$32

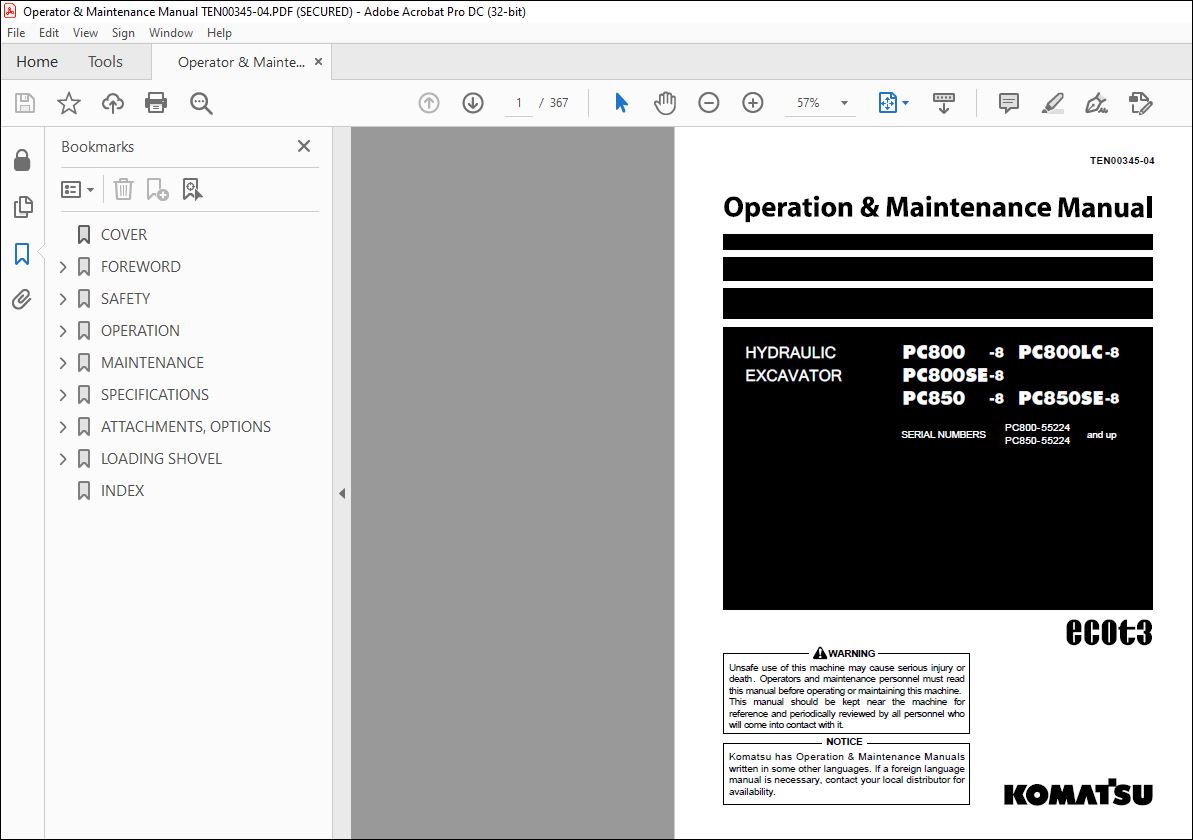

Komatsu PC800-8 PC800LC-8 PC800SE-8 PC850-8 PC850SE-8 Excavator Operation & Maintenance Manual PDF

Komatsu PC800-8 PC800LC-8 PC800SE-8 PC850-8 PC850SE-8 Hydraulic Excavator Operation & Maintenance Manual TEN00345-04 – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu PC800-8 PC800LC-8 PC800SE-8 PC850-8 PC850SE-8 Hydraulic Excavator Operation & Maintenance Manual TEN00345-04 – PDF DOWNLOAD

SERIAL NUMBERS

PC800-55224 and up

PC850-55224 and up

READ THIS MANUAL:

- This manual gives details of the operation and methods of inspection and maintenance for this machine that must

be obeyed in order to use the machine safely. Most accidents are caused by the failure to follow fundamental safety

rules for the operation and maintenance of machines. - Read, understand and follow all precautions and warnings in this manual and on the machine before performing

operation and maintenance. Failure to do so may result in serious injury or death.

Komatsu cannot predict every circumstance that might involve a potential hazard when the machine is used. - Therefore, the safety messages in this manual and on the machine may not include all possible safety precautions.

If you perform any operation, inspection, or maintenance under conditions that are not described in this manual,

understand that it is your responsibility to take the necessary precautions to ensure safety. In no event should you

or others engage in the prohibited uses or actions described in this manual. Improper operation and maintenance

of the machine can be hazardous and could result in serious injury or death. - If you sell the machine, be sure to give this manual to the new owner together with the machine.

- Always keep this Operation and Maintenance Manual in the location shown on the right so that all relevant personnel can read it at any time.

TABLE OF CONTENTS:

Komatsu PC800-8 PC800LC-8 PC800SE-8 PC850-8 PC850SE-8 Hydraulic Excavator Operation & Maintenance Manual TEN00345-04 – PDF DOWNLOAD

FOREWORD 1- 1

READ THIS MANUAL 1- 2

SAFETY INFORMATION 1- 3

INTRODUCTION 1- 4

USE OF MACHINE 1- 4

DIRECTIONS OF MACHINE 1- 4

VISIBILITY FROM OPERATOR’S SEAT 1- 5

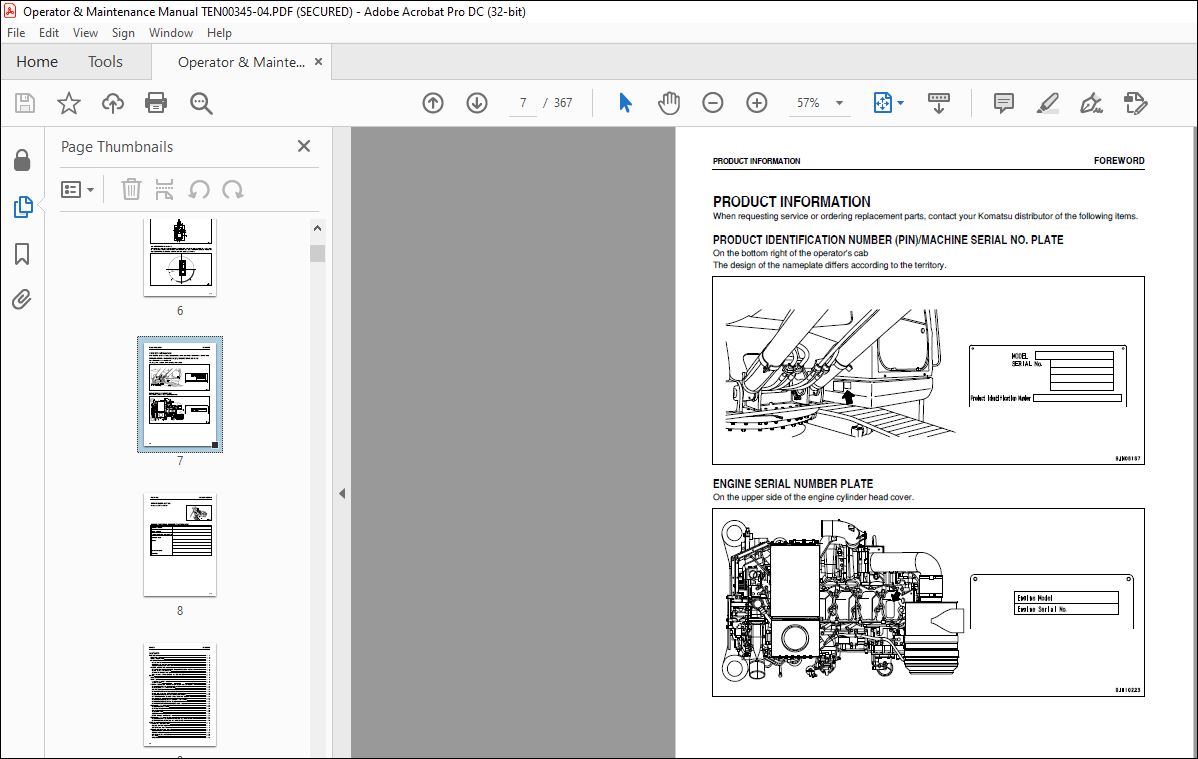

PRODUCT INFORMATION 1- 6

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE 1- 6

ENGINE SERIAL NUMBER PLATE 1- 6

SERVICE METER LOCATION 1- 7

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR 1- 7

SAFETY 2- 1

SAFETY 2- 2

SAFETY LABELS 2- 5

LOCATION OF SAFETY LABELS 2- 6

SAFETY LABELS 2- 7

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE 2- 13

PRECAUTIONS BEFORE STARTING OPERATION 2- 13

PREPARATIONS FOR SAFE OPERATION 2- 13

FIRE PREVENTION 2- 15

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE 2- 16

DO NOT GET CAUGHT IN WORK EQUIPMENT 2- 18

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES 2- 18

PROTECTION AGAINST FALLING, FLYING, INTRUDING OBJECTS 2- 18

UNAUTHORIZED MODIFICATION 2- 19

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS 2- 19

PRECAUTIONS RELATED TO CAB GLASS 2- 19

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING 2- 19

PRECAUTIONS FOR OPERATION 2- 20

PRECAUTIONS FOR JOBSITE 2- 20

STARTING ENGINE 2- 22

OPERATION 2- 24

TRANSPORTATION 2- 31

TOWING 2- 32

LIFTING OBJECTS WITH BUCKET 2- 33

PRECAUTIONS FOR MAINTENANCE 2- 34

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE 2- 34

PRECAUTIONS FOR INSPECTION AND MAINTENANCE 2- 38

OPERATION 3- 1

MACHINE VIEW ILLUSTRATIONS 3- 2

OVERALL MACHINE VIEW 3- 2

CONTROLS AND GAUGES 3- 3

DETAILED CONTROLS AND GAUGES 3- 5

MONITORING SYSTEM 3- 5

SWITCHES 3- 34

CONTROL LEVERS AND PEDALS 3- 41

SUN ROOF 3- 44

WINDSHIELD 3- 44

EMERGENCY EXIT FROM OPERATOR’S CAB 3- 49

DOOR LOCK 3- 49

CAP WITH LOCK 3- 50

HOT AND COOL BOX 3- 52

MAGAZINE BOX 3- 52

ASHTRAY 3- 52

FIRE EXTINGUISHER 3- 53

AIR CONDITIONER CONTROLS 3- 54

RADIO 3- 68

AUXILIARY ELECTRIC POWER 3- 77

FUSE 3- 78

CIRCUIT BREAKER 3- 79

CONTROLLER 3- 80

TOOL BOX 3- 80

GREASE PUMP 3- 81

MACHINE OPERATIONS AND CONTROLS 3- 85

BEFORE STARTING ENGINE 3- 85

STARTING ENGINE 3-104

AFTER STARTING ENGINE 3-107

STOPPING THE ENGINE 3-116

MACHINE OPERATION 3-117

STEERING THE MACHINE 3-121

SWINGING 3-123

WORK EQUIPMENT CONTROLS AND OPERATIONS 3-124

WORKING MODE 3-125

PROHIBITED OPERATIONS 3-127

GENERAL OPERATION INFORMATION 3-132

TRAVELING ON SLOPES 3-134

ESCAPE FROM MUD 3-136

RECOMMENDED APPLICATIONS 3-137

BUCKET REPLACEMENT 3-138

PARKING MACHINE 3-140

MACHINE INSPECTION AFTER DAILY WORK 3-141

LOCKING 3-142

TRANSPORTATION 3-143

TRANSPORTATION PROCEDURE 3-143

LIFTING MACHINE 3-144

SHIPPING MACHINE INFORMATION 3-145

TRANSPORTATION POSTURE 3-146

PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE 3-152

COLD WEATHER OPERATION 3-154

COLD WEATHER OPERATION INFORMATION 3-154

AFTER DAILY WORK COMPLETION 3-157

AFTER COLD WEATHER SEASON 3-157

LONG TERM STORAGE 3-158

BEFORE STORAGE 3-158

DURING STORAGE 3-158

AFTER STORAGE 3-159

STARTING MACHINE AFTER LONG-TERM STORAGE 3-159

TROUBLES AND ACTIONS 3-160

RUNNING OUT OF FUEL 3-160

PHENOMENA THAT ARE NOT FAILURES 3-161

TOWING THE MACHINE 3-162

SEVERE JOB CONDITION 3-162

DISCHARGED BATTERY 3-163

OTHER TROUBLE 3-167

MAINTENANCE 4- 1

MAINTENANCE INFORMATION 4- 2

OUTLINE OF SERVICE 4- 4

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC 4- 4

ELECTRIC SYSTEM MAINTENANCE 4- 7

WEAR PARTS 4- 8

WEAR PARTS LIST 4- 8

RECOMMENDED FUEL, COOLANT, AND LUBRICANT 4- 9

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN

KOMATSU GENUINE OIL 4- 11

TIGHTENING TORQUE SPECIFICATIONS 4- 12

TIGHTENING TORQUE LIST 4- 12

SAFETY CRITICAL PARTS 4- 13

SAFETY CRITICAL PARTS LIST 4- 14

MAINTENANCE SCHEDULE 4- 15

MAINTENANCE SCHEDULE CHART 4- 15

MAINTENANCE PROCEDURE 4- 17

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS) 4- 17

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS) 4- 17

WHEN REQUIRED 4- 18

CHECK BEFORE STARTING 4- 41

EVERY 10 HOURS MAINTENANCE 4- 42

EVERY 100 HOURS MAINTENANCE 4- 44

EVERY 250 HOURS MAINTENANCE 4- 45

EVERY 500 HOURS MAINTENANCE 4- 50

EVERY 1000 HOURS MAINTENANCE 4- 59

EVERY 2000 HOURS MAINTENANCE 4- 72

EVERY 4000 HOURS MAINTENANCE 4- 78

EVERY 5000 HOURS MAINTENANCE 4- 81

EVERY 8000 HOURS MAINTENANCE 4- 85

SPECIFICATIONS 5- 1

SPECIFICATIONS 5- 2

ATTACHMENTS AND OPTIONS 6- 1

GENERAL PRECAUTIONS FOR SAFETY 6- 2

PRECAUTIONS WHEN SELECTING 6- 2

READ THE INSTRUCTION MANUAL THOROUGHLY 6- 2

PRECAUTIONS WHEN REMOVING OR INSTALLING 6- 2

PRECAUTIONS WHEN USING 6- 2

ATTACHMENT GUIDE 6- 3

COMBINATIONS OF WORK EQUIPMENT 6- 4

TRACK SHOES SELECTION 6- 6

HANDLING COUNTERWEIGHT REMOVER 6- 7

HANDLING MACHINES EQUIPPED WITH KOMTRAX 6- 19

BASIC PRECAUTIONS 6- 19

LOADING SHOVEL 7- 1

EXPLANATION OF COMPONENTS 7- 2

SWITCHES 7- 2

FUSE 7- 5

OPERATIONS 7- 6

OPERATION OF WORK EQUIPMENT 7- 6

PRECAUTIONS DURING OPERATION 7- 8

PRECAUTIONS FOR OPERATION 7- 11

LOADING SHOVEL WORK 7- 13

TRANSPORTATION 7- 14

MACHINE CONFIGURATION FOR TRANSPORT 7- 14

WEAR PARTS 7- 15

WEAR PARTS LIST 7- 15

MAINTENANCE 7- 16

CHECK BEFORE STARTING 7- 16

EVERY 10 HOURS MAINTENANCE 7- 18

EVERY 5000 HOURS MAINTENANCE 7- 19

SPECIFICATION 7- 21

COMBINATION OF WORK EQUIPMENT 7- 22

COMBINATION OF WORK EQUIPMENT 7- 22

INDEX 8- 1