$38

Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 524

Downloadable : Yes

File Type : PDF

Size: 8.82 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

SERIAL NUMBER 08203

The Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual provides comprehensive information for the operation, maintenance, and repair of the PC4000-6E hydraulic mining shovel. The manual is intended for use by experienced operators and technicians who have the necessary knowledge and skills to perform the procedures described in the manual.

- The manual covers various topics such as safety information, operating instructions, routine maintenance procedures, and troubleshooting tips. It provides detailed information on the mining shovel’s systems and components, such as the engine, hydraulic system, electrical system, and undercarriage components. The manual also includes a list of recommended tools and spare parts, as well as detailed specifications for the machine.

- The manual provides step-by-step instructions for maintenance procedures, along with diagrams and illustrations to help operators and technicians understand the procedures. It also provides information on how to diagnose problems, as well as how to perform maintenance and repairs to correct those problems. By following the procedures in the manual, operators and technicians can ensure that the mining shovel is operating safely and efficiently.

- It is important to follow the instructions and procedures outlined in the manual to ensure the safe and proper operation of the mining shovel. The manual provides information on how to properly operate the machine, as well as how to perform routine maintenance and repairs to keep the machine in good working order.

- In summary, the Komatsu PC4000-6E Operation & Maintenance Manual provides valuable information for the operation, maintenance, and repair of the PC4000-6E hydraulic mining shovel. The manual is essential for experienced operators and technicians who are responsible for the safe and efficient operation of the machine. By following the procedures in the manual, operators and technicians can ensure that the mining shovel is operating safely and efficiently.

TABLE OF CONTENTS:

Komatsu PC4000-6E Hydraulic Mining Shovel Operation & Maintenance Manual – PDF DOWNLOAD

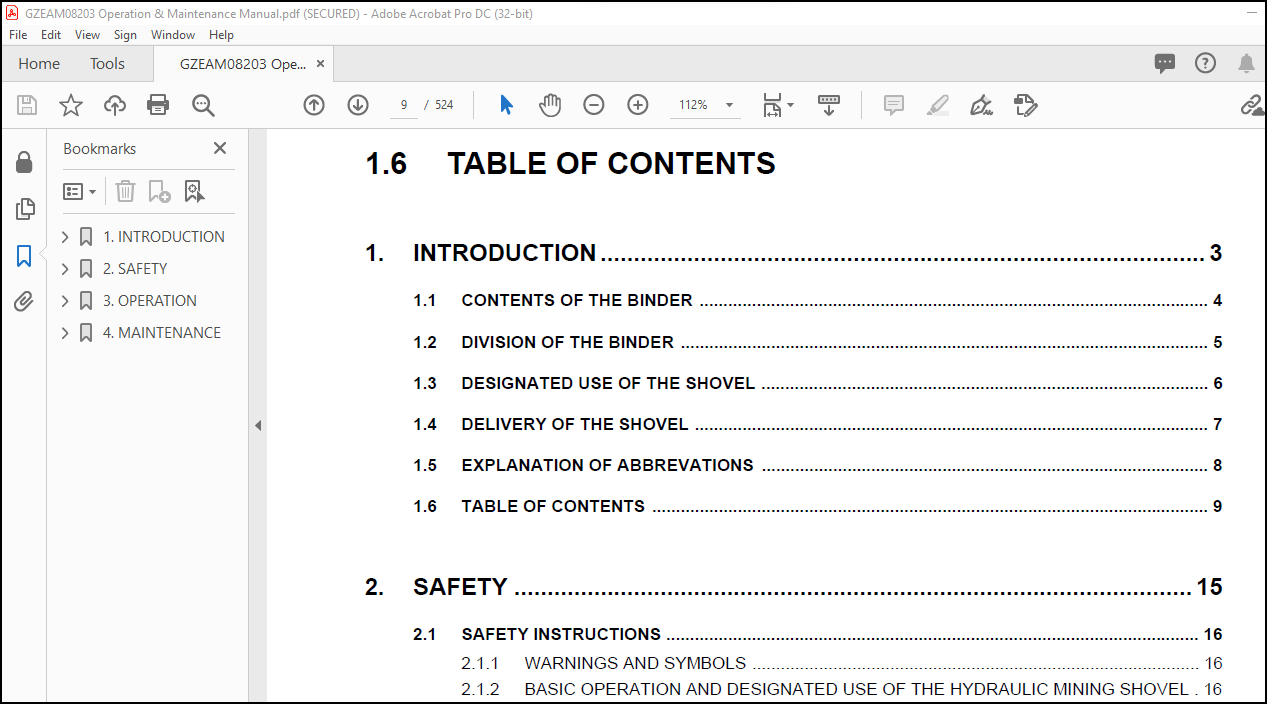

1. INTRODUCTION………………………………………………………………………………………………. 3

1.1 CONTENTS OF THE BINDER…………………………………………………………………………………. 4

1.2 DIVISION OF THE BINDER…………………………………………………………………………………. 5

1.3 DESIGNATED USE OF THE SHOVEL……………………………………………………………………………. 6

1.4 DELIVERY OF THE SHOVEL…………………………………………………………………………………. 7

1.5 EXPLANATION OF ABBREVATIONS…………………………………………………………………………….. 8

1.6 TABLE OF CONTENTS……………………………………………………………………………………… 9

2. SAFETY……………………………………………………………………………………………………. 15

2.1 SAFETY INSTRUCTIONS……………………………………………………………………………………. 16

2.1.1 WARNINGS AND SYMBOLS……………………………………………………………………………… 16

2.1.2 BASIC OPERATION AND DESIGNATED USE OF THE HYDRAULIC MINING SHOVEL……………………………………… 16

2.1.3 ORGANIZATIONAL MEASURES…………………………………………………………………………… 17

2.1.4 SELECTION AND QUALIFICATION OF PERSONNEL – BASIC RESPONSIBILITIES……………………………………… 19

2.1.5 SAFETY INSTRUCTIONS GOVERNING SPECIFIC OPERATIONAL PHASES…………………………………………….. 20

2.1.6 WARNING OF SPECIAL DANGERS………………………………………………………………………… 23

2.1.7 TRANSPORTING AND TOWING -RECOMMISSIONING……………………………………………………………. 25

2.1.8 SPECIAL SAFETY EQUIPMENT………………………………………………………………………….. 25

2.1.9 ELECTROMAGNETIC COMPATIBILITY (EMC)………………………………………………………………… 26

2.1.10 RECOMMENDATIONS FOR ENVIRONMENTALLY FRIENDLY OPERATION AND MAINTENANCE………………………………… 27

2.1.11 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD)…………………………………………. 29

3. OPERATION…………………………………………………………………………………………………. 37

3.1 FOREWORD……………………………………………………………………………………………… 38

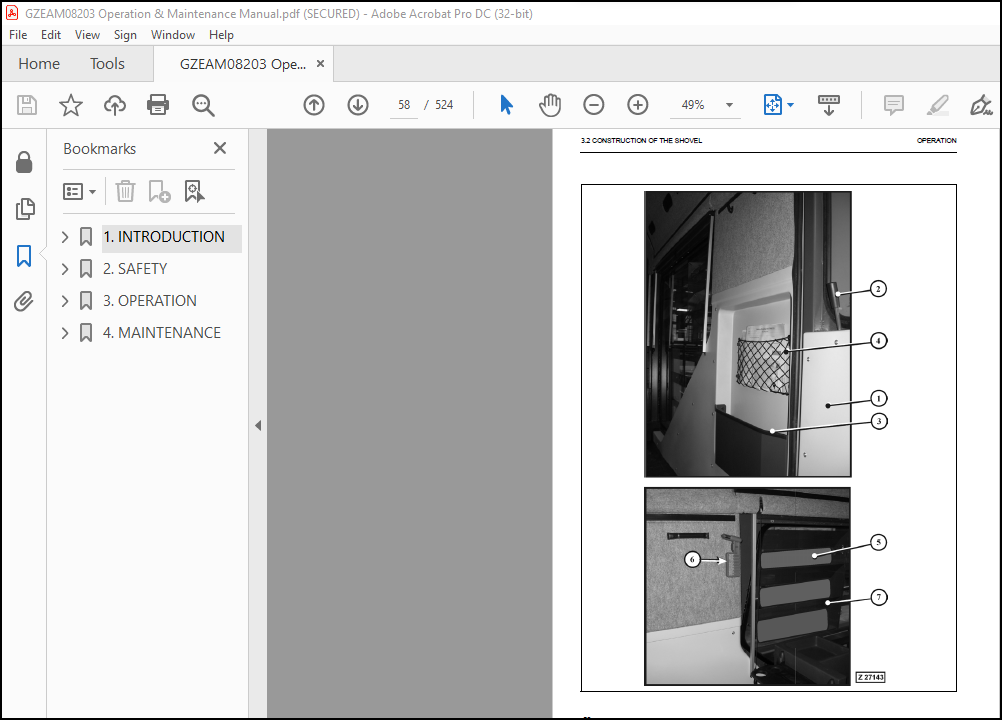

3.2 CONSTRUCTION OF THE SHOVEL……………………………………………………………………………… 39

3.2.1 OVERALL VIEW…………………………………………………………………………………….. 39

3.2.2 SUPERSTRUCTURE…………………………………………………………………………………… 40

3.2.3 HYDRAULICALLY OPERATED ACCESS LADDER……………………………………………………………….. 46

3.2.4 EMERGENCY ESCAPE LADDER…………………………………………………………………………… 50

3.2.5 EMERGENCY MOTOR SHUTDOWN FROM GROUND MAN AND OPERATOR WARNING SYSTEM…………………………………… 52

3.2.6 OPERATOR’S CAB WITH INTEGRATED FALLING OBJECT PROTECTIVE STRUCTURE (FOPS)………………………………. 54

3.2.7 UNDERCARRIAGE……………………………………………………………………………………. 63

3.2.8 WORKING ATTACHMENT……………………………………………………………………………….. 64

3.3 OPERATOR’S CAB – CONTROLS………………………………………………………………………………. 66

3.3.1 CONTROLS WITH BACKHOE ATTACHMENT…………………………………………………………………… 66

3.3.2 SAFETY CIRCUIT FOR CONTROLS……………………………………………………………………….. 67

3.3.3 CONTROLS WITH BOTTOM DUMP BUCKET ATTACHMENT…………………………………………………………. 70

3.3.4 SAFETY CIRCUIT FOR CONTROLS……………………………………………………………………….. 71

3.3.5 AUTOMATIC FLOAT POSITION FOR BOOM AND STICK…………………………………………………………. 73

3.3.6 OPERATORS CONSOLE, OVERVIEW……………………………………………………………………….. 75

3.3.7 INTERFACE PANEL FOR DIAGNOSTICS……………………………………………………………………. 81

3.4 ELECTRONIC MONITORING AND CONTROL SYSTEM ECS……………………………………………………………… 82

3.4.1 INTRODUCTION…………………………………………………………………………………….. 83

3.4.2 OPERATING THE ELECTRONIC MONITORING SYSTEM………………………………………………………….. 91

3.4.3 AUTOMATIC DISPLAY OF MESSAGES……………………………………………………………………… 95

3.4.4 MENU CONTROL AND SERVICE FUNCTIONS………………………………………………………………….119

3.4.5 MENU CONTROL LIST…………………………………………………………………………………146

3.4.6 FAULT AND INFORMATION MESSAGE LIST………………………………………………………………….162

3.5 CAMERA SYSTEM WITH MONITOR………………………………………………………………………………188

3.5.1 LOCATION OF MONITOR AND CONTROL UNIT………………………………………………………………..189

3.6 OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING……………………………………………………..196

3.7 MACHINERY HOUSE………………………………………………………………………………………..200

3.7.1 EMERGENCY MOTOR SHUTDOWN SWITCHES…………………………………………………………………..201

3.7.2 MAINTENANCE SAFETY SWITCH AND BATTERY MAIN SWITCHES…………………………………………………..203

3.7.3 CENTRAL CONTROL AND FILTER PANEL……………………………………………………………………205

3.8 MEDIUM VOLTAGE SWITCH CABINET IN CAB BASE…………………………………………………………………206

3.8.1 SWITCH BOARD (X2) IN CAB BASE………………………………………………………………………209

3.8.2 COMPONENTS IN THE MEDIUM VOLTAGE SWITCH CABINET………………………………………………………217

3.8.3 MONITOR AND CONTROL PANEL………………………………………………………………………….219

3.9 HIGH VOLTAGE SWITCH CABINET……………………………………………………………………………..222

3.10 CHECKS BEFORE STARTING THE MOTOR………………………………………………………………………..224

3.11 STARTING THE MAIN DRIVE MOTOR…………………………………………………………………………..228

3.11.1 STARTING PROCEDURE……………………………………………………………………………….231

3.12 MOVING THE SHOVEL……………………………………………………………………………………..241

3.12.1 TRAVEL CONTROL WITH FOOT PEDALS……………………………………………………………………241

3.12.2 TRAVELLING INSTRUCTIONS…………………………………………………………………………..244

3.13 SLEWING AND BRAKING THE SUPERSTRUCTURE…………………………………………………………………..245

3.13.1 SLEWING THE SUPERSTRUCTURE………………………………………………………………………..245

3.13.2 BRAKING THE SUPERSTRUCTURE………………………………………………………………………..247

3.13.3 SLEW PARKING BRAKE……………………………………………………………………………….248

3.14 WORKING WITH THE ATTACHMENT…………………………………………………………………………….250

3.14.1 MACHINES EQUIPPED WITH ”EURO” CONTROL SYSTEM………………………………………………………..250

3.14.2 MACHINES EQUIPPED WITH ”KMG” CONTROL SYSTEM…………………………………………………………251

3.14.3 BOTTOM DUMP BUCKET……………………………………………………………………………….252

3.14.4 DROP BALL OPERATION………………………………………………………………………………253

3.14.5 COMBINED OPERATION CYCLES…………………………………………………………………………256

3.15 WORKING INSTRUCTIONS…………………………………………………………………………………..258

3.15.1 STABILITY OF THE SHOVEL…………………………………………………………………………..258

3.15.2 SHOVEL OPERATION…………………………………………………………………………………258

3.16 PARKING THE SHOVEL…………………………………………………………………………………….261

3.17 STOPPING THE MOTOR…………………………………………………………………………………….262

3.17.1 RELIEVE PRESSURE IN THE HYDRAULIC SYSTEM……………………………………………………………265

3.18 OPERATION OF THE LUBRICATION SYSTEM……………………………………………………………………..266

3.18.1 CENTRAL LUBRICATION SYSTEM -CLS- FOR SUPERSTRUCTURE AND ATTACHMENT…………………………………….266

3.18.2 SWING CIRCLE PINION LUBRICATION SYSTEM ”SLS”………………………………………………………..268

3.19 TRANSFER PUMP FOR HYDRAULIC OIL…………………………………………………………………………270

3.19.1 OPERATING THE TRANSFER PUMP……………………………………………………………………….271

3.19.2 FUNCTIONS OF THE TRANSFER PUMP…………………………………………………………………….273

3.20 FIRE DETECTION, ACTUATION AND SUPPRESSION SYSTEM………………………………………………………….276

3.20.1 CONTROL UNITS FOR THE FIRE DETECTION, ACTUATION AND SUPPRESSION SYSTEMS………………………………..277

3.20.2 REMOTE HIGH LEVEL ALARM *FIRE* LOCATED ON THE CAB……………………………………………………281

3.20.3 ACTUATION MODES OF THE FIRE SUPPRESSION SYSTEM:……………………………………………………..281

3.20.4 IN CASE OF FIRE………………………………………………………………………………….283

3.21 CENTRAL REFILLING SYSTEM……………………………………………………………………………….284

3.21.1 SYSTEMS CONNECTED TO THE REFILLING SYSTEM…………………………………………………………..285

3.21.2 RECEIVER PANEL AND MONITOR BOX…………………………………………………………………….285

3.21.3 REFILLABLE GREASE CONTAINERS OF THE CENTRAL LUBRICATION SYSTEM AND SWING CIRCLE PINION LUBRICATION SYSTEM….289

3.22 CABLE DRUM (IF SO EQUIPPED)…………………………………………………………………………….292

3.22.1 OPERATION OF THE CABLE DRUM……………………………………………………………………….293

3.22.2 TRAVELLING INSTRUCTIONS…………………………………………………………………………..297

3.23 WORK ON THE LOADER ATTACHMENT…………………………………………………………………………..300

3.24 TRANSPORTATION AND LIFTING OF THE SHOVEL…………………………………………………………………301

3.24.1 DISASSEMBLING OF THE SHOVEL……………………………………………………………………….301

3.24.2 TRANSPORTATION AND LIFTING………………………………………………………………………..301

3.25 RETRIEVAL PROCEDURE……………………………………………………………………………………302

3.26 SHOVEL STORAGE………………………………………………………………………………………..303

3.26.1 PREPARING FOR STORAGE…………………………………………………………………………….303

3.26.2 ONE MONTH REPETITIVE SERVICE PERIOD………………………………………………………………..303

3.26.3 SIX MONTH REPETITIVE SERVICE PERIOD………………………………………………………………..304

3.26.4 PREPARING FOR OPERATION…………………………………………………………………………..304

3.27 TROUBLE SHOOTING………………………………………………………………………………………305

3.27.1 MAIN DRIVE ELECTRIC MOTOR…………………………………………………………………………305

3.27.2 HYDRAULIC SYSTEM…………………………………………………………………………………306

3.27.3 FINAL DRIVES AND SWING GEAR……………………………………………………………………….307

3.27.4 CRAWLER TRACKS…………………………………………………………………………………..307

4. MAINTENANCE………………………………………………………………………………………………..309

4.1 FOREWORD………………………………………………………………………………………………310

4.2 PRECAUTIONS FOR MAINTENANCE……………………………………………………………………………..311

4.3 FLUIDS AND LUBRICANTS…………………………………………………………………………………..313

4.3.1 LUBRICANTS FOR OPERATION IN COLD AND ARCTIC CLIMATES………………………………………………….313

4.3.2 FLUIDS AND LUBRICANTS FOR MODERATE AND HOT CLIMATES…………………………………………………..314

4.3.3 MAIN DRIVE ELECTRIC MOTOR – BEARING LUBRICATION………………………………………………………315

4.4 FILLING CAPACITIES……………………………………………………………………………………..316

4.5 STANDARD TORQUE LIST……………………………………………………………………………………317

4.6 LUBRICATION AND MAINTENANCE SCHEDULE……………………………………………………………………..318

4.6.1 INITIAL SERVICING…………………………………………………………………………………318

4.6.2 PERIODIC SERVICING INTERVALS……………………………………………………………………….318

4.6.3 PERIODIC SERVICING SCHEDULE………………………………………………………………………..319

4.6.4 MAINTENANCE OF THE MAIN DRIVE ELECTRIC MOTOR…………………………………………………………323

4.6.5 REPLACEMENT OF HYDRAULIC HOSE LINES…………………………………………………………………325

4.6.6 PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS………………………………………………………..326

4.7 WHEN NECESSARY…………………………………………………………………………………………328

4.7.1 SWING CIRCLE TOOTHING LUBRICATION…………………………………………………………………..329

4.7.2 AUTOMATIC LUBRICATION SYSTEMS FILL GREASE BARRELS…………………………………………………….331

4.7.3 TRACK ROLLERS AND GUIDE WHEELS – REPLACE FLOATING SEALS……………………………………………….335

4.8 EVERY 10 OPERATING HOURS OR DAILY………………………………………………………………………..336

4.8.1 WALK-AROUND INSPECTION…………………………………………………………………………….337

4.8.2 CLEANING THE TRACK GROUPS………………………………………………………………………….345

4.9 EVERY 50 OPERATING HOURS OR WEEKLY……………………………………………………………………….346

4.9.1 SWING MACHINERY AND MOTOR ADAPTER HOUSINGS – CHECK OIL LEVELS………………………………………….347

4.9.2 TRAVEL GEARS, BRAKE HOUSINGS AND MOTOR ADAPTER HOUSINGS MANUFACTURED BY “L&S” – CHECK OIL LEVELS…………..351

4.9.3 FINAL DRIVE HOUSINGS – CHECK OIL LEVEL………………………………………………………………353

4.9.4 TRAVEL GEARS AND MOTOR ADAPTER HOUSINGS MANUFACTURED BY “ZOLLERN” – CHECK OIL LEVELS……………………..355

4.9.5 FINAL DRIVE HOUSINGS – CHECK OIL LEVEL………………………………………………………………357

4.9.6 PTO (PUMP DISTRIBUTOR GEAR) AND OIL RESERVOIR – CHECK OIL LEVEL………………………………………..359

4.9.7 HYDRAULIC ACCESS LADDER – CHECK SAFETY SENSOR………………………………………………………..361

4.9.8 HYDRAULIC OIL COOLERS – INSPECT AND CLEAN IF NECESSARY………………………………………………..363

4.10 EVERY 250 OPERATING HOURS OR MONTHLY…………………………………………………………………….364

4.10.1 UNDERCARRIAGE PIN CONNECTIONS – LUBRICATE…………………………………………………………..365

4.10.2 HYDRAULIC OIL COOLER FAN BEARING HOUSINGS – CHECK FOR LEAKAGE AND CLEAN BREATHER FILTER………………….365

4.10.3 SIGNAL HORN COMPRESSOR – LUBRICATE…………………………………………………………………365

4.10.4 AUTOMATIC LUBRICATION SYSTEMS – CLEAN IN-LINE GREASE FILTER…………………………………………..367

4.10.5 CAB AIR CLEANER – CLEAN OR REPLACE FILTER ELEMENT……………………………………………………371

4.10.6 WINDSHIELD WASHER RESERVOIR – CHECK FLUID LEVEL……………………………………………………..375

4.10.7 AIR CONDITIONING FOR OPERATOR’S CAB – CHECK REFRIGERANT LEVEL…………………………………………377

4.10.8 AIR CONDITIONING FOR ELECTRICAL SWITCH CABINETS – CHECK REFRIGERANT LEVEL………………………………379

4.11 EVERY 500 OPERATING HOURS OR MONTHLY…………………………………………………………………….382

4.11.1 BATTERIES – CHECK FLUID LEVEL……………………………………………………………………..383

4.11.2 PTO (PUMP DISTRIBUTOR GEAR) MAIN PUMP DRIVE SHAFT HOUSINGS – CHECK OIL LEVEL……………………………385

4.11.3 CRAWLER TRACK – INSPECTION………………………………………………………………………..387

4.11.4 GROUND CABLE OF OPERATOR’S CAB – CHECK FOR CORRECT CONNECTION…………………………………………393

4.12 EVERY 1000 OPERATING HOURS OR EVERY 6 MONTH………………………………………………………………394

4.12.1 HIGH STRENGTH BOLT CONNECTIONS…………………………………………………………………….395

4.12.2 HYDRAULIC SYSTEM – FILTER SERVICE………………………………………………………………….443

4.12.3 PTO (PUMP DISTRIBUTOR GEAR), SWING MACHINERY AND TRAVEL GEARS – OIL SAMPLE ANALYSIS……………………..457

4.12.4 SIGNAL HORN COMPRESSOR – CLEAN AND LUBRICATE………………………………………………………..459

4.12.5 HYDRAULIC TRACK TENSIONING SYSTEM – CHECK ACCUMULATORS……………………………………………….461

4.12.6 HYDRAULIC OIL COOLER – INSPECT AND LUBRICATE DOOR HINGES……………………………………………..463

4.12.7 MACHINERY HOUSE DOORS – INSPECT AND LUBRICATE DOOR HINGES…………………………………………….465

4.12.8 SLIP RING UNIT – LUBRICATE………………………………………………………………………..467

4.13 EVERY 2000 OPERATING HOURS OR YEARLY…………………………………………………………………….468

4.13.1 HYDRAULIC SYSTEM – CHANGE OIL, REPLACE SUCTION STRAINERS AND PULSATION DAMPER…………………………..469

4.13.2 BLEEDING THE HYDRAULIC SYSTEM……………………………………………………………………..481

4.13.3 GEAR PUMP FOR PTO GEAR LUBRICATION…………………………………………………………………483

4.13.4 EMERGENCY ESCAPE LADDER – INSPECTION……………………………………………………………….485

4.14 EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR……………………………………………………486

4.14.1 SWING GEARS AND MOTOR ADAPTER HOUSING – CHANGE OIL…………………………………………………..487

4.14.2 TRAVEL GEARS, BRAKE AND MOTOR ADAPTER HOUSINGS MANUFACTURED BY “L&S”- CHANGE OIL………………………..495

4.14.3 FINAL DRIVE HOUSINGS – CHANGE OIL………………………………………………………………….499

4.14.4 TRAVEL GEARS AND MOTOR ADAPTER HOUSINGS MANUFACTURED BY “ZOLLERN”- CHANGE OIL…………………………..501

4.14.5 FINAL DRIVE HOUSINGS – CHANGE OIL………………………………………………………………….505

4.14.6 PTO (PUMP DISTRIBUTOR GEAR) – CHANGE OIL……………………………………………………………507

4.15 FIRE PREVENTION……………………………………………………………………………………….508

4.16 WELD REPAIRS………………………………………………………………………………………….510

4.16.1 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE UNDERCARRIAGE………………………………….513

4.16.2 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE LOADER ATTACHMENT………………………………515

4.16.3 PROTECTIVE MEASURES BEFORE STARTING WELD REPAIRS ON THE SUPERSTRUCTURE…………………………………517

4.16.4 AFTER FINISHING THE WELD REPAIRS ON THE SUPERSTRUCTURE……………………………………………….518