$47

Komatsu PC360LCi-11 Hydraulic Excavator Shop Manual SEN06601-09 – PDF DOWNLOAD

Komatsu PC360LCi-11 Hydraulic Excavator Shop Manual SEN06601-09 – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC360LCi-11 Hydraulic Excavator Shop Manual SEN06601-09 – PDF DOWNLOAD

Language : English

Pages : 3676

Downloadable : Yes

File Type : PDF

Size: 93.3 MB

DESCRIPTION:

Komatsu PC360LCi-11 Hydraulic Excavator Shop Manual SEN06601-09 – PDF DOWNLOAD

SERIAL NUMBERS 90156 and up

FOREWORD, SAFETY, BASIC INFORMATION

HOW TO READ THE SHOP MANUAL

• Some of the attachments and options described in this shop manual may not be available in some areas. If

they are required, consult your Komatsu distributor.

• The materials and specifications are subject to change without notice.

• Shop Manuals are available for “machine part” and “engine part”. For the engine unit, see the shop manual

for the machine which has the same engine model.

• Actual machine may differ from the images which are contained in this manual. A typical model is shown in

the illustrations of this shop manual.

Composition of the shop manual

This shop manual contains technical information necessary to perform services in workshops. It is divided into

the following chapters for the ease of use.

00 INDEX AND FOREWORD

This section describes the index, foreword, safety, and basic information.

01 SPECIFICATIONS

This section describes the specifications of the machine.

10 STRUCTURE AND FUNCTION

This section describes the structure and operation of each component with respect to each system. “STRUCTURE

AND FUNCTION” is helpful in not only understanding the structure of each component but performing

troubleshooting.

20 STANDARD VALUE TABLE

This section describes the standard values for new machine and failure criteria for testing and adjusting, and

troubleshooting. Use the standard values table to check the standard values for testing and adjusting, and judge

troubles in troubleshooting.

30 TESTING AND ADJUSTING

This section describes the measuring tools and measuring methods for testing and adjusting as well as the adjusting

method of each part. The standard values and repair limit for TESTING AND ADJUSTING are described

in “STANDARD VALUE TABLE”.

40 TROUBLESHOOTING

This section describes troubleshooting of failure part and its remedy method on the occurrence of the failure.

Descriptions of troubleshooting are sorted by failure mode.

50 DISASSEMBLY AND ASSEMBLY

This section describes the special tools, work procedures, and safety precautions necessary for removal, installation,

disassembly, and assembly of the components and parts. In addition, tightening torques, quantity, and

weight of the coating materials, lubricants, and coolant necessary to these works are shown.

60 MAINTENANCE STANDARD

This section describes the maintenance standard value of each component. The maintenance standard shows

the criteria and remedies for disassembly and assembly.

80 THE OTHER INFORMATION

This section describes the structure and function, testing and adjusting, and troubleshooting for all of the other

components or equipment which cannot be separately classified in the appendix.

90 Circuit diagrams

This section describes hydraulic circuit diagrams and electrical circuit diagrams.

General precautions

If the machine is handled incorrectly, it is dangerous. Read and understand what is described in the

operation and maintenance manual before operation. Read and understand what is described in this

manual before operation.

• Read and understand the meaning of all the safety labels stuck to the machine before performing any

greasing or repairs. For the locations of the safety labels and detailed explanation of precautions, see Operation

and Maintenance Manual.

• Tools and removed parts in the workshop should be well organized. Always keep the tools and parts in their

correct places. Always keep the work area clean and make sure that there is no dust, dirt, oil, or water on

the floor. Smoke only in the designated areas. Never smoke while working.

• Keep all tools in good condition, learn the correct way to use them, and use the proper ones. Check the

tools, machine, forklift truck, service car, etc. thoroughly before starting the work.

• Always wear safety shoes and helmet when performing

any operation. Do not wear loose clothes, or clothes with

buttons missing.

• Always wear the protective eyeglasses when hitting parts

with a hammer.

• Always wear the protective eyeglasses when grinding

parts with a grinder, etc.

• When performing any operation with multiple workers, always

agree on the operating procedure before starting. Be

clear in verbal communication, and observe hand signals.

Hang “UNDER REPAIR” warning tag in the operator’s

compartment Before starting work.

• Work and operation which require license or qualification

should be performed by qualified workers.

• Welding repairs should be performed by trained and experienced welders. When performing welding work,

always wear welding gloves, apron, welding goggles, cap and other clothes suited for welding work.

• Warm up before starting the work with exercise which increases alertness and the range of motion in order

to prevent injury.

• Avoid prolonged work, and take a rest at times to keep up a good condition. Take a rest at designated safe

area.

Precautions for preparatory work:

• Place the machine on a firm and level ground, and apply the parking brake and chock the wheels or tracks

to prevent the machine from moving before adding oil or making any repairs.

• Lower the work equipment (blade, ripper, bucket, etc.) to the ground before starting work. If this is not possible,

insert the lock pin or use blocks to prevent the work equipment from falling. In addition, be sure to

lock all the control levers and hang “UNDER REPAIR” warning tag on them.

• When performing the disassembling or assembling work, support the machine securely with blocks, jacks,

or stands before starting the work.

• Remove all mud and oil from the steps or other places for going up and down on the machine. Always use the handrails, ladders or steps when for going up and down on the machine. Never jump on or off the machine. When the scaffold is not provided, use steps or stepladder to secure your footing. Do not use handrails, ladders, or steps if they are damaged or deformed. Repair it or replace it immediately.

TABLE OF CONTENTS:

Komatsu PC360LCi-11 Hydraulic Excavator Shop Manual SEN06601-09 – PDF DOWNLOAD

INDEX

00 INDEX AND FOREWORD 00-1

ABBREVIATION LIST 00-22

FOREWORD, SAFETY, BASIC INFORMATION 00-28

HOW TO READ THE SHOP MANUAL 00-28

SAFETY NOTICE FOR OPERATION 00-30

PRECAUTIONS TO PREVENT FIRE 00-38

ACTIONS IF FIRE OCCURS 00-40

PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS 00-41

ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS 00-42

PRECAUTIONS FOR DEF 00-43

STORE AdBlue/DEF 00-44

PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT 00-45

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS 00-48

PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT 00-55

PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT 00-57

PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT 00-58

PRACTICAL USE OF KOMTRAX 00-59

DISCONNECT AND CONNECT PUSH-PULL TYPE COUPLER 00-60

PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS 00-64

METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR 00-68

METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR 00-69

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL 00-71

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH 00-72

METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

00-74

HOW TO READ ELECTRICAL WIRE CODE 00-75

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD 00-79

STANDARD TIGHTENING TORQUE TABLE 00-82

CONVERSION TABLE 00-89

01 SPECIFICATIONS 01-1

CONTENTS 01-2

ABBREVIATION LIST 01-3

SPECIFICATIONS 01-9

SPECIFICATION DRAWING 01-9

WORKING RANGE DRAWINGS 01-11

SPECIFICATIONS 01-12

WEIGHT TABLE 01-15

TABLE OF FUEL, COOLANT, AND LUBRICANTS 01-17

10 STRUCTURE AND FUNCTION 10-1

CONTENTS 10-2

ABBREVIATION LIST 10-6

UREA SCR SYSTEM 10-12

LAYOUT DRAWING OF UREA SCR SYSTEM 10-12

UREA SCR SYSTEM DIAGRAM 10-16

FUNCTION OF UREA SCR SYSTEM 10-17

COMPONENT PARTS OF UREA SCR SYSTEM 10-33

BOOT-UP SYSTEM 10-42

LAYOUT DRAWING OF BOOT-UP SYSTEM 10-42

SYSTEM OPERATING LAMP SYSTEM 10-44

BATTERY DISCONNECT SWITCH 10-46

ENGINE SYSTEM 10-47

LAYOUT DRAWING OF ENGINE SYSTEM 10-47

ENGINE CONTROL SYSTEM 10-49

AUTO-DECELERATION SYSTEM 10-52

ENGINE AUTOMATIC WARM-UP SYSTEM 10-54

OVERHEAT PREVENTION SYSTEM 10-56

INDEX 00 INDEX AND FOREWORD

00-2 PC360LCI-11

TURBOCHARGER PROTECTION SYSTEM 10-58

AUTOMATIC IDLE STOP SYSTEM 10-60

COMPONENT PARTS OF ENGINE SYSTEM 10-63

COOLING SYSTEM 10-81

LAYOUT DRAWING OF COOLING SYSTEM 10-81

CONTROL SYSTEM 10-83

LAYOUT DRAWING OF CONTROL SYSTEM 10-83

MACHINE MONITOR SYSTEM 10-86

KomVision SYSTEM 10-88

KOMTRAX SYSTEM 10-92

COMPONENT PARTS OF CONTROL SYSTEM 10-93

HYDRAULIC SYSTEM 10-132

LAYOUT DRAWING OF HYDRAULIC SYSTEM 10-132

CLSS 10-135

ENGINE AND PUMP COMBINED CONTROL SYSTEM 10-155

PUMP AND VALVE CONTROL SYSTEM 10-161

COMPONENT PARTS OF HYDRAULIC SYSTEM 10-164

WORK EQUIPMENT SYSTEM 10-258

LAYOUT DRAWING OF WORK EQUIPMENT SYSTEM 10-258

STRUCTURE OF VALVE CONTROL 10-263

ONE-TOUCH POWER MAXIMIZING SYSTEM 10-265

MACHINE PUSH-UP SYSTEM 10-267

PPC LOCK SYSTEM 10-269

WORK EQUIPMENT AND TRAVEL AUTOMATIC LOCK SYSTEM 10-270

OIL FLOW ADJUSTER SYSTEM FOR ATTACHMENT 10-272

COMPONENT PARTS OF WORK EQUIPMENT SYSTEM 10-274

ICT SYSTEM 10-294

LAYOUT DRAWING OF ICT SYSTEM 10-294

ICT CONTROL SYSTEM DIAGRAM 10-296

BUCKET EDGE POSITION DETECTION SYSTEM 10-297

THE INTELLIGENT MACHINE CONTROL SYSTEM 10-299

CUSHION SYSTEM FOR ARM IN END 10-315

CUSHION SYSTEM FOR BOOM RAISE END 10-317

BOOM SECONDARY DRIVE SWITCH 10-319

COMPONENT PARTS OF ICT SYSTEM 10-320

SWING SYSTEM 10-354

LAYOUT DRAWING OF SWING SYSTEM 10-354

SWING CONTROL SYSTEM DIAGRAM 10-357

COMPONENT PARTS OF SWING SYSTEM 10-361

TRAVEL SYSTEM 10-377

LAYOUT DRAWING OF TRAVEL SYSTEM 10-377

TRAVEL CONTROL SYSTEM DIAGRAM 10-381

COMPONENT PARTS OF TRAVEL SYSTEM 10-383

UNDERCARRIAGE AND FRAME 10-404

LAYOUT DRAWING OF UNDERCARRIAGE 10-404

WORK EQUIPMENT 10-405

STRUCTURE OF WORK EQUIPMENT 10-405

FUNCTION OF WORK EQUIPMENT 10-406

WORK EQUIPMENT CLEARANCE ADJUSTMENT SHIM 10-407

BUCKET CLEARANCE ADJUSTMENT SHIM 10-408

CAB AND ITS ATTACHMENTS 10-409

ROPS CAB 10-409

CAB MOUNT 10-410

CAB TIPPING STOPPER 10-411

20 STANDARD VALUE TABLE 20-1

CONTENTS 20-2

ABBREVIATION LIST 20-3

STANDARD VALUE TABLE FOR ENGINE 20-9

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-3

STANDARD VALUE TABLE FOR ENGINE: PC360LCI-11 20-9

STANDARD VALUE TABLE FOR MACHINE 20-14

STANDARD VALUE TABLE FOR MACHINE: PC360LCI-11 20-14

MACHINE POSTURE AND PROCEDURE FOR MEASURING PERFORMANCE 20-38

STANDARD VALUE TABLE FOR ELECTRICAL 20-42

STANDARD VALUE TABLE FOR ELECTRICAL 20-42

30 TESTING AND ADJUSTING 30-1

CONTENTS 30-2

ABBREVIATION LIST 30-6

RELATED INFORMATION ON TESTING AND ADJUSTING 30-12

TOOLS FOR TESTING AND ADJUSTING 30-12

SKETCH OF TOOLS FOR TESTING AND ADJUSTING 30-23

ENGINE AND COOLING SYSTEM 30-25

TEST ENGINE SPEED 30-25

TEST BOOST PRESSURE 30-29

TEST EXHAUST GAS COLOR 30-31

TEST AND ADJUST VALVE CLEARANCE 30-33

TEST COMPRESSION PRESSURE 30-36

TEST BLOWBY PRESSURE 30-39

TEST ENGINE OIL PRESSURE 30-41

TEST EGR VALVE AND VGT OIL PRESSURE 30-43

TEST FUEL PRESSURE 30-45

TEST FUEL DISCHARGE, RETURN AND LEAKAGE 30-52

BLEED AIR FROM FUEL SYSTEM 30-59

TEST FUEL CIRCUIT FOR LEAKAGE 30-60

HANDLE CYLINDER CUT-OUT MODE OPERATION 30-62

HANDLE NO-INJECTION CRANKING OPERATION 30-63

TEST AND ADJUST AIR CONDITIONER COMPRESSOR BELT TENSION 30-64

WRITE ASH IN SOOT ACCUMULATION CORRECTION TO ENGINE CONTROLLER 30-65

TEST SCR RELATED FUNCTIONS 30-66

CLEAN AdBlue/DEF TANK 30-94

POWER TRAIN 30-98

TEST SWING CIRCLE BEARING CLEARANCE 30-98

UNDERCARRIAGE AND FRAME 30-99

TEST AND ADJUST TRACK TENSION 30-99

HYDRAULIC SYSTEM 30-101

RELEASE REMAINING PRESSURE FROM HYDRAULIC SYSTEM 30-101

TEST AND ADJUST OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

30-106

TEST OIL PRESSURE OF CONTROL CIRCUIT 30-119

TEST AND ADJUST OIL PRESSURE IN PUMP PC CONTROL CIRCUIT 30-121

TEST AND ADJUST OIL PRESSURE IN PUMP LS CONTROL CIRCUIT 30-124

TEST OUTLET PRESSURE OF SOLENOID VALVE 30-129

TEST PPC VALVE OUTPUT PRESSURE 30-132

ADJUST WORK EQUIPMENT AND SWING PPC VALVES 30-134

TEST PUMP SWASH PLATE SENSOR 30-135

TEST THE PARTS CAUSING HYDRAULIC DRIFT IN WORK EQUIPMENT 30-136

TEST OIL LEAKAGE 30-138

BLEED AIR FROM HYDRAULIC CIRCUIT 30-141

TEST AND CHARGE ACCUMULATOR (MANUFACTURED BY NOK) NITROGEN GAS PRESSURE

FOR ATTACHMENT (LOW PRESSURE SIDE) 30-146

TEST AND CHARGE ACCUMULATOR NITROGEN GAS PRESSURE FOR ATTACHMENT (HIGH

PRESSURE SIDE) 30-150

REPLACE ACCUMULATOR BLADDER ON HIGH PRESSURE SIDE FOR ACCUMULATOR PIPING

30-154

CAB AND ITS ATTACHMENTS 30-161

TEST CAB TIPPING STOPPER 30-161

METHOD FOR ADJUSTING MIRRORS 30-162

INDEX 00 INDEX AND FOREWORD

00-4 PC360LCI-11

ELECTRICAL SYSTEM 30-167

SET AND OPERATE MACHINE MONITOR 30-167

METHOD FOR STARTING UP KOMTRAX TERMINAL 30-249

ADJUST REARVIEW CAMERA ANGLE 30-254

ADJUST KomVision CAMERA ANGLE 30-257

ADJUST KomVision RELATED ITEMS 30-262

HANDLE VOLTAGE CIRCUIT OF ENGINE CONTROLLER 30-281

HANDLE BATTERY DISCONNECT SWITCH 30-282

TEST DIODES 30-283

ICT SYSTEM 30-284

SET AND OPERATE CONTROL BOX 30-284

CALIBRATE INTELLIGENT MACHINE CONTROL 30-293

Pm CLINIC 30-722

Pm CLINIC SERVICE 30-722

40 TROUBLESHOOTING 40-1

CONTENTS 40-2

ABBREVIATION LIST 40-15

RELATED INFORMATION ON TROUBLESHOOTING 40-21

GENERAL TROUBLESHOOTING POINTS 40-21

TROUBLESHOOTING POINTS FOR UREA SCR SYSTEM 40-22

SEQUENCE OF EVENTS IN TROUBLESHOOTING 40-34

CHECKS BEFORE TROUBLESHOOTING 40-36

INSPECTION PROCEDURE BEFORE TROUBLESHOOTING 40-38

TESTING IN ACCORDANCE WITH TESTING PROCEDURE 40-40

PREPARATION FOR TROUBLESHOOTING OF ELECTRICAL SYSTEM 40-60

PROCEDURE FOR TESTING AND TROUBLESHOOTING 40-67

SYMPTOMS OF FAILURE AND TROUBLESHOOTING NUMBERS 40-70

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE 40-75

TROUBLESHOOTING METHOD FOR OPEN CIRCUIT IN WIRING HARNESS OF PRESSURE SENSOR

SYSTEM 40-77

CONNECTOR LIST AND LAYOUT 40-80

CONNECTOR CONTACT IDENTIFICATION 40-100

T-BRANCH BOX AND T-BRANCH ADAPTER TABLE 40-140

FUSE LOCATION TABLE 40-146

PRECAUTIONS FOR CLEANING AND REPLACING KDPF (KCSF and KDOC) 40-149

PREPARATION OF SHORT CIRCUIT ELECTRICAL CONNECTOR (FOR FAILURE CODES [CA1883]

AND [CA3135]) 40-153

FAILURE CODES TABLE 40-155

TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE) 40-176

FAILURE CODE [879AKA] 40-176

FAILURE CODE [879AKB] 40-177

FAILURE CODE [879BKA] 40-178

FAILURE CODE [879BKB] 40-180

FAILURE CODE [879CKA] 40-182

FAILURE CODE [879CKB] 40-183

FAILURE CODE [879DKZ] 40-184

FAILURE CODE [879EMC] 40-186

FAILURE CODE [879FMC] 40-187

FAILURE CODE [879GKX] 40-188

FAILURE CODE [989L00] 40-190

FAILURE CODE [989M00] 40-191

FAILURE CODE [989N00] 40-192

FAILURE CODE [A1U0N3] 40-193

FAILURE CODE [A1U0N4] 40-195

FAILURE CODE [A900FR] 40-197

FAILURE CODE [A900N6] 40-198

FAILURE CODE [A900NY] 40-199

FAILURE CODE [AA10NX] 40-200

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-5

FAILURE CODE [AB00KE] 40-202

FAILURE CODE [AQ10N3] 40-205

FAILURE CODE [AS00N3] 40-207

FAILURE CODE [AS00R2] 40-209

FAILURE CODE [AS00R3] 40-210

FAILURE CODE [AS00R4] 40-211

FAILURE CODE [AS00R5] 40-212

FAILURE CODE [AS00R6] 40-213

FAILURE CODE [AS00ZK] 40-214

FAILURE CODE [AS10KM] 40-215

FAILURE CODE [AS10NR] 40-216

FAILURE CODE [AS10NT] 40-217

FAILURE CODE [B@BAZG] 40-218

FAILURE CODE [B@BAZK] 40-219

FAILURE CODE [B@BCNS] 40-221

FAILURE CODE [B@BCQA] 40-222

FAILURE CODE [B@BCZK] 40-224

FAILURE CODE [B@HANS] 40-226

FAILURE CODE [CA115] 40-227

FAILURE CODE [CA122] 40-228

FAILURE CODE [CA123] 40-230

FAILURE CODE [CA131] 40-232

FAILURE CODE [CA132] 40-234

FAILURE CODE [CA144] 40-236

FAILURE CODE [CA145] 40-238

FAILURE CODE [CA153] 40-240

FAILURE CODE [CA154] 40-243

FAILURE CODE [CA187] 40-246

FAILURE CODE [CA221] 40-248

FAILURE CODE [CA222] 40-250

FAILURE CODE [CA227] 40-252

FAILURE CODE [CA234] 40-253

FAILURE CODE [CA238] 40-254

FAILURE CODE [CA239] 40-256

FAILURE CODE [CA249] 40-258

FAILURE CODE [CA256] 40-260

FAILURE CODE [CA271] 40-262

FAILURE CODE [CA272] 40-264

FAILURE CODE [CA281] 40-266

FAILURE CODE [CA322] 40-267

FAILURE CODE [CA323] 40-269

FAILURE CODE [CA324] 40-271

FAILURE CODE [CA325] 40-273

FAILURE CODE [CA331] 40-275

FAILURE CODE [CA332] 40-277

FAILURE CODE [CA343] 40-279

FAILURE CODE [CA351] 40-280

FAILURE CODE [CA352] 40-281

FAILURE CODE [CA356] 40-284

FAILURE CODE [CA357] 40-286

FAILURE CODE [CA386] 40-288

FAILURE CODE [CA428] 40-289

FAILURE CODE [CA429] 40-291

FAILURE CODE [CA435] 40-293

FAILURE CODE [CA441] 40-295

FAILURE CODE [CA442] 40-297

FAILURE CODE [CA449] 40-298

FAILURE CODE [CA451] 40-302

INDEX 00 INDEX AND FOREWORD

00-6 PC360LCI-11

FAILURE CODE [CA452] 40-305

FAILURE CODE [CA488] 40-307

FAILURE CODE [CA515] 40-308

FAILURE CODE [CA516] 40-310

FAILURE CODE [CA553] 40-312

FAILURE CODE [CA555] 40-313

FAILURE CODE [CA556] 40-314

FAILURE CODE [CA559] 40-315

FAILURE CODE [CA595] 40-319

FAILURE CODE [CA687] 40-320

FAILURE CODE [CA689] 40-322

FAILURE CODE [CA691] 40-327

FAILURE CODE [CA692] 40-329

FAILURE CODE [CA697] 40-331

FAILURE CODE [CA698] 40-332

FAILURE CODE [CA731] 40-333

FAILURE CODE [CA778] 40-335

FAILURE CODE [CA1117] 40-340

FAILURE CODE [CA1664] 40-341

FAILURE CODE [CA1669] 40-343

FAILURE CODE [CA1673] 40-344

FAILURE CODE [CA1677] 40-345

FAILURE CODE [CA1678] 40-346

FAILURE CODE [CA1682] 40-347

FAILURE CODE [CA1683] 40-349

FAILURE CODE [CA1684] 40-351

FAILURE CODE [CA1686] 40-353

FAILURE CODE [CA1691] 40-354

FAILURE CODE [CA1694] 40-357

FAILURE CODE [CA1695] 40-360

FAILURE CODE [CA1696] 40-361

FAILURE CODE [CA1712] 40-363

FAILURE CODE [CA1713] 40-366

FAILURE CODE [CA1714] 40-368

FAILURE CODE [CA1715] 40-369

FAILURE CODE [CA1776] 40-370

FAILURE CODE [CA1777] 40-373

FAILURE CODE [CA1843] 40-376

FAILURE CODE [CA1844] 40-378

FAILURE CODE [CA1879] 40-381

FAILURE CODE [CA1881] 40-384

FAILURE CODE [CA1883] 40-386

FAILURE CODE [CA1885] 40-389

FAILURE CODE [CA1887] 40-391

FAILURE CODE [CA1921] 40-393

FAILURE CODE [CA1922] 40-396

FAILURE CODE [CA1942] 40-401

FAILURE CODE [CA1993] 40-402

FAILURE CODE [CA2185] 40-405

FAILURE CODE [CA2186] 40-407

FAILURE CODE [CA2249] 40-409

FAILURE CODE [CA2265] 40-410

FAILURE CODE [CA2266] 40-412

FAILURE CODE [CA2271] 40-414

FAILURE CODE [CA2272] 40-417

FAILURE CODE [CA2288] 40-420

FAILURE CODE [CA2311] 40-421

FAILURE CODE [CA2349] 40-422

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-7

FAILURE CODE [CA2353] 40-425

FAILURE CODE [CA2357] 40-427

FAILURE CODE [CA2381] 40-428

FAILURE CODE [CA2382] 40-431

FAILURE CODE [CA2383] 40-434

FAILURE CODE [CA2386] 40-437

FAILURE CODE [CA2387] 40-439

FAILURE CODE [CA2555] 40-440

FAILURE CODE [CA2556] 40-443

FAILURE CODE [CA2637] 40-446

FAILURE CODE [CA2639] 40-448

FAILURE CODE [CA2771] 40-451

FAILURE CODE [CA2777] 40-457

FAILURE CODE [CA2976] 40-460

FAILURE CODE [CA3133] 40-462

FAILURE CODE [CA3134] 40-464

FAILURE CODE [CA3135] 40-466

FAILURE CODE [CA3142] 40-469

FAILURE CODE [CA3143] 40-470

FAILURE CODE [CA3144] 40-471

FAILURE CODE [CA3146] 40-473

FAILURE CODE [CA3147] 40-474

FAILURE CODE [CA3148] 40-475

FAILURE CODE [CA3151] 40-477

FAILURE CODE [CA3165] 40-483

FAILURE CODE [CA3229] 40-485

FAILURE CODE [CA3231] 40-487

FAILURE CODE [CA3232] 40-489

FAILURE CODE [CA3235] 40-493

FAILURE CODE [CA3239] 40-495

FAILURE CODE [CA3241] 40-498

FAILURE CODE [CA3242] 40-501

FAILURE CODE [CA3251] 40-504

FAILURE CODE [CA3253] 40-506

FAILURE CODE [CA3254] 40-509

FAILURE CODE [CA3255] 40-512

FAILURE CODE [CA3256] 40-516

FAILURE CODE [CA3311] 40-518

FAILURE CODE [CA3312] 40-520

FAILURE CODE [CA3313] 40-523

FAILURE CODE [CA3314] 40-524

FAILURE CODE [CA3315] 40-525

FAILURE CODE [CA3316] 40-527

FAILURE CODE [CA3317] 40-528

FAILURE CODE [CA3318] 40-529

FAILURE CODE [CA3319] 40-531

FAILURE CODE [CA3321] 40-532

FAILURE CODE [CA3322] 40-534

FAILURE CODE [CA3419] 40-536

FAILURE CODE [CA3421] 40-538

FAILURE CODE [CA3497] 40-540

FAILURE CODE [CA3498] 40-541

FAILURE CODE [CA3543] 40-542

FAILURE CODE [CA3545] 40-549

FAILURE CODE [CA3547] 40-551

FAILURE CODE [CA3558] 40-552

FAILURE CODE [CA3559] 40-554

FAILURE CODE [CA3562] 40-556

INDEX 00 INDEX AND FOREWORD

00-8 PC360LCI-11

FAILURE CODE [CA3563] 40-558

FAILURE CODE [CA3567] 40-561

FAILURE CODE [CA3568] 40-564

FAILURE CODE [CA3571] 40-568

FAILURE CODE [CA3572] 40-570

FAILURE CODE [CA3574] 40-572

FAILURE CODE [CA3575] 40-574

FAILURE CODE [CA3577] 40-576

FAILURE CODE [CA3578] 40-578

FAILURE CODE [CA3582] 40-580

FAILURE CODE [CA3583] 40-586

FAILURE CODE [CA3596] 40-588

FAILURE CODE [CA3649] 40-590

FAILURE CODE [CA3681] 40-592

FAILURE CODE [CA3682] 40-597

FAILURE CODE [CA3713] 40-603

FAILURE CODE [CA3717] 40-606

FAILURE CODE [CA3718] 40-607

FAILURE CODE [CA3725] 40-608

FAILURE CODE [CA3741] 40-611

FAILURE CODE [CA3748] 40-612

FAILURE CODE [CA3751] 40-614

FAILURE CODE [CA3755] 40-616

FAILURE CODE [CA3866] 40-618

FAILURE CODE [CA3867] 40-622

FAILURE CODE [CA3868] 40-625

FAILURE CODE [CA3899] 40-629

FAILURE CODE [CA3911] 40-631

FAILURE CODE [CA3912] 40-635

FAILURE CODE [CA3932] 40-637

FAILURE CODE [CA3933] 40-639

FAILURE CODE [CA3934] 40-641

FAILURE CODE [CA3935] 40-644

FAILURE CODE [CA3936] 40-646

FAILURE CODE [CA4151] 40-648

FAILURE CODE [CA4152] 40-652

FAILURE CODE [CA4155] 40-656

FAILURE CODE [CA4156] 40-658

FAILURE CODE [CA4157] 40-661

FAILURE CODE [CA4158] 40-663

FAILURE CODE [CA4159] 40-664

FAILURE CODE [CA4161] 40-665

FAILURE CODE [CA4162] 40-668

FAILURE CODE [CA4163] 40-671

FAILURE CODE [CA4164] 40-673

FAILURE CODE [CA4165] 40-675

FAILURE CODE [CA4166] 40-677

FAILURE CODE [CA4168] 40-679

FAILURE CODE [CA4169] 40-682

FAILURE CODE [CA4171] 40-684

FAILURE CODE [CA4249] 40-687

FAILURE CODE [CA4251] 40-689

FAILURE CODE [CA4259] 40-691

FAILURE CODE [CA4261] 40-694

FAILURE CODE [CA4277] 40-697

FAILURE CODE [CA4281] 40-701

FAILURE CODE [CA4459] 40-704

FAILURE CODE [CA4461] 40-707

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-9

FAILURE CODE [CA4658] 40-710

FAILURE CODE [CA4731] 40-714

FAILURE CODE [CA4732] 40-715

FAILURE CODE [CA4739] 40-716

FAILURE CODE [CA4768] 40-717

FAILURE CODE [CA4769] 40-719

FAILURE CODE [CA4842] 40-722

FAILURE CODE [CA4952] 40-726

FAILURE CODE [CA5115] 40-728

FAILURE CODE [CA5179] 40-731

FAILURE CODE [CA5181] 40-733

FAILURE CODE [CA5383] 40-735

FAILURE CODE [D110KB] 40-737

FAILURE CODE [D19JKZ] 40-739

FAILURE CODE [D811MC] 40-741

FAILURE CODE [D862KA] 40-742

FAILURE CODE [D8ALKA] 40-743

FAILURE CODE [D8ALKB] 40-745

FAILURE CODE [D8AQKR] 40-747

FAILURE CODE [DA20MC] 40-749

FAILURE CODE [DA22KK] 40-750

FAILURE CODE [DA25KP] 40-753

FAILURE CODE [DA29KQ] 40-755

FAILURE CODE [DA2LKA] 40-757

FAILURE CODE [DA2LKB] 40-759

FAILURE CODE [DA2QKR] 40-761

FAILURE CODE [DA2RKR] 40-764

FAILURE CODE [DAF0MB] 40-766

FAILURE CODE [DAF0MC] 40-767

FAILURE CODE [DAF8KB] 40-768

FAILURE CODE [DAF9KQ] 40-770

FAILURE CODE [DAFGMC] 40-771

FAILURE CODE [DAFLKA] 40-772

FAILURE CODE [DAFLKB] 40-774

FAILURE CODE [DAFQKR] 40-776

FAILURE CODE [DAZ9KQ] 40-777

FAILURE CODE [DAZQKR] 40-778

FAILURE CODE [DB2QKR] 40-783

FAILURE CODE [DB2RKR] 40-788

FAILURE CODE [DB90MC] 40-793

FAILURE CODE [DB92KK] 40-794

FAILURE CODE [DB95KP] 40-796

FAILURE CODE [DB96KP] 40-800

FAILURE CODE [DB99KQ] 40-804

FAILURE CODE [DB9LKA] 40-807

FAILURE CODE [DB9LKB] 40-809

FAILURE CODE [DB9QKR] 40-811

FAILURE CODE [DB9RKR] 40-818

FAILURE CODE [DBP0KM] 40-824

FAILURE CODE [DBP0KT] 40-825

FAILURE CODE [DBPQKR] 40-826

FAILURE CODE [DBR0MC] 40-831

FAILURE CODE [DBR2KK] 40-832

FAILURE CODE [DBR5KP] 40-835

FAILURE CODE [DBR6KP] 40-837

FAILURE CODE [DBR9KQ] 40-839

FAILURE CODE [DBRLKA] 40-842

FAILURE CODE [DBRLKB] 40-844

INDEX 00 INDEX AND FOREWORD

00-10 PC360LCI-11

FAILURE CODE [DBRQKR] 40-846

FAILURE CODE [DBRRKR] 40-853

FAILURE CODE [DBRSKB] 40-859

FAILURE CODE [DBRTKB] 40-861

FAILURE CODE [DBUSKR] 40-863

FAILURE CODE [DD20MA] 40-867

FAILURE CODE [DDNRKA] 40-870

FAILURE CODE [DDNRKY] 40-872

FAILURE CODE [DDNS00] 40-874

FAILURE CODE [DGH2KB] 40-876

FAILURE CODE [DHA4KA] 40-878

FAILURE CODE [DHAAMA] 40-880

FAILURE CODE [DHACMA] 40-882

FAILURE CODE [DHPAMA] 40-884

FAILURE CODE [DHPBMA] 40-887

FAILURE CODE [DHS3MA] 40-890

FAILURE CODE [DHS4MA] 40-893

FAILURE CODE [DHS8MA] 40-896

FAILURE CODE [DHS9MA] 40-899

FAILURE CODE [DHSAMA] 40-902

FAILURE CODE [DHSBMA] 40-905

FAILURE CODE [DHSCMA] 40-908

FAILURE CODE [DHSDMA] 40-911

FAILURE CODE [DHSFMA] 40-914

FAILURE CODE [DHSGMA] 40-917

FAILURE CODE [DHSHMA] 40-920

FAILURE CODE [DHSJMA] 40-923

FAILURE CODE [DK80KM] 40-926

FAILURE CODE [DK80KR] 40-927

FAILURE CODE [DK80KT] 40-933

FAILURE CODE [DKG1KM] 40-934

FAILURE CODE [DKG1L8] 40-935

FAILURE CODE [DKR0MA] 40-936

FAILURE CODE [DKR1MA] 40-939

FAILURE CODE [DKT0KM] 40-942

FAILURE CODE [DKT0L8] 40-943

FAILURE CODE [DKT1KA] 40-944

FAILURE CODE [DKT1KB] 40-946

FAILURE CODE [DKT2KA] 40-948

FAILURE CODE [DKT2KB] 40-950

FAILURE CODE [DKT4KM] 40-952

FAILURE CODE [DKT4L8] 40-953

FAILURE CODE [DKT5KA] 40-954

FAILURE CODE [DKT5KB] 40-956

FAILURE CODE [DKT6KA] 40-958

FAILURE CODE [DKT6KB] 40-960

FAILURE CODE [DKT8KA] 40-962

FAILURE CODE [DKT8KB] 40-964

FAILURE CODE [DKT9KA] 40-966

FAILURE CODE [DKT9KB] 40-968

FAILURE CODE [DKTAKA] 40-970

FAILURE CODE [DKTAKB] 40-972

FAILURE CODE [DKTAMB] 40-974

FAILURE CODE [DKTBKX] 40-975

FAILURE CODE [DKTBMC] 40-977

FAILURE CODE [DKTEMB] 40-978

FAILURE CODE [DKTFKX] 40-980

FAILURE CODE [DKTFMC] 40-982

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-11

FAILURE CODE [DKTJMB] 40-983

FAILURE CODE [DKU1MA] 40-985

FAILURE CODE [DKU2MA] 40-986

FAILURE CODE [DKUGKA] 40-987

FAILURE CODE [DKUGKB] 40-989

FAILURE CODE [DKUGKY] 40-991

FAILURE CODE [DKUHKA] 40-993

FAILURE CODE [DKUHKB] 40-995

FAILURE CODE [DKUHKY] 40-997

FAILURE CODE [DKULKA] 40-999

FAILURE CODE [DKULKB] 40-1001

FAILURE CODE [DKULKY] 40-1003

FAILURE CODE [DKV0KA] 40-1004

FAILURE CODE [DKV0KY] 40-1007

FAILURE CODE [DKV1KA] 40-1009

FAILURE CODE [DKV1KY] 40-1011

FAILURE CODE [DKV2KA] 40-1013

FAILURE CODE [DKV2KY] 40-1015

FAILURE CODE [DKV3KA] 40-1017

FAILURE CODE [DKV3KY] 40-1019

FAILURE CODE [DKV4MA] 40-1021

FAILURE CODE [DKV5MA] 40-1024

FAILURE CODE [DKV6MA] 40-1027

FAILURE CODE [DKV7MA] 40-1030

FAILURE CODE [DKV8MA] 40-1033

FAILURE CODE [DKV9MA] 40-1036

FAILURE CODE [DKVAMA] 40-1039

FAILURE CODE [DKVBKA] 40-1042

FAILURE CODE [DKVBKB] 40-1044

FAILURE CODE [DKVBKY] 40-1046

FAILURE CODE [DKVCKA] 40-1048

FAILURE CODE [DKVCKB] 40-1050

FAILURE CODE [DKVCKY] 40-1052

FAILURE CODE [DKVDKA] 40-1054

FAILURE CODE [DKVDKB] 40-1056

FAILURE CODE [DKVDKY] 40-1058

FAILURE CODE [DKVDMA] 40-1060

FAILURE CODE [DR10KA] 40-1061

FAILURE CODE [DR21KX] 40-1064

FAILURE CODE [DR31KX] 40-1066

FAILURE CODE [DUMBKA] 40-1068

FAILURE CODE [DUMBKB] 40-1070

FAILURE CODE [DV20KB] 40-1072

FAILURE CODE [DW43KA] 40-1074

FAILURE CODE [DW43KB] 40-1076

FAILURE CODE [DW43KY] 40-1078

FAILURE CODE [DW45KA] 40-1080

FAILURE CODE [DW45KB] 40-1083

FAILURE CODE [DW45KY] 40-1086

FAILURE CODE [DW4CKY] 40-1088

FAILURE CODE [DW4FKA] 40-1089

FAILURE CODE [DW4FKB] 40-1092

FAILURE CODE [DW4FKY] 40-1094

FAILURE CODE [DW4GKA] 40-1096

FAILURE CODE [DW4GKB] 40-1099

FAILURE CODE [DW4GKY] 40-1101

FAILURE CODE [DW4SKA] 40-1103

FAILURE CODE [DW4SKB] 40-1105

INDEX 00 INDEX AND FOREWORD

00-12 PC360LCI-11

FAILURE CODE [DW4SKY] 40-1107

FAILURE CODE [DW91KA] 40-1109

FAILURE CODE [DW91KB] 40-1111

FAILURE CODE [DW91KY] 40-1113

FAILURE CODE [DWA2KA] 40-1115

FAILURE CODE [DWA2KB] 40-1117

FAILURE CODE [DWA2KY] 40-1119

FAILURE CODE [DWK0KA] 40-1121

FAILURE CODE [DWK0KB] 40-1123

FAILURE CODE [DWK0KY] 40-1125

FAILURE CODE [DWK2KA] 40-1127

FAILURE CODE [DWK2KB] 40-1129

FAILURE CODE [DWK2KY] 40-1131

FAILURE CODE [DWK8KA] 40-1133

FAILURE CODE [DWK8KB] 40-1135

FAILURE CODE [DWK8KY] 40-1137

FAILURE CODE [DXA8KA] 40-1139

FAILURE CODE [DXA8KB] 40-1142

FAILURE CODE [DXA9KA] 40-1144

FAILURE CODE [DXA9KB] 40-1147

FAILURE CODE [DXE0KA] 40-1149

FAILURE CODE [DXE0KB] 40-1151

FAILURE CODE [DXE4KA] 40-1153

FAILURE CODE [DXE4KB] 40-1155

FAILURE CODE [DXE4KY] 40-1157

FAILURE CODE [DXE5KA] 40-1158

FAILURE CODE [DXE5KB] 40-1160

FAILURE CODE [DXE6KA] 40-1162

FAILURE CODE [DXE6KB] 40-1164

FAILURE CODE [DXE7KA] 40-1166

FAILURE CODE [DXE7KB] 40-1168

FAILURE CODE [DXE7KY] 40-1170

FAILURE CODE [DXE8KA] 40-1172

FAILURE CODE [DXE8KB] 40-1174

FAILURE CODE [DXE8KY] 40-1176

FAILURE CODE [DXE9KA] 40-1178

FAILURE CODE [DXE9KB] 40-1180

FAILURE CODE [DXE9KY] 40-1182

FAILURE CODE [DXEAKA] 40-1184

FAILURE CODE [DXEAKB] 40-1186

FAILURE CODE [DXEAKY] 40-1188

FAILURE CODE [DY20KA] 40-1190

FAILURE CODE [DY20MA] 40-1193

FAILURE CODE [DY2CKB] 40-1195

FAILURE CODE [DY2DKB] 40-1198

FAILURE CODE [DY2EKB] 40-1200

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE) 40-1202

E-1 ENGINE DOES NOT START (ENGINE DOES NOT CRANK) 40-1202

E-2 MANUAL PREHEATING SYSTEM DOES NOT WORK 40-1208

E-3 AUTOMATIC PREHEATING SYSTEM DOES NOT WORK 40-1211

E-4 WHILE PREHEATING IS WORKING, PREHEATING MONITOR DOES NOT LIGHT UP 40-1213

E-5 WHEN STARTING SWITCH IS TURNED TO ON POSITION, MACHINE MONITOR DISPLAYS

NOTHING 40-1215

E-6 WHILE STARTING SWITCH IS TURNED TO ON POSITION (WITH ENGINE STOPPED), ENGINE

OIL LEVEL MONITOR LIGHTS UP IN YELLOW 40-1218

E-7 WHILE STARTING SWITCH IS TURNED TO ON POSITION (WITH ENGINE STOPPED), RADIATOR

COOLANT LEVEL MONITOR LIGHTS UP IN YELLOW 40-1219

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-13

E-8 ENGINE COOLANT TEMPERATURE MONITOR LIGHTS UP IN WHITE WHILE ENGINE IS RUNNING

40-1220

E-9 HYDRAULIC OIL TEMPERATURE MONITOR LIGHTS UP IN WHITE WHILE ENGINE IS RUNNING

40-1221

E-10 AIR CLEANER CLOGGING MONITOR LIGHTS UP IN YELLOW WHILE ENGINE IS RUNNING

40-1222

E-11 CHARGE LEVEL MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING 40-1223

E-12 FUEL LEVEL MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING 40-1224

E-13 WATER SEPARATOR MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING 40-1225

E-14 ENGINE COOLANT TEMPERATURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

40-1226

E-15 ENGINE OIL PRESSURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING 40-1227

E-16 HYDRAULIC OIL TEMPERATURE MONITOR LIGHTS UP IN RED WHILE ENGINE IS RUNNING

40-1228

E-17 FUEL GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM OR MAXIMUM 40-1229

E-18 DISPLAY OF FUEL GAUGE DIFFERS FROM ACTUAL FUEL LEVEL 40-1231

E-19 ENGINE COOLANT TEMPERATURE GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM

OR MAXIMUM 40-1232

E-20 DISPLAY OF ENGINE COOLANT TEMPERATURE GAUGE DIFFERS FROM ACTUAL COOLANT

TEMPERATURE 40-1233

E-21 HYDRAULIC OIL TEMPERATURE GAUGE DISPLAY DOES NOT MOVE FROM MINIMUM OR

MAXIMUM 40-1234

E-22 DISPLAY OF HYDRAULIC OIL TEMPERATURE GAUGE DIFFERS FROM ACTUAL OIL TEMPERATURE

40-1236

E-23 SOME AREAS OF MACHINE MONITOR SCREEN ARE NOT DISPLAYED 40-1237

E-24 FUNCTION SWITCH DOES NOT OPERATE 40-1238

E-25 AUTOMATIC WARM-UP SYSTEM DOES NOT WORK (IN COLD WEATHER) 40-1239

E-26 WHEN AUTO-DECELERATOR SWITCH IS OPERATED, AUTO-DECELERATOR MONITOR

DOES NOT LIGHT UP OR DOES NOT GO OFF 40-1240

E-27 AUTO-DECELERATOR IS NOT OPERATED OR CANCELED WITH LEVER 40-1241

E-28 WHEN WORKING MODE SWITCH IS OPERATED, WORKING MODE SELECTION SCREEN IS

NOT DISPLAYED 40-1242

E-29 WHEN WORKING MODE IS CHANGED, SETTING OF ENGINE AND HYDRAULIC PUMP IS

NOT CHANGED 40-1243

E-30 WHEN TRAVEL SPEED SWITCH IS OPERATED, TRAVEL SPEED MONITOR DOES NOT

CHANGE 40-1244

E-31 WHEN TRAVEL SPEED SELECTION IS CHANGED, ACTUAL TRAVEL SPEED DOES NOT

CHANGE 40-1245

E-32 ALARM BUZZER CANNOT BE CANCELED 40-1247

E-33 SERVICE METER IS NOT DISPLAYED, WHILE STARTING SWITCH IS IN OFF POSITION

40-1248

E-34 SERVICE MODE CANNOT BE SELECTED 40-1249

E-35 ALL OF WORK EQUIPMENTS, SWING, AND TRAVEL MECHANISM DO NOT MOVE 40-1250

E-36 ALL OF WORK EQUIPMENT, SWING, AND TRAVEL MECHANISM DO NOT LOCK 40-1252

E-37 WHEN SWING BRAKE CANCEL SWITCH IS SET TO CANCEL POSITION, MACHINE CANNOT

SWING 40-1253

E-38 WHEN SWING BRAKE CANCEL SWITCH IS SET TO NORMAL POSITION, SWING HOLDING

BRAKE DOES NOT OPERATE 40-1256

E-39 ONE-TOUCH POWER MAXIMIZING FUNCTION DOES NOT OPERATE PROPERLY, OR INDICATOR

NOT DISPLAYED ON MONITOR 40-1258

E-40 ONE-TOUCH POWER MAXIMIZING FUNCTION IS NOT CANCELLED 40-1260

E-41 ALARM DOES NOT SOUND DURING TRAVEL 40-1261

E-42 ALARM DOES NOT STOP SOUNDING WHILE MACHINE IS STOPPED 40-1263

E-43 HORN DOES NOT SOUND 40-1264

E-44 HORN DOES NOT STOP SOUNDING 40-1268

E-45 WHEN WIPER SWITCH IS OPERATED, WIPER MONITOR DOES NOT LIGHT UP OR GO OFF

40-1270

E-46 WHEN WIPER SWITCH IS OPERATED, WINDSHIELD WIPER DOES NOT OPERATE 40-1271

INDEX 00 INDEX AND FOREWORD

00-14 PC360LCI-11

E-47 WHEN WINDOW WASHER SWITCH IS OPERATED, WINDOW WASHER DOES NOT OPERATE

40-1273

E-48 BOOM RAISE INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1274

E-49 BOOM LOWER INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1275

E-50 ARM OUT INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1276

E-51 ARM IN INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION 40-1277

E-52 BUCKET DUMP INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1278

E-53 BUCKET CURL INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1279

E-54 SWING INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION 40-1280

E-55 TRAVEL INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION40-1281

E-56 SERVICE INDICATOR IS NOT DISPLAYED PROPERLY WITH MONITORING FUNCTION

40-1282

E-57 ATTACHMENT HYDRAULIC CIRCUIT CANNOT BE CHANGED 40-1284

E-58 KOMTRAX SYSTEM DOES NOT OPERATE NORMALLY 40-1285

E-59 MACHINE PUSH-UP FUNCTION CANNOT BE CANCELED 40-1286

E-60 MACHINE PUSH-UP FUNCTION DOES NOT OPERATE 40-1288

E-61 CONTROL BOX SHUTS DOWN AFTER DISPLAYING THE MESSAGES [GPS receiver not connected

!] AND [Slope sensor not connected !] 40-1289

E-62 CONTROL BOX DISPLAYS THE MESSAGE [GPS receiver not connected!] 40-1294

E-63 CONTROL BOX DISPLAYS THE MESSAGE [Waiting for radio link ] 40-1298

E-64 CONTROL BOX DISPLAYS THE MESSAGE [Tilt Bucket Sensor Offline!] 40-1299

E-65 CONTROL BOX DISPLAYS THE MESSAGE [Waiting for satellites ] 40-1300

E-66 CONTROL BOX DISPLAYS THE MESSAGE [Komatsu controller not connected!] 40-1301

E-67 CONTROL BOX DISPLAYS THE MESSAGE [Sensors are invalid] 40-1304

E-68 CONTROL BOX DISPLAYS THE MESSAGE [Waiting to initialize ] 40-1307

E-69 CONTROL BOX DISPLAYS THE MESSAGE [Initializing ] 40-1308

E-70 CONTROL BOX DISPLAYS THE MESSAGE [No GPS Localization ] 40-1309

E-71 CONTROL BOX DISPLAYS THE MESSAGE [Low precisions ] 40-1310

E-72 CONTROL BOX DISPLAYS [Out of design area ] 40-1311

E-73 CONTROL BOX DISPLAYS THE MESSAGE [Avoidance Area Breach!] 40-1312

E-74 CONTROL BOX CAN NOT BE TURNED ON 40-1313

E-75 CONTROL BOX DOES NOT DISPLAY INTELLIGENT MACHINE CONTROL SCREEN 40-1314

E-76 CONTROL BOX DOES NOT DISPLAY HYDRAULIC EXCAVATOR IMAGE 40-1315

E-77 CONTROL BOX DOES NOT DISPLAY DESIGN SURFACE 40-1316

E-78 CONTROL BOX TOUCH PANEL DOES NOT RESPOND 40-1317

E-79 CONTROL BOX TOUCH PANEL IS INACCURATE 40-1318

E-80 WHEN CHECKING AND ADJUSTING THE BUCKET EDGE POSITION, THE VALUE IS DIFFERENT

FROM ACTUAL MACHINE 40-1319

E-81 SEMI-AUTO MODE IS NOT DISPLAYED WHEN AUTO/MANUAL SWITCH IS PRESSED40-1321

E-82 AUTO GRADE ASSIST CONTROL DOES NOT OPERATE WHILE SEMI-AUTO MODE IS DISPLAYED

40-1322

E-83 AUTO STOP CONTROL DOES NOT OPERATE WHILE SEMI-AUTO MODE IS DISPLAYED

40-1323

E-84 BLADE EDGE POSITION ON DESIGN SURFACE IS NOT ACCURATE WHEN AUTO GRADE

ASSIST FUNCTION IS ON 40-1324

E-85 BLADE EDGE STOP POSITION IS NOT ACCURATE FOR DESIGN SURFACE WHEN AUTO

STOP CONTROL FUNCTION IS ON 40-1326

E-86 FACING ANGLE COMPASS DOES NOT BECOME PERPENDICULAR TO TARGET 40-1328

E-87 NG OCCURS VERY OFTEN IN IMU CALIBRATION DIAGNOSIS 40-1329

E-88 CUSHION FOR BOOM RAISE END DOES NOT WORK OR IS WEAK 40-1330

E-89 CUSHION FOR ARM IN END DOES NOT WORK OR IS WEAK 40-1331

TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE) 40-1334

INFORMATION MENTIONED IN TROUBLESHOOTING TABLE (H MODE) 40-1334

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-15

SYSTEM CHART OF HYDRAULIC AND MECHANICAL SYSTEMS 40-1335

FAILURE MODE AND CAUSE TABLE 40-1337

H-1 ALL WORK EQUIPMENT, SWING AND TRAVEL DO NOT WORK 40-1346

H-2 ALL WORK EQUIPMENT, SWING AND TRAVEL LACK SPEED AND POWER 40-1347

H-3 FINE CONTROL PERFORMANCE OR RESPONSE IS POOR 40-1350

H-4 UNUSUAL NOISE IS HEARD FROM AROUND HYDRAULIC PUMP 40-1351

H-5 ENGINE SPEED DROPS LARGELY OR ENGINE STOPS 40-1352

H-6 SPEED OR POWER OF BOOM IS LOW 40-1354

H-7 ARM SPEED OR POWER IS LOW 40-1360

H-8 BUCKET SPEED OR POWER IS LOW 40-1365

H-9 WORK EQUIPMENT DOES NOT MOVE IN SINGLE OPERATION 40-1368

H-10 HYDRAULIC DRIFT OF BOOM IS LARGE 40-1369

H-11 HYDRAULIC DRIFT OF ARM IS LARGE 40-1371

H-12 HYDRAULIC DRIFT OF BUCKET IS LARGE 40-1373

H-13 WHEN SINGLE WORK EQUIPMENT IS RELIEVED HYDRAULICALLY, OTHER WORK EQUIPMENT

MOVES 40-1374

H-14 TIME LAG OF WORK EQUIPMENT IS LARGE 40-1375

H-15 ONE-TOUCH POWER MAXIMIZING FUNCTION DOES NOT OPERATE 40-1376

H-16 MACHINE PUSH-UP FUNCTION DOES NOT OPERATE 40-1377

H-17 ATTACHMENT CIRCUIT CANNOT BE CHANGED 40-1378

H-18 OIL FLOW IN ATTACHMENT CIRCUIT CANNOT BE CHANGED 40-1379

H-19 IN COMBINED OPERATION OF WORK EQUIPMENT, EQUIPMENT HAVING HEAVIER LOAD

MOVES SLOWER 40-1380

H-20 IN COMBINED OPERATION OF SWING AND TRAVEL, TRAVEL SPEED DROPS LARGELY

40-1381

H-21 IN COMBINED OPERATION OF SWING AND BOOM RAISE, BOOM RISING SPEED IS LOW

40-1382

H-22 MACHINE DOES NOT TRAVEL STRAIGHT 40-1383

H-23 MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW 40-1385

H-24 TRAVEL SPEED IS LOW 40-1388

H-25 ONE OF TRACKS DOES NOT RUN 40-1390

H-26 TRAVEL SPEED DOES NOT CHANGE, OR TRAVEL SPEED IS TOO SLOW OR FAST 40-1392

H-27 UPPER STRUCTURE DOES NOT SWING BOTH TO THE RIGHT AND LEFT 40-1393

H-28 SWINGS ONLY IN ONE DIRECTION 40-1394

H-29 SWING ACCELERATION OR SWING SPEED IS LOW IN BOTH DIRECTIONS (RIGHT AND

LEFT) 40-1395

H-30 SWING ACCELERATION PERFORMANCE IS POOR OR SWING SPEED IS SLOW IN ONLY

ONE DIRECTION 40-1396

H-31 UPPER STRUCTURE OVERRUNS EXCESSIVELY WHEN IT STOPS SWINGING (BOTH

RIGHT AND LEFT) 40-1397

H-32 UPPER STRUCTURE OVERRUNS EXCESSIVELY WHEN IT STOPS SWINGING (ONLY ONE

DIRECTION EITHER RIGHT OR LEFT) 40-1398

H-33 SHOCK IS LARGE WHEN UPPER STRUCTURE STOPS SWINGING 40-1399

H-34 LARGE UNUSUAL NOISE IS HEARD WHEN UPPER STRUCTURE STOPS SWINGING40-1400

H-35 SWING DRIFT ON A SLOPE IS LARGE (WHILE SWING PARKING BRAKE IS APPLIED)40-1401

H-36 SWING DRIFT ON A SLOPE IS LARGE (WHILE SWING PARKING BRAKE IS RELEASED)

40-1402

TROUBLESHOOTING OF ENGINE (S-MODE) 40-1403

INFORMATION MENTIONED IN TROUBLESHOOTING TABLE (S MODE) 40-1403

S-1 ENGINE DOES NOT CRANK WHEN STARTING SWITCH IS TURNED TO START POSITION

40-1404

S-2 ENGINE CRANKS BUT NO EXHAUST GAS COMES OUT 40-1405

S-3 FUEL IS BEING INJECTED BUT ENGINE DOES NOT START (MISFIRING: ENGINE CRANKS

BUT DOES NOT START) 40-1406

S-4 ENGINE STARTABILITY IS POOR 40-1408

S-5 ENGINE DOES NOT PICK UP SMOOTHLY 40-1410

S-6 ENGINE STOPS DURING OPERATION 40-1412

S-7 ENGINE RUNS ROUGH OR IS UNSTABLE 40-1414

INDEX 00 INDEX AND FOREWORD

00-16 PC360LCI-11

S-8 ENGINE LACKS POWER 40-1415

S-9 KDPF GETS CLOGGED IN A SHORT TIME 40-1417

S-10 ENGINE OIL CONSUMPTION IS EXCESSIVE 40-1419

S-11 OIL BECOMES CONTAMINATED QUICKLY 40-1420

S-12 FUEL CONSUMPTION IS EXCESSIVE 40-1421

S-13 OIL IS IN COOLANT (OR COOLANT SPURTS BACK OR COOLANT LEVEL GOES DOWN)

40-1422

S-14 OIL PRESSURE DROPS 40-1423

S-15 FUEL MIXES INTO ENGINE OIL 40-1425

S-16 WATER MIXES INTO ENGINE OIL (MILKY) 40-1426

S-17 COOLANT TEMPERATURE RISES TOO HIGH (OVERHEATING) 40-1427

S-18 UNUSUAL NOISE IS HEARD 40-1428

S-19 VIBRATION IS EXCESSIVE 40-1429

S-20 AIR CANNOT BE BLED FROM FUEL CIRCUIT 40-1430

S-21 ACTIVE REGENERATION IS EXECUTED FREQUENTLY 40-1431

S-22 ACTIVE REGENERATION TAKES TIME 40-1433

S-23 WHITE SMOKE IS EXHAUSTED DURING ACTIVE REGENERATION 40-1434

S-24 AdBlue/DEF CONSUMPTION IS EXCESSIVE 40-1435

S-25 THERE IS UNUSUAL SMELL (IRRITATING ODOR) 40-1437

S-26 FOREIGN MATERIALS ENTER AdBlue/DEF (AdBlue/DEF INCREASES) 40-1438

50 DISASSEMBLY AND ASSEMBLY 50-1

CONTENTS 50-2

ABBREVIATION LIST 50-8

RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY 50-14

HOW TO READ THIS MANUAL 50-14

COATING MATERIALS LIST 50-16

SPECIAL TOOLS LIST 50-20

SKETCHES OF SPECIAL TOOLS 50-35

ENGINE AND COOLING SYSTEM 50-44

REMOVE AND INSTALL SUPPLY PUMP ASSEMBLY 50-44

REMOVE AND INSTALL INJECTOR ASSEMBLY 50-57

REMOVE AND INSTALL CYLINDER HEAD ASSEMBLY 50-76

REMOVE AND INSTALL EGR VALVE ASSEMBLY 50-104

REMOVE AND INSTALL EGR COOLER ASSEMBLY 50-107

REMOVE AND INSTALL STARTER ASSEMBLY 50-111

REMOVE AND INSTALL ALTERNATOR BELT 50-113

REMOVE AND INSTALL RADIATOR ASSEMBLY 50-119

REMOVE AND INSTALL HYDRAULIC OIL COOLER ASSEMBLY 50-123

REMOVE AND INSTALL AFTERCOOLER ASSEMBLY 50-128

REMOVE AND INSTALL ENGINE AND MAIN PUMP ASSEMBLY 50-131

REMOVE AND INSTALL ENGINE FRONT OIL SEAL 50-159

REMOVE AND INSTALL ENGINE REAR OIL SEAL 50-167

REMOVE AND INSTALL ENGINE HOOD ASSEMBLY 50-176

REMOVE AND INSTALL FUEL TANK ASSEMBLY 50-180

REMOVE AND INSTALL AdBlue/DEF TANK ASSEMBLY 50-189

REMOVE AND INSTALL AdBlue/DEF TANK SENSOR FLANGE ASSEMBLY 50-200

REMOVE AND INSTALL AdBlue/DEF TANK SENSOR 50-201

REMOVE AND INSTALL AdBlue/DEF TANK STRAINER 50-214

REMOVE AND INSTALL AdBlue/DEF TANK FILLER PORT FILTER 50-215

REMOVE AND INSTALL KDPF ASSEMBLY 50-220

DISASSEMBLE AND ASSEMBLE OF KDPF ASSEMBLY 50-227

REMOVE AND INSTALL SCR ASSEMBLY 50-236

REMOVE AND INSTALL KDPF, SCR ASSEMBLY 50-242

REMOVE AND INSTALL KDPF, SCR ASSEMBLY BRACKET 50-256

REMOVE AND INSTALL KCCV ASSEMBLY 50-264

REMOVE AND INSTALL AdBlue/DEF MIXING TUBE 50-267

REMOVE AND INSTALL AdBlue/DEF INJECTOR 50-275

REMOVE AND INSTALL AdBlue/DEF PUMP 50-282

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-17

REMOVE AND INSTALL AdBlue/DEF HOSE 50-288

REMOVE AND INSTALL AIR CLEANER ASSEMBLY 50-303

REMOVE AND INSTALL AIR CONDITIONER COMPRESSOR ASSEMBLY 50-307

REMOVE AND INSTALL AIR CONDITIONER CONDENSER ASSEMBLY 50-310

POWER TRAIN 50-312

REMOVE AND INSTALL TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY 50-312

DISASSEMBLE AND ASSEMBLE FINAL DRIVE ASSEMBLY 50-315

REMOVE AND INSTALL SWING MOTOR AND SWING MACHINERY ASSEMBLY 50-328

DISASSEMBLE AND ASSEMBLE SWING MACHINERY ASSEMBLY 50-331

REMOVE AND INSTALL SWING CIRCLE ASSEMBLY 50-341

UNDERCARRIAGE AND FRAME 50-343

SEPARATION AND CONNECTION OF TRACK ASSEMBLY 50-343

REMOVE AND INSTALL SPROCKET 50-348

REMOVE AND INSTALL IDLER AND IDLER CUSHION ASSEMBLY 50-350

DISASSEMBLE AND ASSEMBLE IDLER ASSEMBLY 50-352

DISASSEMBLE AND ASSEMBLE OF IDLER CUSHION ASSEMBLY 50-357

DISASSEMBLE AND ASSEMBLE TRACK ROLLER ASSEMBLY 50-360

DISASSEMBLEAND ASSEMBLE CARRIER ROLLER ASSEMBLY 50-364

REMOVE AND INSTALL REVOLVING FRAME ASSEMBLY 50-368

REMOVE AND INSTALL COUNTERWEIGHT ASSEMBLY 50-375

HYDRAULIC SYSTEM 50-379

REMOVE AND INSTALL CENTER SWIVEL JOINT ASSEMBLY 50-379

DISASSEMBLE AND ASSEMBLE CENTER SWIVEL JOINT ASSEMBLY 50-383

REMOVE AND INSTALL HYDRAULIC TANK ASSEMBLY 50-386

REMOVE AND INSTALL MAIN PUMP ASSEMBLY 50-396

REMOVE AND INSTALL JUNCTION BLOCK ASSEMBLY FOR INTELLIGENT MACHINE CONTROL

50-402

REMOVE AND INSTALL PRESSURE SENSOR FOR INTELLIGENT MACHINE CONTROL 50-407

REMOVE AND INSTALL BOOM SPOOL STROKE SENSOR 50-413

REMOVE AND INSTALL ARM SPOOL STROKE SENSOR 50-415

REMOVE AND INSTALL JUNCTION BLOCK BYPASS ADAPTER FOR INTELLIGENT MACHINE

CONTROL 50-419

REMOVE AND INSTALL CONTROL VALVE ASSEMBLY 50-423

DISASSEMBLE AND ASSEMBLE CONTROL VALVE ASSEMBLY 50-435

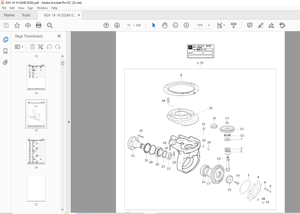

DISASSEMBLE AND ASSEMBLE WORK EQUIPMENT PPC VALVE ASSEMBLY 50-442

DISASSEMBLE AND ASSEMBLE TRAVEL PPC VALVE ASSEMBLY 50-445

WORK EQUIPMENT 50-448

REMOVE AND INSTALL BUCKET ASSEMBLY 50-448

REMOVE AND INSTALL ARM ASSEMBLY 50-450

REMOVE AND INSTALL WORK EQUIPMENT ASSEMBLY 50-456

DISASSEMBLE AND ASSEMBLE STROKE SENSING BOOM CYLINDER ASSEMBLY 50-465

DISASSEMBLE AND ASSEMBLE STROKE SENSING ARM CYLINDER ASSEMBLY 50-478

DISASSEMBLE AND ASSEMBLE STROKE SENSING BUCKET CYLINDER ASSEMBLY 50-493

CAB AND ITS ATTACHMENTS 50-510

REMOVE AND INSTALL OPERATOR’S CAB ASSEMBLY 50-510

REMOVE AND INSTALL OPERATOR CAB GLASS (ADHERED GLASS) 50-529

REMOVE AND INSTALL FRONT WINDOW ASSEMBLY 50-541

REMOVE AND INSTALL FLOOR FRAME ASSEMBLY 50-550

REMOVE AND INSTALL AIR CONDITIONER UNIT ASSEMBLY 50-564

REMOVE AND INSTALL OPERATOR’S SEAT 50-579

REMOVE AND INSTALL SEAT BELT 50-585

REMOVE AND INSTALL FRONT WIPER ASSEMBLY 50-587

ELECTRICAL SYSTEM 50-602

REMOVE AND INSTALL ENGINE CONTROLLER ASSEMBLY 50-602

REMOVE AND INSTALL PUMP CONTROLLER ASSEMBLY 50-608

REMOVE AND INSTALL WORK EQUIPMENT CONTROLLER ASSEMBLY 50-618

REMOVE AND INSTALL KomVision CONTROLLER ASSEMBLY 50-622

REMOVE AND INSTALL MACHINE MONITOR ASSEMBLY 50-624

INDEX 00 INDEX AND FOREWORD

00-18 PC360LCI-11

REMOVE AND INSTALL PUMP SWASH PLATE SENSOR 50-631

REMOVE AND INSTALL MASS AIR FLOW AND TEMPERATURE SENSOR 50-633

REMOVE AND INSTALL KCCV CRANKCASE PRESSURE SENSOR 50-635

REMOVE AND INSTALL SCR TEMPERATURE SENSOR 50-637

REMOVE AND INSTALL REARVIEW CAMERA 50-640

REMOVE AND INSTALL KomVision CAMERA 50-643

REMOVE AND INSTALL KOMTRAX TERMINAL ASSEMBLY 50-646

REMOVE AND INSTALL ICT SENSOR CONTROLLER ASSEMBLY 50-653

REMOVE AND INSTALL JUNCTION HARNESS OF CONTROL BOX 50-659

REMOVE AND INSTALL CONTROL BOX HARNESS 50-665

REMOVE AND INSTALL GNSS RECEIVER 50-668

REMOVE AND INSTALL NETWORK MODEM 50-670

REMOVE AND INSTALL GNSS RECEIVER ANTENNA 50-671

REMOVE AND INSTALL NETWORK MODEM ANTENNA 50-673

REMOVE AND INSTALL GNSS ANTENNA 50-675

REMOVE AND INSTALL IMU SENSOR 50-677

60 MAINTENANCE STANDARD 60-1

CONTENTS 60-2

ABBREVIATION LIST 60-3

ENGINE AND COOLING SYSTEM 60-9

MAINTENANCE STANDARD OF ENGINE MOUNT 60-9

MAINTENANCE STANDARD OF COOLING SYSTEM 60-11

POWER TRAIN 60-13

MAINTENANCE STANDARD OF SWING CIRCLE 60-13

MAINTENANCE STANDARD OF SWING MACHINERY 60-14

MAINTENANCE STANDARD OF FINAL DRIVE 60-16

MAINTENANCE STANDARD OF SPROCKET 60-18

MAINTENANCE STANDARD OF SPROCKET TOOTH PROFILE FULL-SCALE DRAWING 60-19

UNDERCARRIAGE AND FRAME 60-21

MAINTENANCE STANDARD OF TRACK FRAME AND IDLER CUSHION 60-21

MAINTENANCE STANDARD OF IDLER 60-23

MAINTENANCE STANDARD OF TRACK ROLLER 60-25

MAINTENANCE STANDARD OF CARRIER ROLLER 60-27

MAINTENANCE STANDARD OF TRACK SHOE 60-28

MAINTENANCE STANDARD OF TRIPLE SHOE 60-31

HYDRAULIC SYSTEM 60-32

MAINTENANCE STANDARD OF HYDRAULIC TANK 60-32

MAINTENANCE STANDARD OF MAIN PUMP 60-33

MAINTENANCE STANDARD OF SWING MOTOR 60-35

MAINTENANCE STANDARD OF TRAVEL MOTOR 60-38

MAINTENANCE STANDARD OF CONTROL VALVE 60-41

MAINTENANCE STANDARD OF WORK EQUIPMENT AND SWING PPC VALVE 60-53

MAINTENANCE STANDARD OF TRAVEL PPC VALVE 60-56

MAINTENANCE STANDARD OF 1ST-LINE ATTACHMENT PPC VALVE (WITH EPC VALVE) 60-59

MAINTENANCE STANDARD OF 2ND-LINE ATTACHMENT PPC VALVE 60-62

MAINTENANCE STANDARD OF SOLENOID VALVE 60-64

MAINTENANCE STANDARD OF ATTACHMENT CIRCUIT SELECTOR VALVE 60-65

MAINTENANCE STANDARD OF CENTER SWIVEL JOINT 60-66

WORK EQUIPMENT 60-67

MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60-67

MAINTENANCE STANDARD OF BOOM CYLINDER 60-76

MAINTENANCE STANDARD OF STROKE SENSING BOOM CYLINDER 60-77

MAINTENANCE STANDARD OF STROKE SENSING ARM CYLINDER 60-79

MAINTENANCE STANDARD OF STROKE SENSING BUCKET CYLINDER 60-81

MAINTENANCE STANDARD OF STROKE SENSOR FOR BOOM CYLINDER 60-83

MAINTENANCE STANDARD OF STROKE SENSOR FOR ARM CYLINDER 60-84

MAINTENANCE STANDARD OF STROKE AND RESET SENSOR FOR BUCKET CYLINDER 60-85

80 APPENDIX 80-1

00 INDEX AND FOREWORD INDEX

PC360LCI-11 00-19

CONTENTS 80-2

ABBREVIATION LIST 80-4

AIR CONDITIONER SYSTEM 80-10

PRECAUTIONS FOR REFRIGERANT 80-10

AIR CONDITIONER COMPONENT 80-11

SPECIFICATIONS OF AIR CONDITIONER 80-13

CONFIGURATION AND FUNCTION OF REFRIGERATION CYCLE 80-14

OUTLINE OF REFRIGERATION CYCLE 80-15

COMPONENT PARTS OF AIR CONDITIONER SYSTEM 80-17

AIR CONDITIONER UNIT 80-17

COMPONENT PARTS OF AIR CONDITIONER UNIT 80-21

AIR CONDITIONER CONTROLLER 80-25

COMPRESSOR 80-26

CONDENSER 80-27

RECEIVER DRIER 80-28

SENSORS FOR AIR CONDITIONER SYSTEM 80-29

EXPLANATION OF PROCEDURE FOR TESTING AND TROUBLESHOOTING OF AIR CONDITIONER

80-31

CIRCUIT DIAGRAM AND ARRANGEMENT OF CONNECTOR PINS FOR AIR CONDITIONER 80-33

AIR CONDITIONER SYSTEM DIAGRAM 80-35

INPUT AND OUTPUT SIGNALS OF AIR CONDITIONER CONTROLLER 80-36

INSTALLATION LOCATIONS OF AIR CONDITIONER PARTS AND ARRANGEMENT OF CONNECTORS

80-38

TESTING AIR LEAKAGE (DUCT) 80-42

METHOD FOR TESTING AIR LEAKAGE (DUCT) 80-42

TESTING AIR CONDITIONER USING SELF-DIAGNOSIS FUNCTION 80-43

HOW TO OPEN THE ELECTRICAL SYSTEM ABNORMALITY RECORD SCREEN IN SERVICE MODE

OF THE MACHINE MONITOR 80-44

TEST VENT (MODE) CHANGEOVER 80-45

METHOD FOR TESTING VENT (MODE) CHANGEOVER 80-45

TESTING FRESH/RECIRC AIR CHANGEOVER 80-46

METHOD FOR TESTING FRESH/RECIRC AIR CHANGEOVER 80-46

TEST SUNLIGHT SENSOR 80-47

METHOD FOR TESTING SUNLIGHT SENSOR 80-47

TEST (DUAL) PRESSURE SWITCH FOR REFRIGERANT 80-48

METHOD FOR TESTING (DUAL) PRESSURE SWITCH FOR REFRIGERANT 80-48

TEST RELAYS 80-49

METHOD FOR TESTING RELAYS 80-49

AIR CONDITIONER TROUBLESHOOTING CHART 1 80-50

AIR CONDITIONER TROUBLESHOOTING CHART 2 80-51

INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE 80-54

FAILURE CODE [879AKA] 80-56

FAILURE CODE [879AKB] 80-57

FAILURE CODE [879BKA] 80-58

FAILURE CODE [879BKB] 80-60

FAILURE CODE [879CKA] 80-62

FAILURE CODE [879CKB] 80-63

FAILURE CODE [879DKZ] 80-64

FAILURE CODE [879EMC] 80-66

FAILURE CODE [879FMC] 80-67

FAILURE CODE [879GKX] 80-68

A-1 TROUBLESHOOTING FOR POWER SUPPLY SYSTEM (AIR CONDITIONER DOES NOT OPERATE)

80-70

A-2 TROUBLESHOOTING FOR COMPRESSOR AND REFRIGERANT SYSTEM (AIR IS NOT COOLED)

80-72

A-3 TROUBLESHOOTING FOR BLOWER MOTOR SYSTEM (NO AIR COMES OUT OR AIR FLOW IS

ABNORMAL) 80-75

A-4 TROUBLESHOOTING FOR FRESH/RECIRC AIR CHANGEOVER 80-77

INDEX 00 INDEX AND FOREWORD

00-20 PC360LCI-11

TROUBLESHOOTING USING GAUGE PRESSURE 80-79

CONNECTION OF SERVICE TOOL 80-82

METHOD FOR CONNECTING SERVICE TOOL 80-82

PRECAUTIONS FOR DISCONNECTING AND CONNECTING HOSES AND TUBES IN AIR CONDITIONER

PIPINGS 80-84

HANDLE COMPRESSOR OIL 80-86

90 CIRCUIT DIAGRAMS 90-1

CONTENTS 90-2

ABBREVIATION LIST 90-3

HYDRAULIC CIRCUIT DIAGRAM 90-9

SYMBOLS USED IN HYDRAULIC CIRCUIT DIAGRAM 90-9

HYDRAULIC CIRCUIT DIAGRAM (1/3) 90-13

HYDRAULIC CIRCUIT DIAGRAM (2/3) 90-15

HYDRAULIC CIRCUIT DIAGRAM (3/3) 90-17

ELECTRICAL CIRCUIT DIAGRAM 90-19

SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90-19

ELECTRICAL CIRCUIT DIAGRAM (1/14) 90-23

ELECTRICAL CIRCUIT DIAGRAM (2/14) 90-25

ELECTRICAL CIRCUIT DIAGRAM (3/14) 90-27

ELECTRICAL CIRCUIT DIAGRAM (4/14) 90-29

ELECTRICAL CIRCUIT DIAGRAM (5/14) 90-31

ELECTRICAL CIRCUIT DIAGRAM (6/14) 90-33

ELECTRICAL CIRCUIT DIAGRAM (7/14) 90-35

ELECTRICAL CIRCUIT DIAGRAM (8/14) 90-37

ELECTRICAL CIRCUIT DIAGRAM (9/14) 90-39

ELECTRICAL CIRCUIT DIAGRAM (10/14) 90-41

ELECTRICAL CIRCUIT DIAGRAM (11/14) 90-43

ELECTRICAL CIRCUIT DIAGRAM (12/14) 90-45

ELECTRICAL CIRCUIT DIAGRAM (13/14) 90-47

ELECTRICAL CIRCUIT DIAGRAM (14/14) 90-49

INDEX 1