$38

Komatsu PC650-5 PC710-5 Shop Manual(SEBM000607) – PDF DOWNLOAD

Komatsu PC650-5 PC710-5 Shop Manual(SEBM000607) – PDF DOWNLOAD

DESCRIPTION:

Komatsu PC650-5 PC710-5 Shop Manual(SEBM000607) – PDF DOWNLOAD

SAFETY

SAFETY NOTICE

IMPORTANT SAFETY NOTICE

Proper service and repair is extremely important for safe machine operation. The

service and repair techniques recommended by Komatsu and described in this manual are both

effective and safe. Some of these techniques require the use of tools specially designed by

Komatsu for the specific purpose.

To prevent injury to workers, the sym bol 丛is used to mark safety precautions in this manual. The

cautions accompanying these symbols should always be followed care

fully. If any dangerous situation arises or may possibly arise, first consider safety, and take

the necessary actions to deal with the situation.

GENERAL PRECAUTIONS

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual

carefully BEFORE operating the machine.

1. Before carrying out any greasing or repairs, read all the precautions given on the decals

which are fixed to the machine.

2. When carrying out any operation, always wear safety shoes and helmet. Do not wear

loose work clothes, or clothes with buttons missing.

• Always wear safety glasses when hitting parts with a hammer.

• Always wear safety glasses when grind ing parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the

work. When carrying out welding work, al ways wear welding gloves, apron, hand

shield, cap and other clothes suited for weld ing work.

4. When carrying out any operation with two or more workers, always agree on the oper

ating procedure before starting. Always in form your fellow workers before starting any step

of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the

operator’s compartment.

5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the

tools and parts in their correct places. Always keep the work area clean and make sure

that there is no dirt or oil on the floor. Smoke only in the areas provided for smok ing.

Never smoke while working.

PREPARATIONS FOR WORK

7. Before adding oil or making any repairs, park the machine on hard, level ground, and

block the wheels or tracks to prevent the machine from moving.

8. Before starting work, lower blade, ripper, bucket or any other work equipment to

the ground. If this is not possible, insert the safety pin or use blocks to prevent the

work equipment from falling. In addition, be sure to lock all the control levers and hang warn

ing signs on them.

9. When disassembling or assembling, support the machine with blocks, jacks or stands

before starting work.

10. Remove all mud and oil from the steps or other places used to get on and off the

ma chine. Always use the handrails, ladders or steps when getting on or off the

machine. Never jump on or off the machine. If it is impossible to use the handrails,

ladders or steps, use a stand to provide safe footing.

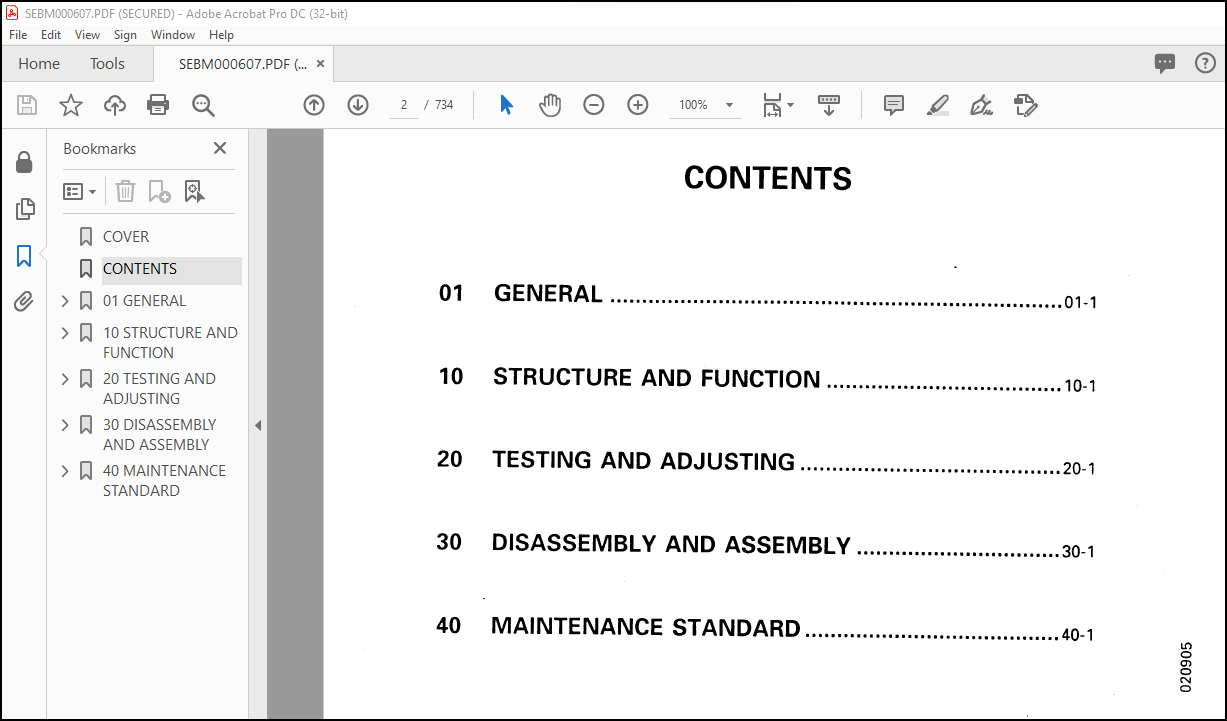

TABLE OF CONTENTS:

Komatsu PC650-5 PC710-5 Shop Manual(SEBM000607) – PDF DOWNLOAD

COVER……………………………………………………………………………………………………………………………….. 1

CONTENTS…………………………………………………………………………………………………………………………….. 2

01 GENERAL…………………………………………………………………………………………………………………………… 23

ASSEMBLY DRAWING………………………………………………………………………………………………………………….. 24

SPECIFICATIONS……………………………………………………………………………………………………………………. 30

WEIGHT TABLE……………………………………………………………………………………………………………………… 36

LIST OF LUBRICANT AND WATER………………………………………………………………………………………………………… 42

10 STRUCTURE AND FUNCTION……………………………………………………………………………………………………………… 43

PTO (POWER TAKE-OFF)………………………………………………………………………………………………………………. 44

PTO LUBRICATION SYSTEM…………………………………………………………………………………………………………….. 45

RADIATOR AND OIL COOLER……………………………………………………………………………………………………………. 46

POWER TRAIN………………………………………………………………………………………………………………………. 47

SWING MACHINERY…………………………………………………………………………………………………………………… 48

SWING CIRCLE……………………………………………………………………………………………………………………… 49

FINAL DRIVE………………………………………………………………………………………………………………………. 50

TRACK FRAME………………………………………………………………………………………………………………………. 51

IDLER CUSHION…………………………………………………………………………………………………………………….. 53

IDLER……………………………………………………………………………………………………………………………. 53

TRACK ROLLER……………………………………………………………………………………………………………………… 54

CARRIER ROLLER……………………………………………………………………………………………………………………. 54

TRACK SHOE……………………………………………………………………………………………………………………….. 55

AIR PIPING……………………………………………………………………………………………………………………….. 56

AIR CIRCUIT DIAGRAM……………………………………………………………………………………………………………….. 57

AIR COMPRESSOR……………………………………………………………………………………………………………………. 57

AIR GOVERNOR……………………………………………………………………………………………………………………… 58

AIR TANK…………………………………………………………………………………………………………………………. 58

SAFETY VALVE……………………………………………………………………………………………………………………… 59

HORN VALVE……………………………………………………………………………………………………………………….. 59

GREASE PUMP………………………………………………………………………………………………………………………. 60

HYDRAULIC UNIT LOCATION……………………………………………………………………………………………………………. 61

HYDRAULIC CIRCUIT DIAGRAM………………………………………………………………………………………………………….. 63

HYDRAULIC TANK……………………………………………………………………………………………………………………. 66

NO.1 PUMP………………………………………………………………………………………………………………………… 67

NO.2 PUMP………………………………………………………………………………………………………………………… 86

SWING PUMP……………………………………………………………………………………………………………………….. 91

CHARGING AND PTO LUBRICATING PUMP…………………………………………………………………………………………………… 96

LINE OIL FILTER…………………………………………………………………………………………………………………… 97

PILOT OIL FILTER………………………………………………………………………………………………………………….. 97

RETURN OIL FILTER…………………………………………………………………………………………………………………. 98

DRAIN OIL FILTER………………………………………………………………………………………………………………….. 98

L.H. 5-SPOOL CONTROL VALVE…………………………………………………………………………………………………………. 99

R.H. 4-SPOOL CONTROL VALVE………………………………………………………………………………………………………….103

SWING CONTROL VALVE………………………………………………………………………………………………………………..108

SWING MOTOR……………………………………………………………………………………………………………………….111

CENTER SWIVEL JOINT………………………………………………………………………………………………………………..115

TRAVEL MOTOR………………………………………………………………………………………………………………………116

CONTROL RELIEF VALVE……………………………………………………………………………………………………………….123

SAFETY LOCK VALVE………………………………………………………………………………………………………………….124

ACCUMULATOR……………………………………………………………………………………………………………………….126

PPC VALVE…………………………………………………………………………………………………………………………127

SOLENOID VALVE ASSEMBLY…………………………………………………………………………………………………………….131

EPC VALVE…………………………………………………………………………………………………………………………136

AUTO-DECELERATION CYLINDER………………………………………………………………………………………………………….138

PPC SHUTTLE VALVE………………………………………………………………………………………………………………….139

HYDRAULIC CYLINDER…………………………………………………………………………………………………………………140

WORK EQUIPMENT…………………………………………………………………………………………………………………….144

ELECTRICAL WIRING DIAGRAM…………………………………………………………………………………………………………..147

ELECTRICAL CIRCUIT DIAGRAM………………………………………………………………………………………………………….153

ENGINE CONTROL…………………………………………………………………………………………………………………….169

MACHINE CONTROL SYSTEM……………………………………………………………………………………………………………..171

WORK EQUIPMENT CONTROL SYSTEM……………………………………………………………………………………………………….201

MACHINE MONITORING SYSTEM…………………………………………………………………………………………………………..206

20 TESTING AND ADJUSTING……………………………………………………………………………………………………………….227

TABLE OF JUDGEMENT STANDARD VALUE……………………………………………………………………………………………………228

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM……………………………………………………………………………………………245

TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING………………………………………………………………………………………254

MEASURING ENGINE SPEED……………………………………………………………………………………………………………..255

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)………………………………………………………………………………………..256

MEASURING EXHAUST GAS TEMPERATURE……………………………………………………………………………………………………257

MEASURING EXHAUST GAS COLOR…………………………………………………………………………………………………………258

ADJUSTING VALVE CLEARANCE…………………………………………………………………………………………………………..259

MEASURING COMPRESSION PRESSURE………………………………………………………………………………………………………260

MEASURING BLOW-BY PRESSURE………………………………………………………………………………………………………….261

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………………………………………………………………..262

MEASURING ENGINE OIL PRESSURE……………………………………………………………………………………………………….264

TESTING AND ADJUSTING ALTERNATOR BELT TENSION…………………………………………………………………………………………265

TESTING AND ADJUSTING FAN BELT TENSION……………………………………………………………………………………………….265

ADJUSTING FUEL CONTROL LINKAGE………………………………………………………………………………………………………266

ADJUSTING ENGINE SPEED SENSOR……………………………………………………………………………………………………….271

CHECKING SWING CIRCLE BEARING CLEARANCE………………………………………………………………………………………………272

TESTING AND ADJUSTING TRACK SHOE TENSION……………………………………………………………………………………………..273

TESTING AND ADJUSTING WORK EQUIPMENT, SWING, TRAVEL CIRCUIT PRESSURE…………………………………………………………………….274

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE………………………………………………………………………………………..277

TESTING AND ADJUSTING PISTON PUMP CONTROL PRESSURE…………………………………………………………………………………….279

MEASURING STROKE OF SERVO PISTON…………………………………………………………………………………………………….285

TESTING AND ADJUSTING TRAVEL DEVIATION……………………………………………………………………………………………….286

MEASURING OIL LEAKAGE………………………………………………………………………………………………………………288

CHECKING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT……………………………………………………………………………292

MEASURING PPC VALVE OUTPUT PRESSURE………………………………………………………………………………………………….293

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE…………………………………………………………………………………………….294

MEASURING SOLENOID VALVE OUTLET PRESSURE……………………………………………………………………………………………..295

BLEEDING AIR………………………………………………………………………………………………………………………296

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT……………………………………………………………………………………..298

TROUBLESHOOTING……………………………………………………………………………………………………………………299

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………………………………………………………………………………………..300

SEQUENCE OF EVENTS IN TROUBLESHOOTING…………………………………………………………………………………………….301

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE…………………………………………………………………………………..302

CHECKS BEFORE TROUBLESHOOTING……………………………………………………………………………………………………310

ELECTRICAL CIRCUIT DIAGRAM………………………………………………………………………………………………………311

POSITION OF CONNECTORS FOR TROUBLESHOOTING………………………………………………………………………………………..336

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS………………………………………………………………………………………..340

SELF-DIAGNOSTIC DISPLAY OF CONTROLLERS……………………………………………………………………………………………350

METHOD OF USING JUDGEMENT TABLE………………………………………………………………………………………………….351

METHOD OF USING TROUBLESHOOTING CHART…………………………………………………………………………………………….353

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)……………………………………………………………………………………..355

JUDGEMENT TABLE FOR ELECTRICAL SYSTEM OR HYDRAULIC, MECHANICAL SYSTEM…………………………………………………………….356

E-1. EXCESSIVE DEVIATION WHEN TRAVEL (CONSTANT DEVIATION)……………………………………………………………………….358

E-2. SPEED OF WORK EQUIPMENT, SWING, TRAVEL IS EXTREMELY SLOW OR LACKS POWER………………………………………………………361

E-3. ENGINE STALLS DURING OPERATIONS, OR ENGINE SPEED DROPS……………………………………………………………………..365

E-4. EVEN WHEN MODE SELECTOR SWITCH IS SWITCHED, OUTPUT DOES NOT CHANGE…………………………………………………………..368

E-5. AUTO-DECELERATION FUNCTION DOES NOT WORK PROPERLY (THERE IS NO DECELERATION, OR DECELERATION STAYS ON)…………………………..375

E-6. UPPER STRUCTURE DOES NOT SWING…………………………………………………………………………………………..383

E-7. EXCESSIVE HYDRAULIC DRIFT OF SWING……………………………………………………………………………………….388

E-8. TRAVEL SPEED DOES NOT CHANGE…………………………………………………………………………………………….392

E-9. EXCESSIVE TRAVEL DEVIATION DURING COMPOUND OPERATIONS (BUT ONLY FOR COMBINATION OF TRAVEL AND WORK EQUIPMENT)…………………….394

E-10. DEFECTIVE OPERATION OF HEAVY LIFT FUNCTION……………………………………………………………………………….405

E-11. MACHINE PUSH UP FUNCTION IS NOT ACTUATED…………………………………………………………………………………413

E-12. ENGINE DOES NOT START………………………………………………………………………………………………….420

E-13. ENGINE DOES NOT STOP…………………………………………………………………………………………………..423

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)…………………………………………………………………………425

BEFORE CARRYING OUT TROUBLESHOOTING OF HYDRAULIC SYSTME (H MODE)…………………………………………………………………426

H-1. EXCESSIVE TRAVEL DEVIATION (GOES OUTSIDE STANDARD ONLY DURING TRAVEL OPERATIONS, WHEN TRAVEL LEVER IS OPERATED TO END OF STROKE)……429

H-2. EXCESSIVE TRAVEL DEVIATION DURING COMPOUND OPERATIONS………………………………………………………………………433

H-3. EXCESSIVE DEVIATION WHEN STARTING………………………………………………………………………………………..434

H-4. CONTROL LEVERS ARE EXTREMELY HEAVY……………………………………………………………………………………….436

H-5. WORK EQUIPMENT, TRAVEL, SWING START TO MOVE SUDDENLY (IN FINE CONTROL RANGE)………………………………………………….437

H-6. SPEED OF WORK EQUIPMENT, SWING, TRAVEL IS EXTREMELY SLOW OR LACKS POWER ……………………………………………………..438

H-7. ENGINE STALLS OR ENGINE SPEED DROPS DURING OPERATION……………………………………………………………………….442

H-8. OUTPUT DOES NOT CHANGE WHEN MODE SELECTOR SWITCH IS OPERATED………………………………………………………………..443

H-9. AUTO-DECELERATION FUNCTION DOES NOT WORK PROPERLY (THERE IS NO DECELERATION OR DECELERATION STAYS ON )…………………………..443

H-10. ABNORMAL NOISE COMES FROM AROUND PUMP……………………………………………………………………………………444

H-11. SWING SPEED IS SLOW, OR THERE IS EXCESSIVE OVERRUN WHEN STOPPING SWING………………………………………………………445

H-12. UPPER STRUCTURE DOES NOT SWING………………………………………………………………………………………….446

H-13. EXCESSIVE HYDRAULIC DRIFT OF SWING………………………………………………………………………………………447

H-14. EXCESSIVE HYDRAULIC DRIFT OF WORK EQUIPMENT………………………………………………………………………………447

H-15. EXCESSIVE TIME LAG OF WORK EQUIPMENT…………………………………………………………………………………….448

H-16. TRAVEL SPEED DOES ONT CHANGE……………………………………………………………………………………………449

H-17. DEFECTIVE ACTUATION OF HEAVY-LIFT FUNCTION (BOOM RAISE SET PRESSURE DOES NOT INCREASE, OR INCREASES BUT DOES NOT GO DOWN)…………450

H-18. DEFECTIVE ACTUATION OF MACHINE PUSH UP FUNCTION (BOOM LOWER SET PRESSURE DOES NOT INCREASE, OR INCRESES BUT DOES NOT GO DOWN)……..450

TABLE OF FAILURE MODES AND CAUSES…………………………………………………………………………………………….451

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)…………………………………………………………………………………453

M-1. WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DISPLAY DOES NOT APPEAR……………………………………………………..454

M-2. WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL DISPLAY DOES NOT GO OUT……………………………………………………..454

M-3. WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH. (FLUID LEVEL OF CHECK ITEMS ARE CORRECT)…………………..455

M-4. WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CHECK ITEMS FLASH……………………………………………………458

M-5. WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CAUTION ITEMS FLASH………………………………………………………460

M-6. WHEN STARTING SWITCH IS TURNED ON AMD ENGINE IS STARTED, CAUTION ITEMS FLASH………………………………………………….461

M-7. WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) FOR 1 SECOND, OR WHEN CAUTION ITEMS ARE FLASHING, WARNING BUZZER DOES NOT SOUND….466

M-8. NO ABNORMAL DISPLAY ON MONITOR BUT WARNING BUZZER SOUNDS……………………………………………………………………467

M-9. PANEL LIGHTING OF MONITOR PANEL DOES NOT LIGHT UP (LIQUID CRYSTAL DISPLAY IS NORMAL)…………………………………………..468

M-10. WHEN ENGINE IS STARTED, SERVICE METER DOES NOT MOVE, WHEN ENGINE IS STOPPED, SERVICE METER MOVES……………………………….470

M-11. COOLANT TEMPERATURE GAUGE SHOWS ABNORMALLY LOW TEMPERATURE…………………………………………………………………472

M-12. COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY……………………………………………………………………………….473

M-13. FUEL LEVEL GAUGE ALWAYS DISPLAYS FULL……………………………………………………………………………………474

M-14. FUEL LEVEL GAUGE GIVES NO DISPLAY……………………………………………………………………………………….475

M-15. HEAD LAMP, WORKING LAMP DO NOT LIGHT UP………………………………………………………………………………….476

M-16. WIPERS DO NOT WORK…………………………………………………………………………………………………….479

30 DISASSEMBLY AND ASSEMBLY…………………………………………………………………………………………………………….481

METHOD OF USING MANUAL……………………………………………………………………………………………………………..483

PRECAUTIONS WHEN CARRYING OUT OPERATION………………………………………………………………………………………………484

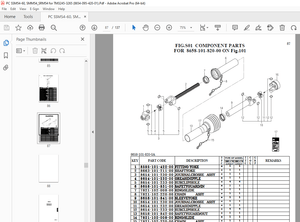

SPECIAL TOOL LIST………………………………………………………………………………………………………………….486

STARTING MOTOR…………………………………………………………………………………………………………………….494

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..494

ALTERNATOR………………………………………………………………………………………………………………………..495

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..495

NOZZLE HOLDER……………………………………………………………………………………………………………………..496

REMOVAL……………………………………………………………………………………………………………………….496

INSTALLATION…………………………………………………………………………………………………………………..497

ENGINE OIL COOLER………………………………………………………………………………………………………………….498

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..498

FUEL INJECTION PUMP………………………………………………………………………………………………………………..499

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..499

WATER PUMP………………………………………………………………………………………………………………………..500

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..500

TURBOCHARGER………………………………………………………………………………………………………………………501

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..501

HYRDAULIC COOLER…………………………………………………………………………………………………………………..502

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..502

CYLINDER HEAD……………………………………………………………………………………………………………………..503

REMOVAL……………………………………………………………………………………………………………………….503

INSTALLATION…………………………………………………………………………………………………………………..506

RADIATOR………………………………………………………………………………………………………………………….508

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..508

AFTER-COOLER CORE………………………………………………………………………………………………………………….509

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..509

ENGINE, PTO, HYDRAULIC PUMP…………………………………………………………………………………………………………510

REMOVAL……………………………………………………………………………………………………………………….510

INSTALLATION…………………………………………………………………………………………………………………..514

PTO………………………………………………………………………………………………………………………………515

REMOVAL……………………………………………………………………………………………………………………….515

INSTALLATION…………………………………………………………………………………………………………………..517

DISASSEMBLY……………………………………………………………………………………………………………………518

ASSEMBLY………………………………………………………………………………………………………………………519

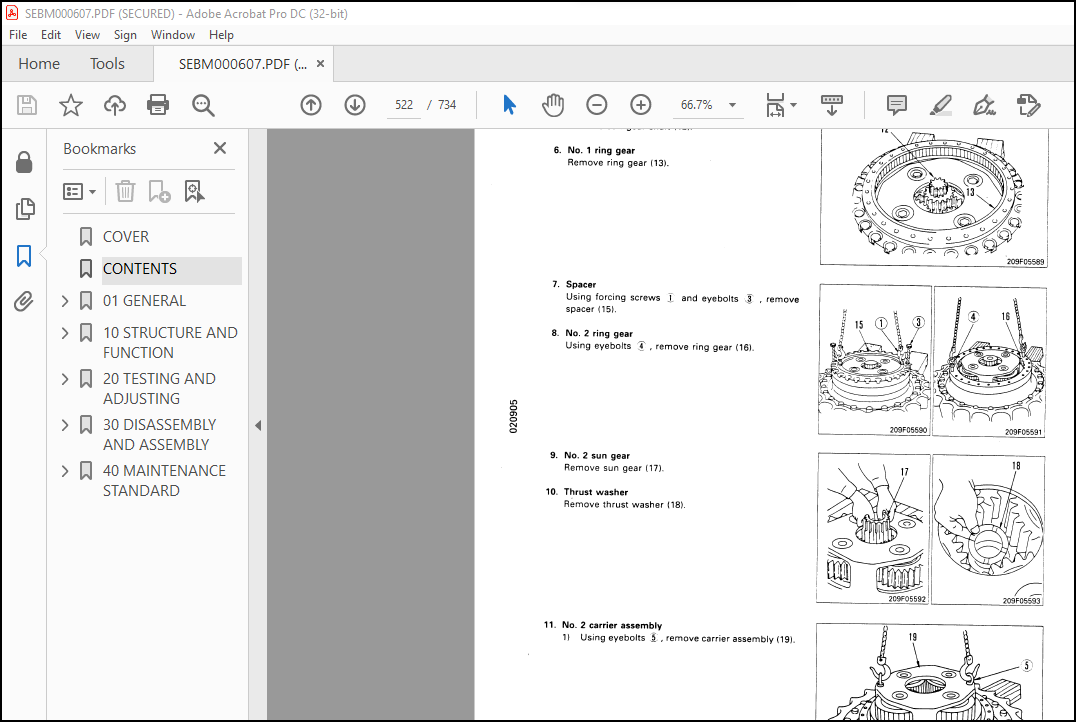

FINAL DRIVE……………………………………………………………………………………………………………………….520

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..520

DISASSEMBLY……………………………………………………………………………………………………………………521

ASSEMBLY………………………………………………………………………………………………………………………525

REVOLVING FRAME……………………………………………………………………………………………………………………530

REMOVAL……………………………………………………………………………………………………………………….530

INSTALLATION…………………………………………………………………………………………………………………..531

SWING MACHINERY……………………………………………………………………………………………………………………532

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..532

DISASSEMBLY……………………………………………………………………………………………………………………533

ASSEMBLY………………………………………………………………………………………………………………………536

SWING CIRCLE………………………………………………………………………………………………………………………540

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..540

TRACK SHOE………………………………………………………………………………………………………………………..541

REMOVAL……………………………………………………………………………………………………………………….541

INSTALLATION…………………………………………………………………………………………………………………..542

ONE LINK………………………………………………………………………………………………………………………….543

FIELD DISASSEMBLY………………………………………………………………………………………………………………543

FIELD ASSEMBLY…………………………………………………………………………………………………………………545

SPROCKET………………………………………………………………………………………………………………………….547

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..547

IDLER…………………………………………………………………………………………………………………………….548

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..548

FRONT IDLER……………………………………………………………………………………………………………………….549

DISASSEMBLY……………………………………………………………………………………………………………………549

ASSEMBLY………………………………………………………………………………………………………………………551

IDLER ADJUSTMENT CYLINDER…………………………………………………………………………………………………………..553

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..553

RECOIL SPRING……………………………………………………………………………………………………………………..554

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..554

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..556

CARRIER ROLLER…………………………………………………………………………………………………………………….557

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..557

DISASSEMBLY……………………………………………………………………………………………………………………558

ASSEMBLY………………………………………………………………………………………………………………………559

TRACK ROLLER………………………………………………………………………………………………………………………561

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..561

DISASSEMBLY……………………………………………………………………………………………………………………562

ASSEMBLY………………………………………………………………………………………………………………………563

NO.1 PUMP…………………………………………………………………………………………………………………………565

REMOVAL……………………………………………………………………………………………………………………….565

INSTALLATION…………………………………………………………………………………………………………………..566

HYDRAULIC PUMP…………………………………………………………………………………………………………………….567

DISASSEMBLY……………………………………………………………………………………………………………………567

ASSEMBLY………………………………………………………………………………………………………………………572

SERVO VALVE……………………………………………………………………………………………………………………….583

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..583

TVC VALVE…………………………………………………………………………………………………………………………584

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..584

CO・NC VALVE……………………………………………………………………………………………………………………….585

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..585

NO.2 PUMP…………………………………………………………………………………………………………………………586

REMOVAL……………………………………………………………………………………………………………………….586

INSTALLATION…………………………………………………………………………………………………………………..587

SWING PUMP………………………………………………………………………………………………………………………..588

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..588

DISASSEMBLY……………………………………………………………………………………………………………………589

ASSEMBLY………………………………………………………………………………………………………………………592

CHARGING, PTO LUBRICATION PUMP………………………………………………………………………………………………………603

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..603

MAIN RELIEF VALVE (FOR SWING CONTROL VALVE)…………………………………………………………………………………………..604

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..604

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..605

MAIN CONTROL VALVE (FOR WORK EQUIPMENT,4-,5-SPOOL CONTROL VALVE)………………………………………………………………………..606

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..606

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..607

SWING CONTROL VALVE………………………………………………………………………………………………………………..608

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..608

DISASSEMBLY……………………………………………………………………………………………………………………609

ASSEMBLY………………………………………………………………………………………………………………………610

CONTROL VALVE (WORK EQUIPMENT)………………………………………………………………………………………………………611

DISASSEMBLY……………………………………………………………………………………………………………………611

ASSEMBLY………………………………………………………………………………………………………………………613

SWING MOTOR……………………………………………………………………………………………………………………….615

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..615

DISASSEMBLY……………………………………………………………………………………………………………………616

ASSEMBLY………………………………………………………………………………………………………………………619

CENTER SWIVEL JOINT………………………………………………………………………………………………………………..624

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..624

DISASSEMBLY……………………………………………………………………………………………………………………625

ASSEMBLY………………………………………………………………………………………………………………………626

TRAVEL MOTOR………………………………………………………………………………………………………………………627

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..627

DISASSEMBLY……………………………………………………………………………………………………………………628

ASSEMBLY………………………………………………………………………………………………………………………638

CHARGING PUMP RELIEF VALVE………………………………………………………………………………………………………….650

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..650

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..651

PPC VALVE (FOR TRAVEL)……………………………………………………………………………………………………………..652

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..652

PPC VALVE (FOR WORK EQUIPMENT, SWING)………………………………………………………………………………………………..653

DISASSEMBLY AND ASSEMBLY………………………………………………………………………………………………………..653

AUTO-DECELERATION CYLINDER………………………………………………………………………………………………………….654

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..654

BOOM CYLINDER (BACK HOE)……………………………………………………………………………………………………………655

REMOVAL……………………………………………………………………………………………………………………….655

INSTALLATION…………………………………………………………………………………………………………………..656

ARM CYLINDER (BACK HOE)…………………………………………………………………………………………………………….657

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..657

BUCKET CYLINDER (BACK HOE)………………………………………………………………………………………………………….658

REMOVAL……………………………………………………………………………………………………………………….658

INSTALLATION…………………………………………………………………………………………………………………..659

BOOM CYLINDER (LOADING SHOVEL)………………………………………………………………………………………………………660

REMOVAL……………………………………………………………………………………………………………………….660

INSTALLATION…………………………………………………………………………………………………………………..661

ARM CYLINDER (LOADING SHOVEL)……………………………………………………………………………………………………….662

REMOVAL……………………………………………………………………………………………………………………….662

INSTALLATION…………………………………………………………………………………………………………………..663

BUCKET CYLINDER (LOADING SHOVEL)…………………………………………………………………………………………………….664

REMOVAL……………………………………………………………………………………………………………………….664

INSTALLATION…………………………………………………………………………………………………………………..665

BOTTOM, DUMP CYLINDER (LOADING SHOVEL)……………………………………………………………………………………………….666

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..666

HYDRAULIC CYLINDER…………………………………………………………………………………………………………………667

DISASSEMBLY……………………………………………………………………………………………………………………667

ASSEMBLY………………………………………………………………………………………………………………………669

BUCKET (BACK HOE)………………………………………………………………………………………………………………….672

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..672

ARM (BACK HOE)…………………………………………………………………………………………………………………….673

REMOVAL……………………………………………………………………………………………………………………….673

INSTALLATION…………………………………………………………………………………………………………………..674

BOOM (BACK HOE)……………………………………………………………………………………………………………………675

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..675

BUCKET AND ARM (BACK HOE)…………………………………………………………………………………………………………..676

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..676

WORK EQUIPMENT (BACK HOE)…………………………………………………………………………………………………………..677

REMOVAL……………………………………………………………………………………………………………………….677

INSTALLATION…………………………………………………………………………………………………………………..678

BUCKET (LOADING SHOVEL)…………………………………………………………………………………………………………….679

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..679

ARM (LOADING SHOVEL)……………………………………………………………………………………………………………….680

REMOVAL……………………………………………………………………………………………………………………….680

INSTALLATION…………………………………………………………………………………………………………………..681

BOOM (LOADING SHOVEL)………………………………………………………………………………………………………………682

REMOVAL……………………………………………………………………………………………………………………….682

INSTALLATION…………………………………………………………………………………………………………………..683

WORK EQUIPMENT (LOADING SHOVEL)……………………………………………………………………………………………………..684

REMOVAL……………………………………………………………………………………………………………………….684

INSTALLATION…………………………………………………………………………………………………………………..685

OPERATOR’S CAB…………………………………………………………………………………………………………………….686

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..686

COUNTERWEIGHT……………………………………………………………………………………………………………………..687

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..687

MONITOR PANEL……………………………………………………………………………………………………………………..688

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..688

AUTO-DECELERATION・OLSS CONTROLLER……………………………………………………………………………………………………689

REMOVAL AND INSTALLATION………………………………………………………………………………………………………..689

40 MAINTENANCE STANDARD………………………………………………………………………………………………………………..690

PTO………………………………………………………………………………………………………………………………691

SWING CIRCLE………………………………………………………………………………………………………………………692

SWING MACHINERY……………………………………………………………………………………………………………………693

FINAL DRIVE……………………………………………………………………………………………………………………….695

TRACK FRAME AND RECOIL SPRING……………………………………………………………………………………………………….697

TRACK ROLLER………………………………………………………………………………………………………………………698

IDLER…………………………………………………………………………………………………………………………….699

CARRIER ROLLER…………………………………………………………………………………………………………………….701

TRACK SHOE………………………………………………………………………………………………………………………..703

CHARGING AND PTO LUBRICATION PUMP……………………………………………………………………………………………………704

L.H. 5-SPOOL CONTROL VALVE………………………………………………………………………………………………………….705

R.H. 4-SPOOL CONTROL VALVE………………………………………………………………………………………………………….709

SWING CONTROL VALVE………………………………………………………………………………………………………………..712

SWING MOTOR……………………………………………………………………………………………………………………….714

CENTER SWIVEL JOINT………………………………………………………………………………………………………………..715

PILOT RELIEF VALVE…………………………………………………………………………………………………………………716

PPC VALVE…………………………………………………………………………………………………………………………717

HYDRAULIC CYLINDER…………………………………………………………………………………………………………………719

WORK EQUIPMENT…………………………………………………………………………………………………………………….721

IMAGES PREVIEW OF THE MANUAL: