$46

Komatsu PC4000-11 T4 Hydraulic Mining Shovel Shop Manual – PDF DOWNLOAD

Komatsu PC4000-11 T4 Hydraulic Mining Shovel Shop Manual – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC4000-11 T4 Hydraulic Mining Shovel Shop Manual – PDF DOWNLOAD

Language : English

Pages : 2402

Downloadable : Yes

File Type : PDF

Size: 76.1 MB

DESCRIPTION:

Komatsu PC4000-11 T4 Hydraulic Mining Shovel Shop Manual – PDF DOWNLOAD

SERIAL NUMBER 08246 and up

BEFORE READING THIS MANUAL:

- This manual gives details of the methods of inspection, maintenance and troubleshooting for this machine that

must be obeyed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental

safety rules for the inspection, maintenance and troubleshooting of machines. - Read, understand and follow all precautions and warnings in this manual and on the machine before performing

inspection, maintenance or troubleshooting. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that may involve a potential hazard when the machine is used. - Therefore, the safety messages in this manual and on the machine may not include all possible safety

precautions. If you carry out any inspection, maintenance and troubleshooting under conditions that are not

described in this manual, understand that it is your responsibility to take the necessary precautions to ensure

safety. In no event should you or others engage in prohibited uses or actions described in this manual. - Improper inspection, maintenance and troubleshooting of the machine can be hazardous and could result in

serious injury or death.

If you sell the machine, be sure to give this manual to the new owner together with the machine. - This manual uses the international units (SI) for units of measurement. For reference, units that have been used

in the past are given in ( ). - The explanations, values, and illustrations in this manual have been prepared based on the latest information

available as of the date of publication. Continuing improvements in the design of this machine may lead to

additional changes that are not reflected in this manual. Consult Komatsu or your Komatsu distributor for the

latest available information concerning your machine or with questions regarding information contained in this

manual. - Komatsu delivers machines that comply with all applicable regulations and standards of the country to which

it has been shipped. If the machine has been purchased in another country, it may lack certain safety devices

and specifications that are necessary for use in your country. If there is any question about whether your

product complies with the applicable standards and regulations of your country, consult Komatsu or your

Komatsu distributor before operating the machine.

CONTENTS OF THIS BINDER:

- This Shop Manual has been prepared as a SERVICE GUIDE for the mechanic responsible for the upkeep of

your hydraulic mining shovel.

It is compiled into different sections and summarizes the procedures for inspection, maintenance and troubleshooting

on the machine. - All information, illustrations and specifications contained herein are based on the development at printing time

and may be subject to possible future changes by KOMATSU without prior notice. - Also note that all procedures given in this manual are for a basic machine. Your machine may be differently

equipped and/or otherwise customized. - This manual may contain attachments and optional equipment that are not available in your area. Please consult

your local Komatsu distributor for those items you may require. Materials and specifications are subject to change

without notice.

TABLE OF CONTENTS:

Komatsu PC4000-11 T4 Hydraulic Mining Shovel Shop Manual – PDF DOWNLOAD

1 INTRODUCTION 1-1

1 1 FOREWORD 1-2

1 2 RECOMMENDATIONS FOR ENVIRONMENTALLY FRIENDLY OPERATION AND

MAINTENANCE OF HYDRAULIC MINING SHOVELS 1-3

1 3 EXPLANATION OF ABBREVIATIONS 1-4

1 4 DIAGRAMS AND ILLUSTRATIONS IN THIS MANUAL 1-5

2 SPECIFICATIONS 2-1

2 1 LIFTING GEARS 2-2

2 2 SAFETY HINTS FOR SLING ACCESSORY 2-4

2 3 STANDARD TIGHTENING TORQUE CHART 2-5

2 4 CONVERSION TABLE 2-6

2 5 BLIND PLUGS 2-12

2 6 CLASSIFICATION OF THREADS TO THE NOMINAL WIDTH 2-14

2 7 PLUGS AND FITTINGS ACCORDING TO ISO 8434-1 / DIN 2353 2-15

3 MAIN ASSEMBLY GROUPS 3-1

3 1 GENERAL LAYOUT 3-2

3 2 SUPERSTRUCTURE 3-4

3 2 1 SIDE VIEW 3-4

3 2 2 TOP VIEW 3-6

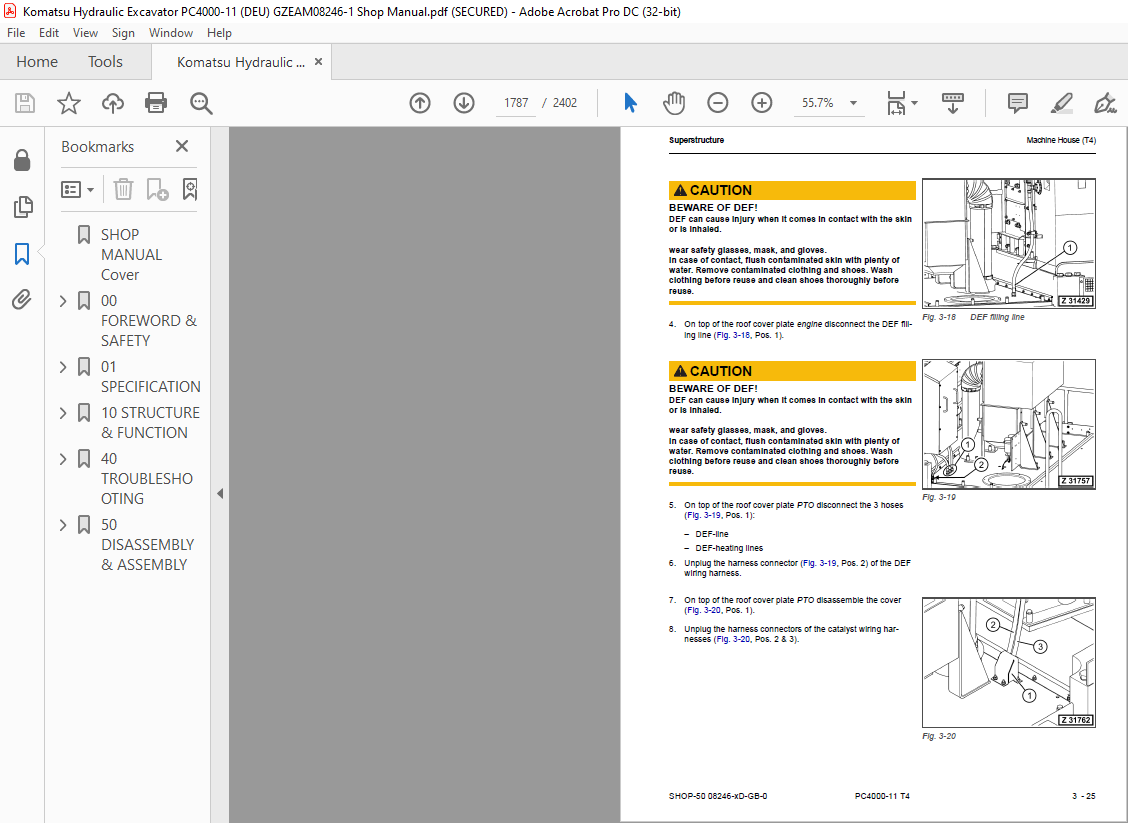

3 3 MACHINE HOUSE 3-8

3 4 HYDRAULIC OIL TANK 3-10

3 5 HYDRAULIC OIL COOLER 3-12

3 6 FUEL TANK 3-14

3 7 CAB BASE 3-16

3 8 OPERATOR’S CAB 3-18

3 9 CONTROL BLOCKS 3-20

3 10 SLEW GEAR 3-22

3 10 1 SLEW GEAR L&S 3-22

3 10 2 SLEW GEAR SIEBENHAAR 3-24

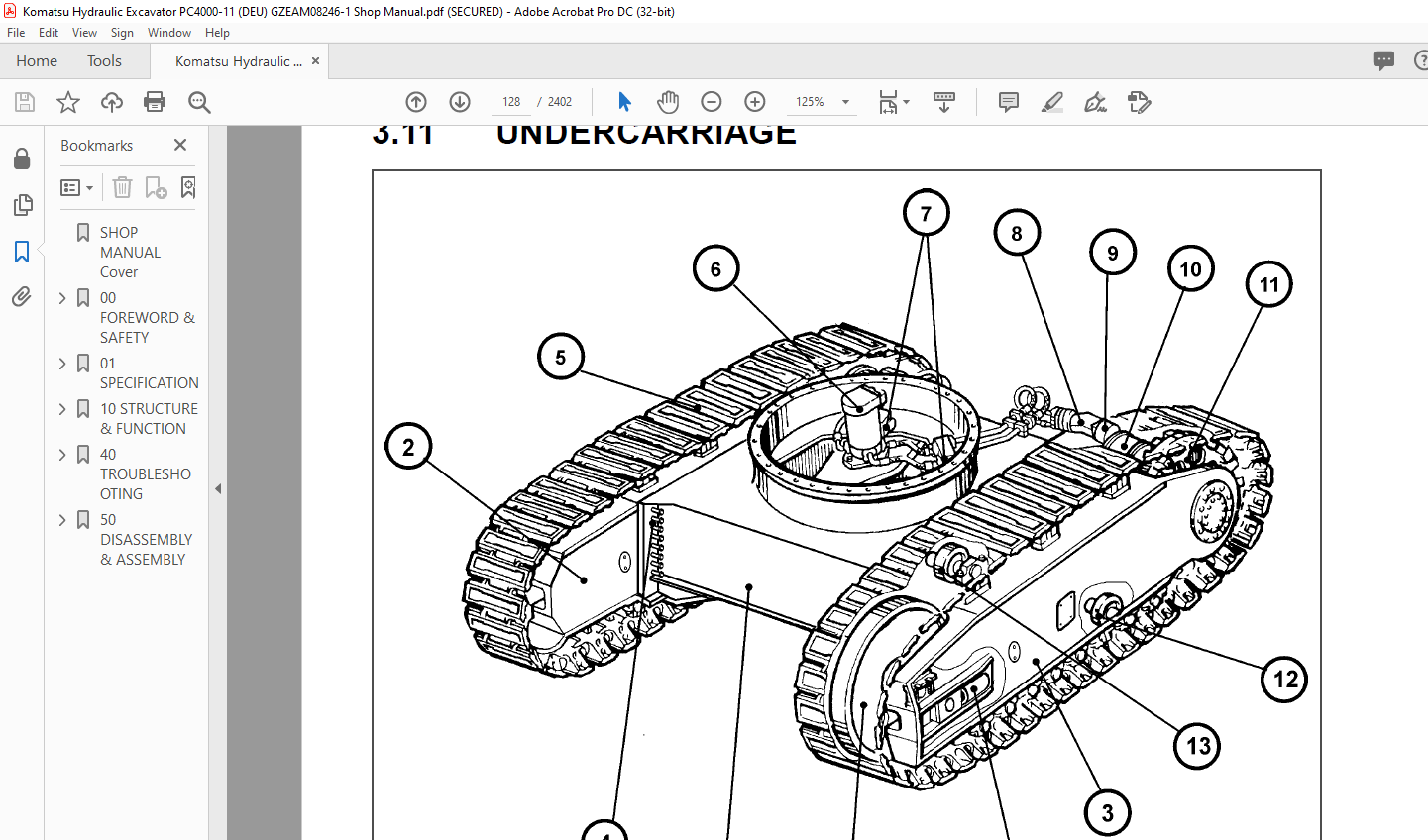

3 11 UNDERCARRIAGE 3-26

3 12 SLEW RING 3-28

3 13 ATTACHMENT 3-30

3 13 1 FRONT SHOVEL ATTACHMENT (FSA) 3-30

3 13 2 BACKHOE ATTACHMENT (BHA) 3-32

3 14 COUNTERWEIGHT 3-34

3 15 SAFETY CIRCUIT (PILOT CONTROL CIRCUIT) 3-36

3 15 1 WIRING DIAGRAM OF 20S105 AND 20S105A 3-38

4 DRIVE 4-1

4 1 PRIME DRIVE ASSEMBLY 4-2

TOC – 2 PC4000-11 T4 SHOP-10 08246-xD-GB-1

4 2 ENGINE AND PTO MOUNTS 4-4

4 2 1 ENGINE MOUNTS 4-4

4 2 2 TORQUE SUPPORT 4-5

4 3 FLEXIBLE COUPLING 4-6

4 3 1 INFORMATION FOR MAINTENANCE 4-8

4 3 2 COUPLING ELEMENTS 4-9

4 3 3 SEPARATION AND ASSEMBLY OF THE COUPLING INNER AND OUTER PART 4-10

4 3 4 OPERATION TROUBLES, CAUSES, AND RECTIFICATION 4-11

4 4 FAN DRIVE AND RADIATOR ASSEMBLY 4-12

4 4 1 RADIATOR FAN DRIVE 4-14

4 4 2 FAN PUMP 4-16

4 4 3 RADIATOR FAN DRIVE SPEED ADJUSTMENT 4-18

4 5 FUEL COOLING (T4 EQUIPMENT) 4-20

4 6 PUMP DISTRIBUTOR GEARBOX (PTO) 4-22

4 6 1 PUMP SPLINE LUBRICATION 4-24

4 6 1 1 OIL LEVEL IN THE MAIN PUMP DRIVE SHAFT HOUSING 4-25

4 6 2 PTO LUBRICATION AND COOLING 4-26

4 6 2 1 CHECKS AND ADJUSTMENTS 4-28

4 7 HYDRAULIC PUMPS – LOCATION, DRIVE SPEED AND FLOW RATES 4-30

4 7 1 PUMP DATA 4-32

4 8 AIR FILTER 4-34

5 HYDRAULIC OIL TANK 5-1

5 1 GENERAL LAYOUT 5-2

5 2 HYDRAULIC OIL TANK, LOCATION OF THE ELECTRIC EQUIPMENT 5-4

5 3 SUCTION OIL TANK WITH STRAINERS 5-6

5 4 RETURN OIL COLLECTOR PIPE WITH STRAINER 5-8

5 5 BACK PRESSURE VALVE 5-10

5 6 TRANSFER PUMP 5-12

5 7 RETURN AND LEAK OIL FILTER 5-14

5 8 BREATHER FILTER 5-16

6 HYDRAULIC OIL COOLING 6-1

6 1 OVERALL VIEW OF THE HYDRAULIC OIL COOLING 6-2

6 2 FUNCTION OF THE HYDRAULIC OIL COOLING CIRCUIT 6-4

6 3 ADJUSTMENT OF THE BACK PRESSURE VALVE 6-6

6 4 TWO STAGE COOLER FAN RPM CONTROL 6-8

6 4 1 PRESSURE REDUCING VALVE 6-10

6 4 2 SOLENOID VALVES 6-12

6 4 3 FAN PUMP 6-14

6 5 CHECKS AND ADJUSTMENTS OF THE COOLER FAN DRIVE SPEEDS 6-16

6 5 1 FUNCTION CHECK OF FAN SPEED CONTROL 6-20

7 CONTROLLING 7-1

7 1 GENERAL LAYOUT 7-2

7 2 CONTROL AND FILTER PANEL 7-4

SHOP-10 08246-xD-GB-1 PC4000-11 T4 TOC – 3

7 3 VALVE CARTRIDGE BLOCK 7-6

7 4 PILOT PRESSURE SUPPLY AND ADJUSTMENTS 7-8

7 4 1 PILOT PRESSURE CONTROL (PPC) CIRCUIT 7-8

7 4 2 CHECKS AND ADJUSTMENT OF PILOT PRESSURE 7-12

7 4 3 REMOTE CONTROL VALVES ARRANGEMENT 7-14

7 5 FUNCTION OF THE ELECTRO-HYDRAULIC CONTROL SYSTEM 7-16

7 5 1 ELECTRONIC HAND LEVER (JOYSTICK) 7-20

7 5 1 1 VOLTAGE SUPPLY OF HAND LEVER 20S020 7-21

7 5 1 2 DIRECTION SIGNAL COURSE FROM HAND LEVER TO CONTROLLERS 7-22

7 5 1 3 DOUBLE RATIOMETRIC* OUTPUT DIAGRAM 7-23

7 6 FOOT PEDAL CONTROL 7-24

7 6 1 VOLTAGE SUPPLY OF FOOT LEVER (20S021A) 7-26

7 6 2 DIRECTION SIGNAL COURSE FROM FOOT PEDAL TO CONTROLLERS 7-27

7 6 3 DOUBLE RATIOMETRIC* OUTPUT DIAGRAM FOR 2 DIRECTION PEDAL 7-28

7 6 4 SINGLE RATIOMETRIC* OUTPUT DIAGRAM FOR 1 DIRECTION PEDAL 7-28

7 7 HAND LEVER & FOOT PEDAL MONITORING 7-29

7 7 1 LEVER MONITORING SCREENS (EXAMPLE) 7-30

7 7 2 VALVE MONITORING SCREEN (EXAMPLE) 7-32

7 8 VALVE SOLENOID ADJUSTMENT 7-34

7 8 1 OVERVIEW SOL MIN/MAX CURRENT & ADJUSTMENT RANGE 7-35

7 9 ACCEL & DECEL TIME ADJUSTMENT 7-36

7 9 1 ACCEL & DECEL TIMES 7-36

8 COMPONENTS 8-1

8 1 MAIN CONTROL BLOCKS AND HIGH PRESSURE SCREENS (FSA) 8-2

8 2 MAIN CONTROL BLOCKS AND HIGH PRESSURE SCREENS (BHA) 8-4

8 3 DISTRIBUTOR MANIFOLD – LOCATION OF RESTRICTOR BLOCKS AND ANTI

CAVITATION VALVES (FSA) 8-6

8 4 DISTRIBUTOR MANIFOLD – LOCATION OF RESTRICTOR BLOCKS AND ANTI

CAVITATION VALVES (BHA) 8-8

8 5 SINGLE CONTROL BLOCKS (FLOATING) FOR STICK AND BOOM (FSA) 8-10

8 6 RESTRICTOR BLOCK WITH SECONDARY RELIEF VALVE 8-12

8 7 ANTI-CAVITATION VALVE (ACV) BLOCK 8-14

8 8 REMOTE CONTROL VALVES 8-16

8 9 4/3 DIRECTIONAL SOLENOID VALVES 8-18

8 10 PROPORTIONAL SOLENOID VALVES 8-20

8 11 HIGH PRESSURE SCREEN 8-22

8 12 CONTROL BLOCKS AND VALVES 8-24

8 12 1 SPOOL TYPES 8-30

8 12 2 MRV, SRV AND ACV 8-32

8 12 3 LOAD HOLDING VALVE 8-34

8 13 TRAVEL BRAKE VALVE 8-38

8 14 PRESSURE REDUCING VALVE 8-40

8 15 4/2 DIRECTIONAL VALVES 8-42

8 16 PRESSURE DOUBLE STAGE VALVE 8-44

8 17 HYDRAULIC CYLINDER WITH NOK-3 SEALING 8-46

TOC – 4 PC4000-11 T4 SHOP-10 08246-xD-GB-1

8 17 1 CYLINDER DATA MARKINGS 8-49

9 MAIN HYDRAULIC PUMPS AND PUMP REGULATION 9-1

9 1 GENERAL 9-2

9 1 1 PUMP LOCATIONS AND PUMP DATA 9-4

9 2 MAIN PUMPS 9-6

9 2 1 HYDRAULIC PUMP TYPE HPV375+375 9-6

9 2 1 1 MAIN PUMP SECTIONAL DRAWINGS 9-8

9 2 2 SERVO VALVE 9-10

9 2 2 1 VC VALVE ⇔ SERVO PISTON 9-11

9 2 2 2 EPC VALVE 9-16

9 3 ELECTRONIC PUMP REGULATION SYSTEM 9-18

9 3 1 CUT-OFF FUNCTION 9-20

9 3 2 SLEW CONTROL 9-21

9 3 2 1 FUNCTION OF SLEW SPEED SWITCH 20S154 9-21

9 3 3 TEMPERATURE CONTROL 9-22

9 3 3 1 HYDRAULIC OIL TEMPERATURE CHARTS 9-22

9 3 4 ENERGY EFFICIENCY (ECONOMY MODE) 9-23

9 4 PUMP CONTROLLER (14K305) 9-24

9 5 MONITORING, ERROR INDICATION, ADJUSTMENT 9-26

9 5 1 MONITORING ITEMS OF THE PUMP CONTROLLER 9-26

9 5 2 ERROR INDICATION OF THE PUMP CONTROLLER 9-29

9 5 3 ADJUSTABLE PARAMETERS OF THE PUMP CONTROLLER 9-30

9 5 3 1 DESCRIPTION OF THE PRIMARY P-FACTOR 9-32

9 5 4 PUMP SOL ’MIN’ CURRENT VALUES ACCORDING TO PUMP TYPE PLATE 9-33

9 5 5 PUMP SOL ’MAX’ CURRENT VALUES ACCORDING TO PUMP TYPE PLATE 9-34

9 6 CHECKS AND ADJUSTMENTS 9-36

9 6 1 ENGINE POWER CHECK 9-36

9 6 2 CUT-OFF FUNCTION CHECK 9-38

9 6 2 1 CUT-OFF FOR CLAM CLOSE (FSA ONLY) 9-39

9 7 ENGINE SPEED SENSOR (PICK-UP) 9-40

9 7 1 GENERAL 9-41

9 7 2 ENGINE SPEED SENSOR (PICK-UP) ADJUSTMENT 9-41

9 7 3 IN CASE OF PROBLEMS – WHEN CORRECT SPEED SENSOR ADJUSTMENT

IS GUARANTEED 9-42

10 OPERATING HYDRAULICS 10-1

10 1 GENERAL 10-2

10 1 1 FLOATING SYSTEM (FSA ONLY) 10-4

10 2 HYDRAULICS FOR THE ATTACHMENT CYLINDERS 10-8

10 2 1 ELECTRIC / HYDRAULIC FLOWCHART “BOOM UP” (FSA) 10-8

10 2 2 ELECTRIC / HYDRAULIC FLOWCHART “BOOM UP” (BHA) 10-10

10 2 3 ELECTRIC / HYDRAULIC FLOWCHART “BOOM DOWN” (FSA) 10-12

10 2 4 ELECTRIC / HYDRAULIC FLOWCHART “BOOM DOWN” (BHA) 10-14

10 2 5 ELECTRIC / HYDRAULIC FLOWCHART “STICK OUT” (FSA) 10-16

10 2 6 ELECTRIC / HYDRAULIC FLOWCHART “STICK OUT” (BHA) 10-18

10 2 7 ELECTRIC / HYDRAULIC FLOWCHART “STICK IN” (FSA) 10-20

10 2 8 ELECTRIC / HYDRAULIC FLOWCHART “STICK IN” (BHA) 10-22

SHOP-10 08246-xD-GB-1 PC4000-11 T4 TOC – 5

10 2 9 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET FILL” (FSA) 10-24

10 2 10 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET FILL” (BHA) 10-26

10 2 11 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET DUMP” (FSA) 10-28

10 2 12 ELECTRIC / HYDRAULIC FLOWCHART “BUCKET DUMP” (BHA) 10-30

10 2 13 ELECTRIC / HYDRAULIC FLOWCHART “CLAM OPEN” (FSA) 10-32

10 2 14 ELECTRIC / HYDRAULIC FLOWCHART “CLAM CLOSE” (FSA) 10-34

10 2 15 CHECKS & ADJUSTMENTS OF THE MAIN RELIEF VALVE (MRV) 10-36

10 2 16 CHECKS AND ADJUSTMENTS OF THE SECONDARY RELIEF VALVES (SRV) 10-38

10 2 16 1 BOOM CYLINDERS, PISTON SIDE (BHA & FSA), BOOM UP 10-38

10 2 16 2 BOOM CYLINDER, PISTON ROD SIDE (BHA & FSA), BOOM DOWN 10-42

10 2 16 3 STICK CYLINDERS, PISTON SIDE (FSA), STICK OUT 10-46

10 2 16 4 STICK CYLINDERS, PISTON SIDE (BHA), STICK IN 10-50

10 2 16 5 STICK CYLINDERS, PISTON ROD SIDE (FSA), STICK IN 10-54

10 2 16 6 STICK CYLINDERS, PISTON ROD SIDE (BHA), STICK OUT 10-58

10 2 16 7 BUCKET CYLINDERS, PISTON SIDE (FSA), BUCKET FILL 10-62

10 2 16 8 BUCKET CYLINDERS, PISTON SIDE (BHA), BUCKET FILL 10-66

10 2 16 9 BUCKET CYLINDERS, PISTON ROD SIDE (FSA), BUCKET DUMP 10-70

10 2 16 10BUCKET CYLINDERS, PISTON ROD SIDE (BHA), BUCKET DUMP 10-74

10 2 16 11CLAM CYLINDERS, PISTON ROD SIDE (FSA), CLAM OPEN 10-78

10 2 16 12CLAM CYLINDERS, PISTON SIDE (FSA), CLAM CLOSE 10-82

10 2 17 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED 10-86

10 2 17 1 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

BOOM (FSA) 10-86

10 2 17 2 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

BOOM (BHA) 10-92

10 2 17 3 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

STICK (FSA) 10-94

10 2 17 4 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

STICK (BHA) 10-100

10 2 17 5 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

BUCKET (FSA) 10-102

10 2 17 6 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

BUCKET (BHA) 10-104

10 2 17 7 CHECKS AND ADJUSTMENTS OF THE LOWERING SPEED –

CLAM (FSA) 10-106

10 3 HYDRAULICS FOR THE SLEW CIRCUIT 10-108

10 3 1 SLEW CIRCUIT 10-108

10 3 2 SLEW MOTOR 10-112

10 3 3 SLEW GEARBOX (L&S) 10-114

10 3 4 SLEW GEARBOX (SIEBENHAAR) 10-116

10 3 5 SLEW PARKING BRAKE (L&S) 10-118

10 3 6 SLEW PARKING BRAKE (SIEBENHAAR) 10-120

10 3 7 SLEW BRAKE VALVE 10-122

10 3 8 ELECTRIC / HYDRAULIC FLOWCHART “SLEW LEFT” 10-126

10 3 9 ELECTRIC / HYDRAULIC FLOWCHART “SLEW RIGHT” 10-128

10 3 10 CHECKS AND ADJUSTMENTS FOR THE SLEW CIRCUIT 10-130

10 3 10 1 CHECKS & ADJUSTMENTS, SLEW SPEED 10-130

10 3 10 2 CHECKS & ADJUSTMENTS, DOUBLE STAGE VALVE 10-132

10 3 10 3 CHECKS OF THE BRAKE PILOT PRESSURE 10-135

10 3 11 FUNCTION CHECK FOR HYDRAULIC SLEW PARKING BRAKE 10-136

10 3 12 SLEW PARKING BRAKE RELEASE FUNCTION CHECK 10-138

TOC – 6 PC4000-11 T4 SHOP-10 08246-xD-GB-1

10 4 HYDRAULICS FOR THE TRAVEL SYSTEM 10-140

10 4 1 TRAVEL CIRCUIT 10-140

10 4 2 TRAVEL MOTOR 10-142

10 4 3 ROTARY JOINT 10-144

10 4 4 TRAVEL GEARBOX 10-146

10 4 4 1 TRAVEL GEARBOX (L&S) 10-146

10 4 4 2 TRAVEL GEARBOX (ZOLLERN) 10-148

10 4 5 TRAVEL PARKING BRAKE 10-150

10 4 5 1 TRAVEL PARKING BRAKE (ZOLLERN) 10-150

10 4 5 2 TRAVEL PARKING BRAKE (L&S) 10-151

10 5 TRAVEL BRAKE VALVE 10-152

10 5 1 ELECTRIC / HYDRAULIC FLOWCHART “TRAVEL FORWARD” 10-154

10 5 2 ELECTRIC / HYDRAULIC FLOWCHART “TRAVEL BACKWARDS” 10-156

10 5 3 CHECKS AND ADJUSTMENTS 10-158

10 5 3 1 CHECKS AND ADJUSTMENTS FOR THE TRAVEL CIRCUIT 10-158

10 5 3 2 FUNCTION CHECK FOR THE TRAVEL PARKING BRAKE 10-162

11 HYDRAULIC TRACK TENSIONING SYSTEM 11-1

11 1 GENERAL 11-2

11 2 FUNCTIONAL DESCRIPTION 11-4

11 3 DOUBLE STAGE VALVE 11-6

11 4 TENSIONING CYLINDER 11-8

11 5 ADJUSTMENTS / CHECKS 11-10

12 ACCESS LADDER, HYDRAULICALLY OPERATED 12-1

12 1 GENERAL 12-2

12 2 FUNCTION OF THE HYDRAULICALLY OPERATED ACCESS LADDER 12-4

12 3 ADJUSTMENTS / CHECKS 12-10

13 CENTRAL REFILLING SYSTEM (SERVICE ARM) 13-1

13 1 GENERAL 13-2

13 2 FUNCTION 13-4

14 HINTS FOR READING THE HYDRAULIC DIAGRAM 14-1

14 1 GENERAL 14-2

14 2 HYDRAULIC SYMBOLS 14-4

14 2 1 LINES, UNIONS 14-5

14 2 2 COMPONENTS, VALVES 14-7

14 2 3 SENSORS 14-7

14 2 4 VALVES, VALVE COMPONENTS 14-8

14 2 5 PUMP, MOTOR, CYLINDER 14-12

15 HINTS FOR READING THE ELECTRIC WIRING DIAGRAM 15-1

15 1 GENERAL 15-2

15 2 REFERENCE CODE OF THE ELECTRICAL COMPONENTS 15-3

15 2 1 AREA CODE 15-3

15 2 2 COMPONENT IDENTIFYING LETTER 15-4

SHOP-10 08246-xD-GB-1 PC4000-11 T4 TOC – 7

15 3 GRAPHICAL SYMBOLS 15-5

15 4 CONCEPT OF THE WIRING DIAGRAM 15-10

15 4 1 COVER PAGE OF THE KOMATSU W/D 15-10

15 4 2 EXAMPLE 1 FROM THE SCHEMATICS IN THE W/D 15-12

15 4 3 EXAMPLE 2 FROM THE SCHEMATICS IN THE W/D 15-14

15 4 4 TABLE OF CONTENTS IN THE W/D (PAGE 1 OF 2) 15-16

15 4 5 LOCATION LIST 15-18

15 4 6 CROSS REFERENCE LIST FOR ELECTR COMPONENTS IN THE W/D 15-20

15 4 7 CROSS REFERENCE LIST FOR TERMINALS IN THE W/D 15-22

15 4 8 CROSS REFERENCE LIST FOR CONNECTORS IN THE W/D 15-24

15 4 9 CROSS REFERENCE LIST FOR TERMINAL BOARDS IN THE W/D 15-26

15 4 10 CONNECTION TABLE 15-28

15 5 CABLE AND CONNECTOR MARKING 15-30

15 6 CABLE COLOR IDENTIFICATION 15-32

16 MONITORING & CONTROL SYSTEM 16-1

16 1 GENERAL 16-2

16 1 1 MONITORING & CONTROL SYSTEM – OVERVIEW 16-2

16 1 2 GLOBAL LAYOUT PC4000-11 T4 16-3

16 1 3 CONTROLLER SYSTEM OVERVIEW PC4000-11 T4 16-4

16 1 4 INTERFACE CONNECTION 16-6

16 1 5 GENERAL DESCRIPTION 16-7

16 2 MACHINE MONITOR – OPERATOR LEVEL 16-8

16 2 1 MAIN GAUGE SCREENS 16-10

16 2 2 OPERATOR MENU / TABS / FUNCTIONS OF KEYS F1 F6 16-14

16 2 2 1 OPERATOR MENU: ECO GUIDANCE – OPERATION RECORDS 16-16

16 2 2 2 OPERATOR MENU: ECO GUIDANCE-AVERAGE FUEL CONSUMPTION

LOGS 16-18

16 2 2 3 OPERATOR MENU: MACHINE SETTING 16-20

16 2 2 4 OPERATOR MENU: AFTERTREATMENT CLEANING 16-22

16 2 2 5 OPERATOR MENU: SCR INFORMATION 16-28

16 2 2 6 OPERATOR MENU: MAINTENANCE 16-32

16 2 2 7 RESET OF ’REMAINING TIME’ TILL NEXT MAINTENANCE INTERVAL 16-34

16 2 2 8 USAGE LIMITATION 16-35

16 2 2 9 OPERATOR MENU: MONITOR SETTING – SCREEN ADJUSTMENT 16-37

16 2 2 10 OPERATOR MENU: MONITOR SETTING – CLOCK ADJUSTMENT –

CALENDER 16-38

16 2 2 11 OPERATOR MENU: MONITOR SETTING – CLOCK ADJUSTMENT – TIME 16-39

16 2 2 12 OPERATOR MENU: MONITOR SETTING – CLOCK ADJUSTMENT –

12H/24H MODE 16-40

16 2 2 13 OPERATOR MENU: MONITOR SETTING – CLOCK ADJUSTMENT –

DAYLIGHT SAVING TIME 16-41

16 2 2 14 OPERATOR MENU: MONITOR SETTING – LANGUAGE 16-42

16 2 2 15 OPERATOR MENU: MESSAGE SCREEN 16-43

16 3 ERROR AND STATUS INDICATION ON THE OPERATOR LEVEL 16-44

16 3 1 PROMPTS (STATUS INDICATIONS) 16-44

16 3 2 CAUTIONS 16-45

16 3 3 WARNING ICONS FOR TIER 4 EQUIPMENT 16-46

16 3 4 EMERGENCY SHUTDOWN SCREEN 16-48

TOC – 8 PC4000-11 T4 SHOP-10 08246-xD-GB-1

16 3 5 FAULT LEVELS FOR ERROR MESSAGES 16-50

16 3 6 ACTION CODE LEVEL L01 16-51

16 3 7 ACTION CODE LEVEL L02 16-52

16 3 8 ACTION CODE LEVEL L03 16-53

16 3 9 ACTION CODE LEVEL L04 16-54

16 3 10 ERROR LIST 16-55

16 4 TABLE OF FAILURE CODES 16-56

16 4 1 FAILURE CODES WITHOUT MONITOR INDICATION 16-69

16 4 2 ADDITIONAL TEXT INFORMATION FOR ACTION CODES 16-69

16 5 TABLE OF C-CODES – DIESEL ENGINE TIER4 16-70

16 6 FLOW CHARTS OF MACHINE MONITOR SCREENS 16-88

16 6 1 FLOW CHART OPERATOR LEVEL 16-88

16 6 2 FLOW CHART SERVICE LEVEL 16-89

16 7 MACHINE MONITOR 16-90

16 7 1 ENTERING THE SERVICE LEVEL 16-90

16 7 2 KEY SYMBOLS (F1 F6) ON THE SERVICE LEVEL 16-92

16 7 3 SERVICE MENU SELECTION SCREENS 16-93

16 8 SERVICE MENU – ITEM 01 MONITORING / CUSTOM 16-95

16 8 1 MONITORING LIST FOR: ENG CONTROLLER 16-95

16 8 2 MONITORING LIST FOR: PUMP CONTROLLER 16-97

16 8 3 MONITORING LIST FOR: VALVE0 CONTROLLER 16-100

16 8 4 MONITORING LIST FOR: VALVE1 CONTROLLER 16-103

16 8 5 MONITORING LIST FOR: VALVE2 CONTROLLER 16-106

16 8 6 MONITORING LIST FOR: MON (MONITOR) 16-108

16 8 7 MONITORING LIST FOR: KOM PLS (K+ CONTROLLER) 16-110

16 8 8 HOW TO PERFORM THE MONITORING FUNCTION 16-112

16 9 SERVICE MENU – ITEM 02 PM CLINIC 16-114

16 9 1 PM CLINIC (GENERAL) 16-114

16 9 2 PM CLINIC (POWER CHECK) 16-115

16 9 3 FUNCTIONS OF PM CLINIC (POWER CHECK) 16-116

16 10 SERVICE MENU – ITEM 03 MEMORY CLEAR 16-117

16 11 SERVICE MENU – ITEM 04 ABNORMALITY RECORD 16-118

16 11 1 RESET ERROR MESSAGES 16-119

16 12 SERVICE MENU – ITEM 05 MAINTENANCE RECORD 16-120

16 13 SERVICE MENU – ITEM 06 MAINTENANCE MODE SETTING 16-121

16 14 SERVICE MENU – ITEM 07 SNAP SHOT 16-122

16 15 SERVICE MENU – ITEM 08 PHONE NUMBER ENTRY 16-123

16 16 SERVICE MENU – ITEM 09 DEFAULT 16-124

16 17 SERVICE MENU – ITEM 10 UNIT 16-126

16 18 SERVICE MENU – ITEM 11 ADJUSTMENT 16-127

16 18 1 ADJUSTMENTS FOR: PUMP CONTROLLER 16-127

16 18 2 PUMP SOL ’MIN’ CURRENT VALUES ACCORDING TO PUMP TYPE PLATE 16-130

16 18 3 PUMP SOL ’MAX’ CURRENT VALUES ACCORDING TO PUMP TYPE PLATE 16-131

16 18 4 ADJUSTMENTS FOR: VALVE0 CONTROLLER 16-132

16 18 5 ACCEL & DECEL TIMES 16-139

16 18 6 ADJUSTMENTS FOR: VALVE2 CONTROLLER 16-140

16 18 7 ADJUSTMENTS FOR: MON (MONITOR) 16-141

SHOP-10 08246-xD-GB-1 PC4000-11 T4 TOC – 9

16 18 7 1 USING THE IDLING STOP TIMER 16-142

16 19 SERVICE MENU – ITEM 12 MACHINE CONFIGURATION 16-144

16 19 1 DETAILS OF MACHINE CONFIGURATION FOR PC4000-11 T4 16-145

16 19 2 CHANGING LEVER CONTROL FROM EURO TO KMG 16-146

16 19 2 1 CHANGING LEVER CONTROL FROM KMG TO EURO 16-146

16 19 3 CHANGING ATTACHMENT TYPE FROM FSA TO BHA 16-148

16 19 3 1 CHANGING ATTACHMENT TYPE FROM BHA TO FSA 16-148

16 19 4 IN CASE OF PROBLEMS DURING CHANGING PROCEDURE FOR LEVER

CONTROL OR ATTACHMENT TYPE 16-149

16 19 5 HYDRAULIC OIL & PTO GEAR OIL DEFINITION TABLES 16-150

16 19 5 1 HYDRAULIC OIL TEMPERATURE CHARTS 16-150

16 19 5 2 PTO GEAR OIL TEMPERATURE CHARTS 16-150

16 20 SERVICE MENU – ITEM 13 KOMTRAX SETTINGS 16-151

16 21 SERVICE MENU – ITEM 14 SERVICE MESSAGE 16-152

16 22 AUTOMATIC ENGINE SPEED CONTROL 16-153

16 22 1 AUTO DECELERATION MODE 16-153

16 22 2 AUTO LOW IDLE MODE 16-153

16 22 3 IDLING STOP TIMER 16-153

16 23 KOMTRAX PLUS CONTROLLER (UM600) 16-154

16 24 CR720 CONTROLLER 16-158

16 24 1 LOCATION OF CR720 CONTROLLERS 16-158

16 25 CONTROLLER REPLACEMENT PROCEDURE 16-160

16 25 1 SEQUENCE OF THE CONTROLLER REPLACEMENT PROCEDURE 16-160

16 25 2 AFTER CONTROLLER REPLACEMENT 16-161

16 25 3 CONTROLLER LOCATION 16-162

17 LUBRICATION SYSTEM 17-1

17 1 GENERAL OVERVIEW (SLS & CLS) 17-2

17 1 1 GENERAL DESCRIPTION 17-3

17 2 BASIC FUNCTION OF THE LUBRICATION SYSTEMS 17-4

17 3 LUBRICATION SYSTEMS (CLS 1 & SLS) 17-6

17 3 1 LUBRICATION PUMP STATION 17-6

17 3 2 GENERAL INFORMATION ON CLS 1 17-8

17 3 3 GENERAL INFORMATION ON THE SLS 17-8

17 3 4 MANUAL LUBE ACTIVATION 17-8

17 4 LUBRICATION CYCLE 17-9

17 4 1 OPERATION AND CONTROL 17-9

17 4 2 LUBRICATION CYCLE – PROCESSING 17-10

17 4 3 TIME SEGMENTS & SWITCH POINTS OF A LUBRICATION CYCLE 17-11

17 4 4 LUBRICATION MODES 17-12

17 4 4 1 AUTOMATIC LUBRICATION MODE 17-12

17 4 4 2 MANUAL LUBRICATION MODE 17-12

17 4 4 3 REDUCED PAUSE TIME FOR SERVICE 17-12

17 5 HYDRAULICALLY DRIVEN LUBE PUMP 17-14

17 5 1 ADJUSTMENT OF LUBE PUMP SPEED 17-16

17 5 1 1 STROKE SPEED ADJUSTMENT 17-17

17 5 1 2 WORKING PRESSURE 17-17

TOC – 10 PC4000-11 T4 SHOP-10 08246-xD-GB-1

17 6 LUBRICANT INJECTORS 17-18

17 6 1 TIGHTENING TORQUES FOR FITTINGS AT GREASE INJECTORS 17-19

17 6 2 DESCRIPTION 17-19

17 6 3 ADJUSTMENT OF THE LUBRICANT OUTPUT 17-20

17 6 4 OPERATION PRINCIPLE OF LUBRICANT INJECTORS 17-22

17 6 4 1 FUNCTION DESCRIPTION 17-23

17 6 5 CONNECTION OF ONE OR MORE INJECTORS 17-24

17 7 VENT VALVE AND GREASE OUTLET FILTER 17-26

17 7 1 VENT VALVE DESCRIPTION 17-27

17 8 END-LINE SWITCH 17-28

17 8 1 DESCRIPTION 17-29

17 8 2 CLS 1 END-LINE SWITCH ADJUSTMENT 17-30

17 8 3 SLS END-LINE SWITCH ADJUSTMENT 17-32

17 9 LUBRICANT LEVEL SENSORS 17-34

17 9 1 DESCRIPTION 17-35

17 9 1 1 CHECKS 17-35

17 10 COMMISSIONING 17-36

17 10 1 COMMISSIONING OF THE CLS 1 LUBRICATION SYSTEM 17-36

17 10 2 FINE ADJUSTMENT 17-37

17 10 3 COMMISSIONING OF THE SLS LUBRICATION SYSTEM 17-38

18 DEEP TEMPERATURE EQUIPMENT (OPTION) 18-1

18 1 GENERAL INFORMATION 18-2

18 1 1 INTRODUCTION 18-2

18 1 2 DEEP TEMPERATURE COMPONENTS OVERVIEW 18-2

18 1 3 POWER SUPPLY PRECONDITIONS FOR PREHEATING 18-3

18 1 4 POWER REQUIREMENTS FOR PREHEATING SYSTEMS 18-4

18 2 PREHEATING PROCEDURE 18-5

18 2 1 GLOBAL FLOW CHART OF THE PREHEATING PROCEDURE 18-5

18 2 2 STARTING THE PREHEATING PROCEDURE 18-6

18 2 3 PREHEATING OF OPERATOR’S CAB AND DIESEL ENGINE [COOLANT SYSTEM] 18-7

18 2 4 PREHEATING OF LUBRICANTS AND SUPERSTRUCTURE (DIESEL)

[ELECTRIC SYSTEM] 18-8

18 3 CONSTANT HEATING OF TRAVEL MOTORS (TTT EQUIPMENT BELOW-40°C ONLY) 18-9

18 4 COMPONENT LOCATION 18-10

18 4 1 ELECTRIC HEATING ELEMENTS FOR HYDRAULIC & BATTERIES

[ELECTRIC MACHINE] 18-10

18 4 2 ELECTRIC HEATING ELEMENTS FOR HYDRAULICS [DIESEL MACHINE] 18-12

18 4 3 ELECTRIC HEATING ELEMENTS FOR ENGINES & BATTERIES

[DIESEL MACHINE] 18-14

18 5 COMPONENTS OF TT EQUIPMENT 18-16

18 5 1 PREHEATING COMPONENTS ON A DIESEL MACHINE 18-16

18 5 2 PREHEATING COMPONENTS ON AN ELECTRIC MACHINE 18-17

18 5 3 WIRING DIAGRAMS FOR PREHEATING SYSTEMS (EXAMPLES) 18-18

18 5 3 1 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 1 OF 3 18-18

18 5 3 2 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 2 OF 3 18-19

18 5 3 3 WIRING DIAGRAM “HYDRAULIC OIL TANK PREHEATING” PART 3 OF 3 18-20

18 5 3 4 WIRING DIAGRAM “SUCTION OIL MANIFOLD PREHEATING” 18-21

SHOP-10 08246-xD-GB-1 PC4000-11 T4 TOC – 11

18 5 3 5 WIRING DIAGRAM “PTO PREHEATING” 18-22

18 5 3 6 WIRING DIAGRAM “BATTERY HEATER PADS” 18-

IMAGES PREVIEW OF THE MANUAL: