$45

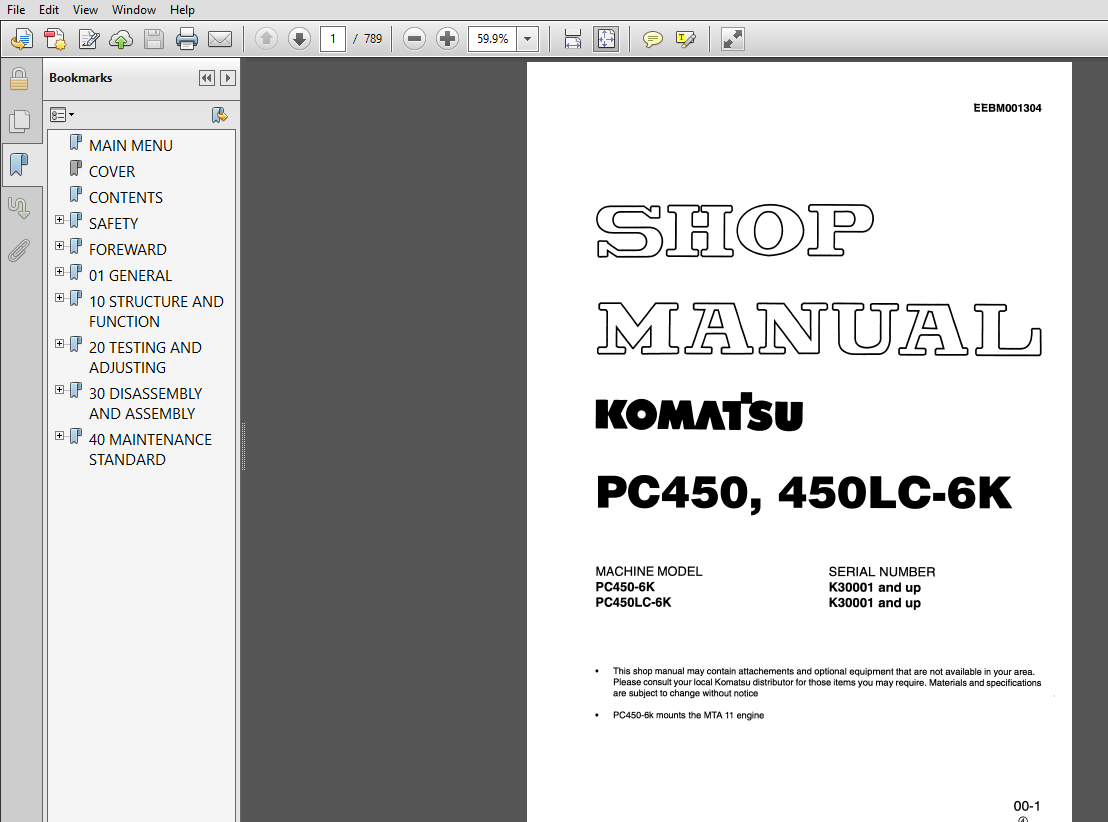

Komatsu PC450-6K, PC450LC-6K Hydraulic Excavator Shop Manual - PDF

Komatsu PC450-6K, PC450LC-6K Hydraulic Excavator Shop Manual

FILE DETAILS:

Komatsu PC450-6K, PC450LC-6K Hydraulic Excavator Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : EEBM001304

Total Pages : 789

DESCRIPTION:

Komatsu PC450-6K, PC450LC-6K Hydraulic Excavator Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance standards.

TESTING AND ADJUSTING:

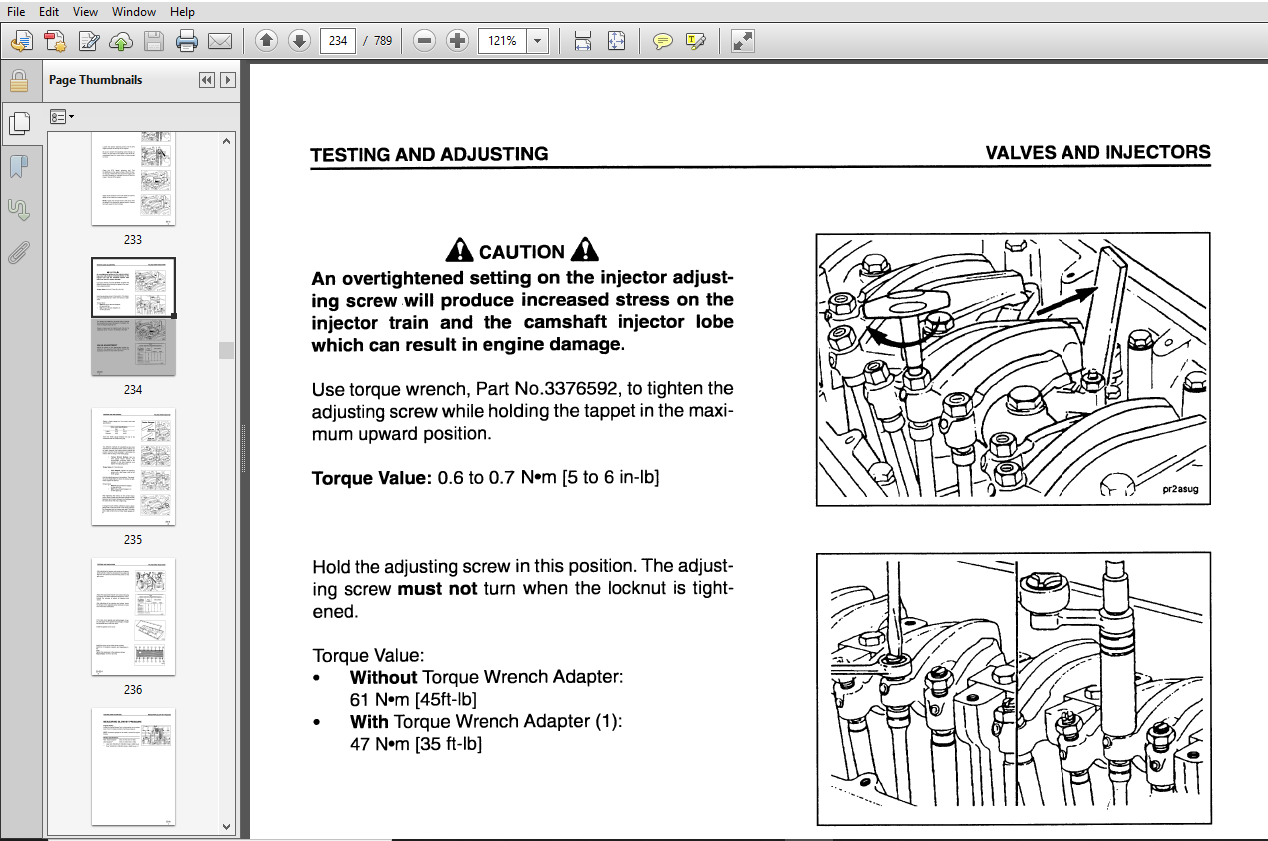

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

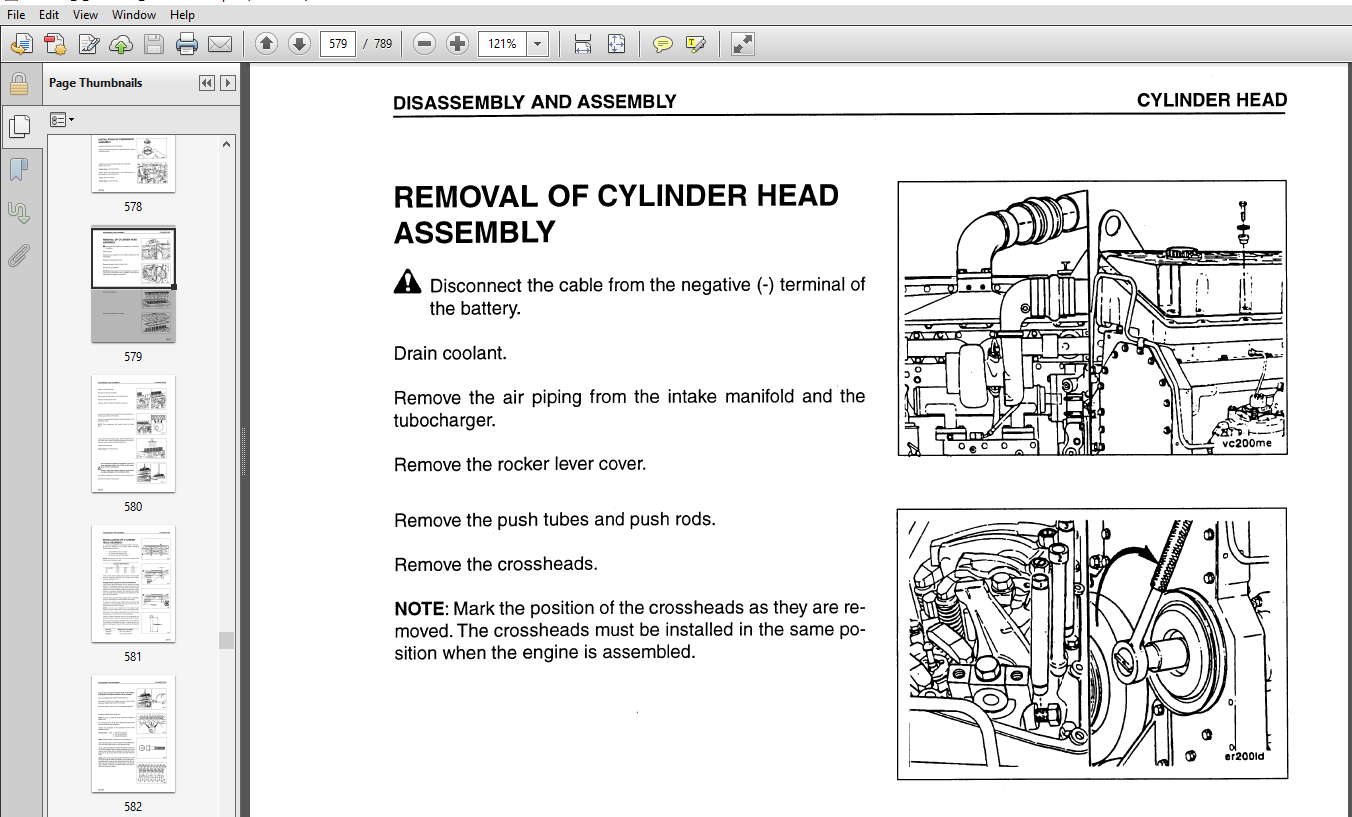

This section explains the procedures for removing, installing, disassembling and assembling each component, as well as precautions for them.

MAINTENANCE STANDARD:

This section gives the judgment standards for inspection of disassembled parts. The contents of this section may be described in STRUCTURE AND FUNCTION.

TABLE OF CONTENTS:

Komatsu PC450-6K, PC450LC-6K Hydraulic Excavator Shop Manual

MAIN MENU.................................................................................................................................... 0 COVER........................................................................................................................................ 1 CONTENTS..................................................................................................................................... 2 SAFETY....................................................................................................................................... 7 SAFETY NOTICE............................................................................................................................ 7 FOREWARD..................................................................................................................................... 9 GENERAL.................................................................................................................................. 9 HOW TO READ THE SHOP MANUAL.............................................................................................................. 10 HOISTING INSTRUCTIONS.................................................................................................................... 11 COATING MATERIALS........................................................................................................................ 12 STANDARD TIGHTENING TORQUE............................................................................................................... 13 ELECTRIC WIRE CODE....................................................................................................................... 15 CONVERSION TABLE......................................................................................................................... 16 01 GENERAL................................................................................................................................... 23 SPECIFICATION DRAWINGS................................................................................................................... 24 SPECIFICATIONS........................................................................................................................... 25 WEIGHT TABLE............................................................................................................................. 27 FUEL, COOLANT AND LUBRICANTS............................................................................................................. 29 10 STRUCTURE AND FUNCTION.................................................................................................................... 32 PARTS RELATED TO ENGINE.................................................................................................................. 33 RADIATOR, OIL COOLER..................................................................................................................... 35 POWER TRAIN.............................................................................................................................. 36 FINAL DRIVE.............................................................................................................................. 37 SWING CIRCLE............................................................................................................................. 38 SWING MACHINERY.......................................................................................................................... 39 TRACK FRAME, RECOIL SPRING............................................................................................................... 40 TRACK SHOE............................................................................................................................... 41 HYDRAULIC PIPING DRAWING................................................................................................................. 42 HYDRAULIC CIRCUIT DIAGRAM................................................................................................................ 43 HYDRAULIC TANK, HYDRAULIC FILTER......................................................................................................... 44 HYDRAULIC PUMP........................................................................................................................... 45 CONTROL VALVE............................................................................................................................ 67 SUCTION SAFETY VALVE..................................................................................................................... 75 CLSS..................................................................................................................................... 76 SWING MOTOR..............................................................................................................................117 CENTER SWIVEL JOINT......................................................................................................................121 TRAVEL MOTOR.............................................................................................................................122 VALVE CONTROL............................................................................................................................131 WORK EQUIPMENT, SWING PPC VALVE..........................................................................................................132 TRAVEL PPC VALVE.........................................................................................................................136 SERVICE PPC VALVE........................................................................................................................140 PPC SAFETY LOCK VALVE....................................................................................................................143 PPC ACCUMULATOR..........................................................................................................................143 PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE.................................................................................................144 EPC SOLENOID VALVE.......................................................................................................................151 FOR LS SELECT, BOOM HI 2 STAGE SAFETY VALVE, MERGE/FLOW DIVIDER, TRAVEL SPEED, SWING BRAKE...........................................151 FOR LS VALVE CONTROL.................................................................................................................153 BOOM SAFETY VALVE........................................................................................................................156 HYDRAULIC CYLINDER.......................................................................................................................159 OVERLOAD WARNING DEVICE..................................................................................................................160 WORK EQUIPMENT...........................................................................................................................164 ACTUAL ELECTRIC WIRING DIAGRAM...........................................................................................................166 ELECTRIC CIRCUIT DIAGRAM.................................................................................................................168 ENGINE CONTROL...........................................................................................................................170 ELECTRONIC CONTROL SYSTEM................................................................................................................176 MACHINE MONITOR SYSTEM...................................................................................................................200 BREAKER MODE HYDRAULIC PERFORMANCE.......................................................................................................208 20 TESTING AND ADJUSTING.....................................................................................................................211 STANDARD VALUE TABLE FOR ENGINE RELATED PARTS............................................................................................212 STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...........................................................................................213 STANDARD VALUE TABLE FOR ELECTRICAL PARTS................................................................................................221 TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING........................................................................................229 MEASURING EXHAUST COLOR..................................................................................................................230 VALVES AND INJECTORS.....................................................................................................................231 MEASURING BLOW-BY PRESSURE...............................................................................................................237 TESTING AND ADJUSTING FUEL INJECTION TIMING..............................................................................................239 MEASURING ENGINE OIL PRESSURE............................................................................................................245 TESTING AND ADJUSTING FAN BELT TENSION...................................................................................................246 TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR........................................................................246 ADJUSTING ENGINE SPEED SENSOR............................................................................................................247 MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)...........................................................................................248 TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE........................................................................................249 TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT........................................................250 TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)............................................................253 TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE................................255 TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE..................................................................................258 TESTING SOLENOID VALVE OUTPUT PRESSURE...................................................................................................260 MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE........................................................................262 ADJUSTING WORK EQUIPMENT, SWING PPC VALVE................................................................................................264 TESTING TRAVEL DEVIATION.................................................................................................................265 TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT..............................................................................266 MEASURING OIL LEAKAGE....................................................................................................................268 RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT........................................................................................270 TESTING CLEARANCE OF SWING CIRCLE BEARING................................................................................................271 TESTING AND ADJUSTING TRACK SHOE TENSION.................................................................................................272 BLEEDING AIR.............................................................................................................................273 TROUBLESHOOTING..........................................................................................................................275 POINTS TO REMEMBER WHEN TROUBLESHOOTING..............................................................................................276 SEQUENCE OF EVENTS IN TROUBLESHOOTING................................................................................................277 POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE.....................................................................................278 CHECKS BEFORE TROUBLSHOOTING.........................................................................................................286 CONNECTOR TYPES AND MOUNTING LOCATIONS...............................................................................................288 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...........................................................................................292 EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM...............................................................................302 DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL................................................................................303 METHOD OF USING JUDGEMENT TABLE......................................................................................................311 METHOD OF USING TROUBLESHOOTING CHARTS...............................................................................................313 DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE.............................................................................315 SERVICE CODE TABLE...................................................................................................................320 TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE).........................................................................321 N-1 [E218] COMMUNICATION ABNORMALITY.............................................................................................322 TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (GOVERNOR CONTROL SYSTEM) (E MODE)......................................................325 POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM.........................................326 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE.......................................................328 JUDGEMENT TABLE FOR GOVERNOR, PUMP GOVERNOR (GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS...................................332 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE SYSTEM.....................................................................................334 E-1 ABNORMALITY IN GOVERNOR, PUMP CONTROLLER POWER SOURCE (CONTROLLER LED IS OFF)................................................336 E-2 [E308] ABNORMALITY IN FUEL CONTROL DIAL INPUT VALUE IS DISPLAYED.............................................................337 E-3 [E317] ABNORMALITY (DISCONNECTION) IN MOTOR DRIVE SYSTEM IS DISPLAYED........................................................338 E-4 [E318] (SHORT CIRCUIT) IN MOTOR DRIVE SYSTEM IS DISPLAYED....................................................................339 E-5 [E306] ABNORMALITY IN FEEDBACK POTENTIOMETER SYSTEM IS DISPLAYED.............................................................340 E-6 [E315] ABNORMALITY (SHORT CIRCUIT) IN BATTERY RELAY OUTPUT SYSTEM IS DISPLAYED...............................................341 E-7 [E316] ABNORMALITY (STEP OUT) IN MOTOR IS DISPLAYED..........................................................................342 E-8 ENGINE DOES NOT START........................................................................................................344 E-9 ENGINE SPEED IS IRREGULAR....................................................................................................346 a) IDLING SPEED IS IRREGULAR.................................................................................................346 b) THERE IS HUNTING..........................................................................................................348 E-10 LACK OF OUTPUT (ENGINE HIGH IDLING SPEED IS TOO LOW)........................................................................350 E-11 ENGINE DOES NOT STOP........................................................................................................352 E-12 DEFECTIVE OPERATION OF BATTERY RELAY SYSTEM (ENGINE DOES NOT STOP)..........................................................354 TROUBLESHOOTING OF ENGINE (S MODE)...................................................................................................357 TROUBLESHOOTING PROCEDURES AND TECHNIQUES........................................................................................358 TROUBLESHOOTING SYMPTOMS CHARTS..................................................................................................358 ALTERNATOR NOT CHARGING OR INSUFFICIENT CHARGING.................................................................................359 ALTERNATOR OVERCHARGING..........................................................................................................360 COOLANT LOSS - EXTERNAL..........................................................................................................361 COOLANT TEMPERATURE ABOVE NORMAL - SUDDEN OVERHEAT (CONTINUED)...................................................................362 COOLANT TEMPERATURE BELOW NORMAL.................................................................................................363 CRANKCASE GASES (BLOWBY) - EXCESSIVE.............................................................................................364 ENGINE ACCELERATION/RESPONSE POOR................................................................................................365 ENGINE CRANKS BUT WILL NOT START (NO SMOKE FROM EXHAUST).........................................................................367 ENGINE DECELERATES SLOWLY........................................................................................................370 ENGINE DIFFICULT TO START OR WILL NOT START - EXHAUST SMOKE PRESENT..............................................................371 ENGINE NOISE EXCESSIVE*..........................................................................................................373 ENGINE NOISE EXCESSIVE - COMBUSTION KNOCKS.......................................................................................376 ENGINE NOISE EXCESSIVE - CONNECTING ROD*.........................................................................................377 ENGINE NOISE EXCESSIVE - MAIN BEARING*...........................................................................................378 ENGINE NOISE EXCESSIVE - PISTON*.................................................................................................379 ENGINE NOISE EXCESSIVE - TURBOCHARGER*...........................................................................................381 ENGINE POWER OUTPUT LOW - BASICS.................................................................................................382 ENGINE POWER OUTPUT - PERFORMANCE MEASUREMENT....................................................................................384 ENGINE RUNS ROUGH AT IDLE........................................................................................................386 ENGINE RUNS ROUGH OR MISFIRES....................................................................................................388 ENGINE SHUTS OFF UNEXPECTEDLY OR DIES DURING DECELERATION........................................................................390 ENGINE SPEED SURGES AT LOW IDLE..................................................................................................391 ENGINE SPEED SURGES (OTHER THAN LOW IDLE)........................................................................................392 ENGINE VIBRATION - EXCESSIVE.....................................................................................................393 ENGINE WILL NOT CRANK OR CRANKS SLOWLY (ELECTRIC STARTING MOTOR).................................................................394 ENGINE WILL NOT SHUT OFF.........................................................................................................396 ENGINE WILL START BUT WILL NOT KEEP RUNNING......................................................................................397 FUEL IN COOLANT..................................................................................................................399 FUEL IN LUBRICATING OIL..........................................................................................................400 INTAKE MANIFOLD AIR TEMPERATURE ABOVE SPECIFICATION..............................................................................401 LUBRICATING OIL CONSUMPTION EXCESSIVE............................................................................................402 LUBRICATING OIL CONTAMINATED.....................................................................................................404 LUBRICATING OIL PRESSURE - HIGH..................................................................................................405 LUBRICATING OIL PRESSURE - LOW...................................................................................................406 LUBRICATING OIL SLUDGE IN THE ENGINE CRANKCASE EXCESSIVE.........................................................................408 LUBRICATING OIL TEMPERATURE ABOVE SPECIFICATION..................................................................................410 LUBRICATING OIL IN THE COOLANT...................................................................................................411 SMOKE, BLACK - EXCESSIVE.........................................................................................................412 SMOKE, BLACK - EXCESSIVE - PERFORMANCE MEASUREMENT...............................................................................413 SMOKE, WHITE - EXCESSIVE.........................................................................................................415 TURBOCHARGER BOOST PRESSURE LOW..................................................................................................417 TURBOCHARGER LEAKS - ENGINE OIL OR FUEL..........................................................................................418 ENGINE NOISE DIAGNOSTIC PROCEDURES - GENERAL INFORMATION.........................................................................419 MAIN BEARING NOISE...............................................................................................................419 CONNECTING ROD BEARING NOISE.....................................................................................................419 PISTON NOISE.....................................................................................................................419 TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (PUMP CONTROL SYSTEM) (C MODE)..........................................................420 POINTS TO REMEMBER WHEN TROUBLESHOOTING PUMP CONTROLLER SYSTEM...................................................................421 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE - CONTINUED...........................................423 JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER (PUMP CONTROL SYSTEM) AND HYDRAULIC RELATED PARTS..................................427 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE............................................................................................429 C-1 ABNORMALITY IN CONTROLLER POWER SOURCE SYSTEM (CONTROLLER LED IS OFF)........................................................430 C-2 [E232] SHORT CIRCUIT IN FRONT PUMP TVC SOLENOID SYSTEM IS DISPLAYED..........................................................431 C-3 [E233] DISCONNECTION IN FRONT PUMP TVC SOLENOID SYSTEM IS DISPLAYED..........................................................433 C-4 [E236] SHORT CIRCUIT IN REAR PUMP TVC SOLENOID SYSTEM IS DISPLAYED...........................................................435 C-5 [E237] DISCONNECTION IN REAR PUMP TVC SOLENOID SYSTEM IS DISPLAYED...........................................................437 C-6 [E202] SHORT CIRCUIT IN LS SELECT SOLENOID SYSTEM IS DISPLAYED...............................................................439 C-7 [E212] DISCONNECTION IN LS SELECT SOLENOID SYSTEM IS DISPLAYED...............................................................440 C-8 [E203] SHORT CIRCUIT IN SWING BRAKE SOLENOID SYSTEM IS DISPLAYED.............................................................441 C-9 [E213] DISCONNECTION IN SWING BRAKE SOLENOID SYSTEM IS DISPLAYED.............................................................443 C-10 [E204] SHORT CIRCUIT IN PUMP MERGE/DIVIDER SOLENOID SYSTEM IS DISPLAYED.....................................................445 C-11 [E214] DISCONNECTION IN PUMP MERGE/DIVIDER SOLENOID SYSTEM IS DISPLAYED.....................................................446 C-12 [E206] SHORT CIRCUIT IN TRAVEL SPEED SOLENOID SYSTEM IS DISPLAYED...........................................................447 C-13 [E216] DISCONNECTION IN TRAVEL SPEED SOLENOID SYSTEM IS DISPLAYED...........................................................448 C-14 [E217] MODEL SELECTION INPUT ERROR IS DISPLAYED.............................................................................449 C-15 [E222] SHORT CIRCUIT IN LS-EPC SOLENOID SYSTEM IS DISPLAYED.................................................................451 C-16 [E223] DISCONNECTION IN LS-EPC SOLENOID SYSTEM IS DISPLAYED.................................................................452 C-17 [E224] ABNORMALITY IN FRONT PUMP PRESSURE SENSOR SYSTEM IS DISPLAYED........................................................453 C-18 [E225] ABNORMALITY IN REAR PUMP PRESSURE SENSOR SYSTEM IS DISPLAYED.........................................................454 C-19 [E226] ABNORMALITY IN PRESSURE SENSOR POWER SOURCE SYSTEM IS DISPLAYED......................................................455 C-20 [E227] ABNORMALITY IN ENGINE SPEED SENSOR SYSTEM IS DISPLAYED...............................................................456 C-21 ABNORMALITY IN MACHINE 2 - STAGE PRESSURE RELIEF SOLENOID SYSTEM (NO SERVICE CODE DISPLAYED)................................457 TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)..........................................................459 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE............................................................................................460 F-1 BIT PATTERN 20-(1) SWING OIL PRESSURE SWITCH DOES NOT LIGHT UP...............................................................461 F-2 BIT PATTERN 20-(2) TRAVEL OIL PRESSURE SWITCH DOES NOT LIGHT UP..............................................................462 F-3 BIT PATTERN 20-(3) BOOM LOWER OIL PRESSURE SWITCH DOES NOT LIGHT UP..........................................................463 F-4 BIT PATTERN 20-(4) BOOM RAISE OIL PRESSURE SWITCH DOES NOT LIGHT UP..........................................................464 F-5 BIT PATTERN 20-(5) ARM IN OIL PRESSURE SWITCH DOES NOT LIGHT UP..............................................................465 F-6 BIT PATTERN 20-(6) ARM OUT OIL PRESSURE SWITCH DOES NOT LIGHT UP.............................................................466 F-7 BIT PATTERN 21-(1) BUCKET CURL OIL PRESSURE SWITCH DOES NOT LIGHT UP.........................................................467 F-8 BIT PATTERN 21-(2) BUCKET DUMP OIL PRESSURE SWITCH DOES NOT LIGHT UP.........................................................468 F-9 BIT PATTERN 21-(3) SWING LOCK SWITCH DOES NOT LIGHT UP.......................................................................469 F-11 BIT PATTERN 22-(6) L.H. KNOB SWITCH DOES NOT LIGHT UP.......................................................................470 TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE).............................................................................472 PUMP MERGE/DIVIDER LOGIC, LS SELECT LOGIC, SOLENOID ACTUATION TABLE..............................................................473 TABLE OF FAILURE MODES AND CAUSES................................................................................................475 H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS....................................................................479 H-3 NO WORK EQUIPMENT, TRAVEL, SWING MOVE........................................................................................480 H-4 ABNORMAL NOISE GENERATED (AROUND PUMP).......................................................................................480 H-5 AUTO-DECELERATION DOES NOT WORK (WHEN PPC SHUTTLE VALVE IS CAUSE)............................................................481 H-6 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR.............................................................................481 H-7 BOOM IS SLOW OR LACKS POWER..................................................................................................483 H-8 ARM IS SLOW OR LACKS POWER...................................................................................................485 H-9 BUCKET IS SLOW OR LACKS POWER................................................................................................487 H-10 WORK EQUIPMENT (BOOM, ARM, BUCKET) DOES NOT MOVE (BUT TRAVEL AND SWING ARE NORMAL)..........................................488 H-11 EXCESSIVE HYDRAULIC DRIFT (BOOM, ARM, BUCKET)...............................................................................488 H-12 EXCESSIVE TIME LAG (ENGINE AT LOW IDLING)...................................................................................489 H-13 OTHER EQUIPMENT MOVES WHEN SINGLE CIRCUIT IS RELIEVED.......................................................................489 H-14 IN L/O, F/O MODES, WORK EQUIPMENT SPEED IS FASTER THAN SPECIFIED SPEED......................................................490 H-15 DEFECTIVE ACTUATION OF MACHINE 2 STAGE PRESSURE RELIEF FUNCTION.............................................................490 H-16 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW.............................................................490 H-17 IN SWING + BOOM RAISE, BOOM RAISE IS SLOW...................................................................................491 H-18 IN SWING + ARM, ARM IS SLOW.................................................................................................491 H-19 IN SWING + TRAVEL, TRAVEL SPEED DROPS EXCESSIVELY...........................................................................491 H-20 TRAVEL DEVIATION............................................................................................................492 H-21 TRAVEL SPEED IS SLOW........................................................................................................493 H-22 STEERING DOES NOT TURN EASILY OR LACKS POWER................................................................................495 H-23 TRAVEL SPEED DOES NOT SWITCH OR IS FASTER THAN SPECIFIED SPEED..............................................................497 H-24 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)........................................................................................497 H-25 DOES NOT SWING..............................................................................................................498 H-26 SWING ACCELERATION IS POOR OR SWING SPEED IS SLOW...........................................................................499 H-27 EXCESSIVE OVERRUN WHEN STOPPING SWING.......................................................................................501 H-28 EXCESSIVE SHOCK WHEN STOPPING SWING (ONE DIRECTION ONLY)....................................................................502 H-29 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING................................................................................502 H-30 EXCESSIVE HYDRAULIC DRIFT OF SWING..........................................................................................503 H-31 SWING SPEED IS FASTER THAN SPECIFIED SWING SPEED............................................................................504 TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)...................................................................................507 ACTION TAKEN BY MONITOR PANEL WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE....................................................509 ELECTRICAL CIRCUIT DIAGRAM FOR M MODE SYSTEM.....................................................................................511 M-1 [E101] ABNORMALITY IN ERROR DATA IS DISPLAYED, [E102] ERROR IN CLOCK DATA IS DISPLAYED.......................................512 M-2 [E103] SHORT CIRCUIT IN BUZZER OUTPUT OR CONTACT OF 24V WIRING HARNESS WITH BUZZER DRIVE HARNESS IS DISPLAYED................513 M-3 [E104] AIR CLOGGING DETECTED IS DISPLAYED....................................................................................514 M-4 [E106] DROP IN ENGINE OIL PRESSURE DETECTED IS DISPLAYED.....................................................................514 M-5 [E108] ENGINE WATER TEMPERATURE 105 C DETECTED IS DISPLAYED..................................................................515 M-6 WHEN STARTING SWITCH IS TURNED ON, NONE OF THE LAMPS ON THE MONITOR PANEL LIGHT UP FOR 3 SECONDS.............................516 M-7 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL LAMPS ALL STAY LIT UP AND DO NOT GO OUT.....................................518 M-8 WHEN STARTING SWITCH IS TURNED ON, ITEMS LIT UP ON MONITOR PANEL ARE DIFFERENT FROM ACTUAL MACHINE (MODEL)...................518 M-9 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), BASIC CHECK ITEMS FLASHES................................................519 M-10 PREHEATING IS NOT BEING USED BUT (PREHEATING MOTOR) LIGHTS UP...............................................................522 M-11 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, BASIC CHECK ITEMS FLASH............................................523 M-12 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CAUTION ITEMS, EMERGENCY ITEMS FLASH (BATTERY, ENGINE OIL PRESSURE L....525 M-13 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CAUTION ITEMS, EMERGENCY ITEMS FLASH (THEN THERE IS NO ABNORMAL....527 M-14 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), BUZZER DOES NOT SOUND FOR 1 SECOND CAUTION ITEM FLASHES BUT BUZZER D....530 M-15 NO ABNORMALITY IS DISPLAYED ON MONITOR BUT BUZZER SOUNDS....................................................................530 M-16 NIGHT LIGHTING ON MONITOR PANEL DOES NOT LIGHT UP (LIQUID CRYSTAL DISPLAY IS NORMAL)........................................531 M-17 COOLANT TEMPERATURE GAUGE DOES NOT RISE.....................................................................................532 M-18 COOLANT TEMPERATURE GAUGE DOES NOT GIVE ANY DISPLAY (NONE OF GAUGE LAMPS LIGHT UP DURING OPERATION).........................532 M-19 FUEL LEVEL GAUGE ALWAYS DISPLAYS FULL.......................................................................................533 M-20 FUEL LEVEL GAUGE DOES NOT GIVE DISPLAY......................................................................................533 M-21 SWING LOCK SWITCH IS TURNED ON (LOCK) BUT (SWING LOCK MONITOR) DOES NOT LIGHT UP............................................534 M-22 SWING PROLIX SWITCH IS TURNED ON (PROLIX), BUT (SWING LOCK MONITOR) DOES NOT FLASH..........................................534 M-23 SERVICE METER DOES NOT ADVANCE WHILE ENGINE IS RUNNING......................................................................535 M-24 WHEN STARTING SWITCH IS AT OFF AND TIME SWITCH IS PRESSED, TIME AND SERVICE METER ARE NOT DISPLAYED.........................535 M-25 DEFECTIVE FUEL LEVEL SENSOR SYSTEM..........................................................................................536 M-26 DEFECTIVE COOLANT TEMPERATURE SENSOR SYSTEM.................................................................................537 M-27 DEFECTIVE ENGINE OIL LEVEL SENSOR SYSTEM....................................................................................538 M-28 DEFECTIVE COOLANT LEVEL SENSOR SYSTEM.......................................................................................539 M-29 DEFECTIVE HYDRAULIC OIL LEVEL SENSOR SYSTEM.................................................................................540 M-30 WIPER DOES NOT WORK OR SWITCH IS NOT BEING USED BUT WIPER IS ACTUATED.......................................................541 M-31 WORKING LIGHT, PANEL LIGHTING DO NOT LIGHT UP, OR SWITCH IS NOT BEING USED BUT LIGHTS UP....................................545 30 DISASSEMBLY AND ASSEMBLY..................................................................................................................547 METHOD OF USING MANUAL...................................................................................................................549 PRECAUTIONS WHEN CARRYING OUT OPERATION..................................................................................................551 SPECIAL TOOL LIST........................................................................................................................553 SKETCHES OF SPECIAL TOOLS................................................................................................................560 STARTING MOTOR ASSEMBLY..................................................................................................................568 REMOVAL AND INSTALLATION.............................................................................................................568 ALTERNATOR ASSEMBLY......................................................................................................................569 REMOVAL AND INSTALLATION.............................................................................................................569 NOZZLE HOLDER ASSEMBLY...................................................................................................................570 REMOVAL AND INSTALLATION.............................................................................................................570 THERMOSTAT ASSEMBLY......................................................................................................................578 REMOVAL AND INSTALLATION.............................................................................................................578 CYLINDER HEAD ASSEMBLY...................................................................................................................579 REMOVAL..............................................................................................................................579 INSTALLATION.........................................................................................................................581 HYDRAULIC COOLER ASSEMBLY................................................................................................................587 REMOVAL..............................................................................................................................587 INSTALLATION.........................................................................................................................588 RADIATOR, HYDRAULIC COOLER ASSEMBLY......................................................................................................589 REMOVAL..............................................................................................................................589 INSTALLATION.........................................................................................................................591 ENGINE, MAIN PUMP ASSEMBLY...............................................................................................................592 REMOVAL..............................................................................................................................592 INSTALLATION.........................................................................................................................595 DAMPER ASSEMBLY..........................................................................................................................596 REMOVAL AND INSTALLATION.............................................................................................................596 FUEL TANK ASSEMBLY.......................................................................................................................597 REMOVAL AND INSTALLATION.............................................................................................................597 CENTER SWIVEL JOINT ASSEMBLY.............................................................................................................598 REMOVAL AND INSTALLATION.............................................................................................................598 DISASSEMBLY AND ASSEMBLY.............................................................................................................599 FINAL DRIVE ASSEMBLY.....................................................................................................................600 REMOVAL AND INSTALLATION.............................................................................................................600 DISASSEMBLY..........................................................................................................................601 ASSEMBLY.............................................................................................................................605 TRAVEL MOTOR ASSEMBLY....................................................................................................................610 DISASSEMBLY..........................................................................................................................610 ASSEMBLY.............................................................................................................................615 SPROCKET.................................................................................................................................627 REMOVAL AND INSTALLATION.............................................................................................................627 SWING MOTOR ASSEMBLY.....................................................................................................................628 DISASSEMBLY..........................................................................................................................628 ASSEMBLY.............................................................................................................................631 REMOVAL AND INSTALLATION.............................................................................................................638 SWING MACHINERY ASSEMBLY.................................................................................................................639 REMOVAL AND INSTALLATION.............................................................................................................639 DISASSEMBLY..........................................................................................................................640 ASSEMBLY.............................................................................................................................644 REVOLVING FRAME ASSEMBLY.................................................................................................................649 REMOVAL..............................................................................................................................649 INSTALLATION.........................................................................................................................650 SWING CIRCLE ASSEMBLY....................................................................................................................651 REMOVAL AND INSTALLATION.............................................................................................................651 IDLER, RECOIL SPRING ASSEMBLY............................................................................................................652 REMOVAL AND INSTALLATION.............................................................................................................652 IDLER ASSEMBLY...........................................................................................................................653 DISASSEMBLY..........................................................................................................................653 ASSEMBLY.............................................................................................................................654 RECOIL SPRING ASSEMBLY...................................................................................................................656 DISASSEMBLY..........................................................................................................................656 ASSEMBLY.............................................................................................................................657 TRACK ROLLER ASSEMBLY....................................................................................................................658 REMOVAL AND INSTALLATION.............................................................................................................658 DISASSEMBLY..........................................................................................................................659 ASSEMBLY.............................................................................................................................660 CARRIER ROLLER ASSEMBLY..................................................................................................................662 REMOVAL AND INSTALLATION.............................................................................................................662 DISASSEMBLY..........................................................................................................................663 ASSEMBLY.............................................................................................................................665 TRACK SHOE ASSEMBLY......................................................................................................................667 REMOVAL AND INSTALLATION.............................................................................................................667 HYDRAULIC TANK ASSEMBLY..................................................................................................................668 REMOVAL..............................................................................................................................668 INSTALLATION.........................................................................................................................669 CONTROL PUMP ASSEMBLY....................................................................................................................670 REMOVAL AND INSTALLATION.............................................................................................................670 MAIN PUMP ASSEMBLY.......................................................................................................................671 REMOVAL..............................................................................................................................671 INSTALLATION.........................................................................................................................672 DISASSEMBLY..........................................................................................................................680 ASSEMBLY.............................................................................................................................686 MAIN PUMP INPUT SHAFT OIL SEAL...........................................................................................................695 REMOVAL AND INSTALLATION.............................................................................................................695 CONTROL VALVE ASSEMBLY...................................................................................................................696 REMOVAL..............................................................................................................................696 INSTALLATION.........................................................................................................................698 DISASSEMBLY..........................................................................................................................699 ASSEMBLY.............................................................................................................................703 PUMP MERGE/DEVIDER VALVE ASSEMBLY........................................................................................................708 DISASSEMBLY AND ASSEMBLY.............................................................................................................708 PRESSURE COMPENSATION VALVE ASSEMBLY.....................................................................................................709 DISASSEMBLY AND ASSEMBLY.............................................................................................................709 SERVO VALVE ASSEMBLY FOR FRONT PUMP .....................................................................................................710 REMOVAL AND INSTALLATION.............................................................................................................710 SERVO VALVE ASSEMBLY FOR REAR PUMP.......................................................................................................711 REMOVAL AND INSTALLATION.............................................................................................................711 LS-EPC SOLENOID VALVE ASSEMBLY...........................................................................................................712 REMOVAL AND INSTALLATION.............................................................................................................712 SOLENOID VALVE ASSEMBLY..................................................................................................................713 REMOVAL AND INSTALLATION.............................................................................................................713 WORK EQUIPMENT PPC VALVE ASSEMBLY........................................................................................................714 REMOVAL AND INSTALLATION.............................................................................................................714 DISASSEMBLY..........................................................................................................................715 ASSEMBLY.............................................................................................................................716 TRAVEL PPC VALVE ASSEMBLY................................................................................................................717 REMOVAL AND INSTALLATION.............................................................................................................717 DISASSEMBLY..........................................................................................................................718 ASSEMBLY.............................................................................................................................719 PPC SHUTTLE VALVE ASSEMBLY...............................................................................................................720 REMOVAL..............................................................................................................................720 INSTALLATION.........................................................................................................................721 DISASSEMBLY..........................................................................................................................722 ASSEMBLY.............................................................................................................................723 BOOM CYLINDER ASSEMBLY...................................................................................................................724 REMOVAL..............................................................................................................................724 INSTALLATION.........................................................................................................................725 ARM CYLINDER ASSEMBLY....................................................................................................................726 REMOVAL..............................................................................................................................726 INSTALLATION.........................................................................................................................727 BUCKET CYLINDER ASSEMBLY.................................................................................................................728 REMOVAL..............................................................................................................................728 INSTALLATION.........................................................................................................................729 HYDRAULIC CYLINDER ASSEMBLY..............................................................................................................730 DISASSEMBLY..........................................................................................................................730 ASSEMBLY.............................................................................................................................732 WORK EQUIPMENT ASSEMBLY..................................................................................................................734 REMOVAL..............................................................................................................................734 INSTALLATION.........................................................................................................................735 BUCKET ASSEMBLY..........................................................................................................................736 REMOVAL..............................................................................................................................736 INSTALLATION.........................................................................................................................737 ARM ASSEMBLY.............................................................................................................................738 REMOVAL..............................................................................................................................738 INSTALLATION.........................................................................................................................739 BUCKET, ARM ASSEMBLY.....................................................................................................................740 REMOVAL..............................................................................................................................740 INSTALLATION.........................................................................................................................741 BOOM ASSEMBLY............................................................................................................................742 REMOVAL..............................................................................................................................742 INSTALLATION.........................................................................................................................743 OPERATOR'S CAB ASSEMBLY..................................................................................................................744 REMOVAL..............................................................................................................................744 INSTALLATION.........................................................................................................................745 COUNTERWEIGHT ASSEMBLY...................................................................................................................746 REMOVAL AND INSTALLATION.............................................................................................................746 GOVERNOR, PUMP CONTROLLER ASSEMBLY.......................................................................................................747 REMOVAL AND INSTALLATION.............................................................................................................747 MONITOR PANEL ASSEMBLY...................................................................................................................748 REMOVAL AND INSTALLATION.............................................................................................................748 CONTROL STAND CASE.......................................................................................................................749 REMOVAL..............................................................................................................................749 INSTALLATION.........................................................................................................................750 40 MAINTENANCE STANDARD......................................................................................................................752 SWING MACHINERY..........................................................................................................................753 SWING CIRCLE.............................................................................................................................755 FINAL DRIVE..............................................................................................................................756 TRACK FRAME AND RECOIL SPRING............................................................................................................758 IDLER....................................................................................................................................759 CARRIER ROLLER...........................................................................................................................761 TRACK ROLLER.............................................................................................................................762 TRACK....................................................................................................................................763 HYDRAULIC PUMP...........................................................................................................................766 CONTROL PUMP AND RELIEF VALVE............................................................................................................768 CONTROL VALVE............................................................................................................................769 SUCTION SAFETY VALVE.....................................................................................................................775 SWING MOTOR..............................................................................................................................776 TRAVEL MOTOR.............................................................................................................................777 WORK EQUIPMENT, SWING PPC VALVE..........................................................................................................778 TRAVEL PPC VALVE.........................................................................................................................779 SERVICE PPC VALVE........................................................................................................................780 PPC SHUTTLE VALVE, TRAVEL JUNCTION.......................................................................................................781 EPC SOLENOID VALVE.......................................................................................................................782 CENTER SWIVEL JOINT......................................................................................................................783 HYDRAULIC CYLINDER.......................................................................................................................784 WORK EQUIPMENT...........................................................................................................................785 DIMENSIONS OF WORK EQUIPMENT.............................................................................................................787

IMAGES PREVIEW OF THE MANUAL: