$36

Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 – PDF DOWNLOAD

Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 – PDF DOWNLOAD

FILE DETAILS:

Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 – PDF DOWNLOAD

Language : English

Pages : 290

Downloadable : Yes

File Type : PDF

Size: 19.6 MB

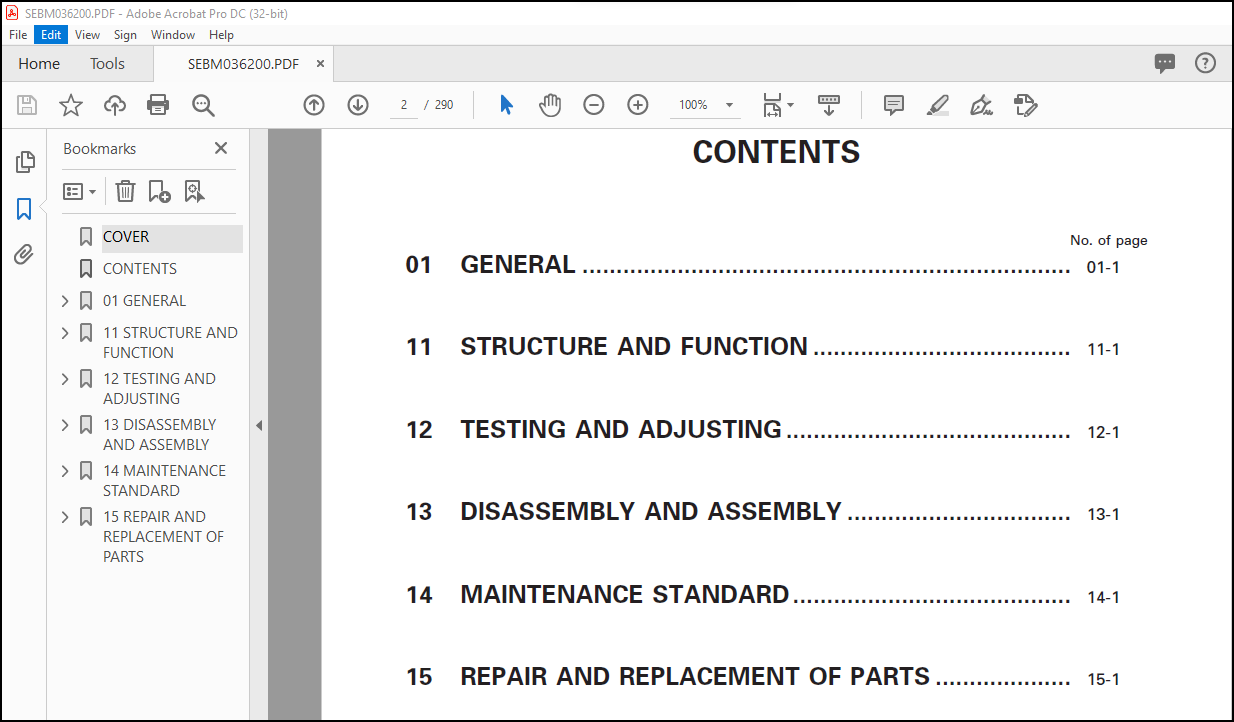

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 – PDF DOWNLOAD

The Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 is a comprehensive guide for the maintenance, repair, and overhaul of the SA6D140-H-1 series engine. This engine is used in a variety of Komatsu equipment, including excavators, bulldozers, and other heavy equipment.

- The manual is organized into several sections, each covering a different aspect of the engine. The first section provides an overview of the engine, including its specifications, performance data, and features. This section also includes a table of contents, a list of illustrations, and a list of symbols and abbreviations used throughout the manual.

- The second section covers engine inspection and measurement procedures. This section provides step-by-step instructions for checking and measuring various components of the engine, including the cylinder block, cylinder head, and crankshaft. The manual includes detailed illustrations to help the reader understand the procedures.

- The third section covers engine disassembly and assembly procedures. This section provides instructions for removing and installing various components of the engine, including the cylinder head, pistons, and crankshaft. The manual also includes torque specifications for each component.

- The fourth section covers engine testing and adjusting procedures. This section provides instructions for testing and adjusting various components of the engine, including the fuel injection system, the turbocharger, and the valve clearance. The manual includes detailed illustrations to help the reader understand the procedures.

- The fifth section covers engine maintenance procedures, including routine maintenance and inspections. This section provides instructions for maintaining the engine to ensure its continued performance and longevity.

- The sixth section covers engine troubleshooting and diagnosis procedures. This section provides instructions for diagnosing and troubleshooting various engine problems, including starting problems, low power output, and excessive smoke. The manual includes a troubleshooting chart and detailed illustrations to help the reader diagnose and fix the problem.

- Overall, the Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 is an essential tool for anyone working on or maintaining this engine. The manual is available in print or digital formats, making it a convenient and accessible resource for mechanics and technicians. It is designed to be user-friendly and easy to understand, with clear instructions and detailed illustrations. With this manual, you can ensure that your Komatsu equipment is operating at its best and avoid costly repairs and downtime.

TABLE OF CONTENTS:

Komatsu SA6D140-H-1 Series Diesel Engine Shop Manual SEBM036200 – PDF DOWNLOAD

COVER…………………………………………………………………………….. 1

CONTENTS………………………………………………………………………….. 2

01 GENERAL………………………………………………………………………… 26

GENERAL VIEW…………………………………………………………………… 27

SPECIFICATIONS…………………………………………………………………. 29

GENERAL ASSEMBLY DRAWING………………………………………………………… 45

WEIGHT TABLE…………………………………………………………………… 57

ENGINE PERFORMANCE CURVE………………………………………………………… 58

11 STRUCTURE AND FUNCTION…………………………………………………………… 90

GENERAL STRUCTURE………………………………………………………………. 91

INTAKE AND EXHAUST SYSTEM……………………………………………………….. 93

TURBOCHARGER………………………………………………………………..100

AFTER-COOLER………………………………………………………………..104

ENGINE BODY…………………………………………………………………….105

CYLINDER HEAD……………………………………………………………….105

VALVE SYSTEM………………………………………………………………..107

CYLINDER BLOCK………………………………………………………………109

MAIN CIRCULATION PART………………………………………………………..111

TIMING GEAR…………………………………………………………………114

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………116

LUBRICATION SYSTEM………………………………………………………………117

LUBRICATION SYSTEM CHART……………………………………………………..117

OIL PUMP……………………………………………………………………118

OIL FILTER AND SAFETY VALVE…………………………………………………..119

OIL COOLER………………………………………………………………….120

OIL PUMP RELIEF VALVE………………………………………………………..122

OIL COOLER BY-PASS VALVE……………………………………………………..122

PISTON COOLING VALVE…………………………………………………………123

MECHANICAL PUMP……………………………………………………………..124

FUEL SYSTEM…………………………………………………………………….125

FUEL SYSTEM CHART……………………………………………………………125

FUEL INJECTION PUMP………………………………………………………….126

FUEL INJECTION NOZZLE………………………………………………………..130

FUEL INJECTION PUMP DRIVE…………………………………………………….131

FUEL FILTER…………………………………………………………………133

FUEL CUT SOLENOID……………………………………………………………134

ENGINE STOP MOTOR……………………………………………………………136

STARTING AID………………………………………………………………..141

OUTLINE OF ELECTRONICAL GOVERNOR SYSTEM (WITH ELECTRONICAL GOVERNOR MADE BY ZEXEL)….142

COOLING SYSTEM………………………………………………………………….148

COOLING SYSTEM CHART…………………………………………………………148

WATER PUMP………………………………………………………………….149

FAN DRIVE AND TENSION PULLEY………………………………………………….150

CORROSION RESISTOR…………………………………………………………..155

THERMOSTAT………………………………………………………………….156

ACCESSORY………………………………………………………………………157

AIR COMPRESSOR MOUNTING………………………………………………………157

AIR COMPRESSOR………………………………………………………………160

ELECTRICAL SYSTEM……………………………………………………………….161

ALTERNATOR………………………………………………………………….161

STARTING MOTOR………………………………………………………………165

WIRING DIAGRAM………………………………………………………………170

12 TESTING AND ADJUSTING…………………………………………………………….172

ENGINE BODY…………………………………………………………………….178

ADJUSTING VALVE CLEARANCE…………………………………………………….178

MEASURING COMPRESSION PRESSURE………………………………………………..179

FUEL SYSTEM…………………………………………………………………….180

TESTING AND ADJUSTING FUEL INJECTION TIMING…………………………………….180

ADJUSTING FUEL CUT SOLENOID…………………………………………………..182

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE…………………………………186

ADJUSTING FUEL INJECTION PRESSURE(VALVE CRACKING PRESSURE)……………………….188

METHOD FOR INSTALLING (ADJUSTMENT) OF ENGINE SPEED SENSOR………………………..189

CALIBRATION DATA…………………………………………………………….191

COOLING SYSTEM………………………………………………………………….255

FNA BELT TENSION…………………………………………………………….255

REPLACING FAN BELT AND ADJUSTING AUTO TENSIONER…………………………………256

PERFORMANCE TEST………………………………………………………………..257

RUN-IN STANDARD……………………………………………………………..257

PERFORMANCE TEST CRITERIA…………………………………………………….267

TESTING AND ADJUSTING TOOL LIST……………………………………………….292

TESTING AND ADJUSTING DATE……………………………………………………293

FAN BELT TENSION…………………………………………………………….313

TROUBLESHOOTING…………………………………………………………………315

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………..316

METHOD OF USING TROUBLESHOOTING CHART………………………………………….317

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………….321

S-2 ENGINE DOES NOT START…………………………………………………….322

(1) ENGINE DOES NOT TURN………………………………………………….322

(2) ENGINE TURNS BUT NO EXHAUST COMES OUT (FUEL IS NOT BEING INJECTED)…………323

(3) EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)……324

S-3 ENGINE DOES NOT PICK-UP SMOOTHLY (FOLLOW-UP IS POOR)…………………………325

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………….326

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………………………………..327

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………….328

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)………………………………..329

S-8 OIL COMSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)………………………330

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………..331

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………….332

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVER GOES DOWN……….333

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………….334

S-13 OIL LEVEL RISES…………………………………………………………335

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)……………………………336

S-15 ABNORMAL NOISE IS MADE…………………………………………………..337

S-16 VIBRATION IS EXCESSIVE…………………………………………………..338

13 DISASSEMBLY AND ASSEMBLY………………………………………………………….356

DISASSEMBLY…………………………………………………………………….357

WASHING…………………………………………………………………….374

WASHING CYLINDER BLOCK……………………………………………………….374

WASHING CRANKSHAFT…………………………………………………………..375

MEASURING PARTS……………………………………………………………..376

ASSEMBLY……………………………………………………………………….382

14 MAINTENANCE STANDARD……………………………………………………………..416

INTAKE AND EXHAUST SYSTEM………………………………………………………..417

TURBOCHARGER………………………………………………………………..417

ENGINE BODY…………………………………………………………………….422

CYLINDER HEAD……………………………………………………………….422

VALVES AND VALVE GUIDE……………………………………………………….423

CROSSHEAD AND CROSSHEAD GUIDE…………………………………………………424

PUSH ROD AND CAM FOLLOWER…………………………………………………….425

CYLINDER BLOCK………………………………………………………………426

CYLINDER LINER………………………………………………………………428

CRANKSHAFT………………………………………………………………….429

CAMSHAFT……………………………………………………………………430

TIMING GEAR…………………………………………………………………431

PISTON, PISTON RING AND PISTON PIN…………………………………………….433

CONNECTING ROD………………………………………………………………435

LUBRICATION SYSTEM………………………………………………………………436

OIL PUMP……………………………………………………………………436

OIL PUMP RELIEF VALVE, PISTON COOLING VALVE AND OIL COOLER BY-PASS VALVE…………..437

COOLING SYSTEM………………………………………………………………….438

WATER PUMP………………………………………………………………….438

ACCESSORY………………………………………………………………………439

AIR COMPRESSOR………………………………………………………………439

15 REPAIR AND REPLACEMENT OF PARTS……………………………………………………441

TABLE OF SPECIAL TOOLS…………………………………………………………..442

CYLINDER HEAD…………………………………………………………………..443

TESTING AND INSPECTING…………………………………………………………..444

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING………………………………..446

REPLACING VALVE SEAT INSERTS……………………………………………………..447

REPLACING NOZZLE HOLDER SLEEVE……………………………………………………453

REPLACING VALVE GUIDE……………………………………………………………457

REPLACING CROSS HEAD GUIDE……………………………………………………….458

GRINDING THE VALVE………………………………………………………………459

CYLINDER BLOCK………………………………………………………………….460

TESTING AND INSPECTING…………………………………………………………..461

GRINDING THE TOP SURFACE OF CYLINDER BLOCK…………………………………………463

REPLACING MAIN METAL CAP…………………………………………………………469

REPLACING CAM BUSHING……………………………………………………………471

CRANKSHAFT……………………………………………………………………..473

REPAIRING THE CRANKSHAFT…………………………………………………………480

CONNECTING ROD………………………………………………………………….485

REPLACING CRANKSHAFT GEAR………………………………………………………..487

REPLACING CAMSHAFT GEAR………………………………………………………….488

REPLACING FLYWHEEL RING GEAR……………………………………………………..489