowly.........................................512 H-17 In swing + travel, travel speed drops sharply..............................................512 H-18 Machine swerves in travel..................................................................513 H-19 Machine travels slowly.....................................................................514 H-20 Machine cannot be easily steered or lacks power............................................515 H-21 Travel speed does not shift, or it is too slow or fast.....................................458 H-22 Track shoe does not turn (on one side only)................................................516 H-23 Machine does not swing.....................................................................517 H-24 Swing acceleration is poor, or swing speed is slow.........................................518 H-25 Excessive overrun when stopping swing......................................................519 H-26 There is big shock when stopping swing.....................................................520 H-27 There is big abnormal noise caused when stopping swing.....................................520 H-28 Swing natural drift is too big.............................................................521 PC340_A2.pdf................................................................................................ 0 hydraulic circuit diagram...............................................................................621 electrical circuit diagram (1/4)........................................................................623 FOR multi monitor...................................................................................623 electrical circuit diagram (2/4)........................................................................625 FOR multi monitor...................................................................................625 electrical circuit diagram (3/4)........................................................................627 FOR multi monitor...................................................................................627 electrical circuit diagram (4/4)........................................................................629 FOR multi monitor...................................................................................629

IMAGES PREVIEW OF THE MANUAL:

1 file (114.3MB)