$45

Komatsu PW160-7K Hydraulic Excavator Shop Manual (K40001 and up) - PDF DOWNLOAD

Komatsu PW160-7K Hydraulic Excavator Shop Manual (K40001 and up)

FILE DETAILS:

Komatsu PW160-7K Hydraulic Excavator Shop Manual (K40001 and up)

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Product Code : UEBM002500

Total Pages : 890

DESCRIPTION:

Komatsu PW160-7K Hydraulic Excavator Shop Manual (K40001 and up)

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters: these chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs , as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the order to be followed when removing, installing, disassembling or assembling eachr component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD:

This section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

Komatsu PW160-7K Hydraulic Excavator Shop Manual (K40001 and up)

PW160-7K........................................................................................................ 1

K40001 AND UP................................................................................................... 1

Sec 00.pdf...................................................................................................... 0

SAFETY...................................................................................................... 3

SAFETY NOTICE........................................................................................... 3

IMPORTANT SAFETY NOTICE............................................................................. 3

GENERAL PRECAUTIONS................................................................................. 3

PREPARATIONS FOR WORK............................................................................... 3

PRECAUTIONS DURING WORK............................................................................. 4

GENERAL..................................................................................................... 5

HOW TO READ THE SHOP MANUAL................................................................................. 6

volumes................................................................................................. 6

DISTRIBUTION AND UPDATING............................................................................... 6

FILING METHOD........................................................................................... 6

REVISED EDITION MARK.................................................................................... 6

REVISIONS............................................................................................... 6

SYMBOLS................................................................................................. 6

HOISTING INSTRUCTIONS....................................................................................... 7

HOISTING................................................................................................ 7

WIRE ROPES.............................................................................................. 7

PUSH-PULL TYPE COUPLERS..................................................................................... 8

COATING MATERIALS........................................................................................... 10

STANDARD TIGHTENING TORQUE.................................................................................. 12

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS............................................................ 12

TIGHTENING TORQUE OF HOSE NUTS.......................................................................... 13

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS................................................................. 13

TIGHTENING TORQUE FOR FLARED NUTS....................................................................... 13

Tightening torque for 102 engine series (bolts and nuts)................................................ 14

Tightening torque for 102 engine series (eye joints).................................................... 14

Tightening torque for 102 engine series (tapered screws)................................................ 14

ELECTRIC WIRE CODE.......................................................................................... 15

CLASSIFICATION BY THICKNESS............................................................................. 15

CLASSIFICATION BY COLOR AND CODE........................................................................ 15

CONVERSION TABLES........................................................................................... 16

METHOD OF USING THE CONVERSION TABLE.................................................................... 16

UNITS....................................................................................................... 22

01.pdf.......................................................................................................... 0

WORKING RANGES.............................................................................................. 26

1 PIECE BOOM............................................................................................ 26

2 PIECE BOOM............................................................................................ 27

SPECIFICATION DIMENSION DRAWINGS............................................................................ 24

DIMENSIONS.................................................................................................. 24

1 pIECE BOOM............................................................................................ 24

DIMENSIONS.................................................................................................. 25

2 PIECE BOOM............................................................................................ 25

SPECIFICATIONS.............................................................................................. 28

WEIGHT TABLE................................................................................................ 30

1 piece boom............................................................................................ 31

2 piece boom............................................................................................ 31

FUEL, COOLANT AND LUBRICANTS................................................................................ 32

10.pdf.......................................................................................................... 0

ENGINE RELATED PARTS........................................................................................ 34

RADIATOR • OIL COOLER • charge air cooler................................................................... 35

POWER TRAIN................................................................................................. 36

SWING CIRCLE................................................................................................ 38

SWING MACHINERY & motor..................................................................................... 40

SWING MOTOR................................................................................................. 44

Operation of swing lock................................................................................. 48

RELIEF VALVE PORTION.................................................................................... 49

Operation............................................................................................... 49

UNDERCARRIAGE............................................................................................... 50

TRANSMISSION................................................................................................ 52

TRAVEL MOTOR................................................................................................ 55

oPERATION OF TRAVEL MOTOR............................................................................... 57

CLUTCH CONTROL CIRCUIT...................................................................................... 59

AXLE........................................................................................................ 61

sUSPENSION LOCK CYLINDER.................................................................................... 65

Braking System.............................................................................................. 68

brake/steer pump............................................................................................ 70

PRIORITY VALVE.............................................................................................. 71

Power brake valve........................................................................................... 72

ACCUMULATOR for brake system................................................................................ 73

STEERING TRAIN.............................................................................................. 74

STEERING COLUMN............................................................................................. 75

ORBITROL VALVE.............................................................................................. 76

hydraulic equipment layout drawingS......................................................................... 78

hydraulic CIRCUIT dIAgRAM................................................................................... 80

HYDRAULIC TANK.............................................................................................. 81

HYDRAULIC PUMP.............................................................................................. 82

HPV125.................................................................................................. 82

LS VALVE................................................................................................ 87

PC VALVE................................................................................................ 87

LS(pc)-EPC VALVE........................................................................................100

PILOT PRESSURE CONTROL (PPC) SYSTEM.........................................................................103

CONTROL VALVE...............................................................................................104

PW160-7K................................................................................................104

CLSS........................................................................................................115

OUTLINE OF CLSS.........................................................................................115

CENTre SWIVEL JOINT.........................................................................................135

travel ppc pedal............................................................................................136

WORK EQUIPMENT • SWING PPC VALVE............................................................................138

SERVICE PPC VALVE...........................................................................................142

solenoid valve MANIFOLD.....................................................................................145

Solenoid valve (2, 4 & 6-stage solenoid)................................................................146

attachment epc valve....................................................................................147

Boom safety valve...........................................................................................150

HYDRAULIC CYLINDER..........................................................................................152

BOOM CYLINDER...........................................................................................152

ARM CYLINDER............................................................................................152

BUCKET CYLINDER.........................................................................................152

ADJUST CYLINDER.........................................................................................153

Outrigger CYLINDER..........................................................................................154

dozer CYLINDER..............................................................................................156

work equipment..............................................................................................158

Work Equipment..........................................................................................159

1. DIMENSION OF ARM.....................................................................................160

2. Dimension of bucket..................................................................................161

air conditioner.............................................................................................162

air conditioner piping..................................................................................162

electrical wiring diagram...................................................................................163

engine control system.......................................................................................164

Governor motor..........................................................................................166

Engine throttle and pump controller.....................................................................168

ELECTRONIC CONTROL SYSTEM...................................................................................170

machine control system diagram..........................................................................172

machine MONITOR SYSTEM......................................................................................195

Monitor panel...........................................................................................196

Overload warning device.....................................................................................215

OUTLINE.................................................................................................215

SENSOR......................................................................................................216

1st attachment circuit hydraulic performance (main valve bypassed)..........................................220

1st attachment circuit hydraulic performance (VIA main valve)...............................................222

travel system...............................................................................................224

TRAVEL CIRCUIT..........................................................................................224

oPERATIONAL AND CONTROL FEATURES........................................................................225

SteeRING system.............................................................................................246

Operating principles....................................................................................246

SERVICE BRAKE AND SUSPENSION SYSTEM.........................................................................259

bRAKING SYSTEM..........................................................................................259

operation...............................................................................................262

20_001.pdf...................................................................................................... 0

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...............................................................266

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS..............................................................267

Flow control characteristic of PC valve (STD)...........................................................278

20_101.pdf...................................................................................................... 0

INSPECTION AND ADJUSTMENT OF ENGINE RPM.....................................................................280

MEASUREMENT OF EXHAUST GAS COLOR............................................................................282

ADJUSTMENT OF VALVE CLEARANCE...............................................................................284

MEASUREMENT OF COMPRESSION PRESSURE.........................................................................286

MEASUREMENT OF BLOW-BY PRESSURE.............................................................................287

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING..........................................................288

MEASUREMENT OF ENGINE OIL PRESSURE..........................................................................291

EMERGENcy sEtting iF FAILURE occurs IN ENGINE CONTROL SYSTEM................................................294

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS...........................................................295

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN...........296

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE...................................................299

INSPECTION AND ADJUSTMENT OF PUMP PC (Valve INLET) CONTROL OIL PRESSURE.....................................301

INSPECTION AND ADJUSTMENT OF PUMP LS valve CONTROL OIL PRESSURE.............................................304

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE...............................................................308

7 - Stage solenoid block................................................................................310

4 - Stage solenoid block................................................................................312

2 - Stage solenoid block................................................................................313

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE....................................................................314

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE............................................................316

testing travel motor relief pressure........................................................................317

adjusting travel motor relief pressure......................................................................318

Testing propshaft speed.....................................................................................319

tESTING TRANSMISSION CLUTCH CONTROL CIRCUIT.................................................................320

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT................................................322

MEASUREMENT OF OIL LEAKAGE AMOUNT...........................................................................324

AIR BLEEDING OF VARIOUS PARTS...............................................................................326

INSPECTION PROCEDURES FOR DIODE.............................................................................328

SPECIAL FUNCTION OF MONITOR PANEL...........................................................................329

Operation of Operator's Menu and Display (Outline)......................................................331

Table for Service and Failure Code Nos..................................................................337

Operation and Display of Service Menu...................................................................340

Way of switching to Service Menu....................................................................340

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM..........................................................360

20_201.pdf...................................................................................................... 0

TROUBLESHOOTING.............................................................................................361

POINTS TO REMEMBER WHEN TROUBLESHOOTING.................................................................362

SEQUENCE OF EVENTS IN TROUBLESHOOTING...................................................................363

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE........................................................364

CHECKS BEFORE TROUBLESHOOTING...........................................................................372

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING............................................................373

Classification of troubleshooting...................................................................373

Steps for troubleshooting...........................................................................373

Failure-looking Phenomenon and Troubleshooting No...................................................374

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM.......................................378

CONNECTOR LOCATION STEREOGRAM.......................................................................384

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS..............................................................392

20_301.pdf...................................................................................................... 0

TROUBLESHOOTING WHEN SERVICE CODE "ELECTRICAL SYSTEM" AND FAILURE CODE "MECHANICAL SYSTEM" ARE IN...........421

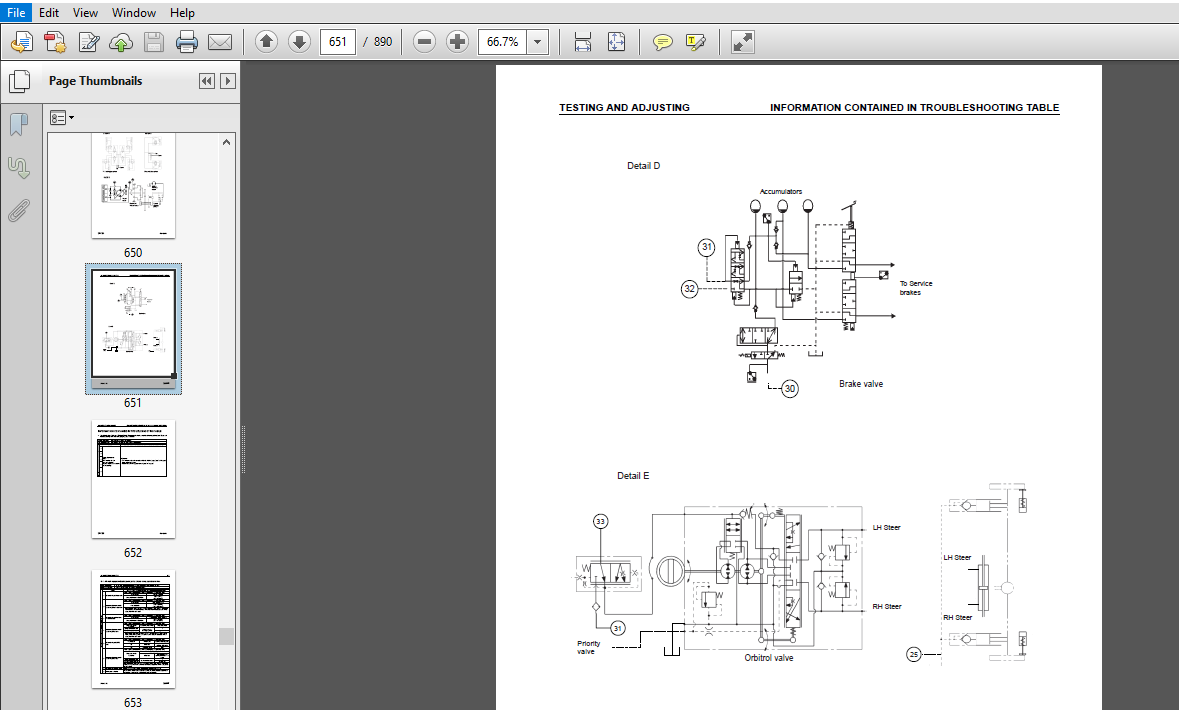

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..........................................................424

Service Code in Electrical System (Abnormal data in Error History)......................................426

Service Code in Electrical System (Disconnection of S-NET signal).......................................428

Service Code in Electrical System (Short-circuiting in Travel Neutral Solenoid).........................430

Service Code in Electrical System (Short-circuiting of Travel F/R solenoid).............................432

Service Code in Electrical System (Short-circuiting in 2-Stage Relief solenoid).........................434

Service Code in Electrical System (Short-circuiting in Transmission Clutch solenoid)....................436

Service Code in Electrical System (Short-circuiting in Creep solenoid)..................................438

Service Code in Electrical System (Disconnection in Creep solenoid).....................................440

Service Code in Electrical System (Disconnection in Travel Neutral solenoid)............................442

Service Code in Electrical System (Disconnection of Travel F/R solenoid)................................444

Service Code in Electrical System (Disconnection in Swing Parking Brake solenoid).......................446

Service Code in Electrical System (Disconnection in 2-stage Relief solenoid)............................448

Service Code in Electrical System (Disconnection in Transmission Clutch solenoid).......................450

Service Code in Electrical System (Abnormality in inputting model code).................................452

Service Code in Electrical System (Abnormality in inputting model code).................................454

Service Code in Electrical System Disconnection of S-NET signal)........................................456

Service Code in Electrical System (Short-circuiting in LS-EPC solenoid).................................458

Service Code in Electrical System (Disconnection in LS-EPC solenoid system).............................459

Service Code in Electrical System (Abnormality in pump pressure sensor).................................460

Service Code in Electrical System (Abnormality in Pressure sensor power source).........................462

Service Code in Electrical System (Abnormality in engine rotation sensor in governor • pump contr.......464

Service Code in Electrical System (Short-circuiting in PC-EPC solenoid).................................466

Service Code in Electrical System (Disconnection in PC-EPC solenoid system).............................468

Service Code in Electrical System (Short circuiting in 2-stage back pressure solenoid)..................470

Service Code in Electrical System (Disconnection in 2-stage Back Pressure solenoid).....................472

Service Code in Electrical System (Short-circuiting in attachment oil flow rate adjusting EPC)..........474

Service Code in Electrical System (Disconnection in attachment oil flow rate adjusting EPC).............475

Service Code in Electrical System (Abnormality in direction control switch).............................476

Service Code In Electrical System (Abnormality in overload caution sensor)..............................478

Service Code in Electrical System (Abnormality in travel PPC sensor)....................................480

Service Code in Electrical System (Disconnection in transmission speed sensor in governor • pump .......482

Service Code in Electrical System (Incorrect non-volatile memory data)..................................484

Service Code in Electrical System (Abnormality in travel PPC switch hydraulics).........................485

Service Code in Electrical System (Abnormality in governor potentiometer)...............................487

Service Code in Electrical System (Abnormality in fuel dial)............................................489

Service Code in Electrical System (Short-circuiting in battery relay)...................................491

Service Code in Electrical System (Step-out in governor motor)..........................................493

Service Code in Electrical System (Disconnection in governor motor Phase A and B).......................495

Service Code in Electrical System (Short-circuiting in governor motor Phase A and Phase B)..............497

Service Code in Electrical System ("Model Selection" function not provided yet).........................499

Service Mode in Electrical System (Model selecting signal fault)........................................500

Failure Code in Mechanical System (Out-of-rate engine rotation at high idling)..........................501

Failure Code in Mechanical System A000N2 (Out-of-rate engine rotation at low idling)....................501

Failure Code in Mechanical System (Air cleaner clogging)................................................502

Failure Code in Mechanical System (Abnormally lowered charging voltage).................................503

Failure Code in Mechanical System (Abnormally lowered engine oil pressure)..............................505

Failure Code in Mechanical System (Abnormally lowered engine oil level).................................506

Failure Code in Mechanical System (Engine cooling water overheating)....................................507

Failure Code in Mechanical System (Abnormally lowered radiator water level).............................508

Failure Code in Mechanical System (Hydraulic oil overheating)...........................................509

20_501.pdf...................................................................................................... 0

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..............................................................512

E-1 Engine does not start (Engine does not rotate)..........................................................513

E-2 Engine stops while in operation.........................................................................516

E-3 Engine speed is irregular, or there is hunting..........................................................518

E-4 Engine does not stop....................................................................................520

E-5 Auto-decelerator does not work..........................................................................522

E-6 Auto engine warm-up device does not work................................................................523

E-7 Pre heater does not work................................................................................524

E-8 All work equipment, swing and travel do not move........................................................526

E-9 One-touch Power Max Switch does not work................................................................528

E-10 No display in monitor panel at all.....................................................................529

E-11 Part of display on monitor panel is missing............................................................530

E-12 Monitor panel displays contents irrelevant to the model................................................530

E-13 Fuel level monitor red lamp lights up while engine is running..........................................531

E-14 Engine cooling water temperature gauge does not indicate correctly.....................................532

E-15 Hydraulic oil temperature gauge does not display correctly.............................................533

E-16 Fuel gauge does not display correctly..................................................................534

E-17 Swing lock monitor does not display correctly..........................................................536

E-18 When the monitor switch is operated, no display appears................................................538

E-19 Windshield wiper does not work.........................................................................540

E-21 "Boom/Stabiliser RAISE" is not correctly displayed in monitor function.................................542

E-22 "Boom LOWER" is not correctly displayed in monitor function............................................543

E-23 "Arm DIGGING" is not correctly displayed in monitor function...........................................544

E-24 "Arm DUMPING" is not correctly displayed in monitor function...........................................545

E-25 "Bucket DIGGING" is not correctly displayed in monitor function........................................546

E-26 "Bucket DUMPING" is not correctly displayed in monitor function........................................547

E-27 "SWING" is not correctly displayed in monitor function.................................................548

E-28 "TRAVEL" is not correctly displayed in monitor function................................................550

E-29 "Service" is not correctly displayed in monitor function...............................................552

E-30 Air Conditioner does not work..........................................................................554

E-31 Travel alarm does not sound............................................................................555

20_601.pdf...................................................................................................... 0

TROUBLESHOOTING OF ELECTRICAL SYSTEM........................................................................557

(Error checking of items without Monitor codes).............................................................557

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..........................................................559

Radio Cassette & Telephone Socket.......................................................................560

PPC Circuit & Brake Light Interlock.....................................................................562

Undercarriage Attachments - Mode Selection..............................................................564

Undercarriage Attachments - Front Left Outrigger........................................................566

Undercarriage Attacments - Front Right Outrigger........................................................568

Undercariage Attachments - Rear Left Outrigger..........................................................570

Undercarriage Attachments - Rear Right Outrigger........................................................572

Heated Seat Does Not Warm Up............................................................................574

Suspension Lock.........................................................................................576

Lower Wiper Does Not Work (Optional Fitment)............................................................578

Work Lights (Operator Cab)..............................................................................580

Worklights (Boom & Counterweight).......................................................................582

Beacon Light............................................................................................584

Air Seat Compressor (Option - Air Suspension Seat)......................................................586

Operator Cab Interior Light.............................................................................588

Quick Coupler...........................................................................................590

Cigar Lighter...........................................................................................592

Park Brake (Not Activating).............................................................................594

Park Brake (Displayed Symbol)...........................................................................596

Clamshell Control - Rotate Right (1st Service)..........................................................598

Clamshell Control - Rotate Left - Check Work Lever Circuit..............................................600

Clamshell Control - Rotate Left - Check EPC Circuit.....................................................601

Horns...................................................................................................604

Swing Lock - Normal Operation...........................................................................606

Swing Lock - Emergency Operation........................................................................608

Neutral Start (Engine)..................................................................................610

Emergency Travel Control - Forward......................................................................614

Emergency Travel Control - Neutral......................................................................616

Emergency Travel Control - Reverse......................................................................618

Driving Lights - Main Beam..............................................................................622

Driving Lights - Main Beam Flash........................................................................626

Driving Lights - Main Beam Dipped.......................................................................628

Driving Lights - Position Lights........................................................................630

Driving Lights - Parking Lights.........................................................................634

Indicators - Right Hand.................................................................................638

Indicators - Left Hand..................................................................................640

Hazard Warning Lights...................................................................................642

20_701.pdf...................................................................................................... 0

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).................................................647

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS.......................................................648

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE..........................................................652

H-1 All work equipment lacks power, or travel and swing speeds are slow.............................653

H-2 Engine speed sharply drops or engine stalls.....................................................654

H-3 No work equipment, travel or swing move.........................................................655

H-4 Abnormal noise is heard from around hydraulic pump..............................................655

H-5 Auto-decelerator does not work..................................................................656

H-6 Fine control mode does not function.............................................................656

H-7 Boom moves slowly or lacks power................................................................657

H-8 Arm moves slowly or lacks power.................................................................658

H-9 Bucket moves slowly or lacks power..............................................................659

H-10 Work equipment does not move in its single operation...........................................659

H-11 Work equipment hydraulic drift is too fast.....................................................660

H-12 Work equipment has big time lag................................................................661

H-13 Other work equipment moves when relieving single circuit.......................................661

H-14 One-touch power max. switch does not operate...................................................661

H-15 In compound operation, work equipment with larger load moves slowly............................662

H-16 In swing + boom RAISE operation, boom moves slowly.............................................662

H-17 In swing + travel, travel speed drops sharply..................................................662

H-18 Travel speed does not switch...................................................................663

H-19 Travel speed does not shift, or it is too slow or fast.........................................664

H-20 Machine does not swing.........................................................................665

H-21 Swing acceleration is poor, or swing speed is slow.............................................666

H-22 Excessive overrun when stopping swing..........................................................667

H-23 There is big shock when stopping swing.........................................................668

H-24 There is loud abnormal noise caused when stopping swing........................................668

H-25 Swing natural drift is too big.................................................................669

H-26 Swing speed is faster than specified swing speed...............................................670

Sec 30.pdf...................................................................................................... 0

HOW TO READ THIS MANUAL.....................................................................................673

REMOVAL AND INSTALLATION OF ASSEMBLIES..................................................................673

DisassemblY and assemblY OF assemblIES..................................................................674

SPECIAL TOOLS...............................................................................................675

SKETCHES................................................................................................675

LIST OF TOOLS...........................................................................................676

PRECAUTIONS WHEN PERFORMING OPERATION.......................................................................677

GOVERNOR MOTOR ASSEMBLY.....................................................................................679

REMOVAL AND INSTALLATION OF Assembly........................................................................680

STARTING MOTOR ASSEMBLY.....................................................................................680

REMOVAL AND INSTALLATION OF Assembly........................................................................681

FUEL INJECTION PUMP ASSEMBLY................................................................................681

ENGINE FRONT SEAL...........................................................................................686

ENGINE REAR SEAL............................................................................................689

CYLINDER HEAD ASSEMBLY......................................................................................691

COMBINATION COOLER..........................................................................................697

ENGINE AND HYDRAULIC PUMP ASSEMBLIES........................................................................700

TRAVEL MOTOR ASSEMBLY.......................................................................................705

TRAVEL MOTOR ASSEMBLY.......................................................................................708

REMOVAL AND INSTALLATION OF.................................................................................712

SWING MOTOR AND SWING MACHINERY ASSEMBLY....................................................................712

SWING MACHINERY ASSEMBLY....................................................................................713

SWING MOTOR ASSEMBLY........................................................................................721

FRONT AXLE ASSEMBLY.........................................................................................730

FRONT AXLE ASSEMBLY.........................................................................................732

REAR AXLE AND TRANSMISSION ASSEMBLY.........................................................................778

REAR AXLE ASSEMBLY..........................................................................................781

TRANSMISSION ASSEMBLY.......................................................................................803

PROPSHAFT ASSEMBLY..........................................................................................817

WHEEL ASSEMBLY..............................................................................................819

SUSPENSION LOCK CYLINDER ASSEMBLY...........................................................................820

SUSPENSION LOCK ASSEMBLY....................................................................................821

OUTRIGGER ASSEMBLY..........................................................................................822

OUTRIGGER ASSEMBLY..........................................................................................823

DOZER BLADE ASSEMBLY........................................................................................824

DOZER BLADE ASSEMBLY........................................................................................825

SWING CIRCLE................................................................................................826

ASSEMBLY....................................................................................................826

REVOLVING FRAME ASSEMBLY....................................................................................827

CENTRE SWIVEL JOINT ASSEMBLY................................................................................830

CENTRE SWIVEL JOINT ASSEMBLY................................................................................833

HYDRAULIC TANK ASSEMBLY.....................................................................................835

FUEL TANK ASSEMBLY..........................................................................................839

CONTROL VALVE ASSEMBLY......................................................................................841

LS SEPARATION VALVE ASSEMBLY................................................................................844

PRESSURE COMPENSATION VALVE ASSEMBLY........................................................................845

MAIN RELIEF VALVE ASSEMBLY..................................................................................846

LS CONTROL EPC VALVE ASSEMBLY...............................................................................847

EPC SOLENOID VALVE ASSEMBLY.................................................................................848

PPC SOLENOID VALVE BLOCK ASSEMBLY...........................................................................849

MANIFOLD BLOCK ASSEMBLY.....................................................................................851

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT......................................................................852

WORK EQUIPMENT PPC VALVE ASSEMBLY...........................................................................853

TRAVEL PEDAL VALVE ASSEMBLY.................................................................................854

HYDRAULIC CYLINDER ASSEMBLY.................................................................................855

MONOBOOM WORK EQUIPMENT ASSEMBLY............................................................................861

2 PIECE BOOM WORK EQUIPMENT ASSEMBLY........................................................................864

AIR CONDITIONER UNIT ASSEMBLY...............................................................................867

COUNTERWEIGHT ASSEMBLY......................................................................................870

OPERATOR CAB ASSEMBLY.......................................................................................872

MONITOR ASSEMBLY............................................................................................875

GOVERNOR / PUMP CONTROLLER ASSEMBLY.........................................................................876

UEBM002500_A2.pdf............................................................................................... 0

hydraulic circuit diagram (1/2).............................................................................881

PW160-7K................................................................................................881

This page left intentionally blank......................................................................882

hydraulic circuit diagram (2/2).............................................................................883

PW160-7K................................................................................................883

This page left intentionally blank......................................................................884

electrical circuit diagram (1/3)............................................................................885

PW160-7K................................................................................................885

This page left intentionally blank......................................................................886

electrical circuit diagram (2/3)............................................................................887

This page left intentionally blank......................................................................888

electrical circuit diagram (3/3)............................................................................889

This page left intentionally blank......................................................................890

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE: