$45

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual PDF DOWNLOAD

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual

FILE DETAILS:

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual

File Format : PDF

Language : English

Printable : Yes

Searchable : Yes

Product Code : UEBM000801

Total Pages : 707

DESCRIPTION:

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters: these chapters are further divided into the each main group of components.

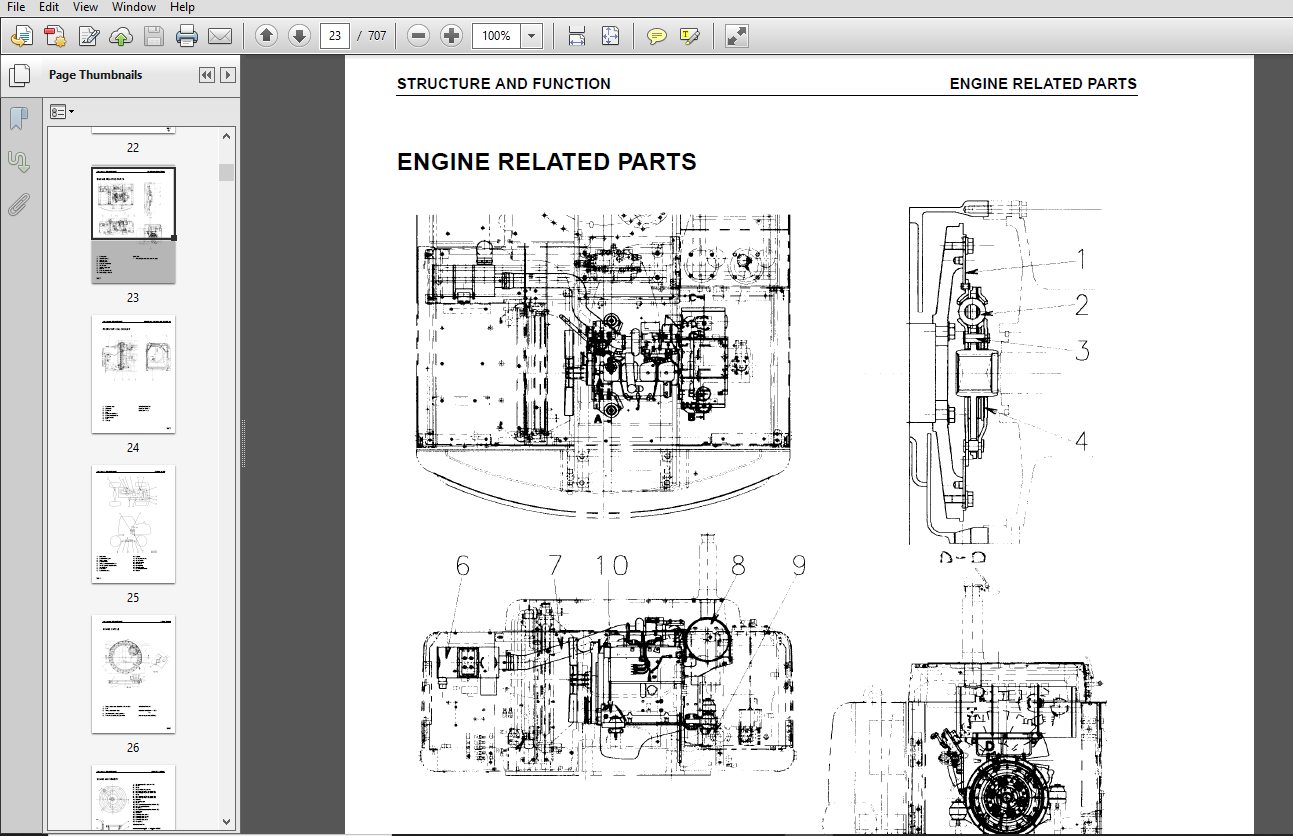

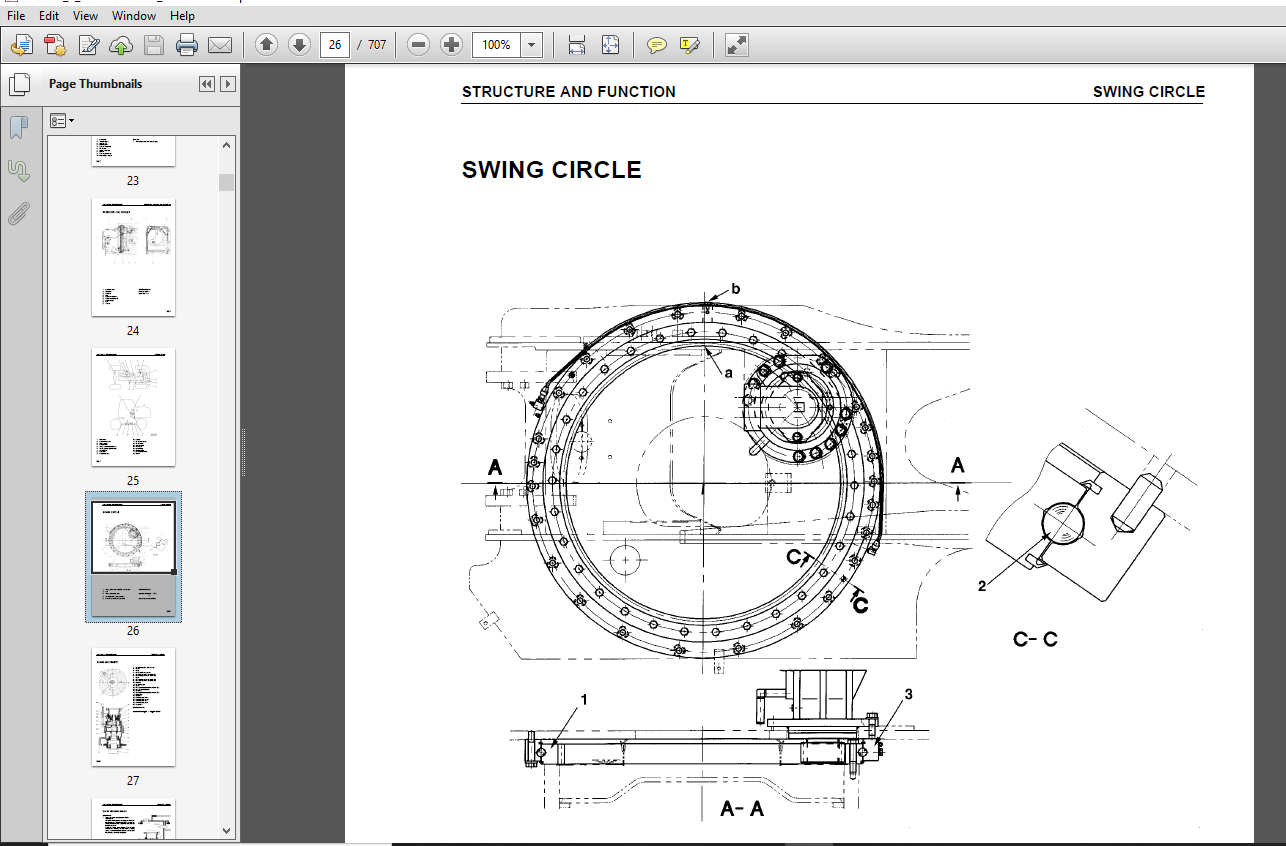

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs , as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the order to be followed when removing, installing, disassembling or assembling eachr component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD:

This section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual

PW170ES- 6K .................................................................................................................................................................... 1 K32001 and up K34001 and up .................................................................................................................................................... 1 CONTENTS ....................................................................................................................................................................... 2 01 GENERAL.........................................................Helvetica-Bold .............................................................................................. 2 10 STRUCTURE AND FUNCTION ...................................................................................................................................................... 2 20 TESTING AND ADJUSTING ....................................................................................................................................................... 2 30 DISASSEMBLY AND ASSEMBLY .................................................................................................................................................... 2 40 MAINTENANCE STANDARD.................................................. ...................................................................................................... 2 SAFETY ......................................................................................................................................................................... 6 SAFETY NOTICE .............................................................................................................................................................. 6 FOREWORD ....................................................................................................................................................................... 8 GENERAL .................................................................................................................................................................... 8 HOW TO READ THE SHOP MANUAL .................................................................................................................................................... 9 HOISTING INSTRUCTIONS .......................................................................................................................................................... 10 COATING MATERIALS .............................................................................................................................................................. 11 STANDARD TIGHTENING TORQUE ..................................................................................................................................................... 12 ELECTRIC WIRE CODE ............................................................................................................................................................. 14 CONVERSION TABLE ............................................................................................................................................................... 15 ENGINE RELATED PARTS ........................................................................................................................................................... 23 RADIATOR Ł OIL COOLER .......................................................................................................................................................... 24 SWING CIRCLE ................................................................................................................................................................... 26 SWING HOLDING BRAKE ........................................................................................................................................................ 28 SWING MACHINERY UNDERCARRIAGE .................................................................................................................................................. 30 CLUTCH CONTROL CIRCUIT ......................................................................................................................................................... 31 FUNCTION ................................................................................................................................................................... 32 AXLE ........................................................................................................................................................................... 33 REAR AXLE .................................................................................................................................................................. 34 REAR AXLE .................................................................................................................................................................. 36 SUSPENSION LOCK CYLINDER ....................................................................................................................................................... 37 CIRCUIT .................................................................................................................................................................... 38 BRAKING TRAIN .................................................................................................................................................................. 39 BRAKE PEDAL .................................................................................................................................................................... 40 BRAKE PEDAL INCORPORATING BRAKE VALVE .......................................................................................................................................... 41 ACCUMULATOR FOR BRAKE SYSTEM ................................................................................................................................................... 42 STEERING TRAIN ................................................................................................................................................................. 43 ITEM ........................................................................................................................................................................... 44 STEERING COLUMN ................................................................................................................................................................ 45 HYDRAULIC CIRCUIT DIAGRAM ...................................................................................................................................................... 46 HYDRAULIC CIRCUIT DIAGRAM ...................................................................................................................................................... 47 HYDRAULIC TANK ................................................................................................................................................................. 48 HYDRAULIC TANK ................................................................................................................................................................. 49 HYDRAULIC PUMP ................................................................................................................................................................. 51 OPERATION .................................................................................................................................................................. 52 PPC PUMPLESS SYSTEM ............................................................................................................................................................ 68 CONTROL VALVE .................................................................................................................................................................. 70 CLSS ........................................................................................................................................................................... 80 POINTS TO REMEMBER WHEN TROUBLESHOOTING ........................................................................................................................................245 SEQUENCE OF EVENTS IN TROUBLESHOOTING ..........................................................................................................................................246 PRECAUTIONS WHEN CARRYING OUT MAINTENANCE ......................................................................................................................................247 1. PRECAUTIONS WHEN HANDLING ELECTRIC EQUIPMENT ............................................................................................................................247 CHECKS BEFORE TROUBLESHOOTING ..................................................................................................................................................254 CONNECTOR TYPES ................................................................................................................................................................255 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS .....................................................................................................................................259 EXPLANATION OF CONTROL MACHANISM FOR ELECTRICAL SYSTEM .........................................................................................................................272 METHOD OF USING JUDGEMENT TABLE ................................................................................................................................................281 METHOD OF USING TROUBLESHOOTING CHARTS .........................................................................................................................................283 DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE .......................................................................................................................285 SERVICE CODE TABLE .............................................................................................................................................................290 POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM .......................................................................................296 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE .....................................................................................................297 JUDGEMENT TABLE FOR GOVERNOR, PUMP GOVERNOR ( GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS ................................................................................301 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 1/ 2 .....................................................................................................................................303 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 2/ 2 .....................................................................................................................................304 E- 1 Abnormality in governor, pump controller power source ( controller LED is OFF) ............................................................................................305 E- 2 [ E308] Abnormality in fuel control dial input value is displayed .........................................................................................................306 E- 3 [ E317] Abnormality ( disconnection) in motor drive system is displayed ...................................................................................................307 E- 4 [ E318] Abnormality ( short circuit) in motor drive system is displayed ...................................................................................................308 E- 5 [ E306] Abnormality in feedback potentiometer system is displayed .........................................................................................................309 E- 6 [ E315] Abnormality ( short circuit) in battery relay output system is displayed ..........................................................................................310 E- 7 [ E316] Abnormality ( step- out) in motor is displayed ....................................................................................................................311 E- 8 Engine does not start .....................................................................................................................................................313 Engine speed is irregular ..................................................................................................................................................315 Defective operation of battery relay system ( engine does not stop) ........................................................................................................323 METHOD OF USING TROUBLESHOOTING CHARTS .........................................................................................................................................325 S- 1 Starting performance is poor ( starting always takes time) ................................................................................................................329 S- 2 Engine does not start .....................................................................................................................................................330 S- 3 Engine does not pick up smoothly ( follow- up is poor) ....................................................................................................................333 S- 4 Engine stops during operations ............................................................................................................................................334 S- 5 Engine does not rotate smoothly ( hunting) ................................................................................................................................335 S- 6 Engine lacks output ( no power) ...........................................................................................................................................336 S- 7 Exhaust smoke is black ( incomplete combustion) ...........................................................................................................................337 S- 8 Oil consumption is excessive ( or exhaust smoke is blue) ..................................................................................................................338 S- 9 Oil becomes contaminated quickly ..........................................................................................................................................339 S- 10 Fuel consumption is excessive ............................................................................................................................................340 S- 11 Oil is in cooling water, or water spurts back, or water level goes down ..................................................................................................341 S- 12 Oil pressure caution lamp lights up ( drop in oil pressure) ..............................................................................................................342 S- 13 Oil level rises ( water, fuel in oil) ....................................................................................................................................343 S- 14 Water temperature becomes too high ( overheating) ........................................................................................................................344 S- 15 Abnormal noise is made ...................................................................................................................................................345 S- 16 Vibration is excessive ...................................................................................................................................................346 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 2/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 2/ 2 ....380 PW170ES- 6K Serial number K32001 and up PW170ES- 6K Serial number K32001 and up INSTALLATION OF OPERATOR'S CAB ASSEMBLY ........................................................539 REMOVAL OF COUNTERWEIGHT ASSEMBLY ..............................................................................................................................................540 INSTALLATION OF COUNTERWEIGHT ASSEMBLY .........................................................................................................................................540 PW170ES- 6K .................................................................................................................................................................... 1 K32001 and up K34001 and up .................................................................................................................................................... 1 CONTENTS ....................................................................................................................................................................... 2 01 GENERAL.........................................................Helvetica-Bold .............................................................................................. 2 10 STRUCTURE AND FUNCTION ...................................................................................................................................................... 2 20 TESTING AND ADJUSTING ....................................................................................................................................................... 2 30 DISASSEMBLY AND ASSEMBLY .................................................................................................................................................... 2 40 MAINTENANCE STANDARD.................................................. ...................................................................................................... 2 SAFETY ......................................................................................................................................................................... 6 SAFETY NOTICE .............................................................................................................................................................. 6 FOREWORD ....................................................................................................................................................................... 8 GENERAL .................................................................................................................................................................... 8 HOW TO READ THE SHOP MANUAL .................................................................................................................................................... 9 HOISTING INSTRUCTIONS .......................................................................................................................................................... 10 COATING MATERIALS .............................................................................................................................................................. 11 STANDARD TIGHTENING TORQUE ..................................................................................................................................................... 12 ELECTRIC WIRE CODE ............................................................................................................................................................. 14 CONVERSION TABLE ............................................................................................................................................................... 15 ENGINE RELATED PARTS ........................................................................................................................................................... 23 RADIATOR Ł OIL COOLER .......................................................................................................................................................... 24 SWING CIRCLE ................................................................................................................................................................... 26 SWING HOLDING BRAKE ........................................................................................................................................................ 28 SWING MACHINERY UNDERCARRIAGE .................................................................................................................................................. 30 CLUTCH CONTROL CIRCUIT ......................................................................................................................................................... 31 STRUCTURE .................................................................................................................................................................. 31 FUNCTION ................................................................................................................................................................... 32 AXLE ........................................................................................................................................................................... 33 FRONT AXLE ................................................................................................................................................................. 33 REAR AXLE .................................................................................................................................................................. 34 FRONT AXLE ................................................................................................................................................................. 35 REAR AXLE .................................................................................................................................................................. 36 SUSPENSION LOCK CYLINDER ....................................................................................................................................................... 37 CIRCUIT .................................................................................................................................................................... 38 BRAKING TRAIN .................................................................................................................................................................. 39 BRAKE PEDAL .................................................................................................................................................................... 40 BRAKE PEDAL INCORPORATING BRAKE VALVE .......................................................................................................................................... 41 ACCUMULATOR FOR BRAKE SYSTEM ................................................................................................................................................... 42 STEERING TRAIN ................................................................................................................................................................. 43 ITEM ........................................................................................................................................................................... 44 STEERING COLUMN ................................................................................................................................................................ 45 HYDRAULIC CIRCUIT DIAGRAM ...................................................................................................................................................... 46 HYDRAULIC CIRCUIT DIAGRAM ...................................................................................................................................................... 47 HYDRAULIC TANK ................................................................................................................................................................. 48 HYDRAULIC TANK ................................................................................................................................................................. 49 HYDRAULIC PUMP ................................................................................................................................................................. 51 OPERATION .................................................................................................................................................................. 52 FUNCTION ................................................................................................................................................................... 57 PPC PUMPLESS SYSTEM ............................................................................................................................................................ 68 CONTROL VALVE .................................................................................................................................................................. 70 CLSS ........................................................................................................................................................................... 80 POINTS TO REMEMBER WHEN TROUBLESHOOTING ........................................................................................................................................245 SEQUENCE OF EVENTS IN TROUBLESHOOTING ..........................................................................................................................................246 PRECAUTIONS WHEN CARRYING OUT MAINTENANCE ......................................................................................................................................247 1. PRECAUTIONS WHEN HANDLING ELECTRIC EQUIPMENT ............................................................................................................................247 2. POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT ....................................................................................................................252 CHECKS BEFORE TROUBLESHOOTING ..................................................................................................................................................254 CONNECTOR TYPES ................................................................................................................................................................255 CONNECTION TABLE FOR CONNECTOR PIN NUMBERS .....................................................................................................................................259 EXPLANATION OF CONTROL MACHANISM FOR ELECTRICAL SYSTEM .........................................................................................................................272 DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL ......................................................................................................................273 METHOD OF USING JUDGEMENT TABLE ................................................................................................................................................281 METHOD OF USING TROUBLESHOOTING CHARTS .........................................................................................................................................283 DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE .......................................................................................................................285 SERVICE CODE TABLE .............................................................................................................................................................290 POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM .......................................................................................296 ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE .....................................................................................................297 JUDGEMENT TABLE FOR GOVERNOR, PUMP GOVERNOR ( GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS ................................................................................301 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 1/ 2 .....................................................................................................................................303 ELECTRICAL CIRCUIT DIAGRAM FOR E MODE 2/ 2 .....................................................................................................................................304 E- 1 Abnormality in governor, pump controller power source ( controller LED is OFF) ............................................................................................305 E- 2 [ E308] Abnormality in fuel control dial input value is displayed .........................................................................................................306 E- 3 [ E317] Abnormality ( disconnection) in motor drive system is displayed ...................................................................................................307 E- 4 [ E318] Abnormality ( short circuit) in motor drive system is displayed ...................................................................................................308 E- 5 [ E306] Abnormality in feedback potentiometer system is displayed .........................................................................................................309 E- 6 [ E315] Abnormality ( short circuit) in battery relay output system is displayed ..........................................................................................310 E- 7 [ E316] Abnormality ( step- out) in motor is displayed ....................................................................................................................311 E- 8 Engine does not start .....................................................................................................................................................313 E- 9 Engine speed is irregular .............................................................................................................................................315 E- 10 Lack of output ( engine high idling speed is too low) ................................................................................................................319 E- 11 Engine does not stop .................................................................................................................................................321 E- 12 Defective operation of battery relay system ( engine does not stop) ..................................................................................................323 METHOD OF USING TROUBLESHOOTING CHARTS .........................................................................................................................................325 S- 1 Starting performance is poor ( starting always takes time) ................................................................................................................329 S- 2 Engine does not start .....................................................................................................................................................330 S- 3 Engine does not pick up smoothly ( follow- up is poor) ....................................................................................................................333 S- 4 Engine stops during operations ............................................................................................................................................334 S- 5 Engine does not rotate smoothly ( hunting) ................................................................................................................................335 S- 6 Engine lacks output ( no power) ...........................................................................................................................................336 S- 7 Exhaust smoke is black ( incomplete combustion) ...........................................................................................................................337 S- 8 Oil consumption is excessive ( or exhaust smoke is blue) ..................................................................................................................338 S- 9 Oil becomes contaminated quickly ..........................................................................................................................................339 S- 10 Fuel consumption is excessive ............................................................................................................................................340 S- 11 Oil is in cooling water, or water spurts back, or water level goes down ..................................................................................................341 S- 12 Oil pressure caution lamp lights up ( drop in oil pressure) ..............................................................................................................342 S- 13 Oil level rises ( water, fuel in oil) ....................................................................................................................................343 S- 14 Water temperature becomes too high ( overheating) ........................................................................................................................344 S- 15 Abnormal noise is made ...................................................................................................................................................345 S- 16 Vibration is excessive ...................................................................................................................................................346 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR C MODE 2/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 1/ 2 ELECTRICAL CIRCUIT DIAGRAM FOR F MODE 2/ 2 ....380 PW170ES- 6K Serial number K32001 and up PW170ES- 6K Serial number K32001 and up INSTALLATION OF OPERATOR'S CAB ASSEMBLY ........................................................539 REMOVAL OF COUNTERWEIGHT ASSEMBLY ..............................................................................................................................................540 INSTALLATION OF COUNTERWEIGHT ASSEMBLY .........................................................................................................................................540 REMOVAL OF GOVERNOR PUMP CONTROLLER ASSEMBLY ...................................................................................................................................541 INSTALLATION OF GOVERNOR, PUMP CONTROLLER ASSEMBLY .............................................................................................................................541 REMOVAL OF MONITOR PANEL ASSEMBLY ..............................................................................................................................................542 INSTALLATION OF MONITOR PANEL ASSEMBLY .........................................................................................................................................542 DISASSEMBLY OF SWING MACHINERY ASSEMBLY ( SPECIAL TOOLS FOR SWING MACHINERY) ( SPECIAL TOOLS FOR SWING MACHINERY) TRANSMISSION .................................................581 FRONT AXLE .....................................................................................................................................................................634 REAR AXLE ......................................................................................................................................................................652 ADAPTER WELDING INSTRUCTION - ELECTRODE WELDING ................................................................................................................................666 OUTRIGGER CYLINDER .............................................................................................................................................................669 REMOVAL OF OUTRIGGER CYLINDER ..............................................................................................................................................669 INSTALLATION OF OUTRIGGER CYLINDER .........................................................................................................................................669 BLADE CYLINDER .................................................................................................................................................................670 REMOVAL OF BLADE CYLINDER ..................................................................................................................................................670 INSTALLATION OF BLADE CYLINDER .............................................................................................................................................670 MAINTENANCE STANDARD ...........................................................................................................................................................672 ENGINE MOUNT ...............................................................................................................................................................673 SWING MACHINERY CONTROL VALVE SUCTION- SAFETY VALVE ........................................................................................................................685 SWING MOTOR WORK EQUIPMENT, SWING PPC VALVE ................................................................................................................................687 EPC SOLENOID VALVE .........................................................................................................................................................688 CENTER SWIVEL JOINT ........................................................................................................................................................689 ARM, BOOM SAFETY VALVE .....................................................................................................................................................690 HYDRAULIC CYLINDER .........................................................................................................................................................691 WORK EQUIPMENT .............................................................................................................................................................692 WORK EQUIPMENT - ONE PIECE BOOM ............................................................................................................................................693 WORK EQUIPMENT - TWO PIECE BOOM ............................................................................................................................................694 DIMENSIONS OF WORK EQUIPMENT ...............................................................................................................................................696 DOZER BLADE AND OUTRIGGERS HYDRAULIC CYLINDERS .............................................................................................................................700 OUTRIGGER BUSH PINS ........................................................................................................................................................701 TRANSMISSION ...............................................................................................................................................................702 FRONT AXLE .................................................................................................................................................................703 REAR AXLE ..................................................................................................................................................................704 ARM ROTATION CIRCLE ........................................................................................................................................................705

IMAGES PREVIEW OF THE MANUAL: