$36

Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 – PDF DOWNLOAD

Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 – PDF DOWNLOAD

FILE DETAILS:

Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 – PDF DOWNLOAD

Language : English

Pages : 286

Downloadable : Yes

File Type : PDF

Size: 6.02 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 – PDF DOWNLOAD

The Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 is a comprehensive guidebook that provides detailed technical information and instructions on how to operate, maintain, and repair the Komatsu SA12V140Z-1 and SAA12V140ZE-2 series diesel engines. These engines are commonly used in heavy construction and mining equipment, as well as power generation applications.

- The manual is organized into several sections, each providing detailed information on specific topics. These sections include specifications, structure and function, testing and adjusting, disassembly and assembly, maintenance, and troubleshooting.

- The specifications section of the manual provides detailed information on the engine’s physical and operational characteristics, including its dimensions, weight, performance, and power output. It also provides information on the engine’s cooling system, fuel system, and lubrication system.

- The structure and function section of the manual provides an overview of the engine’s internal components and their functions. This section includes detailed diagrams and descriptions of the engine’s various components, such as the cylinder block, cylinder head, crankshaft, pistons, and valves.

- The testing and adjusting section of the manual provides instructions on how to test and adjust the engine’s various components to ensure they are functioning correctly. This section includes detailed procedures for testing and adjusting the engine’s fuel injection system, valve clearances, and oil pressure.

- The disassembly and assembly section of the manual provides step-by-step instructions on how to disassemble and reassemble the engine’s various components. This section includes detailed diagrams and photographs to guide the user through the process.

- The maintenance section of the manual provides information on routine maintenance tasks that should be performed to keep the engine in good working condition. This section includes instructions on how to perform tasks such as changing the engine oil and replacing the air filter.

- The troubleshooting section of the manual provides guidance on how to diagnose and resolve common issues that may arise with the engine. This section includes a list of common symptoms and their likely causes, as well as step-by-step instructions for troubleshooting and resolving each issue.

- Overall, the Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 is an essential resource for anyone who operates, maintains, or repairs these powerful diesel engines. With its detailed technical information and comprehensive instructions, this manual is an invaluable tool for ensuring the efficient and reliable operation of Komatsu SA12V140Z-1 and SAA12V140ZE-2 series engines in heavy equipment applications.

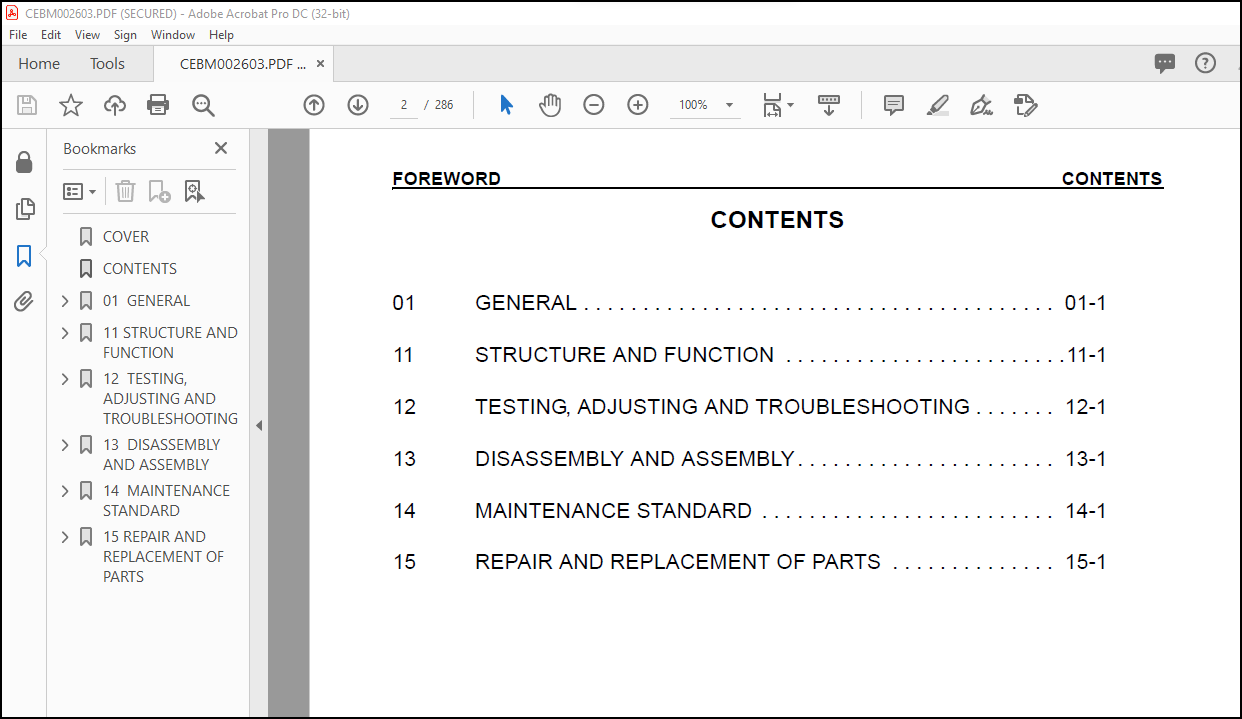

TABLE OF CONTENTS:

Komatsu SA12V140Z-1 SERIES SAA12V140ZE-2 SERIES Diesel Engine Shop Manual CEBM002603 – PDF DOWNLOAD

COVER………………………………………………………………………………. 1

CONTENTS……………………………………………………………………………. 2

01 GENERAL…………………………………………………………………………. 25

SPECIFICATIONS…………………………………………………………………… 26

GENERAL ASSEMBLY DRAWING………………………………………………………….. 27

VIEW FROM LEFT SIDE…………………………………………………………… 27

VIEW FROM RIGHT SIDE………………………………………………………….. 28

VIEW FROM FRONT………………………………………………………………. 29

VIEW FROM REAR……………………………………………………………….. 30

VIEW FROM LEFT SIDE (CUSTOM CONNECTIONS)………………………………………… 31

VIEW FROM TOP………………………………………………………………… 32

ENGINE PERFORMANCE CURVE………………………………………………………….. 33

WA800-2LC……………………………………………………………………. 33

WA900-1LC……………………………………………………………………. 34

330M………………………………………………………………………… 35

11 STRUCTURE AND FUNCTION…………………………………………………………….. 37

GENERAL STRUCTURE………………………………………………………………… 39

INTAKE AND EXHAUST SYSTEM…………………………………………………………. 41

INTAKE SYSTEM………………………………………………………………… 41

EXHAUST SYSTEM……………………………………………………………….. 42

TURBOCHARGER…………………………………………………………………. 43

AFTERCOOLER………………………………………………………………….. 44

ENGINE BODY……………………………………………………………………… 45

CYLINDER HEAD………………………………………………………………… 45

SPECIFICATIONS……………………………………………………………. 46

VALVE SEAT……………………………………………………………….. 46

ROCKER ARM HOUSING COVER…………………………………………………… 46

FUEL INJECTION NOZZLE……………………………………………………… 46

CYLINDER BLOCK……………………………………………………………….. 47

SPECIFICATIONS……………………………………………………………. 48

PISTON COOLING……………………………………………………………. 48

CYLINDER LINER……………………………………………………………. 48

LINER SEAL……………………………………………………………….. 48

MAIN REVOLVING SYSTEM…………………………………………………………. 49

CRANKSHAFT……………………………………………………………….. 50

PISTON…………………………………………………………………… 50

CONNECTING ROD……………………………………………………………. 50

TIMING GEAR………………………………………………………………….. 51

FRONT SEAL……………………………………………………………….. 52

VALVE SYSTEM…………………………………………………………………. 53

VALVE TIMING……………………………………………………………… 54

CAMSHAFT…………………………………………………………………. 54

FLYWHEEL AND FLYWHEEL HOUSING………………………………………………….. 55

REAR SEAL………………………………………………………………… 55

LUBRICATING OIL SYSTEM……………………………………………………………. 56

PISTON COOLING, CONNECTING ROD, OVERHEAD………………………………………… 57

FRONT GEAR TRAIN……………………………………………………………… 58

TURBOCHARGER…………………………………………………………………. 59

FULL FLOW LUBRICATING OIL FILTERS………………………………………………. 60

LUBRICATING OIL PUMP………………………………………………………….. 61

SPECIFICATIONS……………………………………………………………. 61

MAIN RELIEF VALVE…………………………………………………………….. 62

SPECIFICATIONS……………………………………………………………. 62

OIL COOLER BYPASS VALVE……………………………………………………….. 63

SPECIFICATIONS……………………………………………………………. 63

REGULATOR VALVE…………………………………………………………… 63

LUBRICATING OIL FILTER………………………………………………………… 64

SPECIFICATIONS……………………………………………………………. 64

SAFETY VALVE……………………………………………………………… 64

LUBRICATING OIL BYPASS FILTER………………………………………………….. 65

SPECIFICATIONS……………………………………………………………. 65

LUBRICATING OIL COOLER………………………………………………………… 66

SPECIFICATIONS……………………………………………………………. 66

FUEL SYSTEM……………………………………………………………………… 67

FLOW DIAGRAM…………………………………………………………………. 67

FUEL INJECTION PUMP…………………………………………………………… 68

SPECIFICATIONS……………………………………………………………. 68

RIGHT BANK PIPING…………………………………………………………….. 69

LEFT BANK PIPING……………………………………………………………… 70

FUEL INJECTION NOZZLE…………………………………………………………. 71

SPECIFICATIONS……………………………………………………………. 71

FUEL FILTER………………………………………………………………….. 72

SPECIFICATIONS……………………………………………………………. 72

COOLING SYSTEM…………………………………………………………………… 73

THERMOSTAT HOUSING FLOW……………………………………………………….. 74

COOLING FAN BELT……………………………………………………………… 75

WATER PUMP…………………………………………………………………… 76

SPECIFICATIONS……………………………………………………………. 76

COOLING FAN………………………………………………………………….. 77

CORROSION RESISTOR……………………………………………………………. 78

SPECIFICATIONS……………………………………………………………. 78

ACCESSORY……………………………………………………………………….. 79

AIR COMPRESSOR……………………………………………………………….. 79

SPECIFICATIONS……………………………………………………………. 80

UNLOADER VALVE……………………………………………………………. 80

ELECTRICAL SYSTEM………………………………………………………………… 81

ALTERNATOR MOUNTING…………………………………………………………… 81

ALTERNATOR WITH REGULATOR……………………………………………………… 82

STARTING MOTOR……………………………………………………………….. 83

ELECTRICAL INTAKE AIR HEATER…………………………………………………… 84

SPECIFICATIONS……………………………………………………………. 84

12 TESTING, ADJUSTING AND TROUBLESHOOTING……………………………………………… 85

ADJUSTING VALVE CLEARANCE…………………………………………………………. 87

MEASURING COMPRESSION PRESSURE…………………………………………………….. 88

FUEL SYSTEM……………………………………………………………………… 89

FUEL PUMP REMOVAL…………………………………………………………….. 89

FUEL PUMP INSTALLATION AND TIMING………………………………………………. 91

CHECKING INJECTION TIMING…………………………………………………………. 96

USING PROXIMITY SENSOR………………………………………………………… 96

USING FUEL PUMP LOCK PIN………………………………………………………. 99

SENSOR INSTALLATION……………………………………………………………….102

SPEED SENSOR………………………………………………………………….102

TIMING SENSOR (WITH FLYWHEEL TIMING HOLES)……………………………………….102

2ND DESIGN (FLYWHEEL TIMING LUGS)……………………………………………….103

FUEL OVERFLOW VALVE PRESSURE……………………………………………………….104

ADJUSTING FUEL INJECTION PRESSURE…………………………………………………..105

PERFORMANCE TEST………………………………………………………………….106

ENGINE TESTING………………………………………………………………..106

IN SERVICE RUN…………………………………………………………….106

ENGINE DYNAMOMETER RUN-IN…………………………………………………..106

PORTABLE DYNAMOMETER OR LOAD BANK RUN-IN……………………………………..106

INSITE SERVICE TOOL………………………………………………………..106

FUEL FLOW MEASUREMEnT………………………………………………………….107

INSTALLATION………………………………………………………………107

MEASUREMENT OF FUEL CONSUMPTION RATIO………………………………………..107

SPECIFICATIONS…………………………………………………………….108

DYNAMOMETER WORKSHEET………………………………………………………….109

ENGINE DYNAMOMETER TESTING…………………………………………………………110

SETUP………………………………………………………………………..110

COOLANT PLUMBING………………………………………………………………110

GENERAL ENGINE TEST PROCEDURES………………………………………………….110

ENGINE THROTTLE CONTROL………………………………………………………..111

TESTING PROCEDURE……………………………………………………………..112

ENGINE SPEED (RPM) WITH A VERIFIED TACHOMETER…………………………………112

FUEL INLET RESTRICTION……………………………………………………..112

FUEL DRAIN LINE RESTRICTION…………………………………………………113

INTAKE MANIFOLD PRESSURE……………………………………………………113

INTAKE AIR RESTRICTION……………………………………………………..113

EXHAUST RESTRICTION………………………………………………………..113

ENGINE BLOWBY……………………………………………………………..114

LUBRICATING OIL PRESSURE……………………………………………………116

COOLANT PRESSURE…………………………………………………………..116

LUBRICATING OIL TEMPERATURE…………………………………………………116

AIR COMPRESSOR…………………………………………………………….117

STARTING MOTOR…………………………………………………………….117

ENGINE RUN-IN INSTRUCTIONS……………………………………………………..118

TEST LOAD…………………………………………………………………118

TESTING AND ADJUSTING TOOL LIST…………………………………………………….121

COOLING SYSTEM……………………………………………………………………123

CHECKING FAN BELT TENSION………………………………………………………123

330M……………………………………………………………………..123

WA800/WA900……………………………………………………………….123

ALTERNATOR BELT…………………………………………………………………..123

CHECKING BELT TENSION………………………………………………………….123

ADJUSTING BELT TENSION…………………………………………………………124

DRIVE BELT TENSION…………………………………………………………….124

13 DISASSEMBLY AND ASSEMBLY…………………………………………………………..125

DISASSEMBLY………………………………………………………………………127

SPECIAL TOOLS…………………………………………………………………127

WASHING………………………………………………………………………127

SETTING ENGINE STAND…………………………………………………………..127

GENERAL DISASSEMBLY……………………………………………………………127

ENGINE COOLING WATER AND ENGINE OIL………………………………………….127

MUFFLES ASSEMBLY…………………………………………………………..128

FAN………………………………………………………………………128

AIR COMPRESSOR ASSEMBLY…………………………………………………….136

FUEL PUMP DRIVE ASSEMBLY……………………………………………………137

WATER PUMP ASSEMBLY………………………………………………………..139

BREATHER………………………………………………………………….139

OIL COOLER ASSEMBLY………………………………………………………..140

ROCKER LEVER COVER…………………………………………………………140

ROCKER LEVER………………………………………………………………141

CYLINDER HEAD ASSEMBLY……………………………………………………..142

CAM FOLLOWER ASSEMBLY………………………………………………………142

THERMOSTAT HOUSING…………………………………………………………143

ACCESSORY DRIVE ASSEMBLY……………………………………………………143

DAMPER, CRANKSHAFT PULLEY ASSEMBLY…………………………………………..144

OIL PAN…………………………………………………………………..144

MAIN RELIEF VALVE, SUCTION TUBE……………………………………………..144

FRONT SUPPORT……………………………………………………………..144

SENSORS…………………………………………………………………..144

FLYWHEEL………………………………………………………………….145

GEAR CASE…………………………………………………………………145

CYLINDER BLOCK…………………………………………………………….147

WASHING………………………………………………………………………….151

WASHING CYLINDER BLOCK…………………………………………………………151

WASHING CRANKSHAFT…………………………………………………………….153

WASHING CONNECTING ROD…………………………………………………………153

MEASURING PARTS…………………………………………………………………..154

MEASURING CURVATURE OF CRANKSHAFT……………………………………………….154

MEASURING OUTSIDE DIAMETER OF JOURNAL……………………………………………154

MEASURING OUT-OF-ROUNDNESS OF JOURNAL……………………………………………154

MEASURING SURFACE ROUGHNESS OF OUTSIDE DIAMETER OF JOURNAL…………………………155

DIAMETER OF JOURNAL……………………………………………………………155

MEASURING DEPTH OF CYLINDER LINER COUNTERBORE…………………………………….155

MEASURING MAIN BEARING BORE…………………………………………………….156

MEASURING CURVATURE OF CAMSHAFT…………………………………………………156

MEASURING OUTSIDE DIAMETER OF JOURNAL……………………………………………156

MEASURING HEIGHT OF CAM………………………………………………………..157

MEASURING PISTON RING GROOVE……………………………………………………157

SPECIAL TOOLS……………………………………………………………..157

MEASURING PISTON RING END GAP…………………………………………………..157

MEASURING OUTSIDE DIAMETER OF PISTON…………………………………………….158

MEASURING LENGHT OF CONNECTING ROD………………………………………………158

MEASURING INSIDE DIAMTER AT SMALL END OF CONNECTING ROD……………………………159

MEASURING INSIDE DIAMETER AT BIG END OF CONNECTING ROD…………………………….159

MEASURING CURVATURE, TWISTING OF CONNECTING ROD…………………………………..159

STANDARD PRESSURE FOR PARTS PRESSURE TESTING……………………………………..160

ASSEMBLY…………………………………………………………………………161

TIGHTENING BOLTS BY PLASTIC RANGE TURNING ANGLE METHOD…………………………….161

SPECIAL TOOLS…………………………………………………………………162

PREPARATORY WORK………………………………………………………………162

GENERAL ASSEMBLY………………………………………………………………163

CYLINDER BLOCK…………………………………………………………….163

GEAR CASE…………………………………………………………………175

FLYWHEEL………………………………………………………………….181

SENSOR……………………………………………………………………185

FRONT SUPPORT……………………………………………………………..186

MAIN RELIEF VALVE, SUCTION PIPE……………………………………………..186

OIL PAN…………………………………………………………………..186

DAMPER, CRANKSHAFT PULLEY ASSEMBLY…………………………………………..186

ACCESSORY DRIVE ASSEMBLY……………………………………………………187

THERMOSTAT HOUSING…………………………………………………………188

CAM FOLLOWER ASSEMBLY………………………………………………………188

CYLINDER HEAD ASSEMBLY……………………………………………………..188

ROCKER LEVER………………………………………………………………191

ROCKER LEVER COVER…………………………………………………………192

OIL COOLER ASSEMBLY………………………………………………………..193

BREATHER………………………………………………………………….195

WATER PUMP ASSEMBLY………………………………………………………..195

FUEL PUMP DRIVE……………………………………………………………196

AIR COMPRESSOR ASSEMBLY…………………………………………………….198

FUEL INJECTION PUMP………………………………………………………..199

EXHAUST MANIFOLD ASSEMBLY…………………………………………………..199

INTAKE MANIFOLD, AFTERCOOLER ASSEMBLY………………………………………..200

TURBOCHARGER ASSEMBLY………………………………………………………205

INTAKE CONNECTOR…………………………………………………………..206

FAN………………………………………………………………………206

GENERAL ASSEMBLY…………………………………………………………..207

14 MAINTENANCE STANDARD………………………………………………………………209

INTAKE AND EXHAUST SYSTEM………………………………………………………….210

TURBOCHARGER………………………………………………………………….210

ENGINE BODY………………………………………………………………………211

CYLINDER HEAD…………………………………………………………………211

VALVE, VALVE SPRING AND VALVE GUIDE……………………………………………..212

ROCKER ARM AND SHAFT…………………………………………………………..214

CROSSHEAD AND GUIDE……………………………………………………………215

CYLINDER BLOCK………………………………………………………………..216

CYLINDER LINER………………………………………………………………..218

CRANKSHAFT……………………………………………………………………219

CAMSHAFT……………………………………………………………………..221

CAM FOLLOWER AND PUSH ROD………………………………………………………222

TIMING GEAR…………………………………………………………………..223

PISTON, PISTON RING AND PISTON PIN………………………………………………225

CONNECTING ROD………………………………………………………………..227

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………..229

LUBRICATION SYSTEM………………………………………………………………..230

OIL PUMP……………………………………………………………………..230

MAIN RELIEF VALVE……………………………………………………………..232

OIL COOLER BY-PASS VALVE, REGULATOR VALVE………………………………………..233

COOLING SYSTEM……………………………………………………………………234

WATER PUMP……………………………………………………………………234

THERMOSTAT……………………………………………………………………235

15 REPAIR AND REPLACEMENT OF PARTS……………………………………………………..237

TABLE OF SPECIAL TOOLS…………………………………………………………….238

CYLINDER HEAD…………………………………………………………………….239

CYLINDER AND MOUNTING FACE……………………………………………………..242

REPLACING VALVE SEAT…………………………………………………………..243

PRESSURE TEST OF CYLINDER HEAD………………………………………………….247

REPLACING VALVE GUIDE………………………………………………………….248

REPLACING CROSSHEAD GUIDE………………………………………………………248

GRINDING VALVE………………………………………………………………..249

CYLINDER BLOCK……………………………………………………………………250

METHOD OF CHECKING INSIDE DIAMETER OF MAIN BEARING MOUNTING HOLE USING ALIGNMENT BAR….253

CORRECTING CYLINDER BLOCK TOP SURFACE, COUNTERBORE………………………………..254

REPLACING MAIN BEARING CAP……………………………………………………..261

REPLACING CAM BUSHING………………………………………………………….263

CRANKSHAFT……………………………………………………………………….265

CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION…………………………267

GRINDING CRANKSHAFT……………………………………………………………271

CORRECTING FRONT SEAL CONTACT SURFACE……………………………………………278

CORRECTING REAR SEAL CONTACT SURFACE…………………………………………….280

CONNECTING ROD……………………………………………………………………282

REPLACING CONNECTING ROD SMALL END BUSHING……………………………………….284

REPLACING CRANKSHAFT GEAR………………………………………………………285

REPLACING CAMSHAFT GEAR………………………………………………………..286

REPLACING FLYWHEEL RING GEAR……………………………………………………286