Starting from:

$40

Home

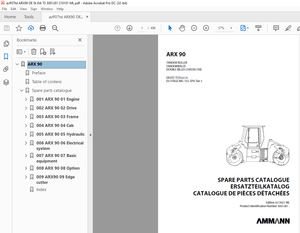

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual PDF

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual PDF

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual

FILE DETAILS:

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Bookmarked : Yes

Product Code : GEN00048-00

Total Pages : 140

DESCRIPTION:

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual

FOREWORD:

- With this machine, the work equipment is extremely heavy and the hydraulic pressure of the chas- sis is used to install it efficiently. For this reason, start the engine and actuate the hydraulic cylinders. Before starting the engine and assembling the work equipment, it is necessary to carry out thorough inspection and maintenance. In addition, this work is frequently carried out with more than one worker in a dangerous place and posture.

- To ensure safety. carry out a safety meeting before starting and decide the operation leader and the person to give signals to the crane to ensure that all workers can carry out the operation in safety. Particularly in places where the workers speak different languages or have different customs, there are various causes of safety problems, so the local liaison officer and person in charge of the opera~ tion should consider fully the above points and take action to ensure safety.

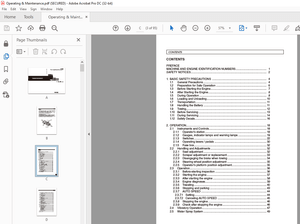

TABLE OF CONTENTS:

Komatsu PC800-5, PC850-5 Galeo Hydraulic Excavator Field Assembly Instruction Manual

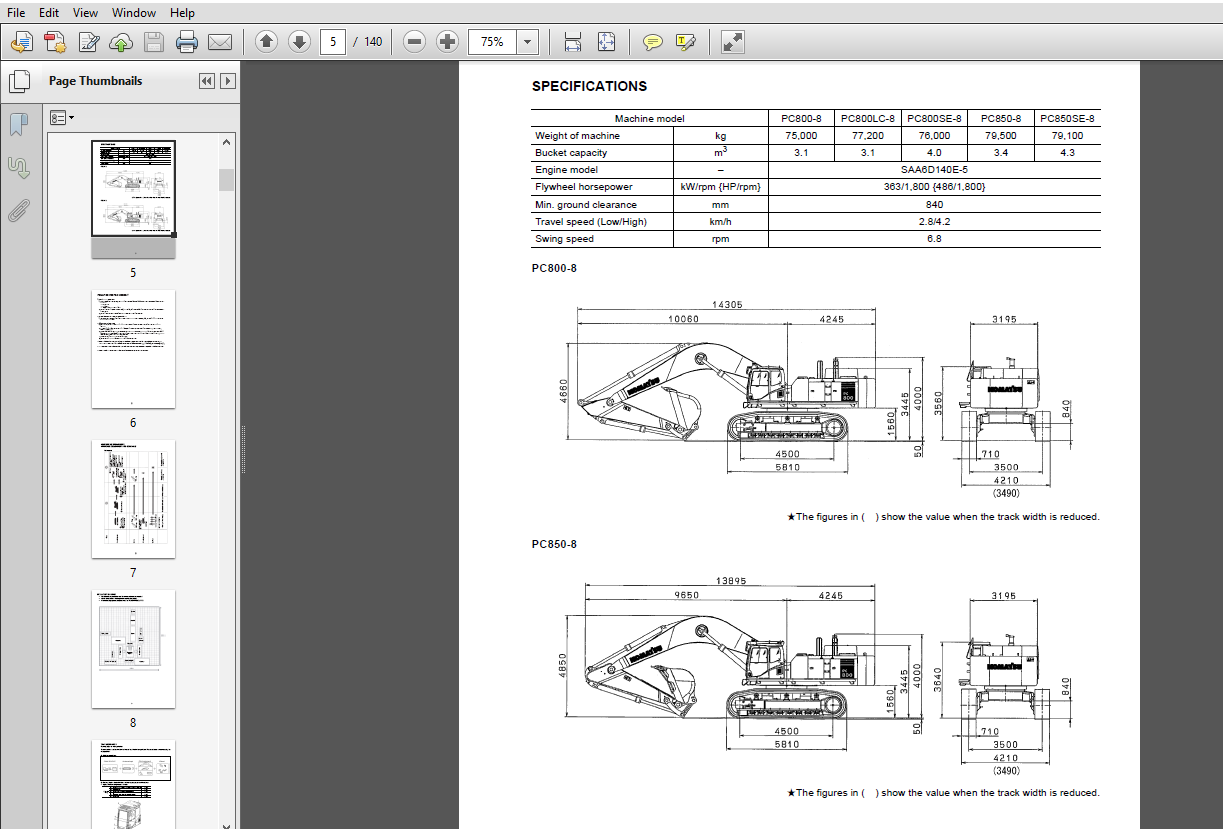

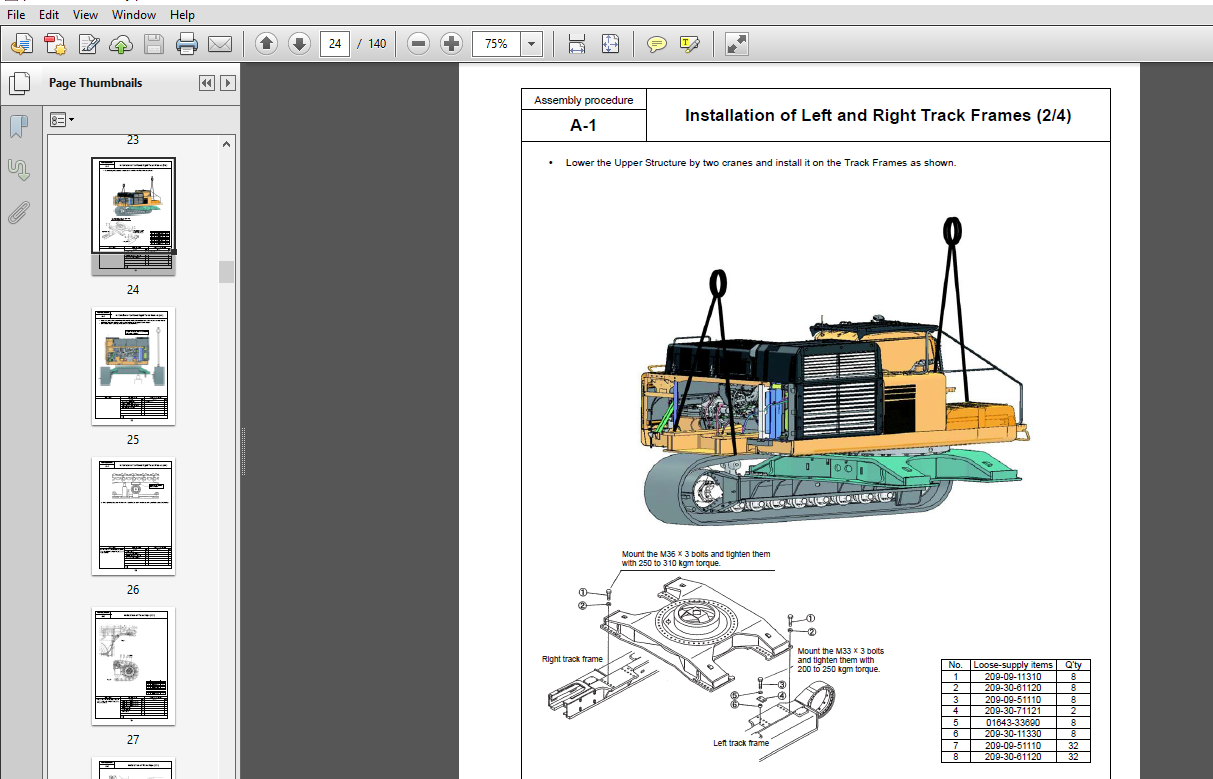

COVER........................................................................... 1 FOREWORD........................................................................ 2 CONTENTS........................................................................ 3 SPECIFICATIONS.................................................................. 5 PRECAUTIONS FOR FIELD ASSEMBLY.................................................. 6 ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE........................ 7 KIT LAYOUT DIAGRAM.............................................................. 8 TRANSPORTATION.................................................................. 9 LIST OF TOOLS FOR FIELD ASSEMBLING.............................................. 15 TIGHTENING TORQUE............................................................... 16 COATING MATERIALS............................................................... 20 A. ASSEMBLY OF BASE MACHINE..................................................... 22 A-1. INSTALLATION OF LEFT AND RIGHT TRACK FRAMES............................ 23 A-2. INSTALLATION OF TRAVEL PIPE............................................ 27 A-3. INSTALLATION OF TOP GUARD.............................................. 30 A-4. INSTALLATION OF RADIATOR COVER......................................... 31 A-5. INSTALLATION OF REARVIEW MIRROR........................................ 32 A-6. INSTALLATION OF LEFT SIDE STEP......................................... 36 A-7. INSTALLATION OF HANDRAIL............................................... 37 A-8. INSTALLATION OF HANDRAIL (WITH TOP GUARD).............................. 38 A-9. INSTALLATION OF MUFFLER TAIL TUBE...................................... 40 A-10. STICKING SHEET TO COUNTERWEIGHT....................................... 41 A-11. INSTALLATION OF COUNTERWEIGHT......................................... 42 A-12. INSTALLATION OF ORBCOMM ANTENNA (IF EQUIPPED)......................... 43 A-13. INSTALLATION OF STEP LIGHT............................................ 44 A-14. AIR BLEEDING OF TRAVEL MOTOR.......................................... 46 A-15. INSTALLATION OF TRAVEL PIPING COVER................................... 47 A-16. TESTING TRACK SHOE TENSION............................................ 49 A-17. CHECK FUEL, COOLANT AND OIL LEVELS ................................... 52 A-18. PARTS TO BE TOUCHED UP AFTER FIELD ASSEMBLY........................... 55 B. ASSEMBLING OF WORK EQUIPMENT OF BACKHOE...................................... 56 B-1. ASSEMBLY OF ARM CYLINDER............................................... 57 B-2. CONNECTION OF ARM CYLINDER HOSES....................................... 58 B-3. INSTALLATION OF BOOM CYLINDER FOOT .................................... 60 B-4. RELIEVING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT.................... 61 B-5. INSTALLATION OF BOOM CYLINDER HOSES.................................... 62 B-6. ASSEMBLY OF BOOM ASSEMBLY.............................................. 63 B-7. HOSE CONNECTION OF ARM AND BUCKET CIRCUITS............................. 64 B-8. INSTALLATION OF QUICK RETURN HOSE...................................... 65 B-9. INSTALLATION OF BOOM CYLINDER ......................................... 66 B-10. INSTALLATION OF ARM ASSEMBLY.......................................... 67 B-11. INSTALLATION OF HOSE BETWEEN BOOM AND BUCKET CYLINDER................. 69 B-12. INSTALLATION OF BUCKET ASSEMBLY....................................... 70 B-13. LUBRICATION PIPING TO WORK EQUIPMENT.................................. 71 B-14. AIR BLEEDING FROM CYLINDER............................................ 72 B-15. WIRING OF WORK EQUIPMENT.............................................. 73 B-16. GREASING AFTER ASSEMBLING WORK EQUIPMENT.............................. 74 M. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY........ 75 M-1. INSPECTION OF OIL LEVEL IN HYDRAULIC TANK AND REFILL................... 76 M-2. REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER)...... 78 M-3. FLUSHING OF HYDRAULIC CIRCUIT ......................................... 81 M-4. ERROR CODE............................................................. 83 C. ASSEMBLING OF WORK EQUIPMENT OF LOADING SHOVEL............................... 85 C-1. RELEASING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT....................... 86 C-2. PULLING OUT BOOM FOOT PIN AND BOOM CYLINDER FOOT PIN................... 87 C-3. INSTALLATION OF BOOM AND ARM ASSEMBLY.................................. 88 C-4. INSTALLATION OF FLUSHING PIPING BETWEEN CHASSIS AND BOOM............... 89 C-5. INSTALLATION OF FLUSHING PIPING FOR BOOM CYLINDER AND ARM CYLINDER .... 90 C-6. INSTALLATION OF FLUSHING PIPING FOR BUCKET CYLINDER.................... 91 C-7. INSTALLATION OF FLUSHING PIPING FOR BOTTOM DUMP CYLINDER............... 92 C-8. INSTALLATION OF BOOM CYLINDER.......................................... 94 C-9. INSTALLATION OF BOOM CYLINDER FOOT..................................... 95 C-10. INSTALLATION OF BOOM CYLINDER HOSES................................... 96 C-11. INSTALLATION OF BOOM CYLINDER ROD PIN................................. 97 C-12. INSTALLATION OF ARM CYLINDER HOSES.................................... 98 C-13. INSTALLATION OF BUCKET CYLINDER....................................... 99 C-14. INSTALLATION OF BUCKET CYLINDER HOSE..................................100 C-15. INSTALLATION OF CONNECTING HOSES BETWEEN CHASSIS AND BOOM TOP.........101 C-16. INSTALLATION OF BOTTOM DUMP CYLINDER HOSES............................102 C-17. INSTALLATION OF BUCKET ASSEMBLY.......................................103 C-18. INSTALLATION OF WORKING LAMPS.........................................105 C-19. INSTALLATION OF WORK EQUIPMENT GREASE PIPING..........................106 C-20. GREASING AFTER ASSEMBLING OF WORK EQUIPMENT...........................107 C-21. BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT..............................108 C-22. CHECKING OIL LEVEL IN HYDRAULIC TANK AND ADDING OIL...................109 C-23. REPLACEMENT OF RETURN FILTER (STANDARD FILTER TO FLUSHING FILTER).....110 C-24. FLUSHING OF HYDRAULIC CIRCUIT.........................................113 FIELD ASSEMBLY INSPECTION REPORT (BACKHOE)......................................115 FIELD ASSEMBLY INSPECTION REPORT (LOADING SHOVEL)...............................128

IMAGES PREVIEW OF THE MANUAL:

1 file (6.9MB)